Documente Academic

Documente Profesional

Documente Cultură

Disclosure To Promote The Right To Information

Încărcat de

Harsh ZopeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Disclosure To Promote The Right To Information

Încărcat de

Harsh ZopeDrepturi de autor:

Formate disponibile

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 2171 (1999, Reaffirmed 2010): Portable Fire

Extinguishers, Dry Powder (Cartridge Type)--Specification

(Fourth Revision). ICS 13.220.10

(Reaffirmed 2010)

IS 2111 : 1999

'?dJ 2/ J.fI 1ifJ

ql\i:S't

-

)

Indian Standard

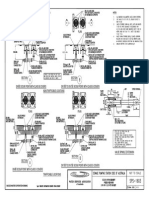

PORTABLE FIRE EXTINGUISHERS, DRY POWDER

(CARTRIDGE TYPE) - SPECIFICATION

February 1999

( Fourth Revision)

First Reprint JUL Y 200 I

ICS 13.220.10

BIS 1999

BUR E A U 0 FIN D I A N S TAN.D A R D S

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

Price Group 4

REAFFIRMEO

_ ....... 2009

M1ENDMENT NO. 1 APRIL 2001

TO

IS 2171 : 1999 PORTABLE FIRE

DRY POWDER (CARTRIDGE 1YPE) - SPECIFICATION

( Fourth Revision)

(Second cover page, Foreword) - Insert the following before last para:

'A scheme for labelling environment friendly products known as ECe Mark

has been introduced at the instance of the Ministry of Environment and

Forests (ME F), Government of India. The ECQ Mark would be

administered by the Bureau of Indian Standards (BIS) under the BIS Act,

1986 as per the Resolution No. 71 dated 21 February 1991 and No. 425 dated

28 October 1992 published in the Gazette of the Government of India. For a

product to be eligible for marking with EeG logo, it sbaH also carry tbe lSI

Mark of BlS besides meeting additional optional environment friendly

requirements. FOT this purpose, tbe Standard Mark of BIS would be a single

mark being a combination of the lSI Mark and the EeD logo. Requirements

to be satisfied for a product to qualify for tbe BIS Standard Mark for ECO

friendliness being included in the relevant published standards through an

amendment. The e requirements are optional; manufacturing units are free

to opt for the lSI Mark alone also.

The amendment is based on the Gazette Notification No. 160 dated 1 April

1999 for Fire Extinguishers as environment friendly products published in the

Gazette of Government of India.'

( PaRe 4, clause 1 ) - Insert the fol1owing new clause after 11 and

renumber the subsequent clauses:

'12 0P110NAL REQUIREMENTS FOR ECO MARK

12.1 General Requirements

12.1.1 Any fire extinguisher baving BIS Standard Mark qualifies for

consideration of EeO

12.1.2 The products manufacturer must produce the consent clearance as per

provision of tbe Water (Prevention and Control of Pollution) Act, 1974, Wal,'!r

(Prevention and Control of Pollution) Cess Act, 1977 and Air (Prevenlion &:

Control of Pollution) Act, 1981 respectively, a]ongwith authorization if

1

required under Environment (Protection) Act, 1986, and the Rules made

thereunder to the Bureau of Indian Standards while applying for Eoo Mark.

12.1.3 The products may display in brief the criteria based on which the

product has been awarded ECO Mark.

12.1.4 The product may carry alongVith instructions for proper use so as to

maximize product performance with statutory warning, if any, minimize waste

and method of safe. disposal.

1%.1.5 The material used for product packaging (excluding refills) shall be

recyclable, reusable or biodegradable.

12.1.6 The product must display aUst of critical ingredients in descending

order of quantity present in percent by weight. The list of such critical

. ingredients. shan be identified by the Bureau of Indian Standards.

1%.% Spec:ific Requirements

1%.%.1 The fire extinguisher shan not contain any Ozone Depleting Substance

(ODS) relevant to fire extinguishers industry as identified under the Montreal

Protocol (Annex E).

12.2.2 Gas based extinguishing media once discbarged in the atmosphere

sholJld not have atmospheric life.time of more than a year (Annex F).

12.2.3 Chemical used should not have global warmingpotentill (Annex G).

12.2.4 The metallic body and other metal parts of the fire extinguishers shaH

be free of lead or lead alloys.

1%.2.5 The coating used for the metalJic part shall not be formulated wit.

mercury and mercury compounds or be tinted with pigments of lead,

cadmium, chromium VI and their oxides. Excluded are natural impUrities

entailed by the production process up to the amount 0.1 . pereent by weight

which are contained in the raw material.

Nom - cxnextinguishcrs may be permitted tin suitable substitutes are available.

2

Amend No.1 to IS 2171 : 1'"

ANNEX E

( Clause 12.2.1 )

UST OF OZONE DEPLETING SUBSTANCES (ODS) CONlROUED

Trade Name

Halon 1211

Halon 1301

Halon 2402

CFC-l1

CFC-12

CFC-U3

CFC-114

CFC-115

CCI4

C2 H3 Cl3

CFC-13

CFC-ll1

CFC-112

CFC-2I1

CFC-2I2

CFC-213

CFC-214

CFC-215

CFC-216

CFC-217

Methyl Bromide

BY MONTREAL PROTOCOL

ODP

3.0

10.0

6.0

1.0

1.0

0.8

1.0

0.6

1.1

0.1

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

0.6

NOTE - ODP values ue relative 10 CFC-lI wbida has heeD assigned Ifbitrary

value of 1.0.

AmeadNo.l tom 21'1: 1"'---

ANNEX F

( Clause 11.2.2)

LIST OF ATMOSPHERIC LIFETIME OF GAS-BASED AGENTS

Trade N am e Desitf'6tion Atm ospheric

Life Time (Year)

Halon-13001

NAFSIII

FElS

FE 241

FE 36

FE 13

FM200

CEA410

Halon 1301

Inergen

Argonite

Argon

(CF 31)

H CFC (Blend A)

HCFC12S

FCFCl24

HFC .. 221fa

HFC23

HFC-221EA

- Fe-3-1-10

Halon 1301

100541

lOSS

1001

ANNEx G

( Clause 11.2.3)

< Iday

12

36

.6

250

250

41

2600

6S

LIST OF SUBSTANCES HAVING GLOBAL WARMING POTENTIAL

(GWp)

T,t.Uk Name GWP(l()()year)

V.C02

Halon 1301

Inergen

Argonite

Argon

CBA410

FM200

FE 13

FE 36

FE 241

FElS

NAFSm

CF31

(CBD22)

4

5600

SSOO

3300

12100

8000

480

3200

1 4SO

<5

AMENDMENT NO.2 MARCH 2003

TO

IS 2171: 1999 PORTABLE FIRE EXTINGUISHERS, DRY

POWDER (CARTRIDGE TYPE) -SPECIFICA nON

( Fourth Revision)

( Page I, clause 3.1) - Insert the following at the end :

'or by pressing the squeeze grip. '

(I)

iii)

iv)

xiv)

(Page I, clause 4.1, illforma/fable )-Substitutethe following for the existing :

Nomillal Capacity of

Extinguisher

kg

5

10

Dry Powder Om/ellis

with tolera"ce + 5 peru!II/)

5

10

( Page 2, Table J ) - Substitute the following fex- the existing, under respective SI No. :

! (2)

1(4) 1(5)

Neck Ting (i) Leading tin bronze Grade LTB 2 of IS 318

(ii) Brass forging Grade FLB of IS 6912

(iii) Seamless mild steel M. S. Tube having

tube phosphorus and sulphur 0.05

percent maximum and other

properties conforming to

IS 1239 (Part I).

Cap including cartridge i) Leaded tin bronze Grade LTB 2 ofIS 318

holder

ii) Brass Grade FLB of IS 6912

iii) Plastic Sr.e Annex B

iv) Stainless steel IS 6529

v) Auminium die cast IS 1804

Plunger i) Brass Grade 2 of IS 291 or Type I

0IS319

Delete ii) Stainless steel IS 6528

Squeeze grip handle i) Mild Steel Any Grade of IS 513

ii) Aluminium Grade 4450 or 4225 ofIS 617

iii) Plastic IS 7328

[ Page 1, clause 6.1. second senlence (including infonnal table ) ] - Delete.

1

A mend No.2 to 2171 : 1999

( Page I. clause 7.1.2. lines 6 alld 7 ) - Substitute 'the clamp shall be of mild steel

sheet thickness of3 mm' jar 'and the clamp shall be of mild steel sheet of the same thickne.l\..-;" .

( 2, clause 7.4, lilies 5 alld 6 ) - Delete '0 1 or I & 2 kg capacity' and' GJ.

( Page 3, clause 7.6, last seJUellce) - Substitute the tollowing tor the existing sentence:

'The capacity of gas cLU"tJidge shall be 120 g for 5 kg and 180 to 200 g tl)J' I 0 kg'.

( Page 3, clause 7.7./il/e 2 ) - Substitute '7 mm' for '10 mm'.

( Page 3, clause 7.11) -Insert the following new clauses after 7.11:

'7.11 The syphon tube shall be fitted inside the body. In case of squeeze grip tyre, syphon

tube shall be fitted in the cap,

7.12 Bottom Ring

Bottom ring/skirting of mild steel of minimtun thickness 3 mm shall be rrovided,'

( Page-3, clause 8.1, line 2) - Delete the words '(under prillt)'.

( Page 3, clause 10.3 ) - Insert the following at the end of first sentence:

'depending upon the powder conforming to IS 4308 or IS 146(1) for class BC & class ABC

respectively which is filled in the extinguisher.'

( Page 3, clause 10.3, third sentence) - Delete.

[ Page 3, clause 11.1 (informal table) }-Delete the following first line:

'1 &2 - 8 10 not less than 2'

( Page 4, clause 11.3 ) -Insert the following new clause after 11.3:

'11.4 Fire knock down properties shall be carried out on dry powder filled inside the

extinguishers as per the pocedure given in 3.7 ofIS 4308 or 4.U of IS 14ffi9 upo(}

the powder used in fire extinguisher.'

[ Page 4, clause 12.1(a) ] - Substitute the following for the existing;

a) Manufacturer's name or trade-mark, serial No. and year of manufacture

shall be embossed at the bottom ring.

[ Page 4, clause 12.1(c) ] - Insert the following at the end:

'class ABC or BC'

2

(CED22 )

Reprography Unit, HIS. New De/hi. India

AMENDMENT NO. 3 SEPTEMBER 2003

TO

IS 2171 : 1999 PORTABLE FIRE EXTINGUISHERS"DRY

POWDER ( CARTRIDGE TYPE) - SPECIFICATION

( Fourth Revision)

( Page J, clauses 7 to 7.2.1 ) - Substitute the following for the existing:

7 CONSTRUCTION

7.1 General

7.1.1 The cylinder shall be of welded construction having cold or hot drawn

cylindrical portion with herni-spherical eHiproidal or torispherical ends welded

to it or two halves (upper half shorter) cold or hot drawn havingiodome and

bottom dish of herni-spherical or ellipsoidal or tori s pherical and

circumferentially welded together. A cylindrical skirt having minimum 2S mm

height shall be welded to the bottom dish. The welding shall be done by an

electric arc welding process and shall conform to IS 2825.

7.1.2 Where carrying handle andlor supporting fittings are fitted to .the body,

these shall be either welded or brazed. The carrying handle shall be made of

mild steel or stainless steel rod not less than 6 nun in diameter or fabricated out

of mild steel or stainless steel sheets of same thickness as the body and the clamp

shall be of mild steel or stainless steel thickness of 3 mm, minimum.

7 2 o ~ o d y

The material used in the construction of extinguisher bodies shall be weldable.

The filler materials shan be compatible to the body steel to given good welds. A

cylindrical ring shall be fitted/welded to the bottom dish. Minimum wall

thickness of the body shaH be calculated using the formula:

a) For carbon steel bodies,

D

1 = - + 0.7

360

b) For austenitic stainless steel bodies,

D

t ;:: - + 0.3

600

Amend No.3 to IS 2171: 1999

where

t :;: minimum thickness, in mm; and

D:;: external diameter of the body, in mm.

I Page 2, Table 1, SI No. (ii), coL 4 ] - Insert 'IS 3074 or IS 3601' after

'IS 513',

[Page 2, Table 1, Sl No. (iv), col 4 ] - Substitute 'IS 318' for 'IS 513'

I Page 2, Table 1, Sl No. (xii), col 4 ] - Substitute 'IS 14933' for the existing

matter.

( Page 2, clause 7.4 ( see also Amendment No.2) J - SubstiWte the

following for the existing:

'7.4 Neck Ring

The neck ring of 57 mm (0 2 V4) for bang on type and of 63 mm (0 1;2) for

squeeze grip type shall be firmly secured by brazing or welding. A paraHel screw

thread for the attachment of cap shall be not less than 16 mm in effective length

and the thread shall be in accordance with of IS 2643 with Class A toLerance .

(Po;ge 2, clause 7.5, line 5) - Substitute '2.5 mm' for '3 mm'.

(Page 3, clause 7.9) - Substitute the following for the existing:

'7.9 Hose

The extinguisher discharge outlet of 5 kg and 10 kg capacity shall be fitted with

the hose of not .less than 500 mm ( or of suitable size ) and 750 mm (or of

sui tab Ie size ) lengths. respecti vely.

(CED22 )

Reprography Unit. BIS. New Delhi, India

2

AMENDMENT NO. 4 APRIL 200S

TO

IS 2171 : 1999 PORTABLE FIRE EXTINGUISHER, DRY

POWDER (CARTRIDGE TYPE) - SPECIFICATION

( Fourth Revision)

[ Page 1, clause 7.1.1 (see also Amendment No.3) ] - Delete last sentence

'The welding ~ ~ IS 2825' and add the following:

'The welded construction shall be one of the types given below, and shall

conform to the relevant Indian Standard:

a) Oxy-acetylene welding shall conform to the requirements specified in

IS 1323.

b) Resistance welding:

1) Spot welding (for attachment of fittings only) shall conform to

IS 819.

2) Stitch welding shaH conform to the requirements specified in

IS 819.

3) Seam welding shall conform to the requirements specified 10

IS 1261.

c) Metal arc welding shall confonn to IS 9595.

d) Electric arc welding shall conform to IS 2825.

[ Page I, clause 7.1.2, last line (see also Amendment No.3) ] - Substitute

'2 mm' for '3 mm'.

( Page 1, clause 7.1.2) - Add new subclause 7.1.3 as follows:

'The thickness of h ~ shell shall be calculated in accordance with 7.2 but it shall

not be less than 1.4 mm.'

[ Page 1, clause 7.2 (see also Amendment No.3) ] - In fonnula, substitute

'300' for 360'.

Amend No.4 to IS 2171 : 1999

( Page 2, Table 1, SI No. (iii) ] - Add the following:

(3) (4)

iv) Stainless Steel IS 6913

r Page 2, Table 1, SI No. (i) ] - Add the following:

Stainless Steel sheet IS 6911

[ Page 2. Table L SI No. (xii). col 4 (see also Amendment No.3) J -

Substitute 'Having burst pressure of not less than 50 kgflcm

2

, for 'IS 14933' .

[ Page 2, clause 7.4 (see a/so Amendment No.3) ] - Substitute the first

sentence with the following:

'The neck ring of 63 mm (0 21;2) or 75 mm (0 3) shall be finnly secured by

brazing or welding.'

( Page 3, clause 7.9 (see also Amendment No.3) ] - In line 3, delete '(or of

suitable size)' .

( Page 3, clause 7.12 (see also Amendment No.2) ] - Substitute '1.6 mm'

for '3 mm',

( Page 3, clause 9 ) - Substitute the following for the existing:

'9.1 All internal and external surfaces of the body shall be completely epoxy

powder coated to minimum 0.050 mm thickness. The thickness of the coating

shall be measured as given in IS 3203. The internal surface of the body shall be

plastic/rubber coated and lining shall be of a minimum thickness of 0.5 mm as an

alternative to powder coating.

9.1.1 Test for Adhesion of Plastic Lining (Type Test) - Subject the unfilled

extinguisher to a pressure 15 kgf/cm

2

and store for 120 + 4 h at 27 SOc.

-0

Release the pressure and examine the extinguisher internally for

separation from the waH of the body or lifting of the lining, and bubbles between

(he lining and the body. '

2

Amend No.4 to 182171: 1m

( Page 3, clause 9.1.1 ) - Renumber '9.1.1' as '9.2' and delete 'to lead-tin

alloy coating.'

( Page 3, clause 9.1.2) - Delete.

( Page 3, clause 10.1 ) Insert 'Post Office red' after 'Fire red' and 'No.

538' after 'No. 536 '.

( Page 4, clause 11.4 (see aLso Amendment No.2) ] - Delete.

(CED 22)

Reprography Unit. SIS. New Delhi. India

3

AMENDI\ilENT NO.5 S'f;PTEI\'1HER 2006

TO

IS 2171 : 1999 PORTABLE l'''IREEXTINGlfISHERS,

DRY PO\VllER (CAR'fRHJGE TYPE)-

SPECIFICATION

( Fourth Revisiofl )

[Page 4, clause l2, Title (see also ,lmendment No. 1)1 - Substitute

'ADDITIONAL'jiw'OPTIONAL',

( eEl) 22 )

Reprography Umt,1TIS';"New Dellii. IO(\!:1

AMENDMENT NO.6 FEBRUARY 2010

TO

IS 2171 : 1999 PORTABLE FIRE EXTINGUISHERS, pRY

:POWDER (CARTRIDGE TYPE) - SPECIFICATIQN

( Fourth Revision)

(Page 3, clause 10.1) - Substitute the following for the existing:

"Each extinguisher body except stainless steel body shall be painted either with

epoxy powder coating or synthetic enamel paint. The shade shall be Red'

or 'Post Office Red' conforming to Shades No, 536 or 538 of IS 5, Stainless

steel body shall be buffed, .

NOTES

1 Whenever epoxy powder coating is applied on the external surface of mild steel body for

anti-corrosive treatment, synthetic enamel paint coating is not required ..

2 The body of extinguisher shalJ be of good finish, clear of all burrs and sharp "

(Page 3, clause 10.4) - Delete,

(CED 22)

Reprography Unit, BIS, New Delhi, India

Fire Fighting Sectional Committee, CED 22

FOREWORD

This Indian Standard (Fourth Revision) was adopted by the Bureau ofIndian Standards, after the draft fmalized

by the Fire Fighting Sectional Committee had been approved by the Civil Engineering Division Council.

Portable dry powder fire extinguishers (other than those used for metal fires) are used for dealing Class

A, B,e fires. Use of these extinguishers have increased due to the banning of CTC type fIre extinguishers and

phasirig out Halon extinguishers as these also act as a substitute for the same in certain risk. This standard has

been prepared with a view to guide the industries for the manufacture and the users in obtaining the extin-

guisher capable of giving satisfactory perfonnance. The details in regard to the maintenance are given in

IS 2190 : 1992 'Code of practice for selection. installation and maintenance of portable first aid fire extinguishers

(third reviSion)'. This standard was first published in 1962 and revised in '1972. 1976 and 1985. This fourth

revision has been prepared so as to incorporate all the amendments issued so far. The provisions in respect of

the fire extinguishers to be used for metal fires have been also covered in separate Indian Standards. The major

changes in the present revision include:

a) Incorporation of Class A also,

b) Materials for some of the parts of the extinguisher. and

c) Size of.filler 'opening added.

Composition of the Committee responsible for fonnulation of this st;mdard is given in Annex D.

For the purpose of deciding whether a particular requirement of this standard is complied with, the fmal value,

observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with

IS 2 : 1960 'Rules for rounding off numerical values (revised)'. The number of significant places retained in

the rounded off value should be the same as that of the specified value in this standard.

IS 2171 : 1999

Indian Standard

PORTABLE FIRE EXTINGUISHERS, DRY POWDER

(CARTRIDGE TYPE) - SPECIFICATION'

( Fourth Revision)

1 SCOPE

1.1 This standard lays down the requirements

regarding material, shape, construction, chemical

charges, anti-corrosive treatment and tests for dry

powder fire extinguishers.

2 REFERENCES

2.1 The Indian Standards listed in Anne.x A contain

provision which, through reference in this text,

constitute provisions of this standard. At the time of

publication, the editions indicated were valid. All

standards are subject to and parties to

agreements based on this standard are encouraged to

investigate the possibility of applying the most recent

editions of the standards given in Annex A.

3 PRINCIPLE

3.1 The method of expulsion of dry powder shaH be

by means of pressure produced from compressed or

Jiquified gas from gas cartridge attached to the cap

after piercing it uprightly.

4 CAPACITY

4.1 The total capacity of the dry powder extinguisher

when filled for the various capacities shaH be as

follows:

Nominal Capacity

of Extinguisher

kg

I

2

5

10

5 MATERIALS

Dry Powder Contents,

(with Tolerance

0/+ 5%)

kg

I

2

5

10

5.1 The materials for the construction for various

parts of the. fire extinguisher shall be as given in

Table I.

6 SHAPE

6.1 The shape of the body shall be cylindrical. The

dimensions shall be as follows:

Capacity of Outside Size of Filler

Exiinguishel' Diameter Opening

of Body

kg mm mm

1 7580 Not less than 35

2 100-110 Not less than 4S

5 150-160 1065-68

00.77-80

10 175-185 ID 75-78

0087-90

7 CONSTRUCfION

7.1 General

The top end (dome) and the bottom end (dish) on the

body shall be dished outward (convex) without reverse

curvature to a radius not exceeding the internal

diameter of the body.

7.1.1 Non-ferrous metal parts shall be brazed to the

body.

7.1.1 Where carrying handle and/or supporting

fittings are fitted to the body. these shall be welded or

brazed. The carrying handle shall be made of mild

steel rod not less than 6 mm in diameter or fabricated

out of nrild steel sheet of the same thickness as body,

and the damp shall be of mild steel sheet of the same

thickness. Alternatively, the handle may take the form

of wheel type handle integral with the cap.

7.1 Body

The construction of the body shall be welded type.

Thickness of sheet shall be not less than t.6 mm

nominal upto 5 kg capacity and 2 mm for 10 kg capacity.

NOTE - The minimum thickness of sheet takes into account the

minimum thickness required based on bursting formulae that is

not less than dli 00 where d is the diameter of body in mm.

7 1 Welded construction shall be one of the types

given below and shallconfonn to relevant Indian

Standards.

a) Oxy-acetylene welding shall confonn to the

.requirements specified in IS 1323.

b) Resistance welding:

I) Spot welding (for attachment of fittings

only) shall confonn to IS 819.

IS 217. : 1999

Table 1 Materials of {::oDstruciion of Various Parts of Fire Extinguisher

(Clause 5.1)

sa Componeat

No.

(2)

i) Body

ii) Inner shell

iii) Neck ring

iv)

v) Cap washer

vi) a) Phmger

b) .Cartridge holder

vii) Pien;er

viii) Spring

ix) Syphon tube

x) Nozzle and discharge fitting

xi) Cartridge

xii) Hose

xiii) Safety clip

i)

ii)

i)

ii)

iii)

i)

ii)

iii)

iv)

i)

ii)

i)

Ii)

i)

ii)

iii)

i)

ii)

iii)

iv)

i)

ii)

Materia.

Ref to Jadian Staudard

(3) (4)

Mild steel sheet Grade any of IS 513, IS 2062, IS 6240

Mild steel sheet Grade any ons 5 13

Plastic IS 7328

Leaded tin bronze Grade LTB 2 ofIS 318

Brass forging IS 6912 Grade FLB

Seamless mild steel pipe IS, 1239 (Part I)

Leaded tin bron7.e Grade LTB 2 o(IS 513

Brass forging IS 6912 Grade FLB

Plastic SeeAnnexB

. Stainless steel IS 6529

Rubber Requirement in respect of hardness as applicable to Type 3 of

IS 5382 and also acid I resistant (see Note)

Brass Grade 2 ofiS 291 or Type I oflS 391

Stainless steel IS (;528

Leaded tin bronze Grade LTB 2 orIS 318

Brass Grade 20flS 291 or Type 1 of IS 319

Stainless steel IS 6528

Carbon steel Grade I ofIS 4454 (Part I)

Mild steel IS 3601

Blass Alloy No.2 ofiS 407

Plastic IS 7328

Aluminium alloy Grade 4450 or 4225 of IS 617

Leaded tin bronze Grade LTD 20flS 318

Brass Grade 2 oflS 29) or Type I ofiS 319

Plastic See AnnexB

Steel IS 4947

Braided PVC/rubber Having bursting pressure of not less than 50 kgf/cml

Steel Grade I ofJS 2507

Plastic IS 7328

NOTE - When a piece of2.5 em cut from any portion is dipped in 20 percent sulphuric acid I 5 percent sodium hydroxide solution for

30 min. there shall be no of corrosion or damage.

2) Stitch welding shall conform to the

requirements specified in IS 819.

3) Seam welding shaH conform to the

requirements specified in IS 1261.

c) Manual metal arc welding, Gas sheilded

metal arc welding or Gas tungeston arc weld-

ing shall confonn to IS 9595.

An butt welds shaH be full penetration welds.

7.3 Expansion Space

A $pace shall be provided above the dry powder level

in the body ofthe extinguisher. It shall be of sufficient

volume to;ensure that when the discharge opening is

temporarily closed and the extinguisher is operated at

a temperature of 27 5C, the internal pressure shall

not exceed 1.5 MN/cm

1

(15 kgf/cm2) and the body

shall not show any sign of leakage.

2

7.4 Neck Ring

The neck ring shan be firmly secured by brazing or

welding. A parallel screw thread for the attachment of

cap shall be not less than 16 mm in effective length

and the threads shall be in acccordance with IS 2643

(Part 1) with class A tolerance of size G 1 for 1 and 2

kg capacity and and G 3 for 5 and 10 kg capacity.

7.5 Cap

The capshaU be screwed for fixing to the neck on

the body for not less than 16 mm in effective length

and the parallel threads shan be in accordance with

IS 2643 (Part 1) to suit neck ring. At least 3 hoJe of

not less than 3 mm diameter each shall be drilled

through the threaded portion of the cap to form vents.

The centres of the vent holes shall be 6.5 mm

maximum from the exposed face of the, cap joint

washer.

7.6 Gas Cartridge and. Cartridge Holder

A cartridge holder shall be provided and fitted inside

the cap in such a way that the cartridge-seal:-piercing

mechanism passes through its centre and shall

puncture the cartridge clean when the cartridge is fitted

to this holder. The threads shall be provided in the

holder and these shall correspond to the threads of

gas cartridge (see IS 4947). Port holes shall also be

provided in the cartridge holder. CO

2

cartridge

100 g capacity fot5: kg; capacity and 200 g capacity

for 10 kg capacity shall conform to IS 4947. The

maximum capacity of gas cartridge shall be 30 g for

1 kg, 60 g for 2 kg, 120 g for 5kg and 200 g for 10 kg.

7.7 Plunger Rod and Piercing Mechanism

The plunger rod shall be of such a length that it has a

minimum stroke of 10 nun. A spring loaded piercing

device shall be provided in the plunger for piercing

the seal of the gas cartridge when fitted to the cartridge

holder. The puncturing end shall be designed so as to

ensure a clear opening in the cartridge seal when

piercer is operated. A safety clip shall be provided to

prevent accidental operation of the piercing

mechanism.

7.8 Cap Joint Washer

The cap joint washer shall be finished smooth and

retained in a recess in the cap.

7.9 Hose

The extinguisher discharge outlet of the capacity 5

and 10 kg shall be fitted with the hose of not less than

500 mm (and not less than to mm bore) and 750 mm

(and not less than 12.5 bore) lengths respectively.

7.10 Nozzle

The nozzle shall be squeeze grip type for 10 kg capacity

and for 5 kg squeeze grip type if required. The nozzle

shall be capable of discharging the dry powder as

in n.I.

7.11 Syphon Thbe

The syphon tube of internal dia 12.5 mm minimum

shall be fitted inside the body. The syphon tube outlet

should have GYl threaded male nipple to suit GYl

female threaded fitting of the discharge hose.

8 DRY POWDER CHARGE

8.1 The dry powder used of BC or ABC Class shall

conform to IS 4308 or IS 14609 (under print).

9 ANTI-CORROSIVE TREATMENT

9.1 All internal surfaces of the body shall be completely

coated with lead-tin alloy (tin oot less than 10 percent)

3

IS 2171 : 1999

applied by hot-dipping process to a thickness of not

less than 0.012 nun. The thickness of the coating shall

be measured as given in IS 32'03. The external surfaces

of the body and b9th surfaces of components, that is

inner shell (ifany), syphon tube (ifofmiJd steel), spring

etc, whichever applicable, shall also be subjected to this

anti-corrosive treatments. There shall be no visible

uncoated area both internally or externally.

9.1.1 Phosphating in accordance with the provisions

of IS 3618 may be applied on the external surface of

the body as an alternative to lead-tin alloy coating.

9.1.2 Epoxy polyster powder coating of 50 micron

thickness may be applied on internal and external surfaces

of the body as an alternative to lead-tin alloy coating.

10 PAINTING

10.1 Each extinguisher shall be painted fire red

conforming to shade No. 536 of IS 5.

10.2 A picture showing a man operating the

extinguisher in the correct manner shall be shown on

the body of the extinguisher.

10.3 The extinguisher shall be marked with the letter

'A', 'B' and 'C', indicating their suitability for

respective classes of fires as laid down in IS 2190.

All ~ h letters 'A', '8' and 'C' shall be of2.5 0.5 cm

size printed in white colour centrally contained in a

square of 4 0.5 cm size and a circle of 2 0.5 em

radius respectively. For 1 and 2 kg capacity, the size

of square shall be 2 0.2 em and circle 1 0.2 cm

radius and size of the letters 1.5 0.2 cm. The square

and circle shall be coloured blue, conforming to shade

No.l66 oflS 5.

10.4 The paint shaH conform to IS 2932.

11 TEST REQUIREMENTS

11.1 The extinguisher shall be capable of discharging

not less than 85 percent by mass of the actual rated

capacity of dry powder, when the extinguisher is

operated with its nozzle at an angle of 45 above

horizontal line at a temperature of 27 5C in still

weather conditions. The contents being expelled in

the fonn ofa continuous discharge which shall comply

with the fo !lowing requirements:

CapaCity Minimum Maximum Range o/Throw

0/ Period/orwhich Periodto o/Jet

Extinguisher Throwas Discharge (as Measured/rom.

kg

1 and 2

5

to

Jet to he alleas/8S Nozzle End to Centre

Maintained percent of 0/ Pattern of Discharge

sec

8

15

23

Rated CJpacliy at the End o/Test)

sec m

to Not less than 2

20 Not less than 4

30 Not less than 6

IS 2171 : 1999

11.2 The extinguisher body and the cap assembly shall

be tested to an internal hydraulic pressure of 3.0

MN/m

2

(30 kgf/cm2) for a period of 2 min. During

tliis test it shall not shown any sign of leakage.

NOTE - The testing may be done either with cap or without cap

and in that case the cap shall be tested separately.

11.3 .In case of hydraJic burst failure test, the

mechanical failure shall not occur at a pressure of less

than 4.5 MN/m

l

(45. kgflcm

l

) .

NOTE - The testing shall be done through discharge fittings

with the cap assembled. '

12 MARKING

12.1 Each extinguisher shall be clearly and

permanently marked with the following information:

a) Name of the manufacturer or trade-mark,if

any;

b) Method of in prominent letter;

c) The words 'Dry Powder Extinguisher';

d) The capacity of the extinguisher in kg;

e) Capacity of gas cartridge;

1) A declaration to the effect that the body of

the extinguisher has been tested to a pres-

sure of 3.0 MN/m

2

(30 kgf/cm2); and

h) Year of manufacture.

12.2 BIS Certification Marking

The product may also be marked with BIS Standard

Mark.

12.2.1 The use of Standard Mark is governed by the

provisions of Bureau of Indian Standards Act, 1986

and the Rules and Regulation made thereunder. The

details of conditions under which the licence for the

use of Standard Mark may be granted to manufac-

turers or producers may be obtained from the Bureau

of Indian Standards.

13 SAMPLING AND CRITERIA FOR

CONFORMITY

13.1 The detail of sampling and criteria for confonnity

is given in Annex B.

ANNEXA

(Clause 2.1)

LIST OF REFERRED INDIAN STANDARDS

IS No. Title IS No. Title

5 : 1994 Colours for ready mixed' paints and welding for structural work in mild

enamels (third revision) steels (second revision)

265: 1993 Hydrochloric acid (fourth revision) 2062: 1992 Steel for general structural purposes

291 : 1989 Naval brass rods and sections for ma- (fourth revision)

chining purposes (third revision) , 2124: 1974 Sodium bicarbonate (first revision)

318: 1981 Leaded tin bronze ingots and cast- 2190: ]992 Selection, installation and mainte-

ings (second revision) nance of first aid fire extinguishers

319: 1989 Free cutting brass bars, rods and sec- - Code of practice (second revision)

tions (fourth revision) 2507: 1975 Cold-rolled steel strips for springs

407: 1981 Brass, tubes for general purposes (first revision)

(third revision) 2643 (Part I) : Dimensions for pipe threads for

50: 1994 Cold rolled low carbon steel sheets

1975 fastening purposes: Part 1 Basic pro-

and strips (fourth revision) file and dimensions (first revision)

7: 1994 Aluminium and aluminium alloy

2932: 1993 Enamel, synthetic, exterior (a)

ingots and castings for general en-

undercoating, (b) finishing (second

gineering purposes (third revision)

revision)

L9..57 ,

3203 : 1982 Methods of testing local thickness of

welding for light assemblies in mild

electroplated coatings (first revision)

steel

3601 : 1984 Steel tubes for mechanical and

1239 (Part J) : Mild steel tubes, tubulars and other

general engineering purposes (first

1990 wrought steel fittings: -Part 1 Mild

revision)

steel tubes (fifth revision)

3618: 1966 Specification for phosphate treat.;.

1261 : 1959 Code -'of practice for seam welding

ment of iron and steel for protection

in mild steel

against corrosion

1323: 1982 Code of practice for oxy-acetylene

4308: 1982 Specification for dry powder for fire

fighting (first revision)

4

IS 2171 : 1999

IS No. Title IS No. ntle

4454 (Part I) :- Steel wires for cold fonned springs: 6912 : 1985 Copper and copper aUoy forging

1981 Part 1 Patented and cold drawn steel stock and forgings-(first revision)

wires-unalloyed (second revision) 7188 : 1974 Methods of test for ceUulose acetate

4947: 1985 Specification for gas cartridges for flakes

use in fire extinguishers (second

7328: 1992 High density polyethylene materials

revision)

for moulding and extrusion

5382: 1985 . Rubber sealing rings for gas

8543 (part 11 Methods of testing plastics: .Partl

water mains and sewers (first

Sec 2): 1979 Characterization polymer structure

revision)

and size, Section 2 Determination of

5762: 1970 Methods for determination of melt-

density of solid plastics

ing range/temperature

9595: 1980 Recommendations for metal arc

6240: 1989 Hot rolled steel plate (up to 6 rnm)

welding of carbon and carbon man-

sheet and strip for the manufacture

ganese steels

of low pressure liquifiable gas

14609: 1999 Dry chemical powder for fighting A,

cylinder (second reviaion)

B and C class fu-es - Specification

6528: 1992 Stainless steel wire

(under print)

6529: 1972 Stainless steel blooms, billets and

slabs forging

ANNEXB

(Table 1)

REQUIREMENTS FOR PLASTIC

1 PHYSICAL TESTS

8-1.1 From a sample, requirements of following

properties shaH be checked:

Property Method of Requirements

Test

Specific gravity IS 8543 1.25 0.02

Part 1/Sec 2)

Melting point IS 5762 215C-225C

Ash content IS 7188 lS2%

B-2 BURST PRESSURE TEST

8-2.0 If the sample passes the requirements mentioned

iIJB::J.1. UW" {oj test shan be. done

on the second sample.

B-2.l The sample shall be subject to internal hydraulic

pressure of 50 kgf/cm2 after blocking plunger hole, if

any. The pressure shall be built up gradually over a period

of 30 s and maintained for 1 min. There shalt be no

mechanical failure of cap and cap threads.

83 AGEING TEST

8-3.0 If the sample passes the requirements mentioned

5

in B-2 the follo\\ring tests shall be done on the third

sample in order as indicated below, and the sample

shaH pass all the tests.

B-3.1 Add Resistance Test

The sample shall be submerged in 10 percent dilute

hydrochloric acid_ (see IS 265) for 72 h at the

temperatUre of 27 5C. It shall be then removed,

rinsed with potable water and dried; The sample shall

not show any sign of discoiourationy distortion or

deterioration of any kind.

B-3.2 Alkali Resistance Test

The sample then shaU be submerged in 10 percent-

sodium bicarbonate (see IS 2124) for 72h at

a temperature ot27 SoC arid thtm shall be removed,

rinsed with potable water and dried. The sample shan

not show any sign of discolouration, distortion or

deterioration of any kind.

B-3.3 The sample then shall be screwed and

unscrewed into neck ring of the fire extinguisher for

100 times The samples shall not show any sign of

damage or distortion of threads. The sample shall

then be first tested for internal hydraulic pressure of

IS 2171 : 1999

4S kgf/cml after blocking plunger holes if any. The

pressure shall be built up over a period of 30 s and

maintained for 1 min. There shall not be any sign of

leakage. It shall be then kept suspended in an oven

. maintaining the temperature of 60 1C for 72 h and

after removing when it attains temperature of27 :!: SOC

it shall be kept in refrigerator at a temperature of

S:t 1C for 72 h ~ After this period the sample shan

be removed and when it attains the temperature

27 SoC and at this stage it does not show any sign

of discolouration, distortion or deterioration of any

kind, shall be subject to internal hydraulic pressure

test as mentioned above and there shall not be any

sign of leakage. This cycle of test shall be further

repeated 2 times with gap of 24 h and the sample

shall be observed and shall not show any sign of

discolouration, distortion and deterioration besides

passing the hydraulic pressure test.

B-3.4 . UV Exposure Test

The sample then shall be exposed at 27 5C to

XERON ARC.V.V. radiations for 100 min followed

by exposure at a R.H. 60 5 percent and temperature

62 SoC for 20 min. The cycle shall be repeated 60

times and the sample shall then be subjected to internal

hydraulic pressure mentioned in 8-3.3 and shaH pass

the requirement.

ANNEXC

(Clause 13.1)

SAMPLING AND CRITERIA FOR CONFORMITY

C-O GENERAL

C-O.I The risk involved in failure of a fire

extinguisher to work when needed is extremely large.

Fire extinguisher, therefore, ought to have a high

degree of reliability of performance during the entire

specified period of its service. It can be achieved only

through adequate design and control in all stages of

manufacture and assembly.

C-l SAMPLING

C-I.l Lot

All portable fire extinguishers of the same type, shape,

design and capacity produced by the same

manufacturer from similar materials under almost

identical conditions of manufacture shall be grouped

together to constitute a lot.

C-l.2 Each lot shall be considered individually for

the purpose of evaluation of quality in accordance with

this specification.

C-1.2.1 The number of samples for testing to be taken

at random from a lot and the criteria for conformity

shaUbe-asgiveninC .. ~ 1 ~ 2 and C .. 1 ~ 3

C-1.2.2 From each lot a number of samples as

indicated in col 2 of Table 2 shall be selected at

random.

C-1.2.3 They shall be examined visually as far as

possible in respect of requirements specified in 4, 7, 10

and 12 and then in respect of hydraulic pressure test

(see 11.1) and corrosion test (see 9).

6

Table 2 For Lots Produced Under Quality

Control System

(Clause C-l.2.2)

No.oi'l\ems Sample Size

in the Lot

(1) (2)

Up to 50 13

51 to 90 20

91 to 150 32

151 to 280 50

281 to 500 80

501 to 1200 125

1201 and above 200

C-1.2.4 In respect of performance test (see 11.1),

expansion space (see 7.3) one sample shall. be tested

for these property and the sample shall pass this test

for the lot to be declared to conform to this

requirements.

C-1.2.S In respect of bursting pressure (see 11.3) type

test shall be done and these should conform to the

requirements laid down in the specification.

C-1.2.6 In the absence of a certificate from a

manufacturer about conformity ofspeciflcatlOii' for

the various components (see 5.1) and the charge

(see 8.1) of the quality specified in this specification,

from a sample fire extinguisher, on item each shall

be taken separately and examined individually in

respect of the relevant requirements laid down in this

specification. The lot shalf be considered satisfactory

if all the items satisfy the relevant requirements of

this specification. .

ANNEXD

(Foreword)

COMMITI'EI COMPOSITlON

Fire Fighting Sectional Committee, CED 22

Chairman

SHRl OM PRAKASH (FIRE ADVISER)

Members

SHRl D. K. SHAMI

OR NAVINCHANDRAJAIN

SHRI P. N. SE11iNA

SHRI N. T. PANJWANI (Ahernate)

SHIU SHIV NATIi

SHJU P. GANESHAN (Alternate)

SHIU P. K. CHAlTEJUEE

SHJU H. S. KAPARWAN (Alternate)

SHRl K. P. SHARMA

AsslT SECURITY COMMISSIONER (FIRE) (Allemale)

SHRl M. GANGARAJU

SHRI V K. VERMA (Alternale)

SHRI S. K. DHw

SHRl R. C. SHARMA (Allernate)

Smu V. L. N. RAo

LT COL S. K. MAltKNDEY (Alternate)

SHRl P. A. DuBEY

SHRI NARlNDER. KUMAR

Flu ADvISER

SHRI S. C. RAy (Allerna/e)

StiR! J. N. V AKit

SHRl K. RAvl(Alternate)

DIR.ECJOR

DEPUTY DIREClOR (Alternate)

DR T. P. SHARMA

DR A. K. GUPTA (Alternate)

SHRI B. PATIfAK

MANAGING DIItECTOR

TECHNICAl EXEC\IT1VE (Alternate)

SHRl P. S. BHANDARI

SHR! D. R. Y ~ V (Alternale)

PltEslDENT

GENERALSECRETARV (Alternate)

SI1R1 S. N. KUNDU

SI1RI P. KHANNA

DIRECTOR OF EQUIPMENT

SENIOR FIRE OFFICER (Alternale)

StiRi C. P. GOSAIN '

S.w P. N. GHOSH

StiR! B. J. SHAH

SHRf A. M. SHAH (Allernale)

StiRi V. V. RAo

SHRJ V. O. SAwANT(Alternale)

StiRi T. Y OGESWAM

Smu JOHN TAKEY (Allemale)

SURI SURESH BABU

SHRI D. N. SINGH{Alternate)

SHRl R. P. SAXENA

Representing

Ministry of Home AffaIrs, New Delhi

MinisUy of Home Affairs

Government ofMaharashtra. Mumbai

Kooverji Devshi "Co (P) Ltd, Mumbai

Steel age Industries Ud, ChennailDelhi

MinisUy of Defence, Delhi

Railway Board, Delhi

Din:ctor3te General ofSuppJies and Disposals, Pone

Delhi Fire Service, Delhi

Controllerate of Quality Assurance. Pune

Design &. Consultancy. CME Campus, Pune

Engineer-inoChiefs Branch. Ncw Delhi

Defence Research" Development Organization, Delhi

Tariff Advisory Committee. Ahmedabad

Home Department (Fire Service), Chennai

Central Building Research Institute (CSIR), Roorkee'

West Bengal Fire Service, Calcutta

Avon Services Pvt ltd, Mumbai

Central Industrial Security Force, New Delhi

The Institution of Fire Engineers (Indi'a). Delhi

Fire & Safety Appliances Co, Calcutta

Jaya Shri Textiles, Delhi

National Airport Authority. New Delhi

Central Public Works Department, New Delhi

In personal capacity (J-l 916 Chitlaranjan Parle. New Delh,)

Newage Industries, Gujarat

Bombay Fire Brigade, Mumbai

Steel Authority oflndia Ltd, Rourke'a

Steel Authority of india Ltd. Dhanbad

Oil & Natural Gas Commission, Debra Dun

IS 2171 : 1999

SHRl NeERAJ SHARMA (A ilernale)

SHRI SWARANJfT SEN Home (Police Department) Governmellt of Andhra Pradesh, Hyderabad

DEPUTI DIRECTOR (Alternale)

SHRI T ARiT SUR

SHRI D. NEOGI (Alternate)

SHRI IiARISH SALOT

Surex Prodution &. Sales Pvt Ltd, Calcutta

Vijay Fire Protection System Pvt Ltd, Mumbai

(Conllnued on page I)

7

IS 2171.= 1999

(Continuedjrom page 7)

SHIU RAMEsIi R. DHO&i..EY

. SHIU S. M. DesAI

SHIU O. B. MENoN

SHRJ A. 1<.. NANDI (Alternate)

MANAGING DiREc:."rOIt

SHIll P. N. P ANCHAL

SHIll VINOO KUMAA,

Director (Civ Eng)

l&p1'e3enJing

Bhabha Atomic Research Centre, Mumbai

Eureka Firetech PYt Mumbai

b1 personal capacity (HOU!Ie No. 33/23/J A-J Puzhakkara Padam Vennala eachin)

Mather & Platt (India) Ltd, Mumbai

Loss Premui<m Associationoflndia. Mumbai

In personal capacity (Flat No. 46. BlOck -1, Pockelfl. Sector 15, Rohini, Delhi)

Director General, SIS (Ex-offic;o Member)

MemHf Secretary

StIU SANJEEV CHAruMDI

Joint Director (Civ Eng). BIS

8

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these pUblications may be reproduced in any form

without the prior pennission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary d e ~ i l s such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendme11ts is reaffirmed when such review indicates that nochanges are

needed; if the review indicates that changes are needed, it is taken up for revision.- Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of 'BIS Handbook' and 'Standards Monthly Additions'.

This Indian StandMd has been developed from Doc: No. CEO 22 (5492).

Amendments Issued Since Publication

Amend No. Date of Issue

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones: 323 01 31,323 3375,323 9402

Regional Offices:

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern : 1/14 C.LT. Scheme VII M, V.l.P. Road, Maniktola

CALCUIT A 700054

Northern : SCO-335-336, Sector 34-A, CHANDIGARH 160022

Southern : C.LT. Campus, IV Cross -Road,CHENNAI 600113

Western Manakalaya, E9 MIDe, Maro], Andheri (East)

MUMBAI 400093

Branches AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATl.

HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.

PATNA. PUNE. THIRUVANANTHAPURAM.

Text Affected

Telegrams: Mtmaksanstha

(Common to all offices)

Telephone

32376 17,3233841

{

337 8499,3378561

33786 26, 33791 20

{

60 38 43

602025

{

23'S 02 16, 23504 42

23515 19,2352315

{

832 92 95, 832 78 58

83278 91, 832 78 <.)2

Printed by Reprography Unit, BIS. New Delhi

S-ar putea să vă placă și

- Bis 3315 1994Document17 paginiBis 3315 1994pramod_20253Încă nu există evaluări

- Is 1391 2 1992 PDFDocument36 paginiIs 1391 2 1992 PDFsusmitamandali100% (1)

- Is 12592 2002Document17 paginiIs 12592 2002sharmak_anil0% (1)

- Is.13349.1992 0Document21 paginiIs.13349.1992 0tharaka.me2018Încă nu există evaluări

- General Specifications: EJX440A Gauge Pressure TransmitterDocument12 paginiGeneral Specifications: EJX440A Gauge Pressure TransmitterapisituÎncă nu există evaluări

- ValvesDocument8 paginiValvespravin_2011Încă nu există evaluări

- Technical Specification FOR Gear Pump With Drives: Std. / Doc. Number Rev. No. 00 Sheet 1 of 25Document304 paginiTechnical Specification FOR Gear Pump With Drives: Std. / Doc. Number Rev. No. 00 Sheet 1 of 25dhanu_lagwankarÎncă nu există evaluări

- Heat Exchanger Design OptimizationDocument26 paginiHeat Exchanger Design OptimizationEhsan MoemeniÎncă nu există evaluări

- Abb MVFTDocument32 paginiAbb MVFTParmar JenishÎncă nu există evaluări

- Sludge Treatment: Efficient Solutions For Wastewater Treatment PlantsDocument10 paginiSludge Treatment: Efficient Solutions For Wastewater Treatment PlantsLaurentiu ApostolÎncă nu există evaluări

- Manifold PDFDocument32 paginiManifold PDFvivek_enggÎncă nu există evaluări

- Tech Specs Part1 1589434282Document200 paginiTech Specs Part1 1589434282AulinoÎncă nu există evaluări

- Valves & ControlsDocument16 paginiValves & ControlseborresonÎncă nu există evaluări

- Pages From 6 - 44 - 0005 Piping Material Specification Part1Document200 paginiPages From 6 - 44 - 0005 Piping Material Specification Part1Anonymous EKxXjqyVHÎncă nu există evaluări

- Eurapipe Abs Design ManualDocument60 paginiEurapipe Abs Design ManualMatthew ButlerÎncă nu există evaluări

- ABB MAG Flow DN400 Water Master SeriesDocument52 paginiABB MAG Flow DN400 Water Master SeriesNad EemÎncă nu există evaluări

- AVK Dam Reservoir Applications Glenfield PDFDocument16 paginiAVK Dam Reservoir Applications Glenfield PDFsexmanijakÎncă nu există evaluări

- Centred disc butterfly valves guideDocument20 paginiCentred disc butterfly valves guideswcciqbalÎncă nu există evaluări

- Siemens Ac Drive Engineering DataDocument61 paginiSiemens Ac Drive Engineering DatabbkjbxkjÎncă nu există evaluări

- Guide Lt2 UvguidanceDocument436 paginiGuide Lt2 Uvguidanceezygadlo6492Încă nu există evaluări

- 0Document193 pagini0Halilibrahim Taktak100% (1)

- K-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Document21 paginiK-RD-DT-28, Rev 5 (Indoor - Outdoor Dist Trafo) .Muhammad KashifÎncă nu există evaluări

- Mixer Calculation PDFDocument19 paginiMixer Calculation PDFzemabder98Încă nu există evaluări

- Hazardous Waste Incineration ManualDocument56 paginiHazardous Waste Incineration ManualnadyamedianaÎncă nu există evaluări

- Personal Data Form: Position Applied ForDocument4 paginiPersonal Data Form: Position Applied Forkapil singhÎncă nu există evaluări

- Thermal Conductivity of MixtureDocument4 paginiThermal Conductivity of MixtureVivek YadavÎncă nu există evaluări

- Motor StandardsDocument17 paginiMotor Standardskodandaram100% (4)

- AMRI ISORIA 16 Type Series Booklet DataDocument20 paginiAMRI ISORIA 16 Type Series Booklet Datarudiskw456Încă nu există evaluări

- Instrument Transformers Catalogue PDFDocument12 paginiInstrument Transformers Catalogue PDFErdyÎncă nu există evaluări

- Pintu KlepDocument12 paginiPintu KlepAndri KwinÎncă nu există evaluări

- Biogas Generator Design Construction and MaintenanceDocument23 paginiBiogas Generator Design Construction and MaintenanceCoevicÎncă nu există evaluări

- Reliable OSY Flanged Gate ValveDocument2 paginiReliable OSY Flanged Gate Valvemina elromany0% (2)

- Is 325 1996Document21 paginiIs 325 1996Ramu NallathambiÎncă nu există evaluări

- Flowtite Product Guide 2010Document28 paginiFlowtite Product Guide 2010Anonymous 87xpkIJ6CFÎncă nu există evaluări

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 paginiAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- 51 Sdms 01rev022 For Distribution TransformerDocument20 pagini51 Sdms 01rev022 For Distribution Transformernadeem UddinÎncă nu există evaluări

- Ansi or Nema Mg1-1998Document596 paginiAnsi or Nema Mg1-1998cuervohijoguachoÎncă nu există evaluări

- Beneficial Uses of Municipal Wastewater Residuals (Biosolids) - Final ReportDocument26 paginiBeneficial Uses of Municipal Wastewater Residuals (Biosolids) - Final Reportrocky21stÎncă nu există evaluări

- Vertical Shaft Flocculator - BrochureDocument8 paginiVertical Shaft Flocculator - BrochureLTE002Încă nu există evaluări

- Variable Area Flowmeter FundamentalsDocument26 paginiVariable Area Flowmeter FundamentalsAvik BhaiÎncă nu există evaluări

- Hilti User Guide Smart Plant 3d Beginner R14 enDocument22 paginiHilti User Guide Smart Plant 3d Beginner R14 enQiuniuÎncă nu există evaluări

- Engineering AppendicesDocument198 paginiEngineering AppendicesAmeetSharmaÎncă nu există evaluări

- CamScanner 05-08-2022 16.37Document11 paginiCamScanner 05-08-2022 16.37nithyaupscÎncă nu există evaluări

- 300045C6Document144 pagini300045C6jdelosriÎncă nu există evaluări

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pagini2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- Bioventing DesignDocument89 paginiBioventing DesignCindhy Ade HapsariÎncă nu există evaluări

- Construction of Balance Works of Main Plant Civil Work in Solapur STPPDocument100 paginiConstruction of Balance Works of Main Plant Civil Work in Solapur STPPPratik GuptaÎncă nu există evaluări

- Triac Actuators and Assy'sDocument16 paginiTriac Actuators and Assy'ssarkaftÎncă nu există evaluări

- Analisis RiesgoDocument2 paginiAnalisis RiesgoabenitechÎncă nu există evaluări

- 4691231Document218 pagini4691231hrabiecÎncă nu există evaluări

- SPS-1603 1 1Document1 paginăSPS-1603 1 1abhijithavalÎncă nu există evaluări

- LPS CalcDocument17 paginiLPS CalcNagoor MeeranÎncă nu există evaluări

- L&T Aquaseal Butterfly Check ValvesDocument24 paginiL&T Aquaseal Butterfly Check ValvesSohail PathanÎncă nu există evaluări

- Is 2171 1999Document27 paginiIs 2171 1999Rao K EswarÎncă nu există evaluări

- Is.2878.2004.PDF Fire Extinguisher, Carbon Dioxide TypeDocument42 paginiIs.2878.2004.PDF Fire Extinguisher, Carbon Dioxide TyperajupetalokeshÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument32 paginiDisclosure To Promote The Right To InformationGuru MishraÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument31 paginiDisclosure To Promote The Right To InformationVaibhavladÎncă nu există evaluări

- Is 15490 2004Document30 paginiIs 15490 2004Vaishnav GireeshÎncă nu există evaluări

- Is 2791 1992Document25 paginiIs 2791 1992Trupti PawarÎncă nu există evaluări

- Environmental Scenario in Indian Mining Industry - an OverviewDe la EverandEnvironmental Scenario in Indian Mining Industry - an OverviewÎncă nu există evaluări

- TATA Schedule of Charges Version 1.1 18012013 - BDocument37 paginiTATA Schedule of Charges Version 1.1 18012013 - BHarsh ZopeÎncă nu există evaluări

- Asso MembDocument4 paginiAsso Membxs1zameenÎncă nu există evaluări

- Ea1a 2004Document7 paginiEa1a 2004marn-in2501Încă nu există evaluări

- Chapter 3.1 Elecrical SystemsDocument24 paginiChapter 3.1 Elecrical SystemspapudasÎncă nu există evaluări

- Check List & TipsDocument9 paginiCheck List & TipsNitish AnandÎncă nu există evaluări

- KP ChartsDocument41 paginiKP ChartsHarsh ZopeÎncă nu există evaluări

- Astrology Hindu EnglishDocument84 paginiAstrology Hindu EnglishHarsh ZopeÎncă nu există evaluări

- Hindu Astrology 1Document45 paginiHindu Astrology 1api-26502404100% (2)

- Disclosure To Promote The Right To InformationDocument10 paginiDisclosure To Promote The Right To Informationsadeeskumar.dÎncă nu există evaluări

- Mrs. Mabhullika Prakash & Mr. Chinmay Dwivedi PDFDocument50 paginiMrs. Mabhullika Prakash & Mr. Chinmay Dwivedi PDFZachariah JosephÎncă nu există evaluări

- Textiles - High Density Polyethylene (HDPE) / Polypropylene (PP) Woven Sacks For Packaging of 50 KG Food Grains - SpecificationDocument15 paginiTextiles - High Density Polyethylene (HDPE) / Polypropylene (PP) Woven Sacks For Packaging of 50 KG Food Grains - SpecificationVishalÎncă nu există evaluări

- Product Manual For Finned Type Heat Exchanger For Room Air Conditioner ACCORDING TO IS 11329:2018Document5 paginiProduct Manual For Finned Type Heat Exchanger For Room Air Conditioner ACCORDING TO IS 11329:2018AMIT VERMAÎncă nu există evaluări

- 302 - 2 - 80 Safety of Household AppliancesDocument12 pagini302 - 2 - 80 Safety of Household AppliancesRajesh VauÎncă nu există evaluări

- Acs-01 Solved Assignment 2020-2021Document16 paginiAcs-01 Solved Assignment 2020-2021Priyanka BediÎncă nu există evaluări

- Is 551 2013Document24 paginiIs 551 2013SamerKhoryÎncă nu există evaluări

- IS 2379 - Pipeline Colour CodeDocument14 paginiIS 2379 - Pipeline Colour CodeNoel Federer SarkarÎncă nu există evaluări

- Amendment No. 3 December 2021 TO Is 209: 1992 Zinc Ingot - SpecificationDocument2 paginiAmendment No. 3 December 2021 TO Is 209: 1992 Zinc Ingot - Specificationvishal.shelareÎncă nu există evaluări

- BIS Management Systems Certification ProfileDocument52 paginiBIS Management Systems Certification Profilewvlltd100% (4)

- Disclosure To Promote The Right To InformationDocument9 paginiDisclosure To Promote The Right To InformationdombipinÎncă nu există evaluări

- Is 2335 2005 PDFDocument9 paginiIs 2335 2005 PDFManoj pandeyÎncă nu există evaluări

- Is-875-Part-4-2021-Design Loads (Other Than Earthquake For Buildings & Structure)Document20 paginiIs-875-Part-4-2021-Design Loads (Other Than Earthquake For Buildings & Structure)Bala SubramanyamÎncă nu există evaluări

- 1659 Block BoardsDocument21 pagini1659 Block BoardsmadhuwadiÎncă nu există evaluări

- 3975 PDFDocument8 pagini3975 PDFManas Kumar SethÎncă nu există evaluări

- Indian Standard: Earth-Moving Machinery - Dumper Bodies - Volumetric Rmati-NgsDocument9 paginiIndian Standard: Earth-Moving Machinery - Dumper Bodies - Volumetric Rmati-NgsVenkatesh RajendranÎncă nu există evaluări

- Standard SpannersDocument13 paginiStandard SpannerspallavÎncă nu există evaluări

- Disinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)Document14 paginiDisinfectant Fluids, Phenolic Type - Specification: (Fourth Revision)eraman_meÎncă nu există evaluări

- IS 5470 Fosfato Dicálcico-Métodos de EnsayoDocument13 paginiIS 5470 Fosfato Dicálcico-Métodos de EnsayoKevin JosueÎncă nu există evaluări

- Is 11166 PDFDocument13 paginiIs 11166 PDFAnonymous NRlowQUcn100% (1)

- Is 16720 Product Manual Fuel AshDocument7 paginiIs 16720 Product Manual Fuel AshKolkata PIUÎncă nu există evaluări

- IS 1161 Steel Tubes Structural PurposeDocument9 paginiIS 1161 Steel Tubes Structural PurposeAnuradhaPatraÎncă nu există evaluări

- Is 7326 1 1992Document15 paginiIs 7326 1 1992Chayan BiswasÎncă nu există evaluări

- Is 9755 2003Document12 paginiIs 9755 2003Deepak BhanjiÎncă nu există evaluări

- Is 12333 1997Document9 paginiIs 12333 1997Nitesh SharmaÎncă nu există evaluări

- Is 15372 2003Document11 paginiIs 15372 2003BaskarÎncă nu există evaluări

- Market Share of WatreDocument109 paginiMarket Share of WatreSwetha SaravananÎncă nu există evaluări

- Is - Iso - 10816 (2) - 2001 PDFDocument14 paginiIs - Iso - 10816 (2) - 2001 PDFsangitaghaisasÎncă nu există evaluări

- Pressure Sensitive Adhesive Tape ManualDocument6 paginiPressure Sensitive Adhesive Tape ManualJurgyan IndustriesÎncă nu există evaluări

- Product Manual For A.C. Static Direct Connected Watthour Smart Meter - Class 1 and Class 2 ACCORDING TO IS 16444 (PART 1) :2015Document11 paginiProduct Manual For A.C. Static Direct Connected Watthour Smart Meter - Class 1 and Class 2 ACCORDING TO IS 16444 (PART 1) :2015SammoonÎncă nu există evaluări