Documente Academic

Documente Profesional

Documente Cultură

Lab Equipment Calibration

Încărcat de

johnDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lab Equipment Calibration

Încărcat de

johnDrepturi de autor:

Formate disponibile

SOP # A-505-01-069Y

STANDARD OPERATING PROCEDURES

Page:1 of 3.

CALIBRATION REQUIREMENTS for LABORATORY EQUIPMENT

1.

PURPOSE

The purpose of this Standard Operational Procedure is to provide a standard calibration procedure and standard calibration sheets for the calibration of all types of laboratory equipment.

2.

Responsibility

- Symbol indicates routine calibration performed by the departmental staff. - Symbol indicates twice annual calibration performed by metrology department - Symbol indicates annual or biannual calibration performed by an external contracted third party metrology firm.

3. 4.

Equipment Frequency

As defined on the calibration sheet and equipment specific SOPs Internal laboratory calibration ; Prior to routine use of equipment (e.g. daily balance calibration, system suitability test, pH meter etc.) Metrology department calibration ; Monthly (Analytical balances only) Metrology department calibration ; Twice per year Metrology department ; and after equipment maintenance or relocation Metrology department ; and after repair of critical part replacement External calibration ; Annually or biannually calibration by contracted Third Party according to equipment specific SOP

5.

Procedure

5.1 Operate the equipment in accordance with the relevant Operating Instructions. 5.2 Perform the equipment calibration according to the equipment specific SOP 5.3 Fill out form Calibration Record Sheet, see Attachment 2. 5.4 Evaluate if "SUITABILITY Sticker has been compromised, [Attachment 1]. 5.5 In cases where the SUITABILITY of equipment has been compromised (e.g dissolution equipment) due to the re-calibration the technician will deface and crossout the "SUITABILITY Sticker and attach a note stating "Performance Verification Invalidated Due To Re-Calibration" 5.6 Attach Calibration Sticker, to equipment [Attachment 1]. 5.7 The performance verification of the equipment (only where necessary) shall be repeated prior to routine laboratory use.

ED. N0: 02 Replaces Ed 01. Ed. Status:

Effective Date : June 1999

APPROVED:

Laboratory Maintenance Metrology QA

Operational

SOP # A-505-01-069Y

STANDARD OPERATING PROCEDURES

Page:2 of 3.

CALIBRATION REQUIREMENTS for LABORATORY EQUIPMENT

6.

Re-calibration

6.1 If the calibration does not conform, repeat the procedure. 6.2 If the second calibration does not conform, clean and check equipment according to the manufacturer's instructions. Then, repeat the procedure.

7.

Limits

Calibration Instructions must be applied in accordance with equipment specific SOP 7.1 General limit of accuracy and sensitivity Acceptance limits : Minimum: 95%, maximum 105%. 7.2 If the manufacturer specifies stricter requirements, these specification may be used. 7.3 If, after the second calibration the equipment still does not conform, replace or repair the non-functional part or unit.

8. 9.

Documentation Labeling

Document calibration results as per the attached Calibration Record Sheet. Refer to attached Calibration Record Sheets as guidance. 9.1. White label (stuck on the apparatus after apparatus SUITABILITY test). 9.2. Green label (stuck on the apparatus after CALIBRATION of apparatus).

WHITE LABEL

SUITABILITY TEST ANALYST: Date: Next Date: _________

GREEN LABEL

CALIBRATION Metrology Dept.: Date: Next Date: _________

3

[End of Document]

ED. N0: 02 Replaces Ed 01. Ed. Status:

Effective Date : June 1999

APPROVED:

Laboratory Maintenance Metrology QA

Operational

SOP # A-505-01-069Y

STANDARD OPERATING PROCEDURES

Page:3 of 3.

CALIBRATION REQUIREMENTS for LABORATORY EQUIPMENT

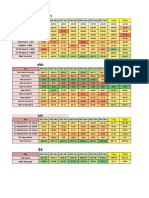

STANDARD CALIBRATION RECORD

Equipment: Location

SOP Number Last Calibrated Scheduled For Next Calibrated Calibration Expiry

I. D. No.

Installation Date Out-of-Use Date Inventory No Classification

PLANT

CRITICAL q MAJOR q System q

MINOR q Line q

TYPE OF EQUIPMENT

Manufacturer TYPE: MODEL: RANGE: ACCURACY Max. Deviation TOLERANCE GRADUATION Acceptance Limits

NLT 95 - NMT 105 %

CALIBRATED AGAINST STANDARD

TESTER ID WEIGHT ID WEIGHT ID TRACE TO NATIONAL STANDARDS YES q - NO q / Certificate q - No q

TEST BEFORE CALIBRATION

REFERENCE VALUE MEASURED DEVIATION

AFTER CALIBRATION

MEASURED DEVIATION

RESULTS Comments:

q CALIBRATED

q NOT CALIBRATED

CALIBRATION DATES

CALIBRATED BY

METROLOGIST

q IN-HOUSE q EXTERNAL

SIGNATURE

Approved by

DATE

SIGNATURE

ED. N0: 02 Replaces Ed 01. Ed. Status:

Effective Date : June 1999

APPROVED:

Laboratory Maintenance Metrology QA

Operational

S-ar putea să vă placă și

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsDe la EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsÎncă nu există evaluări

- Evaluation Reporting of ResultsDocument16 paginiEvaluation Reporting of ResultspurnachandrashekarÎncă nu există evaluări

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 paginiQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshÎncă nu există evaluări

- Facilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFDocument8 paginiFacilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFimran shaukatÎncă nu există evaluări

- LASR01 2015 Supplementary Requirements For Accreditation of Chemical TestingDocument13 paginiLASR01 2015 Supplementary Requirements For Accreditation of Chemical TestingfelicityÎncă nu există evaluări

- Atf-Ls-4.5 Subcontracting of Tests - Final 0 3Document2 paginiAtf-Ls-4.5 Subcontracting of Tests - Final 0 3Jeji HirboraÎncă nu există evaluări

- SOP 4.3 1 0 Control of DocumentsDocument4 paginiSOP 4.3 1 0 Control of DocumentsclairealbertiniÎncă nu există evaluări

- Corrective and Preventive Actions A Five Step ApproachDocument35 paginiCorrective and Preventive Actions A Five Step ApproachMohammed YousffiÎncă nu există evaluări

- Iso 17025 - Corrective Action Request Form (Completed)Document1 paginăIso 17025 - Corrective Action Request Form (Completed)JesseÎncă nu există evaluări

- NCRDocument2 paginiNCRseafoodshrimps100% (1)

- Complaint Handling 60.60 23JUN2020Document11 paginiComplaint Handling 60.60 23JUN2020Abdul RahmanÎncă nu există evaluări

- GLIER QSP ManagementrequirementsDocument72 paginiGLIER QSP ManagementrequirementsMurugan RajaÎncă nu există evaluări

- PAB Supplementary Requirements For Accreditation of Biological Testing Rev. 02 PDFDocument27 paginiPAB Supplementary Requirements For Accreditation of Biological Testing Rev. 02 PDFBernardoÎncă nu există evaluări

- Kejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityDocument3 paginiKejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityAniruddha ChatterjeeÎncă nu există evaluări

- CalibrationDocument6 paginiCalibrationListen TawandaÎncă nu există evaluări

- Quality Strategy A Complete Guide - 2019 EditionDe la EverandQuality Strategy A Complete Guide - 2019 EditionÎncă nu există evaluări

- Procedure For Plant MaintenanceDocument1 paginăProcedure For Plant MaintenancehalawallaÎncă nu există evaluări

- 4.4 Review of Requests, Tenders and ContractsDocument1 pagină4.4 Review of Requests, Tenders and ContractsGajaNand MallickÎncă nu există evaluări

- Iso15189 2022checklistDocument42 paginiIso15189 2022checklistReema Md100% (1)

- QSP Control of Documented InformationDocument2 paginiQSP Control of Documented InformationtriveshÎncă nu există evaluări

- Laboratory HouskeepingDocument3 paginiLaboratory HouskeepingTanvir SiddikiÎncă nu există evaluări

- Procedure For SamplingDocument3 paginiProcedure For SamplingWaqarAhmedButtÎncă nu există evaluări

- Control of Nonconforming ProductsDocument2 paginiControl of Nonconforming ProductsPrince Moni100% (1)

- Department: M.R. & Quality Control Document Title: Control of Non-Conforming ProductDocument3 paginiDepartment: M.R. & Quality Control Document Title: Control of Non-Conforming ProductJamil VoraÎncă nu există evaluări

- RI EGG RecallPolicyDocument26 paginiRI EGG RecallPolicyUli OktariaÎncă nu există evaluări

- Audit Checklist (RM Store)Document1 paginăAudit Checklist (RM Store)Mohamed ShabirÎncă nu există evaluări

- ISODocument11 paginiISOaiswaryacdas9853Încă nu există evaluări

- Corrective and Preventive Action (Capa)Document6 paginiCorrective and Preventive Action (Capa)Nishit SuvaÎncă nu există evaluări

- ORA-LAB.4.3: Sections Included in This Document and Document HistoryDocument14 paginiORA-LAB.4.3: Sections Included in This Document and Document HistorysamirneseemÎncă nu există evaluări

- Temperature Monitoring - Guidelines: AuditDocument14 paginiTemperature Monitoring - Guidelines: AuditS OÎncă nu există evaluări

- Measurement Traceability PDFDocument7 paginiMeasurement Traceability PDFPrashansa ShresthaÎncă nu există evaluări

- Guidlines On Recall by CDSCODocument28 paginiGuidlines On Recall by CDSCONAVNEET BAGGA100% (1)

- Audit Checklist For The Evaluation of Calibration SystemsDocument22 paginiAudit Checklist For The Evaluation of Calibration Systemse2yc100% (2)

- Corrective Action and Preventive Actions and Its Importance in Quality Management System: A ReviewDocument6 paginiCorrective Action and Preventive Actions and Its Importance in Quality Management System: A ReviewsachinÎncă nu există evaluări

- Kejriwal Castings Limited (Testing Lab, DGP) : 1. PurposeDocument1 paginăKejriwal Castings Limited (Testing Lab, DGP) : 1. PurposeAniruddha ChatterjeeÎncă nu există evaluări

- NIST Procedure For Method Validation 20180101Document7 paginiNIST Procedure For Method Validation 20180101Tonio DimaculanganÎncă nu există evaluări

- FDA Volume II - Audits Ora-Lab.4.14Document7 paginiFDA Volume II - Audits Ora-Lab.4.14nilayÎncă nu există evaluări

- ASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal HygieneDocument5 paginiASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal Hygienesunny mgxÎncă nu există evaluări

- FF-17 Service Request FormDocument2 paginiFF-17 Service Request FormMOHIT PRADHANÎncă nu există evaluări

- Handling of Out of Specification ResultsDocument39 paginiHandling of Out of Specification ResultsDevang GondaliyaÎncă nu există evaluări

- Control of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureDocument9 paginiControl of Non-Conforming Product 932-QA13-001 AL: Level 2 - Standard Operating ProcedureMohamedÎncă nu există evaluări

- QMS 060 SampleDocument4 paginiQMS 060 SamplebaluchakpÎncă nu există evaluări

- Equipment Calibration and MaintenanceDocument5 paginiEquipment Calibration and MaintenancePrabath De Silva100% (1)

- SOP of Glassware HandlingDocument1 paginăSOP of Glassware HandlingPrince Moni100% (2)

- Prepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCDocument2 paginiPrepared By: Signature: Name: Khuram Shahzad Date: Designation: SR - Manager QA/QCMhammad NaveedÎncă nu există evaluări

- Sop Capa PDFDocument3 paginiSop Capa PDFnakul tiwariÎncă nu există evaluări

- 2 Protocol For Procurement PDFDocument8 pagini2 Protocol For Procurement PDFChala DabalaÎncă nu există evaluări

- Kejriwal Castings Limited (Testing Lab, DGP)Document3 paginiKejriwal Castings Limited (Testing Lab, DGP)Aniruddha ChatterjeeÎncă nu există evaluări

- CookBook 19 Impartiality and Confidentiality - 10-2018 PDFDocument2 paginiCookBook 19 Impartiality and Confidentiality - 10-2018 PDFJacek SobczykÎncă nu există evaluări

- Dosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceDocument5 paginiDosage Forms - Development - Manufacturing - Quality/Gmps - Analytics - Outsourcing - Pharma MarketplaceMahin patelÎncă nu există evaluări

- Sop Gen 18Document3 paginiSop Gen 18cervantessejÎncă nu există evaluări

- Calibration Thermometer PDFDocument7 paginiCalibration Thermometer PDFGilberto Andrés Jurado100% (1)

- GFCO Certification ManualDocument72 paginiGFCO Certification Manualatila117Încă nu există evaluări

- Standard Operating Procedure For Product Mock RecallsDocument3 paginiStandard Operating Procedure For Product Mock RecallsSolomonÎncă nu există evaluări

- SOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesDocument2 paginiSOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesMosub Al.Dirdiry100% (1)

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiDocument46 paginiWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- Application For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012Document13 paginiApplication For The Accreditation of Medical Laboratories ACCORDING TO EN ISO 15189:2012arvindÎncă nu există evaluări

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocument16 paginiSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarÎncă nu există evaluări

- Please Understand Me II - David KeirseyDocument411 paginiPlease Understand Me II - David Keirseyjohn100% (1)

- 2014 Bear Adult Bow ManualDocument40 pagini2014 Bear Adult Bow Manualjohn0% (1)

- Sop QualificationDocument9 paginiSop Qualificationjohn100% (1)

- Appendix B - Statistical Sampling TechniquesDocument35 paginiAppendix B - Statistical Sampling TechniquesjohnÎncă nu există evaluări

- 2001 Martin Compound Bow ManualDocument24 pagini2001 Martin Compound Bow Manualjohn100% (1)

- Black & Decker The Complete Outdoor BuilderDocument529 paginiBlack & Decker The Complete Outdoor BuilderRadu_IS100% (5)

- 2014 Hoyt Compound Owners ManualDocument32 pagini2014 Hoyt Compound Owners Manualjohn100% (1)

- 6037 - Black & Decker The Complete Guide To Finishing Walls & CeilingsDocument244 pagini6037 - Black & Decker The Complete Guide To Finishing Walls & Ceilingsfrorva100% (25)

- Cookbook HealthDocument84 paginiCookbook HealthManish Vm100% (4)

- Men's Peak ConditioningDocument376 paginiMen's Peak Conditioningjohn0% (1)

- Micom P44X: Numerical Distance Protection RelayDocument152 paginiMicom P44X: Numerical Distance Protection RelayKuenley TiNy OndeÎncă nu există evaluări

- Sr. Devops Engineer Job SampleDocument2 paginiSr. Devops Engineer Job SampleSannithiBalajiÎncă nu există evaluări

- Magnelis Warranty C5M ENDocument2 paginiMagnelis Warranty C5M ENjames schembriÎncă nu există evaluări

- DS-2CD1723G0-IZ-C Datasheet V5.5.122 20210531Document6 paginiDS-2CD1723G0-IZ-C Datasheet V5.5.122 20210531juancarlosÎncă nu există evaluări

- PentesterLab SolutionsDocument48 paginiPentesterLab SolutionsDIPAMA MichelÎncă nu există evaluări

- Electric Machines Principles Applications and Control Schematics 2nd Edition Dino Zorbas Solutions ManualDocument27 paginiElectric Machines Principles Applications and Control Schematics 2nd Edition Dino Zorbas Solutions Manuallaurenstarkntmkfdjrqz100% (16)

- Last Bill This Bill Total Amount DueDocument7 paginiLast Bill This Bill Total Amount DueDjibzlae100% (1)

- Final PPT A PRIVACY PRESERVING FRAMEWORK FOR PRESERVING MOBILE AD PDFDocument11 paginiFinal PPT A PRIVACY PRESERVING FRAMEWORK FOR PRESERVING MOBILE AD PDFlechu-92Încă nu există evaluări

- 5 Turbine ProtectionDocument14 pagini5 Turbine ProtectionSam100% (4)

- NBH DBH BBH Comparision SikarDocument21 paginiNBH DBH BBH Comparision SikarNikhil Kumar Gupta100% (1)

- Sravanti - SSE - MNR SolutionsDocument4 paginiSravanti - SSE - MNR SolutionsshanÎncă nu există evaluări

- Ai, ML, DL PDFDocument2 paginiAi, ML, DL PDFsetiawan.hadiÎncă nu există evaluări

- Embedded Systems DiplomaDocument9 paginiEmbedded Systems DiplomaKarim SamhyÎncă nu există evaluări

- DIREÇÃO DEFENSIVA Selected Issues in Passenger Vehicle Tire SafetyDocument75 paginiDIREÇÃO DEFENSIVA Selected Issues in Passenger Vehicle Tire SafetyCPSSTÎncă nu există evaluări

- Software Dev Processes Project 1Document2 paginiSoftware Dev Processes Project 1ereter50% (8)

- RF-JUR - 24/3 - CT: Mounting InstructionsDocument13 paginiRF-JUR - 24/3 - CT: Mounting InstructionsLim BoraÎncă nu există evaluări

- Switch TI PG541Document3 paginiSwitch TI PG541KeviinCarrilloÎncă nu există evaluări

- INSTRUCTIONS FOR USOL PRIVATE REAPPEAR DE January 2022Document4 paginiINSTRUCTIONS FOR USOL PRIVATE REAPPEAR DE January 2022RaghavÎncă nu există evaluări

- LCD InterfacingDocument22 paginiLCD InterfacingNanduÎncă nu există evaluări

- Basic Introduction To The UCCE Servers and ComponentsDocument24 paginiBasic Introduction To The UCCE Servers and ComponentsDaksin SpÎncă nu există evaluări

- Adspy Product ResearchDocument1 paginăAdspy Product Researchমুমিনুল ইসলাম মুরাদÎncă nu există evaluări

- Locala 11B SubiectDocument5 paginiLocala 11B SubiectAndrei SainciucÎncă nu există evaluări

- Schematics 3250Document9 paginiSchematics 3250pronomixÎncă nu există evaluări

- ACO 3901manual EditionEDocument104 paginiACO 3901manual EditionEs1234tÎncă nu există evaluări

- Complete Manual SCADA SystemsDocument376 paginiComplete Manual SCADA SystemsmohdkamalhaziqÎncă nu există evaluări

- 320/330 Hydraulic Excavators: Technical PresentationDocument104 pagini320/330 Hydraulic Excavators: Technical Presentationramon hidalgo100% (3)

- NTT Data Ai Governance v04Document23 paginiNTT Data Ai Governance v04radhikaseelam1Încă nu există evaluări

- Iec 61724 1 2021Document15 paginiIec 61724 1 2021Loyel RoseÎncă nu există evaluări

- Insider Threat 1Document2 paginiInsider Threat 1Bennet KelleyÎncă nu există evaluări

- Deep Learning in ManufacturingDocument6 paginiDeep Learning in ManufacturingEditor IjasreÎncă nu există evaluări