Documente Academic

Documente Profesional

Documente Cultură

Process Filtration From Pure To Sterile: (P) - GS VE

Încărcat de

Ying Kei ChanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Filtration From Pure To Sterile: (P) - GS VE

Încărcat de

Ying Kei ChanDrepturi de autor:

Formate disponibile

Process Filtration From Pure to Sterile

(P)-GS VE

MAIN FEATURES & BENEFITS:

Excellent material resistance towards steam and aggressive media

Regenerable by Back-flushing or ultrasonication

High dirt holding capacity at low differential pressure and high flow rate

Down to 1 m for culinary steam

For the filtration of air and steam

Approved for Food Contact Use acc. to CFR Title 21 & 1935/2004/EC

INDUSTRIES:

Dairy

Food & Beverage

Fermentation

Pharmaceutical

Chemical

Donaldson Filtration Deutschland GmbH Bssingstr. 1 42781 Haan Germany

Web: www.donaldson.com

Process Filtration PRODUCT DESCRIPTION

The (P)-GS VE filter consists of a regenerable weldless filter pipe made from sintered stainless steel. The retention rate extends from 1 m to 25 m. Steam Filtration The (P)-GS VE filter retains contaminants, such as particles, abrasion of valves and sealings as well as rust. An improved steam quality ensures longer service life of the filters to be sterilized and increases the efficiency of the entire process. The (P)-GS VE filter element offers the possibility of a particularly economic filtration, since the filter medium can be regenerated by ultrasonic bath or by back-flushing. This is especially essential at high particle loads. The porosity level is more than 50 % which ensures high particle and dirt holding as well as a good flow rate at a low differential pressure. Liquid Filtration The heavy-duty construction of the (P)-GS VE filter is designed to withstand a maximum differential pressure up to 5 bar. The filter may also be used in a temperature range of 20 C up to 210 C. Breweries

(P)-GS VE

Typical applications for (P)-GS VE filter elements include:

Chemical industry Pharmaceutical industry Food and beverage Aseptic packaging Electronic industry Dairy industry Plastic industry

Water filtration Chemicals Solvents Pharmaceutical industry Food and beverage Syrup Cosmetics Paints Salt- and Seawater Coolants

Gas Filtration Compressed air Carbon dioxide Nitrogen Tank ventilation Highly aggressive gases

-2-

PRODUCT DESCRIPTION

Process Filtration PRODUCT SPECIFICATIONS

Product Specifications Filtration Surface* Temperature Range

(P)-GS VE

0,05 m2 per 250 mm element (10/30) -50 C (-60 F) to 200 C (400 F) Temperature Resistance of the O-Rings required

Maximum Differential Pressure (Flow Direction: Outside to Inside)

5 bar (75 psid), independent of the system pressure or temperature

Recommended Surface Loads relating to Filtration Surface:

Pore Size [m]

Gases / Air [l/h] per 1 cm2

Liquids up to 3 cp viscosity [l/h] per 1 cm2 1,5 - 5 1,5 - 5 1,5 - 5

Saturated Steam [l/h] per 1 cm2 2 bar 120 140 180 4 bar 80 90 110 6 bar 55 65 80

1 5 25

60 - 200 60 - 200 60 - 200

* For other element sizes see correction factor CF in section Available end cap configurations

RETENTION RATES

Retention Rates (Air, 20 C, 90 Nm3/h,10/30 Element) Pore Size [m] 1 5 25 98 % [m] 0,5 1 5 100 % [m] 1,0 5 22 Minimum Thickness 1,5 mm 2,0 mm 3,0 mm

Retention Rates (Steam, 121 C, 90 kg/h, 10/30 Element) Pore Size [m] 1 5 25 98 % [m] 2 6 12 100 % [m] 12 15 35 Minimum Thickness 1,5 mm 2,0 mm 3,0 mm

Retention Rates (Water, 20 C, 10/30 Element) Pore Size [m] 1 5 25 98 % [m] 2 6 12 100 % [m] 12 15 35 Minimum Thickness 1,5 mm 2,0 mm 3,0 mm

-3-

PRODUCT SPECIFICATIONS & RETENTION RATES

Process Filtration MATERIAL COMPLIANCE USA

(P)-GS VE

All components of the (P)-GS VE filter element are FDA listed for food contact use in the Code of Federal Regulations (CFR), Title 21. Filter Materials Filter Matrix: End Caps: O-Rings: Alternatively: Stainless Steel 1.4404 Stainless Steel 1.4301 EPDM Silicone Buna N PTFE over silicone PTFE over viton CFR Title 211.65 211.65 177.2600 177.2600 177.2600 177.1550 177.1550

All products have been inspected and released by Quality Assurance as having met the following requirements:

All filters are fabricated without the use of binders, adhesives, additives or surfaceactive agents.

All filter components based on plastics are non-toxic and are certified bio-safe in accordance with current USP Class VI Tests for Plastic.

MATERIAL COMPLIANCE EU

The Donaldson (P)-GS VE filter element meets the guideline for Food Contact Use as given in European Regulation (EC) Number 1935/2004. This specific element is suited for Food Contact Use since all components meet the requirements of the 1935/2004/EC for materials and products intended to come in contact with food stuff (excluding o-rings). For specific details on the O-rings, please contact your Donaldson Sales Engineer.

-4-

MATERIAL COMPLIANCE

Process Filtration FLOW CHARACTERISTICS

(P)-GS VE

0,12 Initial Diff. Pressure [bar] 0,1 0,08 0,06 0,04 0,02 0 0 10 20 30 40 Flow [l/min] 50 60 70 80

(P)-GS VE, 10/30, 1 m 5 m 25 m Deionised water, 20 C

120 Initial Diff. Pressure [mbar] 100 80 60 40 20 0 0 100 200 300 Flow [m3/h] 400 500 600

(P)-GS VE, 10/30, air, 20 C, 1 m 5 m 25 m 1 bar absolute

120 Initial Diff. Pressure [mbar] 100 80 60 40 20 0 0 100 200 300 Flow [m3/h] 400 500 600

(P)-GS VE, 10/30, saturated 1 m 5 m 25 m steam, 121 C, 2 bar absolute

-5-

FLOW CHARACTERISTICS

Process Filtration AVAILABLE END CAP CONFIGURATIONS

(P)-GS VE

Dimensions (CODE 7 connection): Size 10 20 30 mm 250 500 750 CODE 7 a b inch mm inch 9,84 315 12,40 19,68 585 22,24 29,53 815 32,08

b

c mm 56,5 56,5 56,5 inch 2,22 2,22 2,22

Dimensions (uf plug connection): Size 03/10 04/10 04/20 05/20 05/25 07/25 05/30 07/30 10/30 15/30 20/30 30/30 30/50 mm 76 104 104 128 128 180 128 180 254 381 510 764 764 a uf plug Connection b C* CF** inch mm inch mm inch 2,99 87 3,42 30 1,18 0,12 4,09 118 4,64 30 1,18 0,17 4,09 118 4,64 37 1,46 0,19 5,04 142 5,59 37 1,46 0,25 5,04 142 5,59 37 1,46 0,32 7,08 194 7,64 37 1,46 0,47 5,04 144 5,67 61 2,40 0,46 7,08 196 7,71 61 2,40 0,68 10 270 10,63 61 2,40 1,00 15 397 15,63 61 2,40 1,55 20 526 20,63 61 2,40 2,10 30 780 30,63 61 2,40 3,28 30 780 30,63 89 3,50 5,89

* Plug-type connection with double o-ring ** Correction factor Filtration surface & Flow rate

Technical alterations reserved 04/2009

For information on integrity test equipment or integrity test services, please contact your Donaldson Sales Engineer and visit our website at www.donaldson.com!

(Rev03 07/10)

S-ar putea să vă placă și

- (P) SRFDocument6 pagini(P) SRFYing Kei ChanÎncă nu există evaluări

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDe la EverandModeling, Control, and Optimization of Natural Gas Processing PlantsEvaluare: 5 din 5 stele5/5 (1)

- Sterile Air and Steam Filtration with (P)-GSL N ElementsDocument6 paginiSterile Air and Steam Filtration with (P)-GSL N ElementsbmsengineeringÎncă nu există evaluări

- 014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamDocument6 pagini014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamNg MeriedÎncă nu există evaluări

- P GS VE Steam Filter ElementsDocument6 paginiP GS VE Steam Filter ElementsmarianraulÎncă nu există evaluări

- Gas Sweetening and Processing Field ManualDe la EverandGas Sweetening and Processing Field ManualEvaluare: 4 din 5 stele4/5 (7)

- TF4 Mar 20 06Document6 paginiTF4 Mar 20 06DANIZACHÎncă nu există evaluări

- Filter Elements For Liquid Filters enDocument22 paginiFilter Elements For Liquid Filters enTony Tony TonyÎncă nu există evaluări

- Dimensions: F - F - r910sDocument2 paginiDimensions: F - F - r910swodrÎncă nu există evaluări

- 75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014De la Everand75th Conference on Glass Problems: A Collection of Papers Presented at the 75th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 3-6, 2014S. K. SundaramÎncă nu există evaluări

- OMEGA AIR - Process and Sterile Filtration - EnglishDocument12 paginiOMEGA AIR - Process and Sterile Filtration - EnglishOMEGA AIR d.o.o. LjubljanaÎncă nu există evaluări

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDe la EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceÎncă nu există evaluări

- GF PipesDocument25 paginiGF PipesbureqqÎncă nu există evaluări

- GMST 8238 4 LowendDocument336 paginiGMST 8238 4 Lowendwinwin2302Încă nu există evaluări

- Ultrapoly PE: The Prefilter For The Removal of Solid Contaminants in Gases With Absolute Retention EfficiencyDocument2 paginiUltrapoly PE: The Prefilter For The Removal of Solid Contaminants in Gases With Absolute Retention EfficiencyDefenceDogÎncă nu există evaluări

- PPR-C Pipe SpecificationDocument25 paginiPPR-C Pipe SpecificationAlex Dulay85% (13)

- TD Pmo 6000 en 080108Document16 paginiTD Pmo 6000 en 080108Ricardo DávilaÎncă nu există evaluări

- GDS134Document4 paginiGDS134Saurabh VermaÎncă nu există evaluări

- EPICCDocument2 paginiEPICCphamtram27Încă nu există evaluări

- Proline Pipe & Fittings GuideDocument32 paginiProline Pipe & Fittings GuideJayakrishnan RadhakrishnanÎncă nu există evaluări

- Compressed Air-Quality Optimisation For Pneumatic Control SystemDocument19 paginiCompressed Air-Quality Optimisation For Pneumatic Control Systemupendra35Încă nu există evaluări

- GF System Specification-PROGEF Standard enDocument23 paginiGF System Specification-PROGEF Standard enKlich77Încă nu există evaluări

- Model 2100bDocument4 paginiModel 2100bkeyur1109Încă nu există evaluări

- 2301 2300 2299 2298 2297 2296 2295 2294 2293 2292 2291 1320Document2 pagini2301 2300 2299 2298 2297 2296 2295 2294 2293 2292 2291 1320gheor21Încă nu există evaluări

- Filters - EPE PDFDocument8 paginiFilters - EPE PDFSyed Mujtaba Ali BukhariÎncă nu există evaluări

- Petrogas Filtration CatalogueDocument12 paginiPetrogas Filtration Catalogueleandroperao5374Încă nu există evaluări

- Filter ElementsDocument8 paginiFilter ElementsSheikh ZakirÎncă nu există evaluări

- EATON Filtration FilterCartridgesDocument20 paginiEATON Filtration FilterCartridgeschris110Încă nu există evaluări

- L-Dens 427F Ex Density Sensor SpecificationsDocument6 paginiL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiÎncă nu există evaluări

- SigmaCover 280Document5 paginiSigmaCover 280ajuhaseenÎncă nu există evaluări

- Filtros Sealkeen Emflon IIDocument2 paginiFiltros Sealkeen Emflon IItheflamebearerÎncă nu există evaluări

- Carte Tehnica Boilere CordivariDocument2 paginiCarte Tehnica Boilere CordivariStan Marius VictorÎncă nu există evaluări

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDocument11 paginiInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisÎncă nu există evaluări

- Tygon TubingDocument23 paginiTygon TubingRip_BarÎncă nu există evaluări

- Compressed Air Treatment, Drier and StorageDocument24 paginiCompressed Air Treatment, Drier and StorageAna PrisacariuÎncă nu există evaluări

- Duplex Filters Lube-Fuel OilDocument10 paginiDuplex Filters Lube-Fuel Oilv_emmeÎncă nu există evaluări

- Select the Right Gas and Air Filter for Your ApplicationDocument8 paginiSelect the Right Gas and Air Filter for Your ApplicationJulio OrtegaÎncă nu există evaluări

- Eaton Internormen Hydraulic and Lubrication Oil Filters BrochureDocument12 paginiEaton Internormen Hydraulic and Lubrication Oil Filters BrochureEaton Filtration0% (1)

- Elements Re51420 2010-10Document14 paginiElements Re51420 2010-10Admir TalicÎncă nu există evaluări

- Brand+Ultradur Range+Chart Ultradur+PBT EnglishDocument20 paginiBrand+Ultradur Range+Chart Ultradur+PBT EnglishLuciano Augusto Gerling GarzaÎncă nu există evaluări

- 5.SH-Vortrag 28-11-02-1Document36 pagini5.SH-Vortrag 28-11-02-1Abd Al-Rahmman Al-qatananiÎncă nu există evaluări

- Polyflex UltrachemDocument2 paginiPolyflex UltrachemBraulio Candela NoriegaÎncă nu există evaluări

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 paginiSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroÎncă nu există evaluări

- High Pressure Filters for Hydraulic ApplicationsDocument12 paginiHigh Pressure Filters for Hydraulic ApplicationsIgor Alberto MarkovÎncă nu există evaluări

- Compressed Air Filters and Water Separators: Intelligent Air TechnologyDocument6 paginiCompressed Air Filters and Water Separators: Intelligent Air TechnologyOliver CambelÎncă nu există evaluări

- VT Voith-Lubricants DIWA 20 BDI VT2452 enDocument12 paginiVT Voith-Lubricants DIWA 20 BDI VT2452 enAhmed HummerÎncă nu există evaluări

- PEPLYN AIR Filter Cartridges: Performance CharacteristicsDocument2 paginiPEPLYN AIR Filter Cartridges: Performance CharacteristicsDucVikingÎncă nu există evaluări

- Filtracion Alta PurezaDocument2 paginiFiltracion Alta PurezaMaik GonzalezÎncă nu există evaluări

- HFD Catalog CN PDFDocument13 paginiHFD Catalog CN PDFPartsGopher.comÎncă nu există evaluări

- 41-60pages From Camfil Farr Product Catalog - Product - Catalogue - 2008 - En-Gb-3 PDFDocument20 pagini41-60pages From Camfil Farr Product Catalog - Product - Catalogue - 2008 - En-Gb-3 PDFali_irvÎncă nu există evaluări

- Bray Butterfly Valves Catalog JECDocument23 paginiBray Butterfly Valves Catalog JECRawadabdoÎncă nu există evaluări

- 61482Document2 pagini61482Izali NizarÎncă nu există evaluări

- Ashcroft PI 1259 Duragauge Pressure GaugeDocument2 paginiAshcroft PI 1259 Duragauge Pressure GaugejplutodÎncă nu există evaluări

- 12CS/50CS Series: Coreless Medium Pressure FiltersDocument11 pagini12CS/50CS Series: Coreless Medium Pressure FiltersPartsGopher.comÎncă nu există evaluări

- Data Sheet Sw30hrle-400Document2 paginiData Sheet Sw30hrle-400Alexis Antonio Jara VidalÎncă nu există evaluări

- Contact Tri-Mer for Proven Glass Furnace Emissions Control SystemsDocument6 paginiContact Tri-Mer for Proven Glass Furnace Emissions Control SystemsYing Kei ChanÎncă nu există evaluări

- 1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Document19 pagini1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Ying Kei ChanÎncă nu există evaluări

- Introducing A New Roots Blower For Water TreatmentDocument4 paginiIntroducing A New Roots Blower For Water TreatmentYing Kei ChanÎncă nu există evaluări

- AMANO ENVIRONMENTAL SYSTEMS GENERAL CATALOGDocument24 paginiAMANO ENVIRONMENTAL SYSTEMS GENERAL CATALOGsundarÎncă nu există evaluări

- PMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Document8 paginiPMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Ying Kei ChanÎncă nu există evaluări

- 3M High Flow Filter System Brochure 2019Document12 pagini3M High Flow Filter System Brochure 2019Ying Kei ChanÎncă nu există evaluări

- Short Test of Strength For Production WasteDocument12 paginiShort Test of Strength For Production WasteYing Kei ChanÎncă nu există evaluări

- PMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Document8 paginiPMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Ying Kei ChanÎncă nu există evaluări

- Air Flow Technology and Paper Waste Disposal Systems: For The Paper IndustryDocument20 paginiAir Flow Technology and Paper Waste Disposal Systems: For The Paper IndustryYing Kei ChanÎncă nu există evaluări

- Rpbid: Serial SolutionDocument5 paginiRpbid: Serial SolutionYing Kei ChanÎncă nu există evaluări

- Amano PiE Operation Manual As of 5-12 - PiE - PKA911008Document52 paginiAmano PiE Operation Manual As of 5-12 - PiE - PKA911008wqukJLKJa1Încă nu există evaluări

- Operation Manual: Mist CollectorDocument40 paginiOperation Manual: Mist CollectorYing Kei ChanÎncă nu există evaluări

- EGE Inductive SensorsDocument72 paginiEGE Inductive SensorsYing Kei ChanÎncă nu există evaluări

- 3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Document8 pagini3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Ying Kei ChanÎncă nu există evaluări

- EGE Infrared DetectorsDocument12 paginiEGE Infrared DetectorsYing Kei ChanÎncă nu există evaluări

- EGE Metal DetectorsDocument8 paginiEGE Metal DetectorsYing Kei ChanÎncă nu există evaluări

- EGE Pressure SensorsDocument8 paginiEGE Pressure SensorsYing Kei ChanÎncă nu există evaluări

- EGE Level SensorsDocument40 paginiEGE Level SensorsYing Kei ChanÎncă nu există evaluări

- EGE Opto SensorsDocument16 paginiEGE Opto SensorsYing Kei ChanÎncă nu există evaluări

- M12 Connector: Cable Plug Housing Pin-AssignmentDocument10 paginiM12 Connector: Cable Plug Housing Pin-AssignmentYing Kei ChanÎncă nu există evaluări

- Greenex Catalog 2021 enDocument17 paginiGreenex Catalog 2021 enYing Kei ChanÎncă nu există evaluări

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocument40 paginiSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaYing Kei ChanÎncă nu există evaluări

- Paper Joggers CatalogDocument20 paginiPaper Joggers CatalogYing Kei ChanÎncă nu există evaluări

- ACOEM Ecotech Continuous Emissions Monitoring Systems (CEMS) BrochureDocument12 paginiACOEM Ecotech Continuous Emissions Monitoring Systems (CEMS) BrochureYing Kei ChanÎncă nu există evaluări

- Chopper FanDocument2 paginiChopper FanJulio CÎncă nu există evaluări

- Pentair Goyen Threaded Pulse Jet ValvesDocument11 paginiPentair Goyen Threaded Pulse Jet Valvesraul_giralÎncă nu există evaluări

- Greenex Catalog 2021 enDocument17 paginiGreenex Catalog 2021 enYing Kei ChanÎncă nu există evaluări

- PMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Document8 paginiPMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Ying Kei ChanÎncă nu există evaluări

- Air Flow Technology and Paper Waste Disposal Systems: For The Paper IndustryDocument20 paginiAir Flow Technology and Paper Waste Disposal Systems: For The Paper IndustryYing Kei ChanÎncă nu există evaluări

- Paper Joggers CatalogDocument20 paginiPaper Joggers CatalogYing Kei ChanÎncă nu există evaluări

- OMM 00023 Maintenance Guide JDocument49 paginiOMM 00023 Maintenance Guide Jkenedi74100% (2)

- Design and Generating Energy As A Car Alternator TDocument7 paginiDesign and Generating Energy As A Car Alternator TJohnny TestÎncă nu există evaluări

- DBB ValveDocument6 paginiDBB ValveshyamÎncă nu există evaluări

- Foster Wheeler Process Engineering Practices IndexDocument86 paginiFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Enclosed Control Product Guide: April 2008Document456 paginiEnclosed Control Product Guide: April 2008MED-ROBIN2000Încă nu există evaluări

- General Design Considerations for Chemical Plant DesignDocument27 paginiGeneral Design Considerations for Chemical Plant DesignTeddy Ekubay GÎncă nu există evaluări

- Power Generation: Selection GuideDocument114 paginiPower Generation: Selection GuideRobiÎncă nu există evaluări

- Photovoltaic Silicon Wafer - SUMCO CORPORATIONDocument21 paginiPhotovoltaic Silicon Wafer - SUMCO CORPORATIONlawrence_yuen_3Încă nu există evaluări

- Energy Conservation Oppurtunities in Boiler SystemDocument34 paginiEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- ELECTRONICDocument13 paginiELECTRONICMahmoued YasinÎncă nu există evaluări

- New Tutorial 2 Solution On ThermodynamicsDocument7 paginiNew Tutorial 2 Solution On ThermodynamicsNaveed AhmadÎncă nu există evaluări

- IFFCO Urea ProcesspdfDocument3 paginiIFFCO Urea ProcesspdfBalas43Încă nu există evaluări

- HKBEAMDocument0 paginiHKBEAMTse Lam ChanÎncă nu există evaluări

- Valve Material ApplicationDocument16 paginiValve Material Applicationehab8320014413100% (1)

- Quality Policy and Quality ObjectivesDocument2 paginiQuality Policy and Quality ObjectivesrabiulfÎncă nu există evaluări

- IGBC Annual Review 2011-2012Document28 paginiIGBC Annual Review 2011-2012Sourav SenÎncă nu există evaluări

- Dolphin by EnOcean enDocument16 paginiDolphin by EnOcean en刘嘉伟Încă nu există evaluări

- Led ComponentsDocument226 paginiLed Componentselcomsrl100% (1)

- Type 316 Stainless Steel Properties & ApplicationsDocument3 paginiType 316 Stainless Steel Properties & Applicationsh4josephÎncă nu există evaluări

- 568100Document2 pagini568100Talha TariqÎncă nu există evaluări

- Syllabus of Diploma in Electrical EngineeringDocument17 paginiSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- Atmospheric Water Generator DesignDocument9 paginiAtmospheric Water Generator Designscribd2Încă nu există evaluări

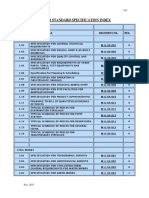

- Water Standard Specification Index As On Dec 2015Document10 paginiWater Standard Specification Index As On Dec 2015afp15060% (1)

- Site Effect Evaluation Using Spectral Ratios With Only One StationDocument15 paginiSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtÎncă nu există evaluări

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 paginiEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarÎncă nu există evaluări

- ECE 1312 Chapter 1Document19 paginiECE 1312 Chapter 1Fatihah AinaÎncă nu există evaluări

- Wiring Diagram FH, NH: GroupDocument110 paginiWiring Diagram FH, NH: GroupStefan AslamÎncă nu există evaluări

- Krff302ess01 Tech Sheet - w10787422 - Rev CDocument10 paginiKrff302ess01 Tech Sheet - w10787422 - Rev CJesikaGomezSaavedraÎncă nu există evaluări

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocument22 paginiMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorÎncă nu există evaluări

- ME6502 Heat and Mass Transfer SyllabusDocument26 paginiME6502 Heat and Mass Transfer Syllabusamdeva0% (1)

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)