Documente Academic

Documente Profesional

Documente Cultură

Product Manager: Production Planning Personnel Production Control Personnel Inventory Control Personnel

Încărcat de

Oyi Lorenzo-LibanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Product Manager: Production Planning Personnel Production Control Personnel Inventory Control Personnel

Încărcat de

Oyi Lorenzo-LibanDrepturi de autor:

Formate disponibile

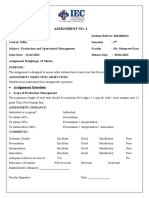

MA. LORELY L.

LIBAN

PRODUCTION MANAGEMENT MIDTERM EXAMINATION

1. Draw and illustrate a simple production organization.

Product Manager

Production Planning Personnel

Production Control Personnel

Inventory Control Personnel

The Product Manager will be the head in the Production. His work will be facilitated by different personnel such as the Production Planning, Production Control and Inventory Control Personnel. The Production Planning Personnel will be in-charge in the order booking, production budget, material records, methods to be used in production, machines & tools, operation layout, time estimating and scheduling. The Production Control Personnel will take care of dispatching or preparing of various documents such as Job Cards, Route sheets, for each and every component of the product. These documents are to be released from Production Management department to give signal for starting the production. He will also take care for the expediting. Once the documents are dispatched, the management wants to know whether the activities are being carried out as per the plans or not. Expediting officer plan and feed back the progress of the work to the management. This will help the management to evaluate the plans. Lastly, the Inventory Control Officer is task to conduct stores management, quality control, handling, receiving, simplification and standardization. 2. Give the objectives of Production Management. There are various objectives of Production management, to wit: a. To be able to create a product that is desirable to the needs and whims of the market while meeting the organizational objectives of effectiveness, efficiency and adaptability. b. To be able to create a product that is in consonance with the trend in the market. c. To be able to create a product at a low cost. d. To be able to create a product that will increase the sales of the company. e. To be able to create a product that will maximize the value of the through productivity. 3. What are the responsibilities of production manager? A Product Manager is the key to every successful production; in lieu he had these following responsibilities: a. To conduct a research regarding the products that a firm should produce. b. To contact suppliers that will offer them raw materials at a reasonable price.

c. To see to it that the raw materials to be use are freshly procured and safe for production and consumption. d. To see to it that the production process is properly and safely undertaken according to the scheduled plan. e. To see to it that there has been a quality test undertaken to the finished products. 4. Discuss the roles of the production management as a decision maker. A Product Managers primordial and most essential task is decision making. Being a decision maker entails a very strict and rigid analysis of the factors that needed to be considered. A common dilemma of a product manager is to determine what he is going to consider in the production. Is it the quantity or the quality of products? The product manager as a decision maker has to consider and weigh both circumstances. If he chooses the quality of goods, of course customers will receive the same however at a higher price which undoubtedly customers will be aloof to buy. On the other hand, if he chooses quantity of goods, customers will definitely buy them however if they are not satisfied with the quality of the product the firm itself will be affected. Therefore, the product manager as a decision maker should choose the one that conforms to the objectives of the firm and at the same time will give them the highest possible profit at the lowest possible cost that will meet the needs and whims of the market. 5. Explain the product planning activity. Production planning focuses on the planning and daily management of production activities. This includes ensuring all necessary supplies are in stock, planning work in process, and handling rework. Production planning also involves managing the human resources needed to build a product. 6. What is product life cycle? Explain. Product Life Cycle is the stages through which a product passes from development to being withdrawn from the market. The first stage is the development stage, where a market research is conducted. From this information, a product will be designed to meet the consumers needs. Then comes the launch of the product, which is likely to be associated with informative advertising and promotion to make consumers aware that the product is now available on the market and what its purpose is. The next stage is the growth stage, which is when sales and revenue increase. Then comes a period of maturity for the product, when sales and revenue level off. Competitors may enter the market and take away sales of the product. Or the market may become saturated. Finally, the product goes into decline as sales fall. 7. Discuss the process planning. Process planning is a key element in project management that focuses on selecting resources for use in the execution and completion of a project. In a manufacturing setting, this aspect of planning also includes establishing the general sequence of steps that begin with the acquisition of materials and end with the creation of a finished product. Process planning is often closely associated with project planning, although the specific functions of each tool are used differently in the overall strategic planning.

8. What is methods study? Methods study is process of subjecting each part of a given piece of work to close analysis to eliminate every unnecessary element or operation, as a means of approaching the quickest and best method of performing the work. It also includes formulation of incentive schemes and improvement and standardization of equipment, methods, operator training, working conditions, etc. 9. Name the factors that influence the selection of a plant site. There are various factors that must be considered in selecting a suitable plant site. The factors to be considered are: a. Location with respect to the target market b. Availability of land c. Availability of raw materials d. Transport facilities e. Availability of labor f. Availability of utilities (Water, Electricity, etc) g. Environmental impact and effluent disposal h. Local community considerations 10. Explain the major objectives of a plant lay out study. The study of plant lay out is very relevant in the production management. Its major object is to optimize the production process within the plant. If this objective had been attained, this would result to productivity of activities, reduction of cost regarding to money, time, labor and land. It would also result to a smooth flow of job, materials and labor force. Another objective would be to provide enough capacity production by better implementation of machineries through suitable locating of them regarding the nature of job, labor force by reduction of movement, easing job and better psychological condition (increased safety and better working environment), material by reduction of wastage through smooth handling, land by maximum usage of space

S-ar putea să vă placă și

- Production Management Full NotesDocument67 paginiProduction Management Full NotesMaja BoyÎncă nu există evaluări

- Chapter#05 Production ManagementDocument13 paginiChapter#05 Production Managementফকির মজুমদার শাহÎncă nu există evaluări

- POM - Assignment A - Answer 1Document2 paginiPOM - Assignment A - Answer 1Prateek BhattacharyaÎncă nu există evaluări

- Indira School of Business Studies, Pune.: The Scope of Operations Management and Elaborate Any Two FunctionsDocument7 paginiIndira School of Business Studies, Pune.: The Scope of Operations Management and Elaborate Any Two FunctionsAnkita ShettyÎncă nu există evaluări

- POM Solved Que BankDocument16 paginiPOM Solved Que BankAniket PatekarÎncă nu există evaluări

- Commerce Module 1-4Document62 paginiCommerce Module 1-4Goutham DasÎncă nu există evaluări

- Module 2 (Lessons 1 - 6)Document5 paginiModule 2 (Lessons 1 - 6)Pob ReÎncă nu există evaluări

- Unit 2Document79 paginiUnit 2sofiya syedÎncă nu există evaluări

- PMM Notes All UnitsDocument205 paginiPMM Notes All UnitsSwethaÎncă nu există evaluări

- Production Planning and ControlDocument68 paginiProduction Planning and ControlNardos YizengawÎncă nu există evaluări

- Functions of Organization: Production, Marketing, and FinanceDocument60 paginiFunctions of Organization: Production, Marketing, and FinancehammadÎncă nu există evaluări

- Production and Materials ManagementDocument114 paginiProduction and Materials ManagementBabasab Patil (Karrisatte)50% (2)

- What Is Production Management? MeaningDocument8 paginiWhat Is Production Management? Meaningrinky_trivediÎncă nu există evaluări

- Enabliers of BPR IN MANUFACTRING - Production PlanningDocument8 paginiEnabliers of BPR IN MANUFACTRING - Production Planningneyom bitvooÎncă nu există evaluări

- MB 0044 - Production and Operation Management: Q1. State The Important Considerations For Locating An Automobile PlantDocument9 paginiMB 0044 - Production and Operation Management: Q1. State The Important Considerations For Locating An Automobile PlantSaju AugustineÎncă nu există evaluări

- Production Planning and Control L - 1Document37 paginiProduction Planning and Control L - 1Tamanna100% (2)

- Assignment No 1 Production & Operations Management (8418) .Document11 paginiAssignment No 1 Production & Operations Management (8418) .noroz innovativeÎncă nu există evaluări

- Production Planning & ControlDocument24 paginiProduction Planning & ControlHari Prasad Reddy Yedula100% (1)

- m2MATERILA AMIEDocument4 paginim2MATERILA AMIEHemantkumar TungÎncă nu există evaluări

- Production & Operation Management GuideDocument6 paginiProduction & Operation Management GuideKhushal SainiÎncă nu există evaluări

- Production Planning and ControlDocument5 paginiProduction Planning and ControlKailash KumarÎncă nu există evaluări

- Production & Operations ManagementDocument6 paginiProduction & Operations ManagementAjay LalwaniÎncă nu există evaluări

- PRODUCTION - and - MATERIAL - MANAGEMENT - 2nd - B.B.ADocument7 paginiPRODUCTION - and - MATERIAL - MANAGEMENT - 2nd - B.B.ANoah JonesÎncă nu există evaluări

- Production and Operational Management AssignmentDocument6 paginiProduction and Operational Management AssignmentVikash KumarÎncă nu există evaluări

- Productions and Operations Management (AutoSave)Document45 paginiProductions and Operations Management (AutoSave)DABHI PARTHÎncă nu există evaluări

- BBA Production and Operations Management AssignmentDocument11 paginiBBA Production and Operations Management AssignmentNageshwar singhÎncă nu există evaluări

- Chapter - 02 LogisticsDocument13 paginiChapter - 02 LogisticsTracy Van TangonanÎncă nu există evaluări

- Operations Management Lecture - 1Document7 paginiOperations Management Lecture - 1tusharÎncă nu există evaluări

- Mba201 - Production and Operation ManagementDocument8 paginiMba201 - Production and Operation ManagementSiya KandpalÎncă nu există evaluări

- Unit 1 POMDocument4 paginiUnit 1 POMAnmolpreet KaurÎncă nu există evaluări

- POM Unit 2Document4 paginiPOM Unit 2kunjapÎncă nu există evaluări

- Operation MNGMNT Group1Document6 paginiOperation MNGMNT Group1Lilian FredelucesÎncă nu există evaluări

- Functions and Responsibilities of A Production ManagerDocument15 paginiFunctions and Responsibilities of A Production ManagerRonak Jain97% (32)

- Definition of Product PlanningDocument8 paginiDefinition of Product PlanningabdullahÎncă nu există evaluări

- Production and Operations Management 1Document7 paginiProduction and Operations Management 1RDX 29Încă nu există evaluări

- Dr. Rajendra Doiphode Ph.D. (IIT Bombay)Document36 paginiDr. Rajendra Doiphode Ph.D. (IIT Bombay)2020 83 Harshvardhan PatilÎncă nu există evaluări

- UntitledDocument112 paginiUntitledvijayÎncă nu există evaluări

- MBA 2nd Semester Operations Management Study MaterialDocument140 paginiMBA 2nd Semester Operations Management Study MaterialViraja GuruÎncă nu există evaluări

- Entrepreneurship 12 Q2 Week 1Document9 paginiEntrepreneurship 12 Q2 Week 1Yasmen MendezÎncă nu există evaluări

- ProdMan Unit 3Document5 paginiProdMan Unit 3Jenalyn floresÎncă nu există evaluări

- Unit 3 - Design of The Operation System Part One.Document32 paginiUnit 3 - Design of The Operation System Part One.Birhanu AdmasuÎncă nu există evaluări

- Production and Material ManagementDocument50 paginiProduction and Material ManagementGuruKPOÎncă nu există evaluări

- Before You Start: Notes on Operations ManagementDocument22 paginiBefore You Start: Notes on Operations ManagementVinayak ChawlaÎncă nu există evaluări

- Optimize production with PPC planning and controlDocument12 paginiOptimize production with PPC planning and controlPardhasaradhi MathiÎncă nu există evaluări

- Manage Production & Forecasting TechniquesDocument19 paginiManage Production & Forecasting TechniquesA KÎncă nu există evaluări

- Operating ManagementDocument19 paginiOperating ManagementSamantha EstilongÎncă nu există evaluări

- Operations Management KeyDocument30 paginiOperations Management KeyNur Al AhadÎncă nu există evaluări

- Production and Operation Management: REG. NO.: BIMS/HP/02/2007/1311Document25 paginiProduction and Operation Management: REG. NO.: BIMS/HP/02/2007/1311anjypetÎncă nu există evaluări

- Industrial ManagementDocument10 paginiIndustrial ManagementHimanshu GautamÎncă nu există evaluări

- Introduction to Production Management and PlanningDocument4 paginiIntroduction to Production Management and PlanningHaseeb KhalidÎncă nu există evaluări

- MS 05Document8 paginiMS 05Rajni KumariÎncă nu există evaluări

- Module 5 PDFDocument8 paginiModule 5 PDFMechanical EngineeringÎncă nu există evaluări

- Production ManagementDocument6 paginiProduction ManagementNeetesh DasÎncă nu există evaluări

- PBM Ass1Document18 paginiPBM Ass1Abdul SamadÎncă nu există evaluări

- Second Chapter: Product and Service DesignDocument8 paginiSecond Chapter: Product and Service DesignMominul MominÎncă nu există evaluări

- Product Development IntroductionDocument3 paginiProduct Development IntroductionFadouaÎncă nu există evaluări

- Defination of POMDocument9 paginiDefination of POMShen MetzÎncă nu există evaluări

- What The Heck You Should Know About Quality Engineering?De la EverandWhat The Heck You Should Know About Quality Engineering?Încă nu există evaluări

- Practical Guide To Production Planning & Control [Revised Edition]De la EverandPractical Guide To Production Planning & Control [Revised Edition]Evaluare: 1 din 5 stele1/5 (1)

- Course Outline in Criminal Law (Book 1)Document2 paginiCourse Outline in Criminal Law (Book 1)Oyi Lorenzo-LibanÎncă nu există evaluări

- Course Outline in Criminal Law (Book 1)Document2 paginiCourse Outline in Criminal Law (Book 1)Oyi Lorenzo-LibanÎncă nu există evaluări

- Liability for breach despite fortuitous eventsDocument2 paginiLiability for breach despite fortuitous eventsOyi Lorenzo-LibanÎncă nu există evaluări

- Dizon Vs GaborroDocument2 paginiDizon Vs GaborroOyi Lorenzo-LibanÎncă nu există evaluări

- Olino vs Medina land dispute caseDocument2 paginiOlino vs Medina land dispute caseOyi Lorenzo-Liban0% (1)

- Case DigestsDocument7 paginiCase DigestsOyi Lorenzo-LibanÎncă nu există evaluări

- Taylor Vs UyDocument1 paginăTaylor Vs UyOyi Lorenzo-LibanÎncă nu există evaluări

- Liability for breach despite fortuitous eventsDocument2 paginiLiability for breach despite fortuitous eventsOyi Lorenzo-LibanÎncă nu există evaluări

- RednotesDocument95 paginiRednotesOyi Lorenzo-LibanÎncă nu există evaluări

- Typewriter Repair DisputeDocument1 paginăTypewriter Repair DisputeOyi Lorenzo-LibanÎncă nu există evaluări

- Evangeline Ladonga Vs PeopleDocument2 paginiEvangeline Ladonga Vs PeopleOyi Lorenzo-LibanÎncă nu există evaluări

- SC rules Norberto Cruz guilty of acts of lasciviousness, not attempted rapeDocument2 paginiSC rules Norberto Cruz guilty of acts of lasciviousness, not attempted rapeOyi Lorenzo-LibanÎncă nu există evaluări

- ApplicationDocument1 paginăApplicationOyi Lorenzo-LibanÎncă nu există evaluări

- Rubric for Creating an ExhibitDocument2 paginiRubric for Creating an ExhibitOyi Lorenzo-LibanÎncă nu există evaluări

- Novel ReviewDocument10 paginiNovel ReviewOyi Lorenzo-LibanÎncă nu există evaluări

- Case DigestDocument5 paginiCase DigestOyi Lorenzo-LibanÎncă nu există evaluări

- Measurement: Teacher-Led Slideshow To Review Units of Measure ForDocument45 paginiMeasurement: Teacher-Led Slideshow To Review Units of Measure ForOyi Lorenzo-LibanÎncă nu există evaluări

- Basic FinanceDocument5 paginiBasic FinanceOyi Lorenzo-LibanÎncă nu există evaluări

- MeasurementDocument14 paginiMeasurementOyi Lorenzo-LibanÎncă nu există evaluări

- Digested Cases in Civil ProcedureDocument4 paginiDigested Cases in Civil ProcedureOyi Lorenzo-LibanÎncă nu există evaluări

- Biofuels Annual - Kuala Lumpur - Malaysia - MY2022-0008Document15 paginiBiofuels Annual - Kuala Lumpur - Malaysia - MY2022-0008magijÎncă nu există evaluări

- LCA Identifies Environmental Impacts of Cement ProductionDocument18 paginiLCA Identifies Environmental Impacts of Cement ProductionarylananylaÎncă nu există evaluări

- ACB Emax - Catalog - ABBDocument278 paginiACB Emax - Catalog - ABBSonia López de ArbinaÎncă nu există evaluări

- Compact Detergents in China A Step Towards More Sustainable LaundryDocument3 paginiCompact Detergents in China A Step Towards More Sustainable LaundryAlain valideÎncă nu există evaluări

- Eco Design and Sustainable Manufacturing in Fashion JKDocument13 paginiEco Design and Sustainable Manufacturing in Fashion JKkarthiba jeganÎncă nu există evaluări

- Cost-Benefit Prediction of Green Buildings: SWOT Analysis of Research Methods and Recent ApplicationsDocument14 paginiCost-Benefit Prediction of Green Buildings: SWOT Analysis of Research Methods and Recent ApplicationsyvanmmuÎncă nu există evaluări

- Energy Efficiency in Pneumatic Production Systems - State of The Art and Future Directions - Springer PDFDocument12 paginiEnergy Efficiency in Pneumatic Production Systems - State of The Art and Future Directions - Springer PDFEASACOLLEGEÎncă nu există evaluări

- Seminar Carbon FootprintDocument35 paginiSeminar Carbon FootprintAli HachemÎncă nu există evaluări

- Introduction To Safety SystemsDocument24 paginiIntroduction To Safety SystemsThiyagarajan SankaranÎncă nu există evaluări

- Gujarat Technological University: W.E.F. AY 2018-19Document3 paginiGujarat Technological University: W.E.F. AY 2018-19prashant4455Încă nu există evaluări

- LP1 - Razmah Ghazali PDFDocument56 paginiLP1 - Razmah Ghazali PDFJessicalba LouÎncă nu există evaluări

- AIDA Model Explained - Stages of Consumer Purchase ProcessDocument3 paginiAIDA Model Explained - Stages of Consumer Purchase ProcessMayukh MaityÎncă nu există evaluări

- TOGAF - Open Business Architecture (O-BA) - Part IIDocument43 paginiTOGAF - Open Business Architecture (O-BA) - Part IIvincentB100% (1)

- Publications FireSafetyDesign SDocument369 paginiPublications FireSafetyDesign SJayachandra Reddy AnnavaramÎncă nu există evaluări

- Eco efficiencyAnalysisofTextileCoatingMaterialsDocument10 paginiEco efficiencyAnalysisofTextileCoatingMaterialsmedraizÎncă nu există evaluări

- Supply Chain SustainanbleDocument5 paginiSupply Chain SustainanbleHanif FajriÎncă nu există evaluări

- SUSD0003 - Course Outline 170724Document11 paginiSUSD0003 - Course Outline 170724Porus VakshoorÎncă nu există evaluări

- ISO 270012013 A15 SuppliernbsprelationshipsDocument13 paginiISO 270012013 A15 Suppliernbsprelationshipsfitriah adjisÎncă nu există evaluări

- Sceduling Project OGDCLDocument11 paginiSceduling Project OGDCLSyed Husnain Ali ShahÎncă nu există evaluări

- Appia II Compact Manual EnglishDocument35 paginiAppia II Compact Manual EnglishTeguh AlifiarachmanÎncă nu există evaluări

- PCB1012 Course Coordination OverviewDocument9 paginiPCB1012 Course Coordination OverviewAbu-Ayman Alameen MohamedÎncă nu există evaluări

- Budgeting For Maintenance: A Behavior-Based Approach: by Sam Mcnair, Pe, CMRP, Life Cycle EngineeringDocument7 paginiBudgeting For Maintenance: A Behavior-Based Approach: by Sam Mcnair, Pe, CMRP, Life Cycle EngineeringDiego UngerÎncă nu există evaluări

- Pompa 212CA1913 - SP - 17-13NDocument15 paginiPompa 212CA1913 - SP - 17-13NDddelta RampockÎncă nu există evaluări

- Saep 13Document25 paginiSaep 13maheshÎncă nu există evaluări

- DS WhitePapers Concurrent-Engineering-with-3DEXPERIENCE V1.0Document28 paginiDS WhitePapers Concurrent-Engineering-with-3DEXPERIENCE V1.0Nikola Bojke BojovicÎncă nu există evaluări

- (Advances in Design and Control) Amarjit Sahota-Sustainability - How The Cosmetics Industry Is Greening Up-Wiley (2014)Document363 pagini(Advances in Design and Control) Amarjit Sahota-Sustainability - How The Cosmetics Industry Is Greening Up-Wiley (2014)Luany VidalÎncă nu există evaluări

- The Adkar Model As A Measurement Framework: Applications of ADKAR Research StudyDocument14 paginiThe Adkar Model As A Measurement Framework: Applications of ADKAR Research StudyPatricia ValenzuelaÎncă nu există evaluări

- Kurisu (2015)Document176 paginiKurisu (2015)Diiana AmézquiitaÎncă nu există evaluări

- Food SCP Circular Economy Report Feb 2018Document32 paginiFood SCP Circular Economy Report Feb 2018Otres100% (1)

- ProjectManager Project Plan Template CMDocument10 paginiProjectManager Project Plan Template CMnandiniÎncă nu există evaluări

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)