Documente Academic

Documente Profesional

Documente Cultură

Filter Water Tank

Încărcat de

Hemant SonawadekarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Filter Water Tank

Încărcat de

Hemant SonawadekarDrepturi de autor:

Formate disponibile

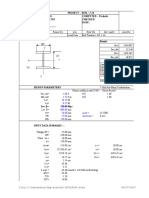

PROJECT

FILTRATION PLANT & ASSOCIATED FACILITIES OF SPRAY COOLING CIRCUIT

CLIENT

THE

TATA

IRON

&

STEEL

CO.

LTD.

CONTRACTOR

THERMAX

WATER & WASTE

LTD.

SOLUTIONS

PUNE.

DOCUMENT NO. : NO. OF PAGES : Rev. : Date. :

WWS/7330/FWT

12 0 24/12/2003

FWT TANK

THERMAX LTD.

DESIGN OF FILTERED WATER STORAGE TANK

DATA : FGL Bottom Level (IL) TWL Width (inside clear) Length (inside clear) Unit Wt. of Concrete Unit Wt. of Soil (gsat) DESIGN CALCULATIONS :

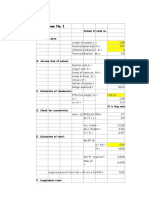

1. DESIGN OF COVER SLAB : (CS)

= = = = = = =

EL (-) 0.5 EL (+) 1.10 (+) 4.10 6.00 3.00 25.00 18

m m kN/m3 kN/m3

Loadings Assume Cover slab Loads :

180

mm thick 0.15 x 25 = = = Total load (w1) = 4.50 3.00 1.00 8.50 kN/m2 kN/m2 kN/m2

Self wt. of slab = Live load = Floor finsh =

Cover slab is designed as One Way slab Short Span of slab (lx) Bending Moments Design as oneway slab Mmax Thk. reqd. for Uncracked section (Q= 0.3216

2

3.400

0.10 x w1 x lx2 = Mmax x 106 Q x 10

3

= =

9.83 174.83 T'fore OK

kNm mm

N/mm ) Effective depth provided = d = =

151 =

mm 482.22 mm2

Reinforcement Ast 150 x 0.9 x d Minimum steel reqd. as per IS 3370 in each direction % Steel Ast min = Ast reqd.

= = =

0.1782857 %

2 320.91429 mm

Ast min provided on each face and in each direction

160.46

mm2

Provide 8F @ 100 c/c (= 502 mm2) as main reinf. at top and bottom Provide 8F @ 230 c/c (= 218 mm2) as distribution reinf. at top and bottom

TISCO_FILT PLANT-SLAB CASTER

FWT TANK

THERMAX LTD.

2. DESIGN OF SIDE WALLS : WALL 1 & WALL 2

Plan Size =

6050

3050

Case 1

: Tank full, and there is no soil pressure from outside......

a. Wall1 : lx = Liquid depth = ( lz) 3.05 m 3.575 m

lx = 3.05 = 0.853 lz 3.575 Refering Reynolds Handbook Chart No. - 53 Condition - Wall Panel with Three Edges fixed and top edge freely supported. Bending Moments Vert. mmt. (-ve) at base Vert. mmt. at center (+ve) Horz. mmt. at support (-ve) Horz. mmt.at center (+ve) = = = = = = = = 0.028 x 35.75 12.79 KNm 0.009 x 35.75 4.11 KNm 0.033 x 35.75 15.08 KNm 0.016 x 35.75 7.31 KNm x x x x 3.575 3.575 3.575 3.575

2

Thickness Thickness of wall required

= = mm

Provide b. Wall2 : lx = Liquid depth = ( lz)

230

15.08 x 1.00E+06 0.3216 x 1000 216.54 mm thick wall.

6.05 m 3.575 m

lx = 6.05 = 1.692 lz 3.575 Refering Reynolds Handbook Chart No. - 53 Condition - Wall Panel with Three Edges fixed and top edge freely supported. Bending Moments Vert. mmt. (-ve) at base Vert. mmt. at center (+ve) Horz. mmt. at support (-ve) = = = = = = 0.0670 x 35.75 30.61 KNm 0.023 x 35.75 10.51 KNm 0.0125 x 35.75 5.71 KNm x x x 3.575 3.575 3.575

2

TISCO_FILT PLANT-SLAB CASTER

FWT TANK

THERMAX LTD.

Horz. mmt.at center (+ve)

= =

0.004 x 35.75 1.83 KNm

3.575

Thickness Thickness of wall required

= = mm

Provide

330

30.61 x 1.00E+06 0.3216 x 1000 308.51 mm thick wall.

Moment Distribution for the horizontal moments : ( This distribution is done in the top portion of the wall.) Distribution factor for wall1 = Distribution factor for wall2 = distribution table : 0.402 wall 1 midspan moments 7.31 3.76 11.07 0.598 wall 2 supp. supp. 15.08 5.71 -3.765 5.61 11.32 11.32 midspan 1.83 -5.61 -3.78 0.402 0.598

final mmts Reinforcement a. Wall 1 :

Ast1 ( Vert. Steel on Water face ) Ast2 ( Vert. Steel on outer face ) Ast31 ( Hori. Steel on at supp. on water face ) Ast41 ( Hori. Steel at center on outer face) Astmin (on each face)

= = = = = = = = = =

12.79 150

x x

1.00E+06 0.87 x 185

2 529.8 mm 4.11 x 1.00E+06 150 x 0.87 x 185 2 170.2 mm 11.32 x 1.00E+06 150 x 0.87 x 185 2 468.7 mm 11.075 x 1.00E+06 150 x 0.87 x 185 2 458.7 mm 0.095 x 100 2 218.17 mm

230

1000

Provide vertical reinf. as below,

TISCO_FILT PLANT-SLAB CASTER

FWT TANK

THERMAX LTD.

8F @ 180 c/c throughtout for full height on inner face + 8F @ 180 c/c extra on water face. 8F @ 230 c/c throughtout for full height on inner face Provide horizontal reinf. as below, 10F @ 230 c/c throughtout for full width on both faces + 8F @ 230 c/c throughout on water face. b. Wall2 : Ast1 ( Vert. Steel on Water face ) Ast2 ( Vert. Steel on other face ) Ast31 ( Hori. Steel on at supp. on water face ) Ast41 ( Hori. Steel at center on outer face) Astmin (on each face) Provide vertical reinf. as below, 10F @ 180 c/c throughtout for full height on inner face + 12F @ 180 c/c extra on water face. 8F @ 160 c/c throughtout for full height on outer face Provide horizontal reinf. as below, 10F @ 230 c/c throughtout for full width on both faces + 8F @ 230 c/c extra at support on water face. Ast =

2 560 mm

Ast = Ast =

2 558 mm 2 219 mm

Ast =

2 560 mm

= = = = = = = = = =

30.61 150

x x

1.00E+06 0.87 x 285

2 823.0 mm 10.51 x 1.00E+06 150 x 0.87 x 285 2 282.6 mm 11.32 x 1.00E+06 150 x 0.87 x 285 2 304.2 mm -3.78 x 1.00E+06 150 x 0.87 x 285 2 -101.5 mm 0.094 x 100 2 309.26 mm

330

1000

Ast = Ast =

2 1064 mm 2 314 mm

TISCO_FILT PLANT-SLAB CASTER

FWT TANK

THERMAX LTD.

3. DESIGN OF BASE SLAB : (BS)

Loadings Assume Cover slab Loads :

380

mm thick t x 25 = = = Total load (w1) = 9.50 35.50 1.00 46.00 kN/m2 kN/m2 kN/m2

Self wt. of slab = water load = Floor finsh =

Cover slab is designed as One Way slab Short Span of slab (lx) Bending Moments Design as oneway slab Mmax Msupp Thk. reqd. for Uncracked section (Q= 0.3216

2

3.400

0.083 x w1 x lx2 0.041 x w1 x lx =

2

= = =

44.3 22.15 371.15 T'fore OK

kNm kNm mm

Mmax x 106 Q x 10

3

N/mm ) Effective depth provided = d = = = Ast 150 x 0.9 x d Ast 150 x 0.9 x d

351 = =

mm 934.90 467.45 mm2 mm2

Reinforcement Ast reqd. Ast reqd.

Minimum steel reqd. as per IS 3370 in each direction % Steel Ast min =

= = =

0.224 851.2 425.60

% mm2 mm2

Ast min provided on each face and in each direction Provide main reinf. as below,

10F @ 180 c/c throughtout for full width on top face + 12F @ 180 c/c extra at walls 10F @ 160 c/c throughtout for full width on bottom face Provide distribution reinf. as below, 10F @ 185 c/c throughtout at top & bottom Ast =

2 425 mm

Ast = Ast =

2 1064 mm 2 491 mm

TISCO_FILT PLANT-SLAB CASTER

FWT TANK

THERMAX LTD.

4. DESIGN WALL2 ACTING AS BEAM -

Width of Beam = b = Depth of Beam = D = Span = l =

330 4380 6.28

mm mm m

Horizontal load on wall beam. UDL on beam i.e. proped cantilever reaction from slab Max BM Max Shear Forec(SF) Depth reqd. Beam is designed as non-cracked section at support : Overall depth reqd. (Q= Reinforcement Ast reqd. for Mmax M x 106 150 x 0.9 x d 0.3216 = Mhog x 106 Qxb

= = =

128.785

kN/m

423.26 kNm 404.3849 kN

1997.04 mm T'fore OK 3008 1042.30 mm mm2

N/mm2) Effective depth provided = d

= =

Provide 20F - 4 Nos (= 1256 mm2) straight bars at on both faces Check for Shear Max Shear Force = SF Reinf. provided at support = Ast

Refer SP 16, Table 80

= = = =

404.38 1256 0.13

kN mm2

100Ast bd Perm. shear stress in concrete = Nominal shear stress = tv = tc SF = bxd Design Shear in stirrups = Vs = (tv - tc) x b x d =

2 0.22 N/mm 2 0.4073832 N/mm

268803.13 N

Use 8F bars as stirrups, ssv = 175 N/mm2 Spacing reqd. ssv=x Asv x d = 195.83105 mm Vs Min. spacing = 0.87fy = x Asv/ 0.4B 273.52 mm Vertical reinf. provided in wall is sufficient.

TISCO_FILT PLANT-SLAB CASTER

S-ar putea să vă placă și

- A23.3-04 CorbelsDocument3 paginiA23.3-04 CorbelsDivyesh MistryÎncă nu există evaluări

- Design of Column: Section ClassificationDocument4 paginiDesign of Column: Section Classificationvenkatesh19701Încă nu există evaluări

- Settling TankDocument70 paginiSettling TankHemant Sonawadekar100% (1)

- UNISA Reinforced Concrete Design Study GuideDocument286 paginiUNISA Reinforced Concrete Design Study GuideRonald Nyirenda83% (24)

- OhsrDocument41 paginiOhsrrk36266_732077041Încă nu există evaluări

- 04-01-2023-WIND LOAD-SEND IIT-SSU - High Rise Buildings Design BasisDocument30 pagini04-01-2023-WIND LOAD-SEND IIT-SSU - High Rise Buildings Design BasismathuÎncă nu există evaluări

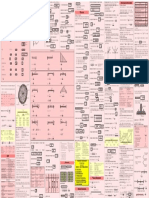

- CIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)Document1 paginăCIVIL ROCKET? CHART Civil Ki Goli (Civil Junction)MR. PRANAV KUMAR67% (3)

- Under Ground SumpDocument7 paginiUnder Ground SumpMariappan .PÎncă nu există evaluări

- Combined FootingDocument2 paginiCombined FootingakhilÎncă nu există evaluări

- Concrete Section Shear Torsion CapacityDocument6 paginiConcrete Section Shear Torsion CapacityjaffnaÎncă nu există evaluări

- 4 - Anchor - Bolts - Base - Plate - DD1-2 - Module 201BDocument8 pagini4 - Anchor - Bolts - Base - Plate - DD1-2 - Module 201Btitir bagchiÎncă nu există evaluări

- 4 - Ce133 - Strength Analysis of Beams According To Aci or NSCP Codes PDFDocument22 pagini4 - Ce133 - Strength Analysis of Beams According To Aci or NSCP Codes PDFRalph PacilÎncă nu există evaluări

- BeamDocument4 paginiBeamAnkit SuriÎncă nu există evaluări

- Staad Pro TutorialDocument572 paginiStaad Pro TutorialSammish8383% (12)

- Design of Equipment Fdns.Document3 paginiDesign of Equipment Fdns.Gaurav Kumar SinghÎncă nu există evaluări

- SAP2000 PushoverDocument20 paginiSAP2000 PushoverHemant Sonawadekar100% (1)

- Retaining Wall For Water PressureDocument9 paginiRetaining Wall For Water Pressuresudipta mandalÎncă nu există evaluări

- Collings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFDocument195 paginiCollings, David - Steel Concrete Composite Bridges (2005, Thomas Telford Publishing) PDFjasmina100% (2)

- Iito Wall: File:///Conversion/Tmp/Scratch/418555233Document7 paginiIito Wall: File:///Conversion/Tmp/Scratch/418555233Saurabh GuptaÎncă nu există evaluări

- Design of Thrust BlockDocument6 paginiDesign of Thrust BlockHemant SonawadekarÎncă nu există evaluări

- Design of Thrust BlockDocument6 paginiDesign of Thrust BlockHemant SonawadekarÎncă nu există evaluări

- PitDocument14 paginiPitJayakumar NarayanÎncă nu există evaluări

- TowerDocument71 paginiTowerS. Chakrabarty MeconÎncă nu există evaluări

- Oh - Tank - Foundation As Per Indian Standard CodeDocument7 paginiOh - Tank - Foundation As Per Indian Standard Codedsananda100% (1)

- Engeurocode Training - En1994-1-1 PDFDocument34 paginiEngeurocode Training - En1994-1-1 PDFAbdulla AljundiÎncă nu există evaluări

- Water Tank - Is 3370-MBBR Tank - 1 & 2Document4 paginiWater Tank - Is 3370-MBBR Tank - 1 & 2Dhayalan PalanisamyÎncă nu există evaluări

- Base Plate1Document6 paginiBase Plate1jobees7850Încă nu există evaluări

- Cantilever BeamDocument3 paginiCantilever BeamSabareesh KumarÎncă nu există evaluări

- Base Plate DesignDocument32 paginiBase Plate DesignGautam Sharma50% (2)

- 2152-0.50LL Esr-Str-Cal-01 - R1Document30 pagini2152-0.50LL Esr-Str-Cal-01 - R1sssmitÎncă nu există evaluări

- Wall DesignDocument13 paginiWall DesignAnantPawarÎncă nu există evaluări

- Design of GLSRDocument263 paginiDesign of GLSRBattula Sridhar100% (2)

- Capping Beam SummaryDocument1 paginăCapping Beam SummaryZohaib Sattar Nagra100% (1)

- EC 2 Structural Fire DesignDocument12 paginiEC 2 Structural Fire Designkengur123Încă nu există evaluări

- IDEA StatiCa Tutorial - Capacity DesignDocument13 paginiIDEA StatiCa Tutorial - Capacity Designd_i_z_z0% (1)

- Week 12 - Design of Pad Footing - 2Document31 paginiWeek 12 - Design of Pad Footing - 2Muhd Fizi100% (1)

- Isolated Footing Design: Forces DetailsDocument7 paginiIsolated Footing Design: Forces DetailsMukhlish AkhatarÎncă nu există evaluări

- Pile Foundation For Tower Type - A-r0-Ntpc Simhadri-Combined Part-1Document85 paginiPile Foundation For Tower Type - A-r0-Ntpc Simhadri-Combined Part-1Hemant SonawadekarÎncă nu există evaluări

- Design of Footing - F5 0.23 X 0.38 MDocument26 paginiDesign of Footing - F5 0.23 X 0.38 MsaravananÎncă nu există evaluări

- Design of Base Raft: Title Conveyor Tunnel 1Bc-3Document6 paginiDesign of Base Raft: Title Conveyor Tunnel 1Bc-3Uttam Kumar GhoshÎncă nu există evaluări

- Abut DesignDocument32 paginiAbut DesignSubir Kunda100% (2)

- Pile DDesignDocument14 paginiPile DDesignshivakumarpatgarÎncă nu există evaluări

- On Base PlateDocument20 paginiOn Base PlateHemant SonawadekarÎncă nu există evaluări

- 0010-SIL-019035-C-HP-16-DC-0010-R0-Design of Second Floor BeamsDocument37 pagini0010-SIL-019035-C-HP-16-DC-0010-R0-Design of Second Floor BeamsHunny VermaÎncă nu există evaluări

- Purlin DesignDocument2 paginiPurlin DesignAnonymous JUn5jis0Încă nu există evaluări

- Flat Slabs11Document50 paginiFlat Slabs11Hemant SonawadekarÎncă nu există evaluări

- SteelDesign Composite Fu NewDocument16 paginiSteelDesign Composite Fu Newpresentasi mankonÎncă nu există evaluări

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocument10 paginiDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5Încă nu există evaluări

- Check Detailing For 160 Mva Fire WallDocument12 paginiCheck Detailing For 160 Mva Fire WallAnindit MajumderÎncă nu există evaluări

- Built-Up Steel ColumnDocument13 paginiBuilt-Up Steel Columnanimesh91Încă nu există evaluări

- Jeppiaar TG Deck DocumentDocument174 paginiJeppiaar TG Deck Documentsmkdigitech100% (1)

- Box+Culvert+by+R S VasneyDocument10 paginiBox+Culvert+by+R S VasneyfwrconsultantÎncă nu există evaluări

- PedestalP2 - (350x350) 7Document23 paginiPedestalP2 - (350x350) 7Feroz Khan PatthanÎncă nu există evaluări

- Isolated Footing For ColumnsDocument8 paginiIsolated Footing For Columnskushaljp8989Încă nu există evaluări

- Check List For Structural DesignDocument1 paginăCheck List For Structural DesignHemant SonawadekarÎncă nu există evaluări

- Isoloated Footing DesignDocument7 paginiIsoloated Footing Designvijay moreÎncă nu există evaluări

- C Ring 40kL 20m 50w 10t Ohsr On PlainDocument20 paginiC Ring 40kL 20m 50w 10t Ohsr On PlainVineel Kumar BapatlaÎncă nu există evaluări

- UG Sump LX by Ly More Than 2Document10 paginiUG Sump LX by Ly More Than 2Mike VictorÎncă nu există evaluări

- Beam DeflectionDocument69 paginiBeam DeflectionMohd Asis Latip67% (3)

- Foundation ForcesDocument9 paginiFoundation ForcesHemant SonawadekarÎncă nu există evaluări

- Area of Steel: A 2 Ac 4 B B XDocument6 paginiArea of Steel: A 2 Ac 4 B B XDipeshÎncă nu există evaluări

- Retaining Wall DesignDocument106 paginiRetaining Wall DesignHAITHAM ALIÎncă nu există evaluări

- Sample Calulation BeamDocument9 paginiSample Calulation Beamche azimÎncă nu există evaluări

- Combined Footing Design CF4-2Document10 paginiCombined Footing Design CF4-2Saugat ThapaÎncă nu există evaluări

- R.C.C Designs As Per Is 456-2000Document188 paginiR.C.C Designs As Per Is 456-2000Umesh ChamaraÎncă nu există evaluări

- Gantry Pole StaadDocument28 paginiGantry Pole StaadEhtesham AliÎncă nu există evaluări

- Design of CW Channel For Section 'A-A'Document30 paginiDesign of CW Channel For Section 'A-A'Hemant SonawadekarÎncă nu există evaluări

- SM-I Lecture NotesDocument121 paginiSM-I Lecture NotessivadhanuÎncă nu există evaluări

- Column Is800Document4 paginiColumn Is800rammohanÎncă nu există evaluări

- Column Base PlateDocument3 paginiColumn Base PlatePurnima ArkalgudÎncă nu există evaluări

- Fixed Beam DesignDocument2 paginiFixed Beam DesignRAVI PRAKASH SAINIÎncă nu există evaluări

- 228 10C 0001 01 Rev0 PDFDocument138 pagini228 10C 0001 01 Rev0 PDFLandon Mitchell0% (1)

- ReportTank 12.0m DiaDocument17 paginiReportTank 12.0m DiasuheilbugsÎncă nu există evaluări

- Column at Node No. A. General DataDocument9 paginiColumn at Node No. A. General DataTarkeshwar Lal SrivastavaÎncă nu există evaluări

- Two Way Slab - IS Code - LSMDocument12 paginiTwo Way Slab - IS Code - LSMNitesh SinghÎncă nu există evaluări

- B85 - Tie Beam Transverse TB-1Document8 paginiB85 - Tie Beam Transverse TB-1FrederickV.VelascoÎncă nu există evaluări

- Isolated Footing DesignDocument19 paginiIsolated Footing Designmohanty_anantakumar6332Încă nu există evaluări

- Hindustan Construction Co. Ltd. Mumbai. Subject: DetailsDocument2 paginiHindustan Construction Co. Ltd. Mumbai. Subject: DetailsHemant SonawadekarÎncă nu există evaluări

- Combined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Document60 paginiCombined Footing: Project Barrack - Mamnoor Silparupa, Hyderabad Title Combined Footing - 2Karthik Kala KondaÎncă nu există evaluări

- Suhas 21/4/2005: Distance Longer DRN Distance Longer DRN From Face of Pedestal/Col From Face of Pedestal/ColDocument26 paginiSuhas 21/4/2005: Distance Longer DRN Distance Longer DRN From Face of Pedestal/Col From Face of Pedestal/ColSuhas MangaloreÎncă nu există evaluări

- Beam Designation:-Member Number: - Load CombinationDocument2 paginiBeam Designation:-Member Number: - Load CombinationdhanarajÎncă nu există evaluări

- Design of Foundation: Design Inputs 120.5 KN 1247.1 KN 127.1 KNDocument7 paginiDesign of Foundation: Design Inputs 120.5 KN 1247.1 KN 127.1 KNprince francisÎncă nu există evaluări

- Crux Prestressing Pvt. LTD.: Pile DataDocument5 paginiCrux Prestressing Pvt. LTD.: Pile DataIlmtalabÎncă nu există evaluări

- Wcee2012 2080 PDFDocument8 paginiWcee2012 2080 PDFHemant SonawadekarÎncă nu există evaluări

- Wcee2012 0301Document10 paginiWcee2012 0301Hemant SonawadekarÎncă nu există evaluări

- Preliminary Study of The Structural Role Played by Masonry Infills On RC Building Performances After The 2011 Lorca, Spain, EarthquakeDocument10 paginiPreliminary Study of The Structural Role Played by Masonry Infills On RC Building Performances After The 2011 Lorca, Spain, EarthquakeHemant SonawadekarÎncă nu există evaluări

- Macro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtDocument28 paginiMacro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtHemant SonawadekarÎncă nu există evaluări

- Wcee2012 0458 PDFDocument10 paginiWcee2012 0458 PDFHemant SonawadekarÎncă nu există evaluări

- Design of Outlet ChamberDocument7 paginiDesign of Outlet ChamberHemant SonawadekarÎncă nu există evaluări

- Settling TankDocument70 paginiSettling TankHemant SonawadekarÎncă nu există evaluări

- Introducing PBL Into Civil and Structural Engineering Introducing PBL Into Civil and Structural EngineeringDocument9 paginiIntroducing PBL Into Civil and Structural Engineering Introducing PBL Into Civil and Structural EngineeringHemant SonawadekarÎncă nu există evaluări

- Design of Effluent Pit: Permissible StressesDocument26 paginiDesign of Effluent Pit: Permissible StressesHemant SonawadekarÎncă nu există evaluări

- Indian LanguagesDocument29 paginiIndian LanguagesHemant SonawadekarÎncă nu există evaluări

- Analysis of Sdof System by Linear Theory of Base IsolationDocument34 paginiAnalysis of Sdof System by Linear Theory of Base IsolationHemant SonawadekarÎncă nu există evaluări

- 27 Bolt Group PulloutDocument14 pagini27 Bolt Group PulloutALPHYL BALASABASÎncă nu există evaluări

- Iti Building Chikodi - ElectricalDocument41 paginiIti Building Chikodi - ElectricalHemant SonawadekarÎncă nu există evaluări

- Grid Floors11Document37 paginiGrid Floors11Hemant SonawadekarÎncă nu există evaluări

- Ssssss Ssssssssss Sssssssssss Ssss Sssssssss Ss Sss Ssss Sssss.Document20 paginiSsssss Ssssssssss Sssssssssss Ssss Sssssssss Ss Sss Ssss Sssss.Hemant SonawadekarÎncă nu există evaluări

- Calculation For Determination of 'R' FactorDocument1 paginăCalculation For Determination of 'R' FactorHemant SonawadekarÎncă nu există evaluări

- Calculation of Wind Pressure: Project: Chimney at GoaDocument11 paginiCalculation of Wind Pressure: Project: Chimney at GoaHemant SonawadekarÎncă nu există evaluări

- SAP - Non Linear Analysis - AzadDocument20 paginiSAP - Non Linear Analysis - AzadHemant SonawadekarÎncă nu există evaluări

- One Way Slabs11Document12 paginiOne Way Slabs11Hemant SonawadekarÎncă nu există evaluări

- Earthquake-Resistant Design of Open Ground Storey RC Framed BuildingsDocument8 paginiEarthquake-Resistant Design of Open Ground Storey RC Framed BuildingsHemant SonawadekarÎncă nu există evaluări

- Mekanika Bahan (Eng)Document3 paginiMekanika Bahan (Eng)gundulpÎncă nu există evaluări

- Cost Optimization of Column of An Industrial BuildingDocument9 paginiCost Optimization of Column of An Industrial BuildingMadhusudan MadhuÎncă nu există evaluări

- CHEN20191 Materials Science & Mech. Design Exam Paper - FinalDocument6 paginiCHEN20191 Materials Science & Mech. Design Exam Paper - FinalSKITTLE BEASTÎncă nu există evaluări

- User Guide A Draft 1Document25 paginiUser Guide A Draft 1Shajit KumarÎncă nu există evaluări

- Torsion 89Document1 paginăTorsion 89bagmassÎncă nu există evaluări

- 3 Sc&s3-Reinforced ConcreteDocument13 pagini3 Sc&s3-Reinforced ConcretedophongxdÎncă nu există evaluări

- Highway Bridge SuperstructuresDocument250 paginiHighway Bridge SuperstructuresJannerjoy PimentelÎncă nu există evaluări

- Energy TestDocument19 paginiEnergy TestDataÎncă nu există evaluări

- 4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Document20 pagini4 Commentary On Standard Practice For Design and Conbstruction of Concrete Silos and Stacking Tubes For Storing Granular Materials ACI 313-97Nikki Marlo CruzÎncă nu există evaluări

- Mechanics of Materials: Pure BendingDocument42 paginiMechanics of Materials: Pure BendingmaycollÎncă nu există evaluări

- Materials and Structural SyDocument9 paginiMaterials and Structural SyPratik ManeÎncă nu există evaluări

- Analysis and Design of Flight Vehicles Structures - BruhnDocument817 paginiAnalysis and Design of Flight Vehicles Structures - BruhnSrinivasan MuthuvelÎncă nu există evaluări

- 0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182Document10 pagini0 - Geotechnical Site Classification and Croatian National Annex For Eurocode 8 - P.kvasnicka, Leo Matesic and K.ivandic - 2011 - 8182nebojsadj6411Încă nu există evaluări

- Design Analysis and Optimization of Offshore ModuleDocument116 paginiDesign Analysis and Optimization of Offshore ModuleMirceaÎncă nu există evaluări

- A Critical Analysis of The Design and Construction of Boyne Bridge, IrelandDocument10 paginiA Critical Analysis of The Design and Construction of Boyne Bridge, Irelandahmed55Încă nu există evaluări

- S 127 ContentDocument13 paginiS 127 ContentAnonymous imkwF8N7TeÎncă nu există evaluări

- S Max-A-Form AgDocument40 paginiS Max-A-Form AgMacelevi DareviÎncă nu există evaluări