Documente Academic

Documente Profesional

Documente Cultură

High-Speed Visualization of Droplet Impingement On High Temperature Solid and Liquid Metal Surfaces

Încărcat de

NejdetEXnTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

High-Speed Visualization of Droplet Impingement On High Temperature Solid and Liquid Metal Surfaces

Încărcat de

NejdetEXnDrepturi de autor:

Formate disponibile

8

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Korea, May 26 - 31, 2013

High-speed visualization of droplet impingement on high temperature solid and liquid metal surfaces

Nejdet Erkan1, Tetsui Yasui1, Koji Okamoto1

1

Nuclear Professional School, The University of Tokyo, Japan

Keywords: Droplet, impingement, sub-atmospheric pressure, boiling, liquid metal, visualization

Abstract Liquid droplet impingement boiling on the hot surfaces has crucial importance for the industries employing spray cooling applications Although numerous experimental and computational efforts exist in the literature, several contradictory approaches, pertaining to the thermal-hydraulic behaviour of droplets, are encountered due to the parametric sensitivity of the phenomena. Complex and uncontrollable boundary conditions, such as surface roughness and ambient pressure, may affect the results in variety of ways that cause one to end up with irrelevant conclusions in every occasion. In order to understand the physical mechanism behind some series of experiments are performed under atmospheric and sub-atmospheric pressures with heated cupper plate and liquid metal which eliminates the effect of surface roughness. A distinct boiling behaviour is observed on the surfaces with/without surface roughness. On the polished cupper surface droplet keeps its integrity with intermittent touching to the surface and bouncing back from the surface at 313 oC, in contrast, trapped vapour layer bursting from periphery breaks the droplet suddenly into small flying out liquid fragments on liquid metal surface. In addition to the surface roughness, ambient pressure is decreased to 50 kPa at which time delay of boiling incipience follows different tendencies in both ambient pressures at similar super heat values suggesting that lesser air molar concentration in the environment cause remarkable delays in the incipience of boiling.

Introduction Hydrodynamic and thermodynamic characteristics of liquid droplet impingement onto hot-surfaces have profound significance for various industrial applications, which utilize spray cooling, such as ex-vessel cooling for in-vessel melted core retention in case of a nuclear power plant (NPP) severe accident, hot-core reflooding by the emergency cooling systems of an NPP, cooling of electronic systems, combustion inside an engine, metallurgical quenching and spacecrafts heat rejection systems etc. Spray cooling is an effective method of cooling employing liquid droplets fragmented by a spray nozzle and directed to a targeted hot surface. The droplets spread on the surface and evaporate or form a thin liquid film removing large amounts of energy due to the latent heat of evaporation. Heat transfer rates, much higher than in pool boiling, can be obtained with sprays since less resistance exists against the removal of vapor film formed in between the hot-surface and liquid (Celata et al 2009, Mohapatra et al 2012, Kim 2007 and so on). In essence, that film layer is speculated to be a mixture of vapor and ambient gas, and it degrades the heat flux in wall-liquid interface severely. Although the spray systems include multiple droplets and an individual droplet behavior cannot be extrapolated to the dynamics of large spray systems, the physics behind still demands fundamental investigations in simplified scales to develop efficient cooling systems.

Although numerous studies, dedicated to the understanding of thermal-hydraulic mechanism of the droplet impingement onto hot-surfaces, exists in the literature, the number of investigations still continues to increase due to the recent availability of more advanced and high-speed experimental and computational tools. Even though those noteworthy amounts of progresses in this branch of research available, contradictory approaches related to the boiling physics of a droplet have arisen due to the parametric sensitivity the phenomena which are originated from the complex uncontrollable boundary conditions (BC) (e.g. surface properties, ambient conditions and so on) of the problem (Moreira et al 2010). Heat transfer from the hot-surface to the droplet is dictated by several parameters which are needed to be identified for most of the cooing applications due to the variety of surface properties determining the critical parameters such as critical heat flux, Leidenfrost boiling point etc. In this study, we presented a parametric study addressing significant factors of droplet impingement boiling phenomena with the experimental results obtained from high-speed visualization tests performed under well-controlled BCs. Polished and etched cupper plate and a liquid metal, contained in a stainless steel pot, services as a hot surface under atmospheric pressure and sub-atmospheric pressure. Liquid metal (U-Alloy) as a hot-surface provides a smooth surface due to its high surface tension that discards the major effects of surface roughness. Additional to the elimination of surface roughness effect, droplet impingement on liquid metal

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Jeju Korea, May 26 - 31, 2013

surface under sub-atmospheric atmospheric pressure is investigated to elucidate interference of air molecules with vapor-liquid interface which forms a heat flux resistance controlling the boiling behavior.

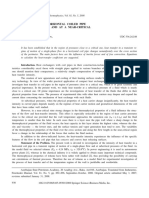

Experimental Facility xperimental setup for the A schematic layout of experimental atmospheric and sub-atmospheric atmospheric pressures is shown in Figure 1. Precision flow controller drives the distilled water flow with a syringe pump. . A plastic microtube, having inner and outer diameters of 150 m and 360 m respectively, is connected to the syringe pump. Droplet dispatch and impinge onto hot-surface surface from a decided height when it reaches to maximum size which can be supported by the surface tension forces against gravity. Utilizing surface tension and gravity force balance, balance nearly uniform dispatching droplet diameter of around 2.5 mm is produced at the tip of the tube. Temperature of the hot plate is controlled according to thermocouple data which is recorded 2 mm below the liquid metal surface. surface U-alloy 70 (an alloy of Bi, Pb, Cd, and Sn, having g melting point of 70 o C, density of 9946.27 kg/m3) is used as a hot surface and assumed to be non-deformable deformable due to the droplet impact since its density and surface tension are much higher than those of water. Liquid metal surface temperature agitated to lover temperatures due to the droplet impingement; however, it recovers to 95% of settled initial temperature in 35s. As a solid hot-surface, surface, polished cupper plate (30x30 mm, 0.5 mm thick) is employed. Time resolved images are recorded with a high-speed camera mera operating at spatial and temporal resolutions of 256x256 pixels and 10 kHz respectively. 200 mm Nikon Micro Nikkor lens is adapted to the camera to have larger spatial resolutions.

tremendously varying characteristics characteristic associated with the type of material and surface chemistry. Figure 2 and Figure 3 show temporal evolution of water droplet after initial contact with the cupper plate and liquid metal respectively with inverted (a) and filtered images (b) under ambient conditions with similar Weber numbers. To amplify the surface roughness effects, relatively relativel low impact velocities are chosen in order to prevent the splashing effects, resulted from energetic impacts, from suppressing the surface roughness contribution. When the droplet impinge onto the cupper plate having a temperature of 313 oC which is well above 225 oC estimated Leidenfrost point (LFP) by Bernardin et al (1997) and regarded as lower temperature boundary of film boiling regime, wavy structures on droplet surface can be discerned from varying non-uniformity uniformity of image intensities (Figure 2a). Disturbances observed after 1.3 ms on droplet surface are characterized with unordinary random motions which are made more explicit with Sobel filtering in Figure 2b. Two modes of surface waves are distinguished during droplet collision onto the hot surface above LFP. First mode is created due to the droplet impact kinetic energy which is partially transferred to the droplet and generates uniform energetic waves encircling the droplet and propagating from the bottom of the droplet to the upward direction. Those hydrodynamic waves are visible to some extent from 1 ms and 1.3 ms after droplets contact with the surface (Figure 2a). . Parallel horizontal lines and smooth pulses on the edge of the droplet (Figure 2b) ) until the 2.3 ms also confirm those structures from another perspective. perspective The he second mode is characterized as nonuniform random fluctuations which begin to appear a on the droplet surface after 2.3 ms that indicates nonuniform non pressure transients taking place beneath the droplet due to the instantaneous vapor generation from the nucleation spots. spots Vapor layer is having intermittent pressure fluctuations which disturbs lower surface of droplet, promote unstable waves propagating whole across the liquid surface. Pressure variations are likely to be caused by non-uniform vapor generation rate attributed to the non-uniformity non of surface structures (surface roughness), since indented uneven structures lead to non-uniform uniform heat transfer to the liquid surface with intermittent direct contact conduction by rupturing the vapor film. Elevated heat transfer rates enhance vapor por production rate resulting in droplet bounce back from the surface with keeping its integrity (7.6 ms later in Figure 2 ).

Figure 1: Schematic view of experimental setup.

Results and Discussions Effect of surface roughness One of the important parameter in boiling phenomena whose effects still cannot be resolved sufficiently due to its

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Jeju Korea, May 26 - 31, 2013

droplet without creating any non-uniform non strain on the water interface (from 0 ms to 2.9 ms in Figure 3). Upon vapor layer reaching sufficient pressure for breaking out its entrapment, , but not sufficient for lifting the t droplet yet, it erupt from the periphery instead of lifting the droplet off (at 2.9 and 3.1 ms in Figure 3).

(a)

(a)

(b) Figure 2: Droplet impingement on cupper plate a) original inverted images b) filtered with Sobel, (313 oC, We=5.2, u=0.39 m/s). On the contrary, in the case of zero surface roughness (liquid metal surface) first mode of waves continued to be monitored until droplet reaches its largest spreading diameter up to 2.9 ms, any notion of uneven disturbances on the droplet surface cannot be discerned (Figure Figure 3a-b). Soon after at 3.1 ms a liquid spurt urt come into sight from the water and liquid metal interface suggesting that droplet spread on the surface as much as surface tension forces allowed and vapor layer reached ched the maximum maximu necessary pressure for disrupting the liquid layer on it and erupted. erupted This blast of vapor wieldy destroys and fragments water in the proximity of interface resulting in flying out of small secondary droplets. Unlike to cupper surface, no major m non-structured disturbances developed on the droplet surface until a sudden blast taking place through the interface up to 3.1 ms. Based on this observation, we may speculate that a stable vapor layer is formed under the droplet in contrast to cupper cuppe surface case in which localized pressure disturbances associated with spotted vapor production are discarded by localized strains of water surface without any lumped liquid fragmentation. However, absence of surface roughness on the liquid metal surface leads to a uniform vapor generation that degraded the heat transfer rate from surface to the droplet equally for every spatial position beneath the water

(b) Figure 3: Droplet impingement on liquid metal a) original inverted images b) filtered with Sobel, (307oC, We=4.7, u=0.37 m/s). Contact angle and boiling incipience dependence on surface roughness The contact angle between a liquid and a solid surface is regarded as one of the important parameters parameter governing boiling phenomena since it characterizes wettability of a certain solid surface by a specific fluid (Tong et al 1990). During droplet impingement onto hot liquid metal surface, we observed erved a sudden stepwise decline in contact angle whereas on cupper er plate such a rigorous variation could not be detected. As mentioned and discussed partially in previous section, droplet on the hot liquid metal surface sits on a vapor/air cushion for a while then suddenly wetted with the liquid metal surface which initiate initia the boiling. g. A description of that rapid change in contact angle is demonstrated in Error! Reference source not found.,

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Jeju Korea, May 26 - 31, 2013

from those time sequential images transient variation of contact angle is detected and

captured at the instants of 2.7 and 2.9 ms in Figure 3, it is clearly visible that sudden change in contact angle is followed by incipience of boiling. Based on this finding a parameter regarded as delay time and identified as the time elapsed until a drastic change of contact angle takes place is employed to investigate the droplet impingement boiling on a surface. Effect of droplet velocity on boiling incipience

Figure 4: Stepwise change of contact angle.

Temperature 307 202 106 108 (Copperplate)

150 [degree] 100 50 0

3 Time[ms]

Figure 5 Variation of contact angle after the collision of droplets to the liquid metal surface with 0.37 m/s velocity. velocity

150 [degree] 100 50 0

Temperature 309 202 105 110 (Copperplate)

Zero surface roughness changes the droplet drople boiling characteristics due to the effect of wettability of droplet with the liquid metal. Delay time for the surface wetting and incipience of boiling is explored for different impact velocities and illustrated in Error! Reference source not found.. For all velocities delay time remains nearly unchanged up to the 80K superheat (corresponding ( to a surface temperature of around 180 oC), later on a peak having different magnitudes are observed. General tendency of delay time variation, especially for the case of 0.37 m/s impact velocity, with respect to the wall super heat resembles the drop evaporation curve introduced by Bernardin and Mudawar (1999). In their study, sessile drop evaporation time me decreases in nucleate boiling regime until the CHF temperature corresponding to minimum drop life time, thereafter droplet life time start to increase in transition to film boiling regime which continues up to the LFP point temperature. From that perspective, perspe the peak in delay times for the case of 0.37 m/s corresponds to an implicit evidence of boiling mode transition point which can be speculated to be critical temperature for the transition to film boiling regime. However, onset of transition to film boiling regime occurs in stepwise manner that differs from the case of sessile droplet. Transition boiling continues up the surface temperature of 238 oC, after that temperature droplet and surface contact could not be observed that t implies the LFP point is i already exceeded.

3 Time[mc]

Figure 6 Variation of contact angle after the collision of droplets to the liquid metal surface with 0.41 m/s velocity. velocity plotted in Error! Reference source not found. and Error! Reference source not found. for the impact velocities of 0.37 m/s and 0.41 m/s respectively. At a first glance on these graphs, droplet is wetted with the liquid metal surface earlier when it impinge on with a higher velocity ve (Error! Reference source not found.) compared to the lower velocity case (Error! Reference source not found.). On the other hand, impingement velocity does not affect gradually the time evolution of contact angle with cupper surface which has 108 oC surface temperature. It increases in first 1 ms then reaches a maximum value and retain this value val for a relatively longer time for both impingement speeds that is likely to be due to the surface roughness of cupper plate. When the shape of two sequential images of one droplet

Figure 7: Delay time or boiling incipience time variation due to the surface temperature for several droplet velocities. Similarly, smaller maller peaks detected at 180 oC surface temperature for the higher impact velocities, however, they may not be attributed to a transition point due to the fact that delay times continues to decrease after that point

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Jeju Korea, May 26 - 31, 2013

as well. That decrement in delay times turn to increment with a steep climb at around 280 oC (at around super heat he of 180K) and any wettability event cannot be observed after around 200K wall superheat. 180K superheat value is likely to be a minimal point for the transition regime to film boiling. Bernardin et al (1997) reported critical heat flux (CHF) temperature on a polished cupper surface for the impinging droplets having a 3 mm diameter and 0.7 m/s velocity as 130 oC. They hey concluded that CHF and LFP temperatures, temperatures 130 oC and 225 oC respectively, seems fairly insensitive to droplet impact velocity over tested range. On the other hand, they demonstrated that while CHF temperature is insensitive to surface roughness, LFP temperature shows higher sensitivity against surface roughness. Considering the e boiling behavior of droplets impinging on solid metallic surfaces, which has some particular level of surface roughness even though surface treatment applied, it would not be inappropriate to come into such a conclusion that under the zero surface roughness ess LFP and CHF temperatures are likely to be varying rying drastically according to the surface superheat and droplet impingement velocity as it is evidenced from the surface wettability transients. transients

beginning earlier than those of atmospheric pressure case ca and rises up to elevated levels at a superheat super temperature of 80K. . If we took into account solely the differences in latent heats of both cases and the time to reach a stable film boiling, the peak in boiling delay in sub-atmospheric sub pressure must have been developed at higher superheats and it must have not been much diverged from the atmospheric pressure. From this point of view, another factor must come into play and govern the film boiling regime by generating more stable blockage against heat transfer er and prevents droplets wetting during boiling in sub-atmospheric pressures.

Effect of pressure The noncondensible gas and ambient pressure press is another important parameter governing verning the boiling phenomena. Emmerson (1975) investigated sessile droplet boiling and found that droplet evaporation time is reduced as the pressure increases. He explained lained that tendency associating with the decrease ease in latent heat of vaporization due to increasing pressure. He also noted that whereas LFP increases with pressure, droplet evaporation time or droplet lifetime remain shorter. Buchmuller et al (2012) studied droplet impingement boiling under high pressures, up to t 16 bars, with water droplets having 2.4 mm diameter and 0.77 m/s impact velocity. They observed shifts in boiling transition points including LFP due to the increase in saturation temperature. Error! Reference source not found. presents pre the delay time variation versus wall superheat heat under atmospheric pressure and sub-atmospheric pressures for the droplets hitting to surface at the speeds of 0.41 m/s and 0.43 m/s. m/s Red line denotes the surface temperatures and superheat values at which peaks are detected for both cases. cases While no significant delay in wettability due to the boiling is observed for the case of sub-atmospheric atmospheric pressure in between 0-60 oK superheat regions, a particular particu level of delay is detected under atmospheric pressure in the same range of superheat. If we extrapolate the Emmerson (1975)s point of view (valid for the pressures higher than the atmospheric one) to the sub-atmospheric pressure; since ince the latent heat of saturated water at 50 kPa (2305 kJ/kg) higher than that of atmospheric pressure (2257 kJ/kg), apparently more heat energy is needed for the creation of vapor layer in sub-atmospheric atmospheric pressure, hence, the reason of no delay in boiling around low super-heats (below 25K) is likely to be the lack of sufficiently thick vapor layer formation. On the other hand, , we observed an intriguing sharp increase in delay time under the sub-atmospheric atmospheric pressure

Figure 8: Delay time versus super-heat sup at atmospheric (0.41 m/s) and sub-atmospheric atmospheric (0.43 m/s) m/s pressures. Air bubble entrapment beneath the impinging droplets on solid surfaces in atmospheric pressures is known from some researches in the literature. Thoroddsen et al (2005) investigated the air bubble entrapment under the impacting droplets onto cold solid surfaces. faces. They explored dynamics of air bubble for several time periods elapsed after the first contact of the droplet. They observed air bubble for various impact velocities of the water droplets having a diameter of 4-5.5 mm and showed that air entrapment occurs ccurs in wide range of Weber numbers. Recently reported by Driscoll et al (2012) that at sub-atmospheric sub pressures, a ring of highly populated microbubbles beneath a 3.1 mm diameter silicon oil droplet impacting with 3.19 m/s velocity, in contrast to the atmospheric tmospheric pressure conditions, encircling a larger bubble are entrapped and their sizes grow with decreasing pressure. Under the light of aforementioned previous findings it can be hypothesized that larger delays under sub-atmoshperic atmoshperic pressure is likely to be caused by entrapped air bubbles and accompanying microbubbles which are blocking the droplet wettability and blanketing conductive heat transfer to the droplet leading to larger delays. Even this is the case, further investigation and quantification is essential for the confirmation of this effect.

Conclusions

th

International Conference on Multiphase Flow ICMF 2013, Jeju, Korea, May 26 - 31, 2013

Effective parameters including surface roughness and ambient pressure in droplet impingement boiling phenomena are investigated utilizing polished cupper plate and liquid metal. Boiling behaviour of water droplets demonstrated completely different manner on the liquid metal surface, it is characterized by sudden vapour burst and droplet fragmentation instead of bounce back from the surface. Wetting behavior of droplet shows different tendency with respect to surface roughness. When the droplet hits the liquid metal surface, it remains nonwetted for a while then a rapid wetting is observed, whereas on the cupper surface contact angle increases monotonically and remained constant. With zero surface roughness boiling transition temperatures are likely to be varying drastically according to the surface superheat and droplet impingement velocity as it is evidenced from the surface wettability transients. Under sub-atmospheric pressure boiling behavior of the droplet indicates harsh difference such that delay time increases while the pressure decreases. The reason of this tendency is likely to be associated with the differences in air entrapment dynamics in subatmospheric pressure. References Bernardin J.D. Stebbins C.J. and Mudawar I. Effects of surface roughness on water droplet impact history and heat transfer regimes, Int. J. Heat Mass Transfer, 40-1: 73-88 (1997). Bernardin J.D. Mudawar I. The Leidenfrost point: Experimental study and assessment of existing models. Journal of Heat Transfer, 121:894-903 (1999). Buchmuller I. Roisman I, Tropea C. Influence of elevated pressure on impingment of a droplet upon a hot surface. ICLASS 2012, Heidelberg, Germany (2012). Celata G.P, Cumo M, Mariani A., Saraceno L. A comparison between spray cooling and film boiling during the rewetting of a hot surface. Heat Mass Transfer, 45:1029-1035 (2009). Driscoll M.M. Stevens C.S. and Nagel S.R. Thin film formation during splashing of viscous liquids, Ph. Rev. E, 82:036302 (2010). Emmerson G.S: The effects of pressure and surface material on the Leidenfrost point of discrete dropes of water, Int. J. Heat Mass Transfer, 18:381-386 (1975).

Tong W. Bar-cohen A. Simon T.W and You S.M. Contact angle effects on boiling incipience of highly wetting liquids. Int. J. Heat Mass Transfer, 33-1:91-103 (1990). Thoroddsen S.T. Etoh T.G. Takehara K. Ootsuka N. And Hatsuki Y. The air bubble entrapment under a drop impacting on a solid surface. J. Fluid Mech. 545:203-2012 (2005).

Kim J. Spray cooling heat transfer: The state of the art, Int. J. of Heat and Fluid Flow, 28:753-767 (2007). Mohapatra S.S. Chakraborty S. and Pal K. Experimental studies on different cooling process to achieve ultra-fast cooling rate for hot steel plate. Exp. Heat Transfer, 25:111-126 (2012). Moreira A.L.N. Moita A.S. Panao M.R. Advance and challenges in explaining fuel spray impingement: How much of single droplet impact research is useful?, Prog. in Energy and Combustion Sci., 36:554-580 (2010).

S-ar putea să vă placă și

- 1 s2.0 S2214157X20305712 MainDocument22 pagini1 s2.0 S2214157X20305712 MainRohit BudhwaniÎncă nu există evaluări

- Thermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleDocument23 paginiThermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleHéctor ParrAlÎncă nu există evaluări

- High-Pressure Pool-Boiling Heat Transfer Mechanism On Sintered-Particle WickDocument32 paginiHigh-Pressure Pool-Boiling Heat Transfer Mechanism On Sintered-Particle WickJoel Jr Rudinas (Remodulator)Încă nu există evaluări

- Effects of Symmetry On Magnetohydrodynamic Mixed Convection Flow in A Vertical DuctDocument22 paginiEffects of Symmetry On Magnetohydrodynamic Mixed Convection Flow in A Vertical Ducthabo XuÎncă nu există evaluări

- Film Boiling Heat Transfer of Droplet Streams and SpraysDocument15 paginiFilm Boiling Heat Transfer of Droplet Streams and SprayseidelsayedÎncă nu există evaluări

- Wang Et Al. - 2022 - Droplet Impact On A Heated Porous Plate Above The Leidenfrost Temperature A Lattice Boltzmann StudyDocument18 paginiWang Et Al. - 2022 - Droplet Impact On A Heated Porous Plate Above The Leidenfrost Temperature A Lattice Boltzmann Studydongwang12126Încă nu există evaluări

- An Experimental Study of Convective Heat Transfer in Silicon Microchannels With Different Surface ConditionsDocument10 paginiAn Experimental Study of Convective Heat Transfer in Silicon Microchannels With Different Surface ConditionsRam MurtyÎncă nu există evaluări

- Explanation of Early Failure in Porous Media Confined With FL 2020 ComputersDocument22 paginiExplanation of Early Failure in Porous Media Confined With FL 2020 ComputersarifyunandoÎncă nu există evaluări

- HP New Analysis For FlaresDocument0 paginiHP New Analysis For Flareskataria200784Încă nu există evaluări

- Micromechanics of Hydro-Thermal Damage and Fracturing in Rocks Based On DEM Modeling With Thermal ConvectionDocument4 paginiMicromechanics of Hydro-Thermal Damage and Fracturing in Rocks Based On DEM Modeling With Thermal ConvectionMarcelo AguilarÎncă nu există evaluări

- Pag. 144 149 - INFLUENCE OF THE MAGNETIC FIELD ON THE VISCOSITY COEFFICIENT1Document6 paginiPag. 144 149 - INFLUENCE OF THE MAGNETIC FIELD ON THE VISCOSITY COEFFICIENT1Sifra hotritama LumbantoruanÎncă nu există evaluări

- DattaDocument2 paginiDattaArnav BhattacharyaÎncă nu există evaluări

- Numerical Modelling of Second Grade Fluid Flow Past A Stretching SheetDocument34 paginiNumerical Modelling of Second Grade Fluid Flow Past A Stretching SheetSarifulÎncă nu există evaluări

- Commun Nonlinear Sci Numer Simulat: A.A. BakrDocument13 paginiCommun Nonlinear Sci Numer Simulat: A.A. BakrPrashanth GudlaÎncă nu există evaluări

- Thermal Analysis of Concrete DamDocument9 paginiThermal Analysis of Concrete DamchayoubhaasÎncă nu există evaluări

- ACF Journal Vol.7-2Document11 paginiACF Journal Vol.7-2Motz GamingÎncă nu există evaluări

- Development of Hard Secondary Cooling by High-Pressure Water Spray in Continuous CastingDocument7 paginiDevelopment of Hard Secondary Cooling by High-Pressure Water Spray in Continuous CastingaÎncă nu există evaluări

- Fluid Dynamics Research TopicsDocument6 paginiFluid Dynamics Research TopicsJohn Rhey Almojallas BenedictoÎncă nu există evaluări

- Wjarr 2024 0086Document8 paginiWjarr 2024 0086BALOGUNÎncă nu există evaluări

- Ecuación 1Document9 paginiEcuación 1StebanmorenoÎncă nu există evaluări

- The Effects of Hydrophilicity On Water Drainage and Condensate Retention On Air-Conditioning EvaporatorsDocument9 paginiThe Effects of Hydrophilicity On Water Drainage and Condensate Retention On Air-Conditioning EvaporatorsSaheera HazarikaÎncă nu există evaluări

- Rewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceDocument21 paginiRewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceH. LEOCADIOÎncă nu există evaluări

- Artigos para CrtiticoDocument7 paginiArtigos para CrtiticoYves GarnardÎncă nu există evaluări

- Advanced Fluid DynamicsDocument282 paginiAdvanced Fluid DynamicsDjalma G. de SousaÎncă nu există evaluări

- 7-Flow Boiling of R245fa in 1.1 MM Diameter Stainless Stell, Brass and Copper TubesDocument18 pagini7-Flow Boiling of R245fa in 1.1 MM Diameter Stainless Stell, Brass and Copper TubesRamalho12345Încă nu există evaluări

- Heat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidDocument5 paginiHeat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidM. SukarmanÎncă nu există evaluări

- Numerical Modeling of Slot-Jet Impingement Cooling of A Constant Heat Flux Surface Confined by A Parallel WallDocument11 paginiNumerical Modeling of Slot-Jet Impingement Cooling of A Constant Heat Flux Surface Confined by A Parallel WallAEÎncă nu există evaluări

- Leidenfrost EffectDocument10 paginiLeidenfrost EffectSnowswimmerÎncă nu există evaluări

- Advanced Fluid DynamicsDocument281 paginiAdvanced Fluid Dynamicspeyvand100% (3)

- Aik Papyr 1707 Aiche J V41 Iss2 PP241 250 Y1995Document10 paginiAik Papyr 1707 Aiche J V41 Iss2 PP241 250 Y1995fallo1989Încă nu există evaluări

- CFD Analysis On Solar Flat Plate CollectorDocument7 paginiCFD Analysis On Solar Flat Plate CollectorkalirajgurusamyÎncă nu există evaluări

- Local Convective Heat Transfer From A Constant Heat Flux Flat Plate Cooled by Synthetic Air JetsDocument11 paginiLocal Convective Heat Transfer From A Constant Heat Flux Flat Plate Cooled by Synthetic Air JetsEKKACHAI PRABNAKORNÎncă nu există evaluări

- Determination of The Deflector Wall Thickness and Influence of The Maximum Angle of Shock Wave On Heat Exchange in The Combustion Gases of Solid ParticlesDocument10 paginiDetermination of The Deflector Wall Thickness and Influence of The Maximum Angle of Shock Wave On Heat Exchange in The Combustion Gases of Solid ParticlesIJAET JournalÎncă nu există evaluări

- Boiling Crisis Phenomenon Part1Document18 paginiBoiling Crisis Phenomenon Part1jojovaliaveetilÎncă nu există evaluări

- Heat Transfer Boundary Conditions For The Numerical Simulation of The DC Casting ProcessDocument6 paginiHeat Transfer Boundary Conditions For The Numerical Simulation of The DC Casting ProcessOctaviano MichinelÎncă nu există evaluări

- Almanza DSG PTC Bimetallic Receivers PDFDocument7 paginiAlmanza DSG PTC Bimetallic Receivers PDFTaahirÎncă nu există evaluări

- Film-Wise and Drop-Wise Condensation of Steam On Short Inclined PlatesDocument7 paginiFilm-Wise and Drop-Wise Condensation of Steam On Short Inclined PlatessabriinderasabarÎncă nu există evaluări

- 2021-Study On Temperature Rise Distribution of Contact Surface Under Cyclic LoadDocument11 pagini2021-Study On Temperature Rise Distribution of Contact Surface Under Cyclic Loadsaba shirzadiÎncă nu există evaluări

- International Journal of Heat and Fluid Flow: J. Cui, W.Z. Li, Y. Liu, Y.S. ZhaoDocument12 paginiInternational Journal of Heat and Fluid Flow: J. Cui, W.Z. Li, Y. Liu, Y.S. ZhaoFahmi KhaerulÎncă nu există evaluări

- Crompton PaperDocument4 paginiCrompton PaperDeepak C. RajwarÎncă nu există evaluări

- Blowdown of Carbon Dioxide From Initially Supercritical ConditionsDocument9 paginiBlowdown of Carbon Dioxide From Initially Supercritical ConditionsSatyanarayan Sahoo100% (1)

- Effect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat ExchangerDocument9 paginiEffect of Fouling On Thermal and Hydraulic Parameter of Shell and Tube Heat Exchangern.hartonoÎncă nu există evaluări

- Analysis of Water Hammer Forming On The Sheet MetalDocument6 paginiAnalysis of Water Hammer Forming On The Sheet MetalAlexander DeckerÎncă nu există evaluări

- Analysis and Simulation of Residual Stresses of Thermal Barrier CoatingDocument18 paginiAnalysis and Simulation of Residual Stresses of Thermal Barrier Coatingfares99Încă nu există evaluări

- 348 2004 Article BF00266263 PDFDocument11 pagini348 2004 Article BF00266263 PDFRishikesh MusaleÎncă nu există evaluări

- Electrohydrodynamic Enforcement of Evaporation and Gas FlowDocument7 paginiElectrohydrodynamic Enforcement of Evaporation and Gas FlowMichael ReznikovÎncă nu există evaluări

- Morphological Change of Plain and Nano-Porous Surfaces During Boiling and Its Effect On Nucleate Pool Boiling Heat TransferDocument9 paginiMorphological Change of Plain and Nano-Porous Surfaces During Boiling and Its Effect On Nucleate Pool Boiling Heat TransferHany Elsawy AbdelrahmanÎncă nu există evaluări

- Heat Transfer Enhancement of Falling Film Evaporation On A Horizontal Tube BundleDocument18 paginiHeat Transfer Enhancement of Falling Film Evaporation On A Horizontal Tube BundledonyaÎncă nu există evaluări

- CFD, A Design Tool For A New Hot Metal Desulfurization TechnologyDocument14 paginiCFD, A Design Tool For A New Hot Metal Desulfurization Technologyjagadish mahataÎncă nu există evaluări

- A Geomechanical Mechanism That Counteracts Flow Channeling Induced by Reservoir Thermal DrawdownDocument11 paginiA Geomechanical Mechanism That Counteracts Flow Channeling Induced by Reservoir Thermal Drawdownmaribo2005Încă nu există evaluări

- Heat Transfer and Solidification Model of Continuous Slab Casting: Con1DDocument60 paginiHeat Transfer and Solidification Model of Continuous Slab Casting: Con1DGarapati MurarjiÎncă nu există evaluări

- Propane Combustion Reaction MechanismDocument11 paginiPropane Combustion Reaction MechanismAzharuddin Ehtesham FarooquiÎncă nu există evaluări

- An Experimental Investigation of Free and Submerged Miniature Liquid Jet Array Impingement Heat TransferDocument13 paginiAn Experimental Investigation of Free and Submerged Miniature Liquid Jet Array Impingement Heat TransferEKKACHAI PRABNAKORNÎncă nu există evaluări

- The Effect of Polarity and Hydrostatic Pressure On (OK)Document17 paginiThe Effect of Polarity and Hydrostatic Pressure On (OK)Rafi ZhaffÎncă nu există evaluări

- RMI AndersonDocument11 paginiRMI AndersonRebecca ClarkÎncă nu există evaluări

- 2001 - Study of Free Convection Frost Formation On A Vertical PlateDocument8 pagini2001 - Study of Free Convection Frost Formation On A Vertical PlateDeyaeÎncă nu există evaluări

- Experimental Investigation On Forced Convection Over A Rough Flat Plate and Related ImplicationsDocument5 paginiExperimental Investigation On Forced Convection Over A Rough Flat Plate and Related ImplicationsInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Cooling of Plastic On Metallic MandrelDocument16 paginiCooling of Plastic On Metallic MandreljournalÎncă nu există evaluări

- Unsteady MHD Flow of Radiating and Reacting Fluid Past A Vertical Porous Plate With Cosinusoidally Fluctuating TemperatureDocument17 paginiUnsteady MHD Flow of Radiating and Reacting Fluid Past A Vertical Porous Plate With Cosinusoidally Fluctuating Temperaturerakesh_lectÎncă nu există evaluări

- MCAT Chemistry ReviewDocument9 paginiMCAT Chemistry ReviewStellaÎncă nu există evaluări

- 4.4.clapp OscillatorDocument6 pagini4.4.clapp OscillatorRohit KumarÎncă nu există evaluări

- Guoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDocument5 paginiGuoyin Shen, Ho-Kwang Mao and Russell J. Hemley - Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating With Multimode Nd:YAG LaserDeez34PÎncă nu există evaluări

- YSS Cold Working Die PDFDocument11 paginiYSS Cold Working Die PDFHoang Le VuÎncă nu există evaluări

- Fe2o3 Trên CNTDocument96 paginiFe2o3 Trên CNTlumineurÎncă nu există evaluări

- Solution Manual For Introductory Chemistry An Atoms First Approach 1st Edition Burdge Driessen 0073402702 9780073402703Document26 paginiSolution Manual For Introductory Chemistry An Atoms First Approach 1st Edition Burdge Driessen 0073402702 9780073402703stevenÎncă nu există evaluări

- Syllabus MtechDocument8 paginiSyllabus MtechYogesh BadheÎncă nu există evaluări

- Dhakal ArtigoDocument28 paginiDhakal ArtigoMelo PereiraÎncă nu există evaluări

- Schneider Electric - Easy-Harmony-XA2 - XA2ED41Document6 paginiSchneider Electric - Easy-Harmony-XA2 - XA2ED41Trung Trinh BaoÎncă nu există evaluări

- Assignment - Flexibility Method PDFDocument3 paginiAssignment - Flexibility Method PDFZazliana IzattiÎncă nu există evaluări

- Advanced Design of GlassDocument47 paginiAdvanced Design of GlassPaloma ValeÎncă nu există evaluări

- NREL Thin Film Overview-2008Document7 paginiNREL Thin Film Overview-2008eitanc369Încă nu există evaluări

- Tut 8Document1 paginăTut 8Chandra Shekhar BishnoiÎncă nu există evaluări

- RT Relevant DiscontinuitiesDocument70 paginiRT Relevant Discontinuitiesabdo50% (2)

- E207 - Communication Systems: Worksheet For Lesson 07: Standing WavesDocument8 paginiE207 - Communication Systems: Worksheet For Lesson 07: Standing Waves张瑜征Încă nu există evaluări

- Welding of P91Document11 paginiWelding of P91mahmoud_allam3100% (1)

- Steel SectionDocument33 paginiSteel Sectionuthaya kumar100% (2)

- Che 4009 Transport Phenomena Assignment # 1Document7 paginiChe 4009 Transport Phenomena Assignment # 1Bao-Ngoc HoangÎncă nu există evaluări

- Composite Materials ReportDocument47 paginiComposite Materials ReportPatrickÎncă nu există evaluări

- Antonio Zichichi (Ed.), Steven Weinberg (Auth.) - Understanding The Fundamental Constituents of MatterDocument912 paginiAntonio Zichichi (Ed.), Steven Weinberg (Auth.) - Understanding The Fundamental Constituents of MatterMartin Stojanovic100% (1)

- DataSheet-SlimVac en v7Document2 paginiDataSheet-SlimVac en v7pimoesÎncă nu există evaluări

- Aluminium Extrusions - Technical Design GuideDocument174 paginiAluminium Extrusions - Technical Design Guideoliviamaslinuta100% (3)

- Hdpe 3255uDocument1 paginăHdpe 3255udiana sarmientoÎncă nu există evaluări

- Soft Story PDFDocument7 paginiSoft Story PDFאחמד סלאח כאמלÎncă nu există evaluări

- 115 Terram 700 and Ekotex 06 Comparison v1 PDFDocument1 pagină115 Terram 700 and Ekotex 06 Comparison v1 PDFStefan CioaraÎncă nu există evaluări

- Bitumen EmulsionDocument2 paginiBitumen EmulsionSaurabh ShrivastavaÎncă nu există evaluări

- I / Imax Vs Angle Between Polarizer and Analyzer For Laser DiodeDocument2 paginiI / Imax Vs Angle Between Polarizer and Analyzer For Laser DiodeJohn Louie CarmenÎncă nu există evaluări

- Chapter 8 Bonding General ConceptsDocument79 paginiChapter 8 Bonding General Conceptsabd jaf100% (1)

- Mathcad Vle Eos Svna7Document7 paginiMathcad Vle Eos Svna7Saeed AbdÎncă nu există evaluări

- DLL - Science 5 - Q3 - W8Document7 paginiDLL - Science 5 - Q3 - W8Merlyn S. Al-osÎncă nu există evaluări