Documente Academic

Documente Profesional

Documente Cultură

Bridge Design in Finland

Încărcat de

अरुण कुमार सोनीDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bridge Design in Finland

Încărcat de

अरुण कुमार सोनीDrepturi de autor:

Formate disponibile

The XXVIII International Baltic Road Conference

IMPLEMENTATION OF EUROCODES FOR BRIDGE DESIGN IN FINLAND

Mr. Heikki Lilja M.Sc. (Civ. Eng.) and Mr. Panu Tolla M.Sc. (Civ. Eng.) Finnish Transport Agency, Helsinki, Finland

Abstract. The Eurocodes are expected to contribute to the establishment and functioning of the internal market for construction products and engineering services by eliminating the disparities that hinder their free circulation within the Community. Furthermore, they are meant to lead to more uniform levels of safety in construction in Europe. Under the Public Procurement Directive, it is mandatory that Member States accept designs according to the Eurocodes. The Eurocodes are the standard technical specifications for all public works contracts and likely to become the de-facto standard for the private sector both in Europe and world-wide. The EN Eurocodes have been mandatory for the design of bridges in Finland since 1June 2010. The transition from the old codes has been relatively challenging but nevertheless steady. This paper presents the required actions for the transition from the old codes to the Eurocodes, including the most important national choices as well as the needed additional non-contradictory guidance to ease the transition process. Keywords. Eurocodes, load models, bridge, national annex

INTRODUCTION The Finnish Transport Agency (FTA) was established in 2010, when three national agencies (Road, Rail and Maritime Administrations) were merged as a governing body to promote the efficient functioning of the whole traffic system in Finland. Eurocodes have been a mandatory standard for the design of bridges in FTAs projects since June 2010. The change to Eurocodes was implemented "overnight", though the on-going projects continued to follow the old codes of practice. The change created challenges to both the design consultants and the authorities. The transition process was eased by a rather intensive training period in 2007-2010 when all Finnish bridge design consultants participated in an Agency-run comparison calculation project. FTA has prepared a set of design guides (NCCI-documents) in order to give guidance on how to apply Eurocodes and to publish the Agencys official interpretations of the Eurocodes. This paper describes the main features of the relevant parts of Eurocodes and some examples of the national choices made during the preparation of National Annexes (NA), when about 250 national choices concerning bridges had to be made. A short introduction to FTAs design guidelines presented in NCCI-documents is also given. 1 BASIS OF DESIGN (EN 1990) 1.1 General The scope of the Eurocode 1990 is to establish the principles and requirements for the safety, serviceability and durability of structures, to describe the basis for their design and verification and give guidelines for related aspects of structural reliability. It is important to comprehend the Assumptions behind the Eurocodes (chapter 1.3 of EN 1990) and the distinction between Principles and Application rules (chapter 1.4 of EN 1990) [6]. The Principles, identified by the letter P, are statements and definitions indicating that there are obligatory. Application rules, on the other hand, are generally recognised rules which comply with the Principles and satisfy their requirements (i.e. other methods may exist that satisfy the requirements set by Principles). All application rules presented in NCCI documents, published by the FTA, fulfil the requirements of the above mentioned Principles.

The XXVIII International Baltic Road Conference

1.2 Annex A2 (EN1990:2002/A1) EN 1990 is paramount for bridge design. The load combinations are presented in the EN 1990 Amendment, which is a separate document, commonly known as Annex A2 [7]. Annex A2 contains 32 pages and it is a crucial document for a designer, and it shall be applied with great care. Annex A2 gives the combination rules for ultimate limit state (ULS) and three different serviceability limit states (SLS) design. The load combinations to be applied in design are presented in tables A2.4A2.6 taking into consideration the combination values (y-values) that take into account the simultaneity of variable loads in each limit state. Various written rules are also given to form the design load combinations. In order to give an official interpretation of combinations, all rules are compiled in chapter G of FTAs Eurocode application guide NCCI 1 (Bridge loads and design basis)[1]. By using the combination tables presented in Annex 1 of NCCI 1, all relevant information presented in EN 1990:2002/A1 is taken into consideration and all designers end up with exactly the same combinations.

Fig. 1. Excerpt of combination table: ULS-combinations for road bridges[1]

Perhaps the biggest deficiency of EN 1990 is the fact that sometimes the link between EN 1990 and material standards is lost. For example, there is no clear introduction as to when the three given serviceability limit states are applied. For some limit states information is scattered in more than one standard and for some limits states (e.g. certain deflection limits) information is missing altogether. Some examples of the SLS-checks are collected into NCCI 1. The same list is reproduced below: Characteristic combination (irreversible serviceability limit state, as defined in 3.4 of EN 1990): stress limits (0,6*fck) for concrete[15,2] stress limits for steel[16,3] stress limits for shear connectors[17,3] deflection limits for railway bridges[7,9,1] deformation limits for bearings and expansion joints[7,12,16,1] Frequent combination (reversible serviceability limit state): deflection limit for road and pedestrian bridges[1518,14] decompression limit for prestressed concrete[15,2] concrete crack width check[15,2] breathing of steel web[16,3]

The XXVIII International Baltic Road Conference

Quasi-permanent combination is used for: stress limit (0,45*fck) for concrete[15,2] decompression limit for prestressed concrete[15,2] concrete crack width check[15,2] pre-camber for structures[1518,14] 1.3 Annex B One of the best, but somewhat hidden, tools in Eurocode is the informative Annex B of EN 1990 that gives guidelines for the management of structural reliability. The essential concept in the management of structural reliability in Eurocode is Consequence Class (CC), which differentiates engineering structures with the consequences that arise due to possible failure of the structure. Each consequence class corresponds to reliability classes that have predetermined target reliabilities (b) defined in B3.2 of EN 1990.

Consequence Class CC3 CC2 Table 1. Definition of consequence classes[6] Description Examples of buildings and civil engineering works

High consequences for loss of human life, or economic, social or environmental consequences are very great. Medium consequences for loss of human life, economic, social or environmental consequences are considerable. Low consequences for loss of human life, and economic, social or environmental consequences are small or negligible. Grandstands, public buildings where consequences of failure are high (e.g. a concert hall). Residential and office buildings, public buildings where consequences of failure are medium (e.g. an office building). Agricultural buildings where people do not normally enter (e.g. storage buildings, greenhouses).

CC1

In addition to the Consequence and Reliability Classes (CC1CC3 and RC1RC3), Annex B introduces the concepts of design supervision level (DSL1DSL3) and inspection level (IL1IL3). These possible actions, however only vaguely described in the code, offer a useful tool when handling more demanding bridge structures. It is clear that the determined CC and the measures ruled by CC may vary between structural elements in one structure. High-risk elements may be identified as key elements, as defined in the EN 1991-1-7[14]. By identifying the key elements of the bridge, the designer can effectively focus on the most important details of the structure in a way that the robustness of the structure is adequate. Robustness can be defined as the ability of a structure and its members to keep the amount of deterioration or failure within reasonable limits in relation to the cause[23]. FTA has adopted a practice that all bridges are determined to fall into Consequence Class CC2 at the beginning of the design phase. After a risk review the structures may be moved to the higher consequence class CC3. Any further measures are decided after the comprehensive risk assessment. A principle of this process is presented in figure 2.

The XXVIII International Baltic Road Conference

Fig. 2. Selection of consequence class for bridges

Below is an example of a consequence class CC3-bridge and its decided measures. :

Fig. 3. Ahvenkoski Bridge (E18 motorway), Consequence Class 3 structure.

KFI factor of 1.1 is used for key elements (B3.3[6]) 3rd party independent comparison calculations (B4[6], ~DSL 3) separate design supervision team established (B4[6], ~DSL 3) monitoring is used during and after construction (B5[6], ~IL 3) tension rods are protected with H4-railings welds for key elements manufactured in execution class EXC 4 execution comply with EN 1090-2 2 LOADS (EN 1991) 2.1 General The characteristic values of actions (loads) for bridges are presented in seven separate parts of Eurocode 1 and corresponding National Annexes[814]. The relevant information on the loads for the bridge design is collected in FTAs guide NCCI 1. In some loading situations certain simplifications are used; for example the wind load is given in an easy-to-use table (that complies with EN 1991-1-4) for the design of small to medium size bridges (Table 2). For large bridges the designer shall calculate the wind load precisely as required by the standard.

The XXVIII International Baltic Road Conference

Table 2. Excerpt of wind pressure [kN/m2] table for empty bridge[1]

Terrain class b/dtot <0,5 >4a >5b 0 ze<20 m 3,58 1,94 1,49 ze=50 m 4,18 2,26 1,74 ze<20 m 2,54 1,37 1,06 I ze=50 m 3,02 1,64 1,26 ze<20 m 2,23 1,21 0,93 II ze=50 m 2,75 1,49 1,15 ze<20 m 1,73 0,94 0,72 III ze=50 m 2,28 1,24 0,95 ze<20 m 1,30 0,71 0,54 IV ze=50 m 1,86 1,01 0,77

2.1 Traffic Loads For bridge design the most important standard is obviously EN 1991-2 Traffic Loads on Bridges[9]. For road bridges the a- and b-values of LM 1 are set to 1.0 in Finland. For railway bridges the classification factor a= 1.46 is adopted in order to accommodate the possible increase of axle loads especially on tracks serving the mining industry. During the comparison calculations it was observed that certain types of road bridge superstructures do not have sufficient capacity under heavy transports at the intermediate support area. In order to ensure adequate capacity FTA developed its own special vehicle load type (LM 3) to be applied instead of the heavy vehicle loads defined in informative Annex A of EN 1991-2. LM3 shall basically be applied for all new bridges. The Finnish LM 3 has two uniformly distributed loads that have variable lengths and distance between loads as shown in figure 4. The maximum characteristic weight of the LM 3 vehicle is 270 tons. The appearance of the load model corresponds well with the common heavy transports on Finnish roads.

Fig. 4. The Finnish LM 3 /9/, /1/

3 MATERIAL PARTS OF EUROCODES (EN 1992EN 1997) 3.1 Concrete bridges For the design of concrete bridges both standards EN 1992-1-1 and EN 1992-2[9] shall be used. Concrete is traditionally a locally-produced material, hence the design rules throughout Europe differ considerably. However many countries have previously adopted the methods presented in CEB-FIB Model Code and it is anticipated that the next generation of Eurocodes will embrace the just-published Model Code 2010[22]. FTA has collected the relevant information from concrete standards and National Annexes to NCCI 2[2]. As an example the decompression limit and the crack width rules (National choices for chapter 7.3 of EN 1992-2) are presented in NCCI 2 (see Table 3). Note that the limits may be affected on the applied protection level of the concrete.

The XXVIII International Baltic Road Conference

Table 3. Crack width requirements [15,2]

Exposure class X0, XC1 XD1d, XC2, XC3, XC4, XS1d XD2, XD3, XS2, XS3d Reinforced members and prestressed members without bonded tendons Frequent Quasi-permanent 0,3c 0,2 0,15 0,15 0,1 Prestressed members with bonded tendons Frequent 0,07 decompression Quasi-permanent 0,2 decompression decompression

The Eurocodes present the execution standard EN 13670[20] as a normative references, i.e. when a concrete structure is designed in accordance with the Eurocodes, the execution (construction works) has to be carried out according to European standard EN 13670. The tolerances and construction methods in European execution standards are in conformity with the Eurocodes and the required reliability level is achieved when using the aforementioned standards together. 3.2 Steel and composite bridges For steel bridge design, practically the complete set of standards of the EN 1993family is needed. In Finland most of the steel bridges are composite concrete-steel bridges, therefore standard EN 1994-2[12] is also a necessary tool for any bridge engineer. Steel, as opposed to concrete, is regarded as international material, and many design rules are universal around the world. FTA has collected the relevant information needed for the design of a traditional Finnish composite bridge (welded I-beam equipped with shear connectors and concrete deck) in one document NCCI 4[3] although it has not been published yet. During the preparation of NCCI 4 it became clear that the functionality of a dozen standards for the design of one bridge is close to impossible, and some sort of summary of relevant information is needed. In Eurocode system design and construction (execution) are more closely connected together than in the previous Finnish design system. Some choices made by the designer have a big influence on the cost and reliability of the structure. At the moment the execution standard EN 1090-2, that by definition has to be applied for structures designed with Eurocodes, states 4 execution classes EXC1EXC4. Informative annex B of EN 1090-2 presents a table for the selection of the execution class. In the table PC denotes production class (depending on welding and yield limit of steel) and SC denotes service class (that takes into account the fatigue).

Table 4. Selection of excecution class according to EN 1090-2 [21] Consequence classes Service categories Production PC1 categories PC2

a

CC1 SC1 EXC1 EXC2 SC2 EXC2 EXC2 SC1 EXC2 EXC2

CC2 SC2 EXC3 EXC3 SC1 EXC3a EXC3a

CC3 SC2 EXC3a EXC4

EXC4 should be applied to special structures or structures with extreme consequences of a structural failure as required by national provisions.

As for the Consequence Class, the Execution Class may vary between structural elements in one single structure, and due to cost the highest class (EXC 4) should be reserved only for the key elements of the Consequence Class CC3 structures. The differences between the requirements of the Execution Classes are presented in table A.3 of EN 1090-2. Since bridge designers are normally not familiar with the execution standard EN 1090-2, the table is going to be moved to design standard EN 1993-1-1, Design of Steel Structures. At the same time the table is going to be considerably revised. Basically pedestrian bridges belong mainly to EXC 2 and bridges with fatiguing loads belong mainly to EXC 3, apart from the key elements that may be in EXC 4.

The XXVIII International Baltic Road Conference

3.3 Timber bridges Timber bridges are designed with EN 1995-2[13]. FTA commissions only a small amount of timber bridges for road traffic annually. However the Finnish timber industry has prepared a series of standard bridges for road traffic according to Eurocodes and FTA is at the moment preparing application guide NCCI 5[4] for timber structures in general. 3.4 Geotechnical design Applying Eurocodes have caused more changes in geotechnical design than in any other field of civil engineering. The most significant change is applying several design approaches for limit state design methods with partial factors of safety. In structural engineering the material strength or capacity is typically not depended on load (stress state). In geotechnical engineering material strength depends on stresses caused by loads, e.g. soil strength on a slip surface depends on the weight of the soil above it. This dependency creates quite a complex environment to apply partial factors of safety. The other special characteristics of Eurocodes are: The recommended partial factors in persistent and transient situations are defined in the standard. However the values of the partial factors may also be set by the National annexes. Partial factors for actions may be applied either to the actions themselves or to their effects. For ground properties the partial factors may be applied either to soil/rock parameters or to ground resistances or to both. In Finland, and in many other European countries, the geotechnical design codes and guidelines have been based on an allowable stress and deformations approach or a total factor of safety design approach. From the design engineers point of view the former design practise was quite straight forward: the loads (and their effects) were compared with the capacity (or resistance) of soil or structure and they were both calculated applying characteristic values. The design of geotechnical structures require the evaluation of five different ultimate limit states (EQU, STR, GEO, UPL and HYD) in order to consider all relevant design situations with corresponding partial factors of safety. In addition, EC 7 includes three different design approaches (DA) to be applied for verification of resistance for structural (STR) and ground limit states (GEO). All DAs are composed of a different combination of partial factors. The DAs were created as a response to demands for maintaining national practices within the design process. The member countries have chosen design approaches so that the design calculations would result in physically similar structures as the previous system provided. Figure 5 illustrates the national choices in case of a footing foundation design. The scatter between national choices is remarkably wide, and it demonstrates well the differences between national practices.

The XXVIII International Baltic Road Conference

Fig. 5. Design approaches for footing foundations in the northern member countries according to A. Bond

[24]

The design approaches (DA1DA3) to be applied in various geotechnical structures are defined in the National Annex. In Finland, as in many other European countries, NCCI-documents have been prepared to guide designers to choose the most relevant limit states and design approach. In Finland, DA2 is applied for design of footings and slab foundations design, pile foundations, ground anchors and retaining structures in ULS (STR/GEO). DA2 requires studying only one combination of partial factors. The default values of the partial factors, as they are presented in EN1997-1[20], results in similar structures (or the similar level of factor of safety) as the previous Finnish design system. Due to the above described nature of geotechnical design, and especially the stress dependency of ground properties, the most common design approach is DA2* (a revised DA2), which enables an engineer to carry out design calculation, applying characteristic values of actions and factor them to design values when capacity assessment is made at the end of the calculation phase. DA3 is applied for slope stability analyses in ULS (STR/GEO). It also requires only one combination of partial factors and the default values of the factors result to a similar level of safety as the previous system. Another example of the specific national choices is pile design, where local geological conditions and local practices related to the design and piling works have resulted in strongly empirical local codes. In Finland, the dynamic load testing (PDA) is an example of such local practice. It has been applied widely for some 20 years and has created confidence on the method especially for predominately end-bearing piles (supported by dense till or hard rock). The Finnish National Annex correlation factors were lowered from the Eurocode default values to promote the testing. On the other hand, confidence in analytical pile design (based on sounding resistance or soil strength parameters) is lower than in some others countries and therefore the partial factors are higher than default values for such methods. A geotechnical design of a bridge requires typically complex load combinations when studying and analysing various structures. A typical structure is an abutment which can be analyzed with similar principals as a classical geotechnical structure, e.g. a cantilever retaining wall. At ULS (STR/GEO) the DA2 and DA3 are both required in order to define the structural and geotechnical capacity/stability of the structure. In addition, ULS (EQU) is needed for the safety against overturning in case the footing is laid on a rock or a corresponding hard ground. For EQU assessment FTA has given an additional model factor to increase the level of safety against the

The XXVIII International Baltic Road Conference

overturning since some design situations lead to more unsafe structures when compared to previous design. The abutment design demonstrates the challenges to partial factors of safety for loads, when soil and water behind and on the structure creates both favorable (stabilizing) and unfavorable actions in calculation models. Discussion of geotechnical design according to Eurocodes is commonly focused on EN 1997-1 that determines the dimensioning of the structures to the loads and combinations as specified in EN 1990 and EN 1991. However there are several other standards that are determined as Normative References in Eurocodes. In geotechnical engineering, practical engineers shall be able to incorporate all relevant standards such as EN 1997-2 Geotechnical Design: Ground investigation and testing[25], as well as Normative reference standards mentioned in EN 1997-2, e.g: EN ISO 22476 Field Testing (Parts 1 13) EN ISO 14688 & EN ISO 14689 Identification and classification of soil and rock EN ISO 22475 Sampling and groundwater measurements CEN ISO/TS 17892 Laboratory tests (Parts 1 12) In addition the relevant EN execution standards for geotechnical works have to be applied. 3.5 Other engineering structures Eurocodes do not have any rules for the design of many common infrastructures, e.g. concrete tunnels. FTAs design guides can be applied to plenty of structural elements outside the exact scope of Eurocodes, for example embankment pile slabs which are dealt with in NCCI 7 and the accompanying design guides. Exposure classes and corresponding concrete specifications for various infrastructures are listed in NCCI 2. Loads and load combinations for other infrastructures such as retaining walls and quays are under preparation. 4 CONSTRUCTION PRODUCTS REGULATION The Construction Products Directive (CPD) will be replaced with construction products regulation on 1 July 2013. National implementation of CPR is not required and the CE-marking of construction products will automatically become mandatory for all construction products in all Member States of the European Economic Area. If there is a harmonised European standard (hEN) or European Technical Assessment (ETA) in place for the product, the manufacturer, in most cases, must acquire the appropriate CE marking. This is going to influence some infrastructures directly, for example bridge and road railings have to be CE-marked. CPR also sets certain requirements for workshops and factories. CONCLUSIONS Eurocode implementation for bridge design In Finland has been a challenging learning process for FTA and consultants. It has been necessary to study Eurocodes and former Finnish design system thorough out in order to set the load and material safety factors to appropriate level. Applying the same design philosophy both for geotechnical and structural design has been especially challenging. The vast amount of national choices has undoubtedly been a necessity for the first version of Eurocodes since the goal of harmonized design across Europe is enormous. However the next step of the Eurocode development should, and will be, the further harmonization of national choices by decreasing the amount of national parameters. All in all the Eurocodes provide a common language and framework for researchers across Europe for the successful development of more cost effective and safe design codes for civil engineering structures.

10

The XXVIII International Baltic Road Conference

REFERENCES

[1] Finnish Transport Agency 2011. NCCI 1, Eurocode application guide, Bridge loads and desing basis (Finnish language, electronic only). ISBN 978-952-255-733-9. [2] Finnish Transport Agency 2012. NCCI 2, Eurocode application guide, Concrete structures (Finnish language, electronic only). ISBN 978-952-255-157-3. [3] Finnish Transport Agency. NCCI 4, Eurocode application guide, Steel and composite structures (Unpublished) [4] Finnish Transport Agency. NCCI 5, Eurocode application guide, Timber structures (Unpublished) [5] Finnish Transport Agency 2011. NCCI 7, Eurocode application guide, Geotechnical design (Finnish language, electronic only). ISBN 978-952-255-692-9. [6] CEN 2006. EN 1990, Basis of structural design. (+ Finnish NA) [7] CEN 2006. EN 1990/A1, Basis of structural design, Annex A2. (+ Finnish NA) [8] CEN 2002. EN 1991-1-1, General actions. Densities, self-weight, imposed loads for building. (+ Finnish NA) [9] CEN 2004. EN 1991-2, Traffic loads on bridges. (+ Finnish NA) [10] CEN 2004. EN 1991-1-3, General actions. Snow loads. (+ Finnish NA) [11] CEN 2011. EN 1991-1-4, General actions. Wind actions. (+ Finnish NA) [12] CEN 2004. EN 1991-1-5, General actions. Thermal actions. (+ Finnish NA) [13] CEN 2005. EN 1991-1-6, General actions. Actions during execution. (+ Finnish NA) [14] CEN 2007. EN 1991-1-7, General actions. Accidental actions. (+ Finnish NA) [15] CEN 2006. EN 1992-2, Design of concrete structures, concrete bridges. (+ Finnish NA) [16] CEN 2006. EN 1993-2, Design of steel structures, steel bridges. (+ Finnish NA) [17] CEN 2006. EN 1994-2, Design of composite structures, composite bridges. (+ Finnish NA) [18] CEN 2004. EN 1995-2, Design of timber structures, timber bridges. (+ Finnish NA) [19] CEN 2007. EN 1997-1, Geotechnical design. (+ Finnish NA) [20] CEN 2010. EN 13670, Execution of concrete structures [21] CEN 2012. EN 1090-2, Execution of steel structures and aluminium structures [22] FIB 2012. Model Code 2010, Vol 1 Bulletin n:o 65 ISBN 978-2-88394-105-2, Vol 2 Bulletin n:o 66 ISBN 978-288394-106-9 [23] VOGEL T. Robustness of structures, Safety, Failures and Robustness of Large Sructures, IABSE Workshop, Tuusula, Finland. 2013, p.22. FIB 2012 p.22. ISBN 978-3-85748-130-7 [24] Bond A., Evolution of Eurocode, Delft Workshop 2011 [25] CEN 2007. EN 1997-2 Geotechnical Design: Ground investigation and testing

S-ar putea să vă placă și

- Cable Supported Bridges: Concept and DesignDe la EverandCable Supported Bridges: Concept and DesignEvaluare: 5 din 5 stele5/5 (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDe la EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionÎncă nu există evaluări

- Hif12003 EVALUAT SCOUR ON BRIDGES BEST PDFDocument340 paginiHif12003 EVALUAT SCOUR ON BRIDGES BEST PDFAnonymous VkzquW39Încă nu există evaluări

- BD21Document80 paginiBD21imranthinkingÎncă nu există evaluări

- Composite Structures Full Notes Part 7 PDFDocument25 paginiComposite Structures Full Notes Part 7 PDFsvnÎncă nu există evaluări

- Civil 2021 v11 Release Note PDFDocument27 paginiCivil 2021 v11 Release Note PDFdak comeiÎncă nu există evaluări

- Management of Fatigue Cracking West Gate Bridge, Melbourne PDFDocument9 paginiManagement of Fatigue Cracking West Gate Bridge, Melbourne PDFAVSSSÎncă nu există evaluări

- Fiber Cho 80 60 NBDocument3 paginiFiber Cho 80 60 NBSandesh GiriÎncă nu există evaluări

- 5 - VasoflonDocument16 pagini5 - Vasoflonstavros_stergÎncă nu există evaluări

- Collapse analysis of externally prestressed structuresDe la EverandCollapse analysis of externally prestressed structuresÎncă nu există evaluări

- First Prs EditedDocument38 paginiFirst Prs EditedMathew SebastianÎncă nu există evaluări

- Numerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionDocument10 paginiNumerical Analysis of Composite Steel-Concrete Columns of Arbitrary Cross SectionNasar KhanÎncă nu există evaluări

- Surrey ENGM030 Unit 9 Presentation1aDocument26 paginiSurrey ENGM030 Unit 9 Presentation1aPhilip YapÎncă nu există evaluări

- WadiLeban IWSHMDocument9 paginiWadiLeban IWSHMishu vohraÎncă nu există evaluări

- Catalogue Helcor and Helcor PaDocument31 paginiCatalogue Helcor and Helcor PaVincentiu RautaÎncă nu există evaluări

- ETSI - Stage2 (Bridge Life Cycle Optimisation)Document140 paginiETSI - Stage2 (Bridge Life Cycle Optimisation)Jan BooysenÎncă nu există evaluări

- Horizontal Construction JointsDocument18 paginiHorizontal Construction JointsPremasiri KarunarathnaÎncă nu există evaluări

- Design and Construction of Frank Gehry Bridge. First Access To The New Island of Zorrotzaurre in Bilbao, SpainDocument9 paginiDesign and Construction of Frank Gehry Bridge. First Access To The New Island of Zorrotzaurre in Bilbao, SpainMiguel Sacristán100% (1)

- Iabse Iass-2011Document6 paginiIabse Iass-2011Amuana RalteÎncă nu există evaluări

- Bridges With Multiple Cable-Stayed SpansDocument12 paginiBridges With Multiple Cable-Stayed SpanssergioÎncă nu există evaluări

- Free Cantilever Method (Método Del Voladizo Libre)Document48 paginiFree Cantilever Method (Método Del Voladizo Libre)German SanchezÎncă nu există evaluări

- 03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Document34 pagini03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Oscar Mendoza100% (1)

- Expansion Joint SystemDocument9 paginiExpansion Joint SystemhassanÎncă nu există evaluări

- The New Guide To Stability Design Criteria For Metal StructuresDocument3 paginiThe New Guide To Stability Design Criteria For Metal StructuresBilly BobÎncă nu există evaluări

- Design Guide For Composite Bridges enDocument141 paginiDesign Guide For Composite Bridges enjelonyÎncă nu există evaluări

- Investigation of the Chirajara Bridge CollapseDe la EverandInvestigation of the Chirajara Bridge CollapseÎncă nu există evaluări

- 2002 FIB SegmentDocument6 pagini2002 FIB SegmentPunithan PunithanÎncă nu există evaluări

- ETA Freyssinet enDocument90 paginiETA Freyssinet enbulbucataÎncă nu există evaluări

- LRB Non-LinearDocument24 paginiLRB Non-LinearJames McguireÎncă nu există evaluări

- Staggered Truss System - Wikipedia, The Free EncyclopediaDocument3 paginiStaggered Truss System - Wikipedia, The Free EncyclopediashawnideaÎncă nu există evaluări

- Cable Stays of Cable-Stayed Bridges (T 5140.25)Document9 paginiCable Stays of Cable-Stayed Bridges (T 5140.25)Mohamed BahgatÎncă nu există evaluări

- Ultimate Punching Shear Strength Analysis of Slab-Column ConnectionsDocument13 paginiUltimate Punching Shear Strength Analysis of Slab-Column ConnectionssamannikÎncă nu există evaluări

- Diff Strain Concrete 13 1 FinalDocument8 paginiDiff Strain Concrete 13 1 FinalDoug JenkinsÎncă nu există evaluări

- Prestressed For Composite SectionsDocument39 paginiPrestressed For Composite Sectionsbeast4Încă nu există evaluări

- MC3D™ Short Bench Casting Geometry Control For Windows: Interactive Design SystemsDocument51 paginiMC3D™ Short Bench Casting Geometry Control For Windows: Interactive Design Systemscu1988Încă nu există evaluări

- PCM For Waterproofing WorksDocument23 paginiPCM For Waterproofing WorksChris AdaminovicÎncă nu există evaluări

- Integral BridgeDocument25 paginiIntegral Bridgesbacchi amedeoÎncă nu există evaluări

- Kano River: Crossing BridgeDocument6 paginiKano River: Crossing Bridgejulia camposÎncă nu există evaluări

- Computer Models of Concrete StructuresDocument10 paginiComputer Models of Concrete Structuresbobmarley20161934Încă nu există evaluări

- General Aspects of The Structural Behavior in The Messina Strait Bridge DesignDocument8 paginiGeneral Aspects of The Structural Behavior in The Messina Strait Bridge DesignlucasgambiÎncă nu există evaluări

- The Staggered Truss System-Structural Considerations: John B. ScalziDocument6 paginiThe Staggered Truss System-Structural Considerations: John B. Scalzisaber javidÎncă nu există evaluări

- Effect of Lathe Waste Review 1Document22 paginiEffect of Lathe Waste Review 1dreamboy87Încă nu există evaluări

- Evaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteDocument9 paginiEvaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteHuda JawadÎncă nu există evaluări

- MAU Expansion Joints GB OwefwewenlineDocument16 paginiMAU Expansion Joints GB OwefwewenlineJacob GrechÎncă nu există evaluări

- Shear Behavior of Unbonded Post-TensionedDocument10 paginiShear Behavior of Unbonded Post-TensionedAnonymous eB2AZT3Încă nu există evaluări

- Guidelines For Design of Integral AbutmentsDocument10 paginiGuidelines For Design of Integral Abutmentsc1366Încă nu există evaluări

- 2011 Bridge SarkadyDocument17 pagini2011 Bridge SarkadyTan Duy LeÎncă nu există evaluări

- Bridge Bearings PDFDocument6 paginiBridge Bearings PDFsidiq7Încă nu există evaluări

- Staggered Truss Frames SEAOC BlueDocument4 paginiStaggered Truss Frames SEAOC BlueHirad GrivaniÎncă nu există evaluări

- Submitted By: Under The Guidance: Dr. K. AshaDocument23 paginiSubmitted By: Under The Guidance: Dr. K. AshaMohammed AhmedÎncă nu există evaluări

- Concrete Slab Track - 2011 - : Section/Article DescriptionDocument30 paginiConcrete Slab Track - 2011 - : Section/Article DescriptionMike2322Încă nu există evaluări

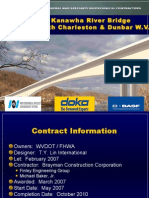

- OTEC (Kanawha River Bridge) S WilliamsonDocument59 paginiOTEC (Kanawha River Bridge) S Williamsonstevewv100% (1)

- Kuchma Et Al-1998-Progress in Structural Engineering and MaterialsDocument10 paginiKuchma Et Al-1998-Progress in Structural Engineering and MaterialsxforceÎncă nu există evaluări

- Civil2015 v2 1 Release NoteDocument30 paginiCivil2015 v2 1 Release NoteJorge Luis Molluni BalconaÎncă nu există evaluări

- FEM Design-Manual CONTENTSDocument18 paginiFEM Design-Manual CONTENTSLocal UserÎncă nu există evaluări

- Strut and Tie ModelDocument3 paginiStrut and Tie ModelBenard OmondiÎncă nu există evaluări

- Structural Analysis 1: Statically Determinate StructuresDe la EverandStructural Analysis 1: Statically Determinate StructuresÎncă nu există evaluări

- Volcano Types ChartDocument2 paginiVolcano Types Chartअरुण कुमार सोनीÎncă nu există evaluări

- Project: Construction of High Level Bridge Across Jawas River On Kenda-Barpali RoadDocument1 paginăProject: Construction of High Level Bridge Across Jawas River On Kenda-Barpali Roadअरुण कुमार सोनीÎncă nu există evaluări

- Calender 2015Document1 paginăCalender 2015अरुण कुमार सोनीÎncă nu există evaluări

- Calender 2014Document1 paginăCalender 2014अरुण कुमार सोनीÎncă nu există evaluări

- Column DesignDocument17 paginiColumn Designअरुण कुमार सोनीÎncă nu există evaluări

- Finland - Advances in Concrete and Cementitious Composites and Applications To Civil InfrastructureDocument8 paginiFinland - Advances in Concrete and Cementitious Composites and Applications To Civil Infrastructureअरुण कुमार सोनीÎncă nu există evaluări

- Index of EMDocument11 paginiIndex of EMअरुण कुमार सोनीÎncă nu există evaluări

- Layout PlanDocument1 paginăLayout Planअरुण कुमार सोनीÎncă nu există evaluări

- Maintenance, Repair and Operating Supplies Cogs Cogs Asset: Cycle Time X Actual Production÷ Actual Production TimeDocument2 paginiMaintenance, Repair and Operating Supplies Cogs Cogs Asset: Cycle Time X Actual Production÷ Actual Production TimejozsefczÎncă nu există evaluări

- 660Document160 pagini660Chris ParkinsonÎncă nu există evaluări

- DATWYLER Katalog Safety 0713 eDocument120 paginiDATWYLER Katalog Safety 0713 ePep VasilevaÎncă nu există evaluări

- Software Quality Chapter 1 2 3Document78 paginiSoftware Quality Chapter 1 2 3Thalia SerranoÎncă nu există evaluări

- Thesis BOOK 69D PDFDocument116 paginiThesis BOOK 69D PDFMd Saddam HossainÎncă nu există evaluări

- Kathryn NewcomerDocument19 paginiKathryn NewcomerEnvironmental Evaluators NetworkÎncă nu există evaluări

- Omar Hisham 19104677 (HIL) AssignmentDocument2 paginiOmar Hisham 19104677 (HIL) AssignmentOmar HishamÎncă nu există evaluări

- A Conceptual Study Into The Implementation of A Centralized Blasting System at Samancor's Mooinooi MineDocument7 paginiA Conceptual Study Into The Implementation of A Centralized Blasting System at Samancor's Mooinooi MinehieuÎncă nu există evaluări

- Unit 6: Quality Management (Pmbok: Guide, Chapter 8)Document26 paginiUnit 6: Quality Management (Pmbok: Guide, Chapter 8)RodolfoMarín100% (1)

- Better Networks For Better SurveilanceDocument2 paginiBetter Networks For Better SurveilanceJason LackeyÎncă nu există evaluări

- Product Analysis Report FormatDocument2 paginiProduct Analysis Report FormatNadiva ManopoÎncă nu există evaluări

- Graduate DoctorateDocument18 paginiGraduate DoctoratesamjerÎncă nu există evaluări

- PODEM ANUPAM Brochure CraneComponentDocument28 paginiPODEM ANUPAM Brochure CraneComponentJnanamÎncă nu există evaluări

- API Rbi Software BrochureDocument3 paginiAPI Rbi Software BrochureOsniÎncă nu există evaluări

- Analytical Method ValidationDocument57 paginiAnalytical Method ValidationYuliusDenisChrismaajiÎncă nu există evaluări

- Integration of Asset Management Standard ISO 55000 With A Maintenance Management ModelDocument7 paginiIntegration of Asset Management Standard ISO 55000 With A Maintenance Management Modelheri iiÎncă nu există evaluări

- Robert B. Abernethy-The New Weibull Handbook-R.B. Abernethy (2006)Document334 paginiRobert B. Abernethy-The New Weibull Handbook-R.B. Abernethy (2006)mohmehr89% (9)

- Reliability Centered Maintenance (RCM) ProgramDocument8 paginiReliability Centered Maintenance (RCM) ProgramWily Fitra Dermawan100% (1)

- 5 - System Reliability and Ancillary ServicesDocument63 pagini5 - System Reliability and Ancillary ServicesSari M.IÎncă nu există evaluări

- ETAP 12.6 - Tutorial para o ProgramaDocument82 paginiETAP 12.6 - Tutorial para o Programacoringa1340% (5)

- E3051 16Document10 paginiE3051 164romi89Încă nu există evaluări

- Epri Instrumentation and Control Program - Complete Product ListDocument20 paginiEpri Instrumentation and Control Program - Complete Product ListkaicyemÎncă nu există evaluări

- Evaluating The Condition & Remaining Life of Older Power PlantsDocument7 paginiEvaluating The Condition & Remaining Life of Older Power PlantsAlif Nur FirdausÎncă nu există evaluări

- TIL 1744 - TIL 1744 Stage 17 EGV1 and EGV2 Stator Ring Rail and CDC Hook Fit Wear InspectionDocument7 paginiTIL 1744 - TIL 1744 Stage 17 EGV1 and EGV2 Stator Ring Rail and CDC Hook Fit Wear InspectionBouazzaÎncă nu există evaluări

- Relationships Among Service Quality, Customer Satisfaction and Customer Loyalty: A Case Study On Mobile Shopping AppsDocument8 paginiRelationships Among Service Quality, Customer Satisfaction and Customer Loyalty: A Case Study On Mobile Shopping AppsChun Chriz TadeyuÎncă nu există evaluări

- Qualitative Financial ReportingDocument7 paginiQualitative Financial ReportingarshadÎncă nu există evaluări

- Conditionandriskassessment HealthIndexDocument9 paginiConditionandriskassessment HealthIndexTHILAKKUMARÎncă nu există evaluări

- Dod3235 1-H PDFDocument287 paginiDod3235 1-H PDFAlexandre Gelsi0% (1)

- Software RequirementsDocument31 paginiSoftware RequirementssaravananÎncă nu există evaluări

- Impact of Accreditation On The Quality of Madrasah Aliyah Education at East Lampung DistrictDocument7 paginiImpact of Accreditation On The Quality of Madrasah Aliyah Education at East Lampung DistrictIJAR JOURNALÎncă nu există evaluări