Documente Academic

Documente Profesional

Documente Cultură

Well Commander

Încărcat de

ice_PLDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Well Commander

Încărcat de

ice_PLDrepturi de autor:

Formate disponibile

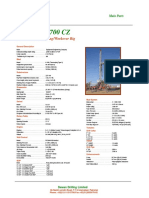

WELL COMMANDER

Mitigate drilling hazards with the industrys most versatile drilling valve

Features

Generous flow-through area via

multiple ports

Ball catcher has up to 18 ball capacity

(9 cycles)

The same-size ball opens and closes

the ports

Available in 5 in., 7 in., 8

1

/4 in. and 9

1

/2 in.

outer diameter for all drillstring

configurations

No internal tool connections

Tool activation mechanism locks into

open or closed position

Tool activation mechanism isolated from

circulating fluids

Ball catcher permits smaller ball and/or

limited wireline access below the

WELL COMMANDER* tool even after it

has been activated

Optional shut-off ball prevents coarse

lost-circulation material (LCM) from

entering sensitive bottomhole assembly

elements such as logging while drilling

(LWD)/measurement while drilling

(MWD)/core barrel, mud motor and more

Benefits

Easy spotting of LCM or

wellbore strengthening material (WSM)

while drilling

Cuttings-beds removal, enhanced hole

cleaning and efficient fluid displacement

by boosting annular velocities in

conjunction with pipe rotation

Will not function prematurely from high

circulation or tripping rates

Saves tripping time; multiple trips

without redressing the tool

Simplifies reverse circulation through

the tool

Boosts annular velocities above an

underreamer for enhanced hole cleaning

Elevates circulation rates with minimal

pressure drop

Functions in water or invert-emulsion

drilling fluids as well as clear brines

Provides jetting functionality in the

blowout preventer (BOP)

Permits running other ball-activated

tools below

Permits limited wireline access for

freepoint indicators or other elements

Promotes filling or draining the

workstring while tripping

APPLICATIONS

Extended-reach drilling, spotting

LCM or kill-weight fluid, underreaming

operations, underbalanced and

managed-pressure drilling, and other

applications for conditioning or

displacing wellbore fluids at high

flow rates.

PROBLEMS

During drilling operations, many hazards

may be encountered that must be

mitigated to permit successful

completion on the interval. For instance,

restrictive bottom hole assemblies

(BHAs) can limit the flow rate and

annular velocity, preventing effective

hole cleaning while drilling or displacing

wellbore fluids. These same BHAs can

also limit the size and concentration of

LCM or WSM that can be placed in

troublesome zones.

SOLUTIONS

The WELL COMMANDER tool lets you

perform the necessary operations by

providing a large flow area bypass on

demand through as many as nine

open-and-close cycles in one trip.

ECONOMICS

The high flow rates achieved through

the tools generous ports save time and

money in spotting effective LCM/WSM

treatments or kill-weight fluids and

reduce circulating time during

displacements. The tool also helps avoid

problems such as cuttings beds and

packoffs in extended-reach wells.

ENVIRONMENTAL

The tool allows even small-diameter

workstrings to drain easily during a trip

by bypassing restrictive BHA equipment,

so a slug can work every time at any

angle, thus avoiding drilling fluid spills

and promoting a safer work environment.

The WELL COMMANDER tool is a

ball-activated drilling valve placed above

sensitive bottomhole assembly equipment

such as MWD and LWD tools, core barrels,

and mud motors. It provides an alternate

circulation path for performing critical

functions including placing LCM or, for

I-BOSS* applications WSM, in troublesome

zones, without having to pass the material

through size- and concentration-limiting

downhole tools.

The WELL COMMANDER tool also boosts

annular velocities during drilling or

completion operations. This is typically

done to prevent or remove cuttings-beds

buildup, enhance fluid displacement or

simplify reverse circulation. Placing the

tool above other ball-drop tools, such

as an underreamer, can also be highly

advantageous.

The tool is also used to help fill or drain the

drillstring during trips to control surge and

swab pressures and to enhance tripping

operations by minimizing fluid discharge.

Spot pills and increase

circulation exactly where you

want, with no impact on the

BHA, logging tools or the bit.

Open circulating ports provide generous flow area The WELL COMMANDER tool uses the same size

operating ball to open and close the ports

WELL COMMANDER tool

1. Ball landing

7. Bypass ball catcher

4. BHA shut off

Drop ball on connection and pump down to tool. Ball lands on seat.

Pressure is applied.

Optional shut-off ball can be landed on lower ball seat to prevent

LCM or WSM from entering the BHA while treating the formation.

Bypass ball catcher captures activation and BHA shut-off balls to

the side permitting high flow rate with minimal pressure loss and

allowing smaller balls to pass through it.

How it works

The WELL COMMANDER tool is run into or pulled out of the hole

with the ports locked open or closed. The ports remain in the

same position until the tool is activated by dropping a ball and

pressuring up to shift the circulating port. The tool uses the

same size operating ball to open and close the ports, with the

capacity of the ball catcher (18 balls/9 cycles) being the only

limit. A smaller BHA shut-off ball can be dropped to prevent

fluid flow or solids deposition at the top of the BHA. This ball is

expelled with the subsequent operating ball.

The operating balls and BHA-shutoff balls are collected in the

ball-catcher assembly below the tool. This bypass ball catcher

captures the balls to one side of the inside diameter to

facilitate positioning other ball-drop tools below it, as smaller

activation balls can pass through the WELL COMMANDER tool

and ball catcher.

Advantages

Unique ball-seat technology allows the same-size ball to open

and close the tool, eliminating the risk of dropping the wrong

size ball. No complicated ball/dart sequence or potentially

problematic pump on/off hydraulic sequencing is required to

open and close the tool. Additionally, high circulation rates

will not cause the tool to function prematurely.

2. Valve activation

5. Valve closing

8. Other activation balls

When pressure exceeds activation pressure, ports open and ball

proceeds to ball catcher below tool.

The BHA shut-off ball is removed when subsequent activation ball

closes the ports.

Other ball activation tools that use smaller diameter balls can be

positioned below the WELL COMMANDER tool as the ball will not

activate it.

3. Open circulation

9. Ball bypassing

6. BHA shut off removal

Majority of flow passes through the ports with lower pressure to

allow increased pump rates, while some flow is maintained

through the bit for lubrication.

After pressuring up on the activation ball, the BHA shut-off and

activation balls move to the ball catcher.

The activation balls for these other tools will pass through the

bypass ball catcher.

Applications

The WELL COMMANDER tool provides an

alternate circulation path for mitigating

drilling hazards, such as preventing

cuttings-beds buildup by boosting

circulating annular velocities during drilling

or completion operations and/or spotting

LCM or WSM (I-BOSS applications) in

troublesome zones without passing the

material through size- and concentration-

limiting downhole tools.

The WELL COMMANDER tool can assist

in removing cuttings beds in high-angle/

horizontal wells and can efficiently

displace fluids by boosting annular

velocities.

This very versatile and reliable tool also

permits easy spotting of LCM during

drilling operations. Other applications

include enhanced hole cleaning during

hole-opening/underreaming operations.

In extended-reach drilling (ERD) or other

drilling applications that encroach on

fracture pressure, the tool can assist in

spotting WSM pills in troublesome zones

without routing the treatments through

the BHA and bit.

In horizontal underbalanced and

managed-pressure drilling (UBD/MPD)

applications, the WELL COMMANDER tool

allows spotting/removing of kill-weight

fluid in the vertical section prior to

commencing the trip/additional drilling.

The tool can be used to good effect for

conditioning wellbore fluids at high flow

rates in any drilling or displacement

string. The ports also promote jetting

BOP cavities at high flow rates,

when properly positioned.

Finally, it can be used as a fill-and-drain

sub in any drilling or displacement string to

avoid swabbing or surging the open hole.

The WELL COMMANDER tool is easily redressed.

A smaller BHA shut-off ball can be used to isolate

flow to the bit during LCM or WSM operations.

The WELL COMMANDER tool is placed above sensitive bottomhole assembly equipment such as

MWD and LWD tools, core barrels, and mud motors.

Operations

The WELL COMMANDER tool is normally

positioned above the BHA, MWD/LWD

tools, motor or small-diameter drillstring.

The valve is run in the hole in the closed

position. The tool remains inactive during

normal drilling operations.

When the need arises to open the

circulating ports, an operating ball

is dropped and pumped down to the

WELL COMMANDER tool. When the

operating ball lands on the seat and

pressure is applied, the tool is primed to

open. Increased pressure drives the ball

through the ball seat and a pressure drop

is observed. The operating ball is expelled

into the ball catcher, and the tool advances

to the locked-open position.

With the circulating ports open, the pump

rate can then be increased to circulate

at higher annular velocities through the

open ports. Note that in this open position,

there is still a small percentage of fluid

circulating around the BHA, keeping

it lubricated. In this position, the tool

can be used to spot LCM or, for I-BOSS

applications, WSM. If these materials have

the potential for damaging any of the BHA

components, flow to the bit can be isolated

by dropping a smaller, differently colored

BHA shut-off ball. This smaller-diameter

shut-off ball can also be used for stopping

flow to the bit.

To close the WELL COMMANDER tool and

restore all the flow through the BHA again,

another operating ball is dropped and

pumped down to the tool ball seat. When

the ball lands on the seat and pressure is

applied, the tool is primed to close via an

indexing system. Increased pressure drives

the ball through the ball seat and a

pressure drop is observed. The operating

ball and the BHA shut-off ball are both

expelled into the ball catcher and the valve

returns to its original, closed position. The

pressure is allowed to bleed off before

continuing operations.

In managed-pressure or underbalanced

drilling operations, the WELL COMMANDER

tool can be opened to displace kill-weight

fluid prior to tripping to simplify the

operation. It can remain open while tripping

out of the hole to avoid swabbing and

permit tripping dry.

It can also remain open while tripping

into the hole to avoid surging and allow

the pipe to readily fill. Once on bottom, an

operating ball can be pumped to close the

WELL COMMANDER valve and commence

operations. The open and close cycling

can be repeated on a single trip until the

maximum capacity of the ball catcher

is reached. The ball catcher can be

emptied at surface during each trip. The

WELL COMMANDER tool can be run on

multiple trips before redress is required.

Get more done on your next

well with the WELL COMMANDER

tool from M-I SWACO

Let one of our representatives introduce

you to all the benefits you can get from

this versatile workhorse of a drilling valve.

Contact M-I SWACO today to hear how the

reliable WELL COMMANDER tool is saving

time and money on drilling projects around

the world.

This information is supplied solely for informational purposes and M-I SWACO makes no guarantees or

warranties, either expressed or implied, with respect to the accuracy and use of this data. All product

warranties and guarantees shall be governed by the Standard Terms of Sale. Nothing in this document

is legal advice or is a substitute for competent legal advice.

Specialized Tools Locations

M-I SWACO (Headquarters)

5950 North Course Drive

Houston, Texas 77072

Tel: +1 713 739 0222

M-I SWACO

305 Ida Road

Broussard, Louisiana 70518

Tel: +1 337 837 8655

M-I SWACO

Endeavour Drive

Arnhall Business Park

Westhill, Aberdeenshire,

AB32 6UF

Tel: +44 (0)1224 742 200

P.O. Box 42842

Houston, Texas 77242-2842

www.miswaco.slb.com

Email: questions@miswaco.slb.com

2012 M-I L.L.C. All rights reserved. *Mark of M-I L.L.C.

SBR.1961.1201.R2 (E)

S-ar putea să vă placă și

- Tom Mile Calculation PDFDocument6 paginiTom Mile Calculation PDFBeni N SoloÎncă nu există evaluări

- BOP BoltsDocument5 paginiBOP BoltsHadirah DunglahÎncă nu există evaluări

- Drilling Supervisor: Passbooks Study GuideDe la EverandDrilling Supervisor: Passbooks Study GuideÎncă nu există evaluări

- AirComp Air Drilling ManualDocument36 paginiAirComp Air Drilling ManualWilliamÎncă nu există evaluări

- Fundamentals and Applications of Bionic Drilling FluidsDe la EverandFundamentals and Applications of Bionic Drilling FluidsÎncă nu există evaluări

- RTTS Packer: Technical Data SheetDocument5 paginiRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- Stabilizer TypeDocument14 paginiStabilizer TypeAdin PraviMoški PartAdisÎncă nu există evaluări

- CTU ComponentsDocument28 paginiCTU ComponentsRufo WuarnerÎncă nu există evaluări

- Make Up Torque For BitDocument1 paginăMake Up Torque For BitashadÎncă nu există evaluări

- Liner OperationDocument22 paginiLiner OperationHosam Ali100% (1)

- 7" Liner - Cementing Preparation and Procedure ChecklistDocument2 pagini7" Liner - Cementing Preparation and Procedure ChecklistYougchu LuanÎncă nu există evaluări

- Cup Tester Torque ValuesDocument3 paginiCup Tester Torque ValuesDorin Radu100% (1)

- ToolfaceDocument15 paginiToolfaceAdin PraviMoški PartAdis0% (1)

- Drawworks and Rig Sizing PDFDocument8 paginiDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Stripping With Volumetric Control Steps and Example Calculations - Drilling Formulas and Drilling Calculations PDFDocument19 paginiStripping With Volumetric Control Steps and Example Calculations - Drilling Formulas and Drilling Calculations PDFAmine MimoÎncă nu există evaluări

- DC Make-Up TorqueDocument5 paginiDC Make-Up TorquepatelsujanÎncă nu există evaluări

- Pressure Rating For SSII Float EquipmentDocument2 paginiPressure Rating For SSII Float EquipmentMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Specs ZJ 30 2Document1 paginăSpecs ZJ 30 2fatehul alamÎncă nu există evaluări

- Drill String RotaryDocument111 paginiDrill String RotaryAboZaidÎncă nu există evaluări

- Tie Back Liner RunDocument3 paginiTie Back Liner RunkangrassÎncă nu există evaluări

- Drillstring Design ManualDocument23 paginiDrillstring Design ManualAdil Aytekin93% (14)

- Mud LoggingDocument15 paginiMud Loggingspydaman4uÎncă nu există evaluări

- Drilling Bit DesignDocument14 paginiDrilling Bit DesignMajedur Rahman100% (1)

- Torque and Drag CalculationsDocument67 paginiTorque and Drag CalculationsStalin ChugchilánÎncă nu există evaluări

- Casing and CementingDocument17 paginiCasing and CementingAlex VianaÎncă nu există evaluări

- Bit HydraulicsDocument1 paginăBit HydraulicsstevebeardsleyÎncă nu există evaluări

- 4a Torque DragDocument31 pagini4a Torque DragIvan Ricardo CarballoÎncă nu există evaluări

- Model "Jyq" Mechanical-Hydraulic Drilling Jar: Instruction ManualDocument8 paginiModel "Jyq" Mechanical-Hydraulic Drilling Jar: Instruction ManualMarvin William Montes Cristo100% (1)

- Drill Pipe ChartsDocument11 paginiDrill Pipe ChartsSean PorterÎncă nu există evaluări

- Whipstock 9.625 Mechanical Running ProceduresDocument16 paginiWhipstock 9.625 Mechanical Running ProceduresTudor virgil100% (1)

- Max Overpull To Apply When StuckDocument3 paginiMax Overpull To Apply When StuckHenry Mata100% (1)

- Casing & CementingDocument13 paginiCasing & CementingBharat Kumar HaraniÎncă nu există evaluări

- Shaffer (Nov) Shearing Blind RamsDocument1 paginăShaffer (Nov) Shearing Blind RamsOscar BustosÎncă nu există evaluări

- Tut-126 ProgramDocument28 paginiTut-126 Programhamdi1000Încă nu există evaluări

- Rig DesginDocument25 paginiRig DesginImam PranadipaÎncă nu există evaluări

- Jars and Accelerators.Document10 paginiJars and Accelerators.gaddasalimÎncă nu există evaluări

- Diverter Drilling System For Well Control Full GuideDocument19 paginiDiverter Drilling System For Well Control Full GuiderahulÎncă nu există evaluări

- Casing Scraper ManualDocument8 paginiCasing Scraper ManualMinnyeong YoonÎncă nu există evaluări

- 15 Fishing ToolsDocument15 pagini15 Fishing ToolsRizki RamadhanÎncă nu există evaluări

- Spe 196232 MSDocument18 paginiSpe 196232 MShijoetigreÎncă nu există evaluări

- Liner Tie-Back StringDocument1 paginăLiner Tie-Back StringYougchu LuanÎncă nu există evaluări

- Pack OffDocument2 paginiPack OffMohammad RizwanÎncă nu există evaluări

- BHA StabilizationDocument14 paginiBHA StabilizationenantioagaÎncă nu există evaluări

- Quiz 1-10 Minutes: Hoisting System?Document40 paginiQuiz 1-10 Minutes: Hoisting System?fabianandres23100% (1)

- III. Basic CalculationDocument14 paginiIII. Basic Calculationdidin kenyalÎncă nu există evaluări

- Griffith Drilling JarDocument1 paginăGriffith Drilling JarFakhrurrozi ArbianÎncă nu există evaluări

- Kick Off Procedure For Directional WellsDocument9 paginiKick Off Procedure For Directional WellsAdin PraviMoški PartAdisÎncă nu există evaluări

- Aluminum Alloy Drill PipeDocument20 paginiAluminum Alloy Drill PipeMark Garrett100% (1)

- Catalogs - SchlumbergerDocument2 paginiCatalogs - SchlumbergerchengcaiwangÎncă nu există evaluări

- Dull Grading ChartDocument1 paginăDull Grading Chartkenan192Încă nu există evaluări

- How To Run and Cement Liners Part 4Document5 paginiHow To Run and Cement Liners Part 4Blanche NeigeÎncă nu există evaluări

- KickDocument22 paginiKickyarra suryatejaÎncă nu există evaluări

- Manual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesDocument11 paginiManual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesChristian Matteo100% (1)

- Drilling With Casing 04Document15 paginiDrilling With Casing 04Dian Sikumbang100% (2)

- Agitator Handbook 2005Document22 paginiAgitator Handbook 2005casda73Încă nu există evaluări

- BHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Document2 paginiBHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Animesh ChoudharyÎncă nu există evaluări

- 4 SolidControlDocument27 pagini4 SolidControlJorge VidaurreÎncă nu există evaluări

- SM SeriesDocument36 paginiSM SeriesGiorgiana RosuÎncă nu există evaluări

- MINE5009 Mining Methods and Processes Semester 1 2023 Kalgoorlie Campus FODocument14 paginiMINE5009 Mining Methods and Processes Semester 1 2023 Kalgoorlie Campus FOice_PLÎncă nu există evaluări

- Stuck Pipe PreventionDocument64 paginiStuck Pipe PreventionmmbatainehÎncă nu există evaluări

- (Ulf Langefors) The Modern Technique of Rock Blast (B-Ok - CC) PDFDocument440 pagini(Ulf Langefors) The Modern Technique of Rock Blast (B-Ok - CC) PDFkike100% (1)

- Mathcad FunctionsDocument3 paginiMathcad FunctionsAzwan MahmudÎncă nu există evaluări

- MINE5008 Responsible Mining Semester 1 2023 Kalgoorlie CampusDocument13 paginiMINE5008 Responsible Mining Semester 1 2023 Kalgoorlie Campusice_PLÎncă nu există evaluări

- Introduction Rev1Document22 paginiIntroduction Rev1ice_PLÎncă nu există evaluări

- Deformation of Drill Pipe Held in Rotary SlipsDocument20 paginiDeformation of Drill Pipe Held in Rotary Slipsice_PL100% (1)

- ASME Paper by Sparks - The Influence of Tension, Pressure & WeightDocument9 paginiASME Paper by Sparks - The Influence of Tension, Pressure & Weightice_PLÎncă nu există evaluări

- Doris: Dropped Objects Register of Incidents & StatisticsDocument15 paginiDoris: Dropped Objects Register of Incidents & Statisticsice_PLÎncă nu există evaluări

- History of OCTGDocument7 paginiHistory of OCTGice_PLÎncă nu există evaluări

- Hole Cleaning Pipe RotationDocument8 paginiHole Cleaning Pipe Rotationice_PLÎncă nu există evaluări

- Holliday Steam Well DesignDocument8 paginiHolliday Steam Well Designice_PLÎncă nu există evaluări

- Halliburton Packer Information PDFDocument76 paginiHalliburton Packer Information PDFrlk2806100% (4)

- Arc VISIONDocument4 paginiArc VISIONBASÎncă nu există evaluări

- Well Commanddfsder HollandDocument2 paginiWell Commanddfsder Hollandice_PLÎncă nu există evaluări

- IntroductionDocument10 paginiIntroductionice_PLÎncă nu există evaluări

- Hydra JarDocument4 paginiHydra Jarice_PLÎncă nu există evaluări

- Hydra Jar Accelerator AP CsDocument1 paginăHydra Jar Accelerator AP Csice_PLÎncă nu există evaluări

- Hydra Jar ProceduresDocument3 paginiHydra Jar Proceduresice_PLÎncă nu există evaluări

- Powerdrive x6Document7 paginiPowerdrive x6ice_PLÎncă nu există evaluări

- Powerpak HandbookDocument0 paginiPowerpak HandbookPehr HedströmÎncă nu există evaluări

- DocumentDocument12 paginiDocumentice_PLÎncă nu există evaluări

- ImpulseDocument2 paginiImpulseice_PLÎncă nu există evaluări

- UsingDocument16 paginiUsingガンディー サガールÎncă nu există evaluări

- Powerpak HandbookDocument0 paginiPowerpak HandbookPehr HedströmÎncă nu există evaluări

- PPC Product SheetDocument18 paginiPPC Product SheetSantanu LayekÎncă nu există evaluări

- SLB PosterDocument3 paginiSLB Posterice_PL100% (2)

- Schlumberger Log Interpretation ChartsDocument287 paginiSchlumberger Log Interpretation Chartsice_PL100% (10)

- Toyota 5L Terminales de EcmDocument9 paginiToyota 5L Terminales de EcmAlfred Nayb Cañoli Ildefonso0% (1)

- Snare Drum: Some Entries From Various Sources (Loosely Cited)Document6 paginiSnare Drum: Some Entries From Various Sources (Loosely Cited)gljebglejebÎncă nu există evaluări

- Lab 11&12Document9 paginiLab 11&12Divyashini MohanÎncă nu există evaluări

- Ar10 Jig Instructions PDFDocument5 paginiAr10 Jig Instructions PDFterrencebelles100% (2)

- Pump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Document1 paginăPump Installation Report: 30 Damascus Road, Suite 115 Bedford, Nova Scotia B4A 0C1Yosif BabekerÎncă nu există evaluări

- Ti 59 - A Note On Battery CorrosionDocument3 paginiTi 59 - A Note On Battery CorrosionLeon ZieglerÎncă nu există evaluări

- Design and Analysis of Different Orders of Active-Rc Butterworth FilterDocument124 paginiDesign and Analysis of Different Orders of Active-Rc Butterworth FilterPradeep Kumar Goud NadikudaÎncă nu există evaluări

- Manual Yamaha Clavinova P100Document69 paginiManual Yamaha Clavinova P100Nelon Rocha100% (1)

- Vatufeku Longman Writing Academic English Xufex PDFDocument4 paginiVatufeku Longman Writing Academic English Xufex PDFNZAR AREFÎncă nu există evaluări

- Rectangular Tank SizingDocument8 paginiRectangular Tank Sizingvofaith100% (16)

- Manual ArchicadDocument67 paginiManual ArchicadkhajaimadÎncă nu există evaluări

- Adobe Transaction No 0991059129 20190125Document2 paginiAdobe Transaction No 0991059129 20190125Mohamed WinnēriÎncă nu există evaluări

- Android User GuideDocument15 paginiAndroid User GuideAnonymous 1Wb6JCkÎncă nu există evaluări

- (The M.I.T. Introductory Physics Series) A. P French - Vibrations and Waves-Norton (1971)Document9 pagini(The M.I.T. Introductory Physics Series) A. P French - Vibrations and Waves-Norton (1971)Simran GiriÎncă nu există evaluări

- ERPtips SAP Training Manual SAMPLE CHAPTER From Basic PayrollDocument20 paginiERPtips SAP Training Manual SAMPLE CHAPTER From Basic Payrollravibabu1620Încă nu există evaluări

- Phone Genesys ConfigurationDocument22 paginiPhone Genesys ConfigurationRodolfo TobiasÎncă nu există evaluări

- Reduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentDocument4 paginiReduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentjesusÎncă nu există evaluări

- User Manual SteadyControlDocument57 paginiUser Manual SteadyControlrobiny100% (2)

- SB658Document3 paginiSB658ricardo novoa saraviaÎncă nu există evaluări

- Calculating The Pathlength of Liquid Cells by FTIR PIKEDocument1 paginăCalculating The Pathlength of Liquid Cells by FTIR PIKEMoises RomeroÎncă nu există evaluări

- Heidegger Midterm DissDocument72 paginiHeidegger Midterm Dissrhoda mae a. paquinolÎncă nu există evaluări

- NAD Factory Default and Software CheckDocument13 paginiNAD Factory Default and Software CheckNorma FloresÎncă nu există evaluări

- Pressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationDocument11 paginiPressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationxzxÎncă nu există evaluări

- BPO Ricario2Document2 paginiBPO Ricario2Jalen RossÎncă nu există evaluări

- Performance CH 33Document54 paginiPerformance CH 33Yasichalew sefinehÎncă nu există evaluări

- Slide Chooser PDFDocument2 paginiSlide Chooser PDFArchana LenkaÎncă nu există evaluări

- Ic 1403 2 MarksDocument14 paginiIc 1403 2 MarksJeya Prakash100% (2)

- 1762 Um002 - en PDocument144 pagini1762 Um002 - en PDavid LucioÎncă nu există evaluări

- SAP Lot Sizing ParameterDocument1 paginăSAP Lot Sizing ParameterWilliam HolidiÎncă nu există evaluări

- Swiss FCM Ordinance - EuPIA QDocument6 paginiSwiss FCM Ordinance - EuPIA Qiz_nazÎncă nu există evaluări

- Endure: Mind, Body, and the Curiously Elastic Limits of Human PerformanceDe la EverandEndure: Mind, Body, and the Curiously Elastic Limits of Human PerformanceEvaluare: 4.5 din 5 stele4.5/5 (237)

- Eat & Run: My Unlikely Journey to Ultramarathon GreatnessDe la EverandEat & Run: My Unlikely Journey to Ultramarathon GreatnessÎncă nu există evaluări

- Whole Body Barefoot: Transitioning Well to Minimal FootwearDe la EverandWhole Body Barefoot: Transitioning Well to Minimal FootwearEvaluare: 4 din 5 stele4/5 (16)

- Mind Gym: An Athlete's Guide to Inner ExcellenceDe la EverandMind Gym: An Athlete's Guide to Inner ExcellenceEvaluare: 3.5 din 5 stele3.5/5 (18)

- Showing Up: Get Comfortable Being UncomfortableDe la EverandShowing Up: Get Comfortable Being UncomfortableEvaluare: 5 din 5 stele5/5 (2)

- Can't Nothing Bring Me Down: Chasing Myself in the Race Against TimeDe la EverandCan't Nothing Bring Me Down: Chasing Myself in the Race Against TimeEvaluare: 4 din 5 stele4/5 (1)

- The Longest Race: Inside the Secret World of Abuse, Doping, and Deception on Nike's Elite Running TeamDe la EverandThe Longest Race: Inside the Secret World of Abuse, Doping, and Deception on Nike's Elite Running TeamEvaluare: 5 din 5 stele5/5 (59)

- Run the Mile You're In: Finding God in Every StepDe la EverandRun the Mile You're In: Finding God in Every StepEvaluare: 4.5 din 5 stele4.5/5 (72)

- Long Road to Boston: The Pursuit of the World's Most Coveted MarathonDe la EverandLong Road to Boston: The Pursuit of the World's Most Coveted MarathonEvaluare: 5 din 5 stele5/5 (1)

- The Inner Runner: Running to a More Successful, Creative, and Confident YouDe la EverandThe Inner Runner: Running to a More Successful, Creative, and Confident YouEvaluare: 4.5 din 5 stele4.5/5 (61)

- 80/20 Running: Run Stronger and Race Faster by Training SlowerDe la Everand80/20 Running: Run Stronger and Race Faster by Training SlowerEvaluare: 4.5 din 5 stele4.5/5 (97)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersDe la EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersEvaluare: 5 din 5 stele5/5 (13)

- Whole Body Barefoot: Transitioning Well To Minimal FootwearDe la EverandWhole Body Barefoot: Transitioning Well To Minimal FootwearEvaluare: 4.5 din 5 stele4.5/5 (33)

- Sick to Fit: 3 Simple Techniques that Got Me from 420 Pounds to the Cover of Runner's World, Good Morning America, and The Today ShowDe la EverandSick to Fit: 3 Simple Techniques that Got Me from 420 Pounds to the Cover of Runner's World, Good Morning America, and The Today ShowEvaluare: 4.5 din 5 stele4.5/5 (6)

- Your Pace or Mine?: What Running Taught Me About Life, Laughter and Coming LastDe la EverandYour Pace or Mine?: What Running Taught Me About Life, Laughter and Coming LastEvaluare: 4 din 5 stele4/5 (27)

- Strength Training For Runners : The Best Forms of Weight Training for RunnersDe la EverandStrength Training For Runners : The Best Forms of Weight Training for RunnersEvaluare: 2 din 5 stele2/5 (5)

- Above the Clouds: How I Carved My Own Path to the Top of the WorldDe la EverandAbove the Clouds: How I Carved My Own Path to the Top of the WorldEvaluare: 4.5 din 5 stele4.5/5 (25)

- Depression Hates a Moving Target: How Running With My Dog Brought Me Back From the BrinkDe la EverandDepression Hates a Moving Target: How Running With My Dog Brought Me Back From the BrinkEvaluare: 4 din 5 stele4/5 (35)

- Mind Gym: An Athlete's Guide to Inner ExcellenceDe la EverandMind Gym: An Athlete's Guide to Inner ExcellenceEvaluare: 3 din 5 stele3/5 (18)

- Eat And Run: My Unlikely Journey to Ultramarathon GreatnessDe la EverandEat And Run: My Unlikely Journey to Ultramarathon GreatnessEvaluare: 4.5 din 5 stele4.5/5 (23)

- The Pants Of Perspective: One woman's 3,000 kilometre running adventure through the wilds of New ZealandDe la EverandThe Pants Of Perspective: One woman's 3,000 kilometre running adventure through the wilds of New ZealandEvaluare: 4.5 din 5 stele4.5/5 (82)

- 80/20 Running: The Ultimate Guide to the Art of Running, Discover How Running Can Help You Improve Your Fitness, Lose Weight and Improve Your Overall HealthDe la Everand80/20 Running: The Ultimate Guide to the Art of Running, Discover How Running Can Help You Improve Your Fitness, Lose Weight and Improve Your Overall HealthEvaluare: 4 din 5 stele4/5 (53)

- Hansons Marathon Method: Run Your Fastest Marathon the Hansons WayDe la EverandHansons Marathon Method: Run Your Fastest Marathon the Hansons WayEvaluare: 4 din 5 stele4/5 (3)

- How to Run a Marathon: The Go-to Guide for Anyone and EveryoneDe la EverandHow to Run a Marathon: The Go-to Guide for Anyone and EveryoneEvaluare: 5 din 5 stele5/5 (17)

- In the Spell of the Barkley: Unravelling the Mystery of the World's Toughest UltramarathonDe la EverandIn the Spell of the Barkley: Unravelling the Mystery of the World's Toughest UltramarathonÎncă nu există evaluări