Documente Academic

Documente Profesional

Documente Cultură

Spreadsheet To Design Separators

Încărcat de

grabettyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Spreadsheet To Design Separators

Încărcat de

grabettyDrepturi de autor:

Formate disponibile

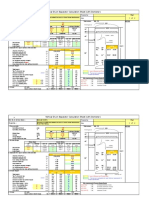

SEPARATOR SIZING SPREADSHEET

MAIN MENU

INSTRUCTIONS

HORIZONTAL SEPARATOR ( 3 PHASE WITH BOOT)

HORIZONTAL SEPARATOR ( 3 PHASE, NO BOOT, DRAW OFF PIPE FOR CONDENSATE )

VERTICAL SEPARATOR ( 2 PHASE )

FILE SEPARP

SEPARATOR SIZING SPREADSHEET

REV: DATE:

A FEBRUARY 1999

SPREADSHEET INFORMATION

HORIZONTAL SEPARATOR ( 3 PHASE, NO BOOT, WEIRPLATE PARTITION )

HORIZONTAL SEPARATOR ( 2 PHASE )

FILE SEPARP1.XLS

SEPARATOR SIZING SPREADSHEET

INSTRUCTION NOTES

REV: DATE:

A February 1999

I.PURPOSE

The aim of the separator sizing spreadsheet is to assist the designer in saving valuable time resources by providing a user-friendly spreadsheet in Excel to calculate sizing parameters for both horizontal and vertical separators.

II.DESIGN BASES

A. Gas residence times are calculated using the normal liquid level as the basis. In the case of the horizontal separator with weirplate partition, the basis used is the height of the weir for the gas volume. Dished end volumes have been neglected for the gas residence time calculations. B. K-values to be used as input data for the spreadsheets are found in the GPSA Handbook(10thedition), figure 7.9 on page 7-7. The K factors must be converted to m/s to be placed into the spreadsheet. The purpose of the K-factor is for designs which include woven wire demisters. Demisters (mist extractors) can significantly reduce the required diameter of vertical separators. C. Dished-end volume calculations have been included for both vertical and horizontal separators. For the vertical separator, an option is provided for choosing between semi-ellipsoidal and semi-hemispherical ends, however, for all horizontal separators, the ends have been assumed to be semi-ellipsoidal. (Reference: GPSA Handbook section 6 Fig 6.21-6.22) D. Other standards used in calculations include API RP 521 Section 5.4.2 and calculations for the standpipe were from EXXON Criteria in Design Practice 5B (September 1978).

III.METHOD The following procedure is a step-by step outline for the designer. A. Step One: Choose the type of separator required. The separators available in this spreadsheet include: -Horizontal, 3 Phase, with boot -Horizontal, 3 Phase, no boot, weirplate partition. -Horizontal, 3 Phase, no boot, standpipe for condensate. -Horizontal, 2 Phase -Vertical, 2 Phase

Page 1 of 3

SEPARATOR SIZING SPREADSHEET - INSTRUCTION NOTES

Vertical separators are usually selected when the gasliquid ratio is high or total gas volumes are low. Horizontal separators are most efficient where large volumes of total fluids and large amounts of dissolved gas are present with the liquid. For more information on separators please refer to GPSA Handbook, Section 7. B. Step Two: After the separator type is chosen, begin inputting data into the cells of the spreadsheet which have blue italicised text. Do not write in cells which contain red or black text! Input data is summarised in the top left hand side of the spreadsheet. Feed flowrates, properties and nozzle velocity specifications are entered in this section. Data on vessel length, diameter and liquid levels are entered on the vessel sketch. Unknown values need to be assumed, otherwise errors will occur in the results. C. Step Three: When all blue cells are filled - including the dimensions on the sketch, the spreadsheet will calculate all relevant values. The intermediate calculations can be found below the sketch. Final output results are listed on the sketch and in the top section of the spreadsheet. All formulae are in red text. D. Step Four: Before final outputs can be used, warnings must be considered. Warnings appear in bold green text, and will appear as "OK" when there is no warning present. If a warning does exist, try to change the relevant parameters to remove or reduce the warnings. These generally relate to liquid levels in the separator and gas residence times. E. Step Five: Check your units!!! The units defined on the spreadsheets can be found in the nomenclature section. The notes section may also assist with understanding which units to use. You can change the values in the blue cells as many times as you like. F. Step Six: When you have your final output, SAVE your file by choosing the "SAVE AS" option under the "FILE" menu in Excel . Make sure that you use a different file name to the original master copy. (this will safeguard against deletion of the master copy) G. Step Seven: Your work is now ready to PRINT. You may find that Excel does not have enough memory to display the spreadsheet fully. The print range has been setup for A4 landscape paper and will print only the first 2-3 pages of the spreadsheet (the rest of the spreadsheet consists of intermediate calculations). If you find that the spreadsheet will not fit on the paper, choose "PAGE SETUP" from the "FILE" menu in Excel and reduce the size of the sheet.

Page 2 of 3

SEPARATOR SIZING SPREADSHEET - INSTRUCTION NOTES

Another option available is to choose A3 sized paper (page setup menu) to print out your spreadsheet. It is not recommended that the print area be altered as this has been preset. However, if the print area needs to be altered, please use the following procedure. "TOOLS" "OPTIONS" "GENERAL" "MICROSOFT EXCEL 4 MENUS" "OK" (HIGHLIGHT THE AREA THAT YOU WISH TO PRINT) "OPTIONS" "SET PRINT AREA" IV. ADDITIONAL NOTES A. THE CALCULATION TITLE BLOCK

There is a title block at the bottom of each page of the spreadsheet. Spaces have been provided for entering the calculation title, project number and calculation number. These spaces are accessed by moving the mouse pointer into the particular box and clicking once with the left hand mouse button. At this point, an object box will appear. Simply click inside the box once using the left hand mouse button and enter the data in the normal way. When you have finished typing the information, move the mouse pointer to another part of the spreadsheet and click once with the left hand mouse button. NOTE: While space has been provided on the title block for entering the originators and checkers initials and relevant dates, these spaces cannot be accessed by the user. This is because signatures are required to be hand written by the originator and checker. B. MAIN MENU The main menu on the separator sizing spreadsheet allows the user to access any of the sheets in the workbook through the use of a macro button. Once the designer is in a particular worksheet, they can return to the menu by clicking the "MENU" macro button in the individual worksheet.

Page 3 of 3

SEPARATOR SIZING SPREADSHEET

SEPARATORS HORIZONTAL SEPARATOR (3 phase with boot) HORIZONTAL SEPARATOR (3 phase, no boot, weirplate partition) HORIZONTAL SEPARATOR (3 phase, no boot, standpipe for condensate.) HORIZONTAL SEPARATOR (2 phase) VERTICAL SEPARATOR (2 phase)

SPREADSHEET APPLICATION Sizing of oil/gas/water separators for the hydrocarbon production industry.

BASIS GPSA Handbook, Volume 1, Section 7. And also Section 6 Fig 6-21,6-22 API RP 521, Section 5.4.2 - Sizing a Knockout Drum

REVISION HISTORY Revision P1 issued in February 1996 - file SEPARP1.XLS With help from Don Borchert, Rod Harper, Nerrida Scott and Mark Sloma

INSTRUCTIONS FOR USE Spreadsheet Conventions & Format

Input

Data to be entered by the user is shown on the screen in blue italicised type. When printed the input appears in italics only. Input data is summarised at the top left hand side of the spreadsheet. Feed flowrates, properties and nozzle velocity specifications are entered in this section. Information on vessel length, diameter and liquid levels is entered on the vessel sketch described below.

Output

Cells containing formulae are shown in red text. Cells containing formulae have been protected. Final output data refers specifically to gas, oil and water residence times and oil and water droplet settling times. This data is summarised at the top centre of the spreadsheet. Data on calculated nozzle sizes and other vessel specific dimensions are shown on the vessel sketch.

Warnings

Warning messages will appear to the right of the output data summary to indicate when results fall outside the design criteria described in the KRJB procedure. Where results satisfy the design requirements the message 'OK' will appear in the WARNINGS section. Warning messages may also appear on the vessel sketch, however in this case there will be no message if the input/output data meets the design requirements. Messages are shown on the screen in bold green type. When printed, the messages appear in bold type and will be enclosed in double asterisks.

Page 1 of 2

Date and time printed:

9-Apr-14

9:15 AM

Kvaerner RJ Brown Pte Ltd

SEPARATOR SIZING SPREADSHEET - INFORMATION

Sketch

The vessel sketch appears immediately below the input section. Some input and final output data is shown on this sketch as noted above. Intermediate calculation results such as volumes and flowrates are also shown on the sketch. This section follows the sketch and includes all the equations and intermediate calculations of the spreadsheet. These include specified residence and settling times. Defaults are the minimum design requirements that are required for comparison against calculations. Other recommended values for variables or constants such as K, droplet size, rV2 , maximum nozzle velocities and liquid levels may be found in the KRJB procedure. This section includes some important equations and general assumptions used in the spreadsheet. Nomenclature used in the spreadsheets including units used, is detailed below the notes section.

Calculations

Defaults

Notes

Nomenclature

Calculation Title Block There is a title block at the bottom of each page of the spreadsheet. Spaces are provided for entering the calculation title, project number and calculation number. These spaces are accessed by moving the mouse pointer into the particular box and clicking once with the left hand mouse button. At this point an object box will appear. Simply click inside the box once using the left hand mouse button and enter the data in the normal manner. When you have finished typing the information, move the mouse pointer to another part of the spreadsheet and click once with the left hand mouse button. Note: While space has been provided on the title block for entering the originators and checkers initials and relevant dates, these spaces cannot be accessed by the user. This is because signatures are required to be hand written by the originator and checker. Printing The print range is pre-set and covers all of the sections described above. Printing is carried out by selecting the 'Print' command from the normal EXCEL pull down menu and selecting 'OK'.

Date and time printed:

9-Apr-14

9:15 AM

Page 2 of 2

Kvaerner RJ Brown Pte Ltd

HORIZONTAL SEPARATOR (3 phase with boot)

INPUT OUTPUT

Feed Flow (t/d) Density (kg/m3) Viscosity (cP) Droplet Size (m) Droplet Size (m) Droplet Size (m)

2

GAS

2950.0 11.1 0.02

OIL

500.0 829.2 7.00 100 1000

WATER

50.0 972.0 0.49

Oil in Gas Oil in Water Water in Oil

2

500 1500 3750 1.0 1.0 0.06

r.v max for inlet nozzle (kg/m.s ) r.v2 max for gas outlet nozzle (kg/m.s2) Max vel. in Oil out nozzle (m/s) Max vel. in water out nozzle (m/s) K Value (m/sec) Mixture density (kg/m3)

RESIDENCE TIMES Shell Gas residence time (seconds) HLL-HLSD NLL-HLL NLL-LLL LLL-LLSD LLSD to Outlet Oil Residence Time at NLL RESIDENCE TIMES Boot HIL-HILSD NIL-HIL NIL-LIL LIL-LILSD LILSD to bottom Water residence time at NIL

Specified (mins) 3.0 3.0 3.0 3.0 3.0

Actual (mins) 17.7 5.4 5.0 4.4 5.4 3.0 12.8 Actual (mins) 5.5 3.3 3.3 3.3 4.8 11.4

** WARNINGS **

OK OK OK OK ** Warning ! Residence time insufficient **

Specified (mins) 3.0 3.0 3.0 3.0 3.0

** WARNINGS **

OK OK OK OK OK

13.1

SETTLING VELOCITY CRITERION Maximum allowable Gas Velocity (m/s) Gas Velocity (m/s) - calculated Oil Droplet Velocity (m/s) - Gravity Settling Method Oil from Gas Water from Oil Oil from Water Droplet fall time (Oil in gas) 0.52 m/s 0.51 m/s OK Water velocity in Boot 0.145 m/s 0.003 m/s 0.038 m/s OK 16.5 secs OK 0.00 m/sec

NOTE:

Gas Velocity Criteria are based on HLSD

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ. CALCULATION SHEET

BY

DATE

CHECKED

DATE

SK.CALC.NO

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 1 OF 3

HORIZONTAL SEPARATOR (3 phase with boot)

SKETCH

Min. Gas Out. nozzle ID 462 mm Length T/T=

9000 mm

Gas =

2950.00 t/d 11073.57 Am3/h

Inlet Minimum Inlet nozzle ID 606 mm

GAS Height I. D. =

3000 mm

Vol. (m3)

54.56 2.27 2.08 1.86 2.27 1.24

HLSD HLL NLL LLL LLSD

600 mm 500 mm 400 mm 300 mm 150 mm

OIL

(Gas) (HLL-HLSD) (NLL-HLL) (NLL-LLL) (LLL-LLSD) (LLSD-Boot)

Interface Boot Height (mm)

1000 mm

Height

1000 ID 750 mm 500 mm 350 mm 200 mm 100 mm

Vol.(m3)

0.196 0.118 0.118 0.118 0.170

Min Oil Outlet nozz ID: 94 mm (HIL-HILSD) (NIL-HIL) (NIL-LIL) (LIL-LILSD) (LILSD-Btm) Oil = 500.00 t/d 25.12 m3/h

HILSD HIL NIL LIL LILSD

WATER

Min. Water out nozzle ID: 50 mm Water = NOMENCLATURE LLL LIL LLSD LILSD NLL NIL HLL Low Liquid Level Low Interface Level Low Level Shut Down Low Interface Level Shut Down Normal Liquid Level Normal Interface Level High Liquid Level HIL HLSD HILSD Btm X-Area rl rv High Interface Level High Level Shut Down High Interface Level Shut Down Bottom Cross sectional area Liquid density kg/m3 Vapour density kg/m

3

50.00 t/d 2.14 m3/h

Dp m Vt VMAX K KCR

Droplet (particle diameter) m Gas viscosity Cp Settling Velocity m/s Maximum vapour velocity m/s Design vapour velocity factor m/s Proportionality constant, dimensionless.

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET BY DATE CHECKED DATE SK.CALC.NO

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 2 OF 3

HORIZONTAL SEPARATOR (3 phase with boot)

CALCULATIONS

SETTLING VELOCITIES

Dmax is the upper particle size limit for each of the laws.

Oil in Gas (Gravity Settling Laws method)

Oil From Gas ("K" Value method) K Value (m/s) *Max Allowable Velocity,Vmax Gas Horiz. Velocity *note 2 Actual Gas Velocity OK

0.06 0.52 m/s 0.51 m/s

Dmax is the upper particle size limit for each of the laws. Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the settling velocity in m/s. see note 1

Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law Kcr 0.03 0.33 18.13 0.15 m/s Intermediate Law Vt (m/s) 0.28 0.15 0.47 Dp max ( m) 47 621 33733

Oil in Water (Gravity Settling Laws method) Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law 0.038 m/s Intermediate Law Vt Dp max ( m) (m/s) 0.03 0.158 194 0.33 0.038 2588 18.13 0.072 140464

Water in Oil (Gravity Settling Laws method) Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law 0.003 m/s Stoke's Law Vt Dp max ( m) (m/s) 0.003 1134 0.006 15153 0.051 822517

Kcr

Kcr 0.03 0.33 18.13

Stoke's Law (Kcr = 0.025) Vt = 1488 g Dp2 (rl - rv) 18m

Intermediate Law (Kcr = 0.334) Vt = 3.54*g0.71 Dp1.14 (rl - rv)0.71 rv

0.29

Newton's Law (Kcr = 18.13) Vt = 1.74 * SQRT(g Dp (rl-rv) / rv )

*m

0.43

NOTES 1.

Equations for Stokes Law, Intermediate Law and Newtons Law are taken from GPSA Handbook, Volume 1, Section 7. Figure 7.4 Maximum allowable vapour velocity is calculated from the equation in GPSA Handbook, Volume 1, Section 7: VMAX 3. = K [ (rl - rv) / rv ] 0.5

2.

LLSD height calculation is based on the distance between the bottom of the cylinder and the low level shut down for the oil. LILSD height calculation is based on the distance from the base of the boot dished end to the low interface level shut down for the water.

4. 5

Information for partial volumes and dished ends was from GPSA handbook (10 th edition) Section 6, and in particular, fig.6-21.6-22. Calculations for gas residence time and area/volume calculations use the normal liquid level, NLL as the height basis. End volumes is ignored for gas volume calculations.

TITLE

SEPARATOR SIZING SPREADSHEET

CALCULATION SHEET BY DATE CHECKED DATE PROJ.

SK.CALC.NO

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 3 OF 3

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

INPUT

Feed Flow (t/d) Density (kg/m3) Viscosity (cP) Droplet Size (m) Droplet Size (m) Droplet Size (m) Oil in Gas Oil in Water Water in Oil GAS

0.240 3.24 0.01

OUTPUT

OIL

268.4 836.6 17.10 150 150 150 7543 280 1.0 1.0 0.12

RICH MEG

2927.6 1028.2 0.89

RESIDENCE TIMES Gas Right Side of Weir HLL-HLSD NLL-HLL NLL-LLL LLL-LLSD LLSD to Outlet Oil Residence Time at NLL

Specified (mins) 60.0

Actual (mins)

4500

** WARNINGS **

seconds

1.0 1.5 2.0 1.0 1.0 5.00

r.v2 max for inlet nozzle (kg/m.s2) r.v2 max for gas outlet nozzle (kg/m.s2) Max vel. in Oil out nozzle (m/s) Max vel. in water out nozzle (m/s) K Value (m/s) per GPSA fig 7.9 Mixture density (kg/m3)

4.00 4.29 4.24 4.21 4.25 12.70

OK OK OK OK OK OK

985.8 RESIDENCE TIMES Left Side of Weir HIL-Weir NIL-HIL NIL-LIL LIL-LILSD

Specified (mins)

Actual (mins) 1.1 1.16 3.60 4.12 11.25 19.72 18.97

** WARNINGS ** OK OK OK OK OK mins mins

SETTLING VELOCITY CRITERION Maximum Allowable Gas Velocity (m/s) Gas Velocity (m/s) - calculated Oil Droplet Velocity (m/s) - Gravity Settling Method Oil from Gas Water from Oil Oil from Water DROPLET FALL TIMES (Left Side of Weir) Oil in Gas (Top-Liquid) 0.8 secs MEG in Oil (NIL to Weir) 25.5 min Oil in MEG (Btm-NIL) 10.95 min

1.0 1.0 2.0 1.0

1.96 m/s 0.00244 m/s 0.39 m/s 0. m/s 0.003 m/s

OK

LILSD to Outlet 1.5 Oil Residence Time (NIL to Weir) Rich MEG Residence Time (Btm to NIL)

OK ** Warning ! Residence time insufficient! ** OK

NOTE:

Gas Velocity Criteria are based on weir height, Hw.

TITLE

SEPARATOR SIZING SPREADSHEET

LIQUID SEPARATOR

PROJ.

CALCULATION SHEET

RELIANCE'S KGD6 FIELD DEVELOPMENT

BY SV

DATE

CHECKED

DATE

CALC.NO 2001 - KGD6 - D1 - PF - B - PRR - 402

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 2 OF 4

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

SKETCH

Gas Outlet nozzle ID 50 mm Length T/T = Inlet Nozzle ID 131 mm Vol. (m 3)

3.86 2.10 2.29 7.12 8.15 22.24 (Gas) (HIL-Weir) (NIL-HIL) (NIL-LIL) (LIL-LILSD) (LILSD-Out) 12000 mm

Gas =

0.24 t/d 3 3.09 Am /h

Ht.(mm) 1935.00 Interface 1835 HIL 1735 NIL 1435 LIL 1135 LILSD

GAS Weir Height,Hw = 1945 mm I. D. = 2267 mm OIL Ht(mm) HLSD HLL NLL LLL LLSD OIL

1845 1545 1245 945 645

Vol. (m 3)

0.89 0.95 0.94 0.94 0.95

RICH MEG

(HLL-HLSD) (NLL-HLL) (NLL-LLL) (LLL-LLSD) (LLSD-Out)

T/W = 11000 mm (If 2 phase set Hw=0, t/w=t/t)

Oil Outlet nozzle ID 69 mm Oil = 268.36 13.37 t/d m3/h

Rich MEG outlet Nozzle ID 205 mm

Rich MEG =

2927.60 118.64

t/d m3/h

TITLE

SEPARATOR SIZING SPREADSHEET

LIQUID SEPARATOR

PROJ.

RELIANCE'S KGD6 FIELD DEVELOPMENT

CALCULATION SHEET BY SV

DATE

CHECKED

DATE

CALC.NO 2001 - KGD6 - D1 - PF - B - PRR - 402

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 3 OF 4

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

CALCULATIONS

SETTLING VELOCITIES Oil From Gas ("K" Value method) K Value, m/s Max allowable velocity,Vmax Gas Horiz. Velocity Actual Gas Velocity OK Stoke's Law Intermediate Law Newton's Law Oil in Water (Gravity Settling Laws method) Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law Stoke's Law (Kcr = 0.025) Vt = 1488 g Dp2 (rl - rv) 18m Water in Oil (Gravity Settling Laws method) Particle size calc for determination of appropriate law m/s Dp max (m) 259 3463 188003 Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law Newton's Law (Kcr = 18.13) Vt = 1.74 * SQRT(g Dp (rl-rv) / rv ) 0.03 0.33 18.13 0.12 1.96 m/s 0.00244 m/s

Dmax is the upper particle size limit for each of the laws. Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the settling velocity in m/s.

Oil in Gas (Gravity Settling Laws method) Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Kcr

0.39 m/s Intermediate Law

Vt (m/s) 0.90 0.39 1.07 Dp max (m) 55 740 40150

0.003

Kcr 0.03 0.33 18.13 Stoke's Law Vt (m/s) 0.003 0.004 0.03

0.000

Kcr Stoke's Law Vt (m/s) 0.03 0.000 0.33 0.001 18.13 0.032

m/s Dp max (m) 1860 24846 1348657

Intermediate Law (Kcr = 0.334) Vt = 3.54*g0.71 Dp1.14 (rl - rv)0.71 rv

0.29

NOTE:

*m

Equations for Stokes Law, Intermediate Law and Newtons Law are taken from GPSA Handbook, Volume 1, Section 7, Figure 7.4

0.43

NOMENCLATURE

LLL LIL LLSD LILSD NLL NIL HLL HIL HLSD HILSD Btm Low Liquid Level Low Interface Level Low Level Shut Down Low Interface Level Shut Down Normal Liquid Level Normal Interface Level High Liquid Level High Interface Level High Level Shut Down High Interface Level Shut Down Bottom

TITLE

X-Area rl rv Dp m Vt VMAX K KCR Hw

Cross sectional area Liquid density kg/m3 3 Vapour density kg/m Droplet diameter m Gas viscosity Cp Settling Velocity m/s Maximum vapour velocity m/s Design vapour velocity factor m/s Proportionality constant, dimensionless. Height of Weir, mm

SEPARATOR SIZING SPREADSHEET

CALCULATION SHEET

BY

LIQUID SEPARATOR

PROJ.

RELIANCE'S KGD6 FIELD DEVELOPMENT

DATE CALC.NO

DATE

CHECKED

SV

2001 - KGD6 - D1 - PF - B - PRR - 402

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 4 OF 4

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

INPUT

Feed Flow (t/d) Density (kg/m3) Viscosity (cP) Droplet Size (m) Droplet Size (m) Droplet Size (m)

OUTPUT GAS

250.0 11.1 0.02

OIL

1116.2 829.2 5.00 150 1000

WATER

1000.0 972.0 0.40

RESIDENCE TIMES

Gas HLL-HLSD NLL-HLL NLL-LLL LLL-LLSD LLSD to Withdrawl pipe height HIL-HILSD NIL-HIL NIL-LIL LIL-LILSD LILSD to Outlet

Specified (mins) 1.0 1.0 1.5 1.0 0.5 1.0 1.0 2.0 1.0 1.0

Oil in Gas Oil in Water Water in Oil

500 1500 3750 1.0 1.0 0.06

r.v 2 max for inlet nozzle (kg/m.s2) r.v 2 max for gas outlet nozzle (kg/m.s 2) Max vel. in Oil out nozzle (m/s) Max vel. in water out nozzle (m/s) K Value (m/s) Mixture density (kg/m3)

Actual (mins) 10.44 0.95 0.99 1.00 0.86 0.68 1.3 1.24 1.70 1.40 1.09 4.1 4.30 4.2

** WARNINGS ** seconds

** Warning ! Residence time insufficient ** ** Warning ! Residence time insufficient ** ** Warning ! Residence time insufficient ** ** Warning ! Residence time insufficient ** OK OK OK ** Warning ! Residence time insufficient ** OK OK

95.0 NIL-Standpipe Oil residence time (NLL - NIL) Water residence time (NIL-Bottom) mins mins mins

SETTLING VELOCITY CRITERION

K Factor Gas Velocity (m/s) Gas Velocity (m/s) - calculated Oil Droplet Velocity (m/s) - Gravity Settling Method Oil from Gas Water from Oil Oil from Water 0.52 m/s 0.46 m/s 0.23 m/s 0.004 m/s 0.042 m/s

OK

DROPLET FALL TIMES

Oil in Gas Top-Liquid Water from Oil NLL-NIL Oil from Water Btm-NIL 3.0 2.4 0.2 seconds mins mins

OK OK OK

NOTE:

Gas Velocity Criteria are based on HLSD Height.

STANDPIPE CALCULATIONS - FROM VESSEL BASE

INTERMEDIATE CALCULATIONS

WATER INTERFACE HILSD

700.00

DIST. BETWEEN WATER HILSD AND OIL OUTLET NOZZLE OIL OUTLET NOZZLE (STANDPIPE) ELEVATION, (Hs) DIST. BETWEEN OIL OUTLET NOZZLE AND OIL LLSD OIL LEVEL LLSD

117 817 50.0 867

mm mm mm mm

116.89 47.11

1.00 1.00

40.88

0.6

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ. CALCULATION SHEET

BY

DATE

CHECKED

DATE

SK.CALC.NO

DATE and TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 1 OF 3

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

SKETCH

Gas = Inlet Minimum Inlet nozzle ID 304 mm Length T/T= 4800 mm

250.00 t/d 938.44 Am3/h

Minimum Gas Out Nozzle ID = 134 mm

Ht. (mm) oil HLSD oil HLL oil NLL oil LLL oil LLSD

1250 mm

Incremental Vol. (m3)

2.72 0.89 0.93 0.93 0.80 0.48

GAS

(Gas) (HLL-HLSD) (NLL-HLL) (NLL-LLL) (LLL-LLSD) (LLSD-HILSD)

1150 mm 1050 mm

950 mm 867 mm

I. D. = 1750 mm

Height of draw off pipe, Hs =

Interface

817 mm

water HILSD water HIL water NIL water LIL water LILSD HEIGHT WARNINGS

700 mm 600 mm 500 mm 350 mm 200 mm

OIL

0.91 0.89 1.21 1.00 0.78

(HIL-HILSD) (NIL-HIL) (NIL-LIL) (LIL-LILSD) (LILSD-Outlet)

WATER

Minimum Water out nozzle ID = 123 mm OK OK Minimum Oil Outlet nozzle ID = OK

OK

Water = 141 mm

1000.00 t/d 3 42.87 m /h

Oil = OK OK

1116.20 t/d 56.09 m3/h

NOMENCLATURE

LLL LIL LLSD LILSD NLL NIL HLL Low Liquid Level Low Interface Level Low Level Shut Down Low Interface Level Shut Down Normal Liquid Level Normal Interface Level High Liquid Level HIL HLSD HILSD KCR Hs rl rv High Interface Level High Level Shut Down High Interface Level Shut Down Proportionality constant, dimensionless. Height of Standpipe, mm Liquid density kg/m3 3 Vapour density kg/m

TITLE

Dp m Vt VMAX K

Droplet diameter m Gas viscosity Cp Settling Velocity m/s Maximum vapour velocity m/s Design vapour velocity factor m/s

SEPARATOR SIZING SPREADSHEET

CALCULATION SHEET

PROJ. CHECKED DATE SK.CALC.NO

BY

DATE

DATE and TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 2 OF 3

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

CALCULATIONS Cont'd) Oil in Gas (Gravity Settling Laws method)

Particle size calc for determination of appropriate law 0.06 0.52 0.46 m/s m/s

SETTLING VELOCITIES Oil From Gas ("K" Value method)

K Value, m/s Max allowable velocity,Vmax Gas Horiz. Velocity Actual Gas Velocity OK

Dmax is the upper particle size limit for each of the laws. Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the settling velocity in m/s. see note 1

Settling Velocity Settling Law Used Law Used: Kcr Stoke's Law Intermediate Law Newton's Law

0.23 m/s Intermediate Law Vt (m/s) 0.03 0.62 0.33 0.23 18.13 0.57

Dp max (m) 47 621 33733

Oil in Water (Gravity Settling Laws method)

Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law

Water in Oil (Gravity Settling Laws method)

Particle size calc for determination of appropriate law m/s Dp max (m) 168 2248 122026 Settling Velocity Settling Law Used Law Used: Kcr Stoke's Law Intermediate Law Newton's Law

0.042

Kcr Intermediate Law Vt (m/s) 0.03 0.195 0.33 0.042 18.13 0.07

0.004

Stoke's Law Vt (m/s) 0.03 0.004 0.33 0.006 18.13 0.051

m/s Dp max (m) 906 12108 657243

NOTES

1.

Stoke's Law (Kcr = 0.025) Vt = 1488 g Dp (rl - rv)

2

Intermediate Law (Kcr = 0.334) Vt = 3.54*g

0.71

Newton's Law (Kcr = 18.13) Vt = 1.74 * SQRT(g Dp (rl-rv) / rv )

Dp

1.14

(rl - rv)

0.71

18m

rv 0.29 * m0.43

Equations for Stokes Law, Intermediate Law and Newtons Law are taken from GPSA Handbook, Volume 1, Section 7. Figure 7.4 2. Maximum allowable vapour velocity is calculated from the equation in GPSA Handbook, Volume 1, Section 7: VMAX 3. 4. 5. = K [ (rl - rl) / rl ] 0.5

Settling times for water and oil are based on the normal interface level (NIL). Information for partial volumes and dished ends was from GPSA handbook Section 6, and in particular, fig. 6-21,6-22. Calculations for gas residence time and area/volume calculations use the NLL height as the height basis. End volumes ignored for gas volume calculations.

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY DATE CHECKED DATE SK.CALC.NO

DATE and TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 3 OF 3

CALCULATION FOR SUMP TANK T-2Y40

INPUT

Feed Flow (t/d) Density (kg/m3) Viscosity (cP) Droplet Size (m) Oil in Gas r.v2 max for inlet nozzle (kg/m.s2) 2 2 r.v max for gas outlet nozzle (kg/m.s ) Max vel. in Oil out nozzle (m/s) K Value (m/s) Mixture density (kg/m3) GAS

42.6 1.10 0.01

OUTPUT

Mixed Liquid

0.1 853 2.39 300 6000 3750 1.00 0.08

RESIDENCE TIMES Gas (seconds) HLL-HLSD NLL-HLL NLL-LLL LLL-LLSD LLSD to bottom SETTLING VELOCITY CRITERION Maximum allowable Gas Velocity (m/s) Gas Horiz. Velocity (m/s) - calculated Oil Droplet Velocity (m/s) (Gravity Settling Method) Droplet fall time (seconds)

Specified (mins) 1.0 1.0 1.0 1.0 0.5

Actual (mins) 3 4909.8 65.2 5978.0 3446.1 10914.7 (m/s) 2.27 1E+00 1.16 0.5

** WARNINGS **

OK OK OK OK OK

OK

NOTE:

Gas velocity critera all based on HLSD

OK

CALCULATIONS

SETTLING VELOCITIES Oil From Gas ("K" Value method) K Value Max Allowable Velocity,Vmax Gas Horiz. Velocity Minimum Vessel Diameter

0.08 2.27 1.10 501

m/s m/s m/s mm

Dmax is the upper particle size limit for each of the laws. Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the settling velocity in m/s.

Oil from Gas (Gravity Settling Laws method) Particle size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Kcr 0.03 0.33 18.13 Vt (m/s) 3.48 1.16 2.63 1.16 m/s Intermediate Law Dp max ( m) 82 1089 59113

Stoke's Law (Kcr = 0.025) Vt = 1488 g Dp2 (rl - rv) 18m

Intermediate Law (Kcr = 0.334) Vt = 3.54*g0.71 Dp1.14 (rl - rv)0.71 rv0.29 * m0.43

Newton's Law (Kcr = 18.13)

Stoke's Law

Vt = 1.74 * SQRT(g Dp (rl-rv) / rv )

Intermediate Law Newton's Law

NOTE:

Equations for Stoke's Law, Intermediate Law and Newton's Law are taken from GPSA Handbook, Volume 1, Section 7, Figure 7.4. Results of these calculations will not be used for Sump Tank Sizing.

13

12 11

27.11.07

16.03.07 29.09.06 23.08.06 DATE

APPROVED FOR DESIGN APPROVED FOR DESIGN APPROVED FOR DESIGN ISSUED FOR COMMENTS DESCRIPTION AUT SUP SUP

BY

TITLE

SKP PJ PJ

CHECK APPR.

CALCULATION FOR SUMP TANK (T-2Y40)

PROJ. BONGKOT 3F

10

Rev.

THAI NIPPON STEEL ENGINEERING & CONSTUCTION CO., LTD

DOCUMENT NUMBER THAI-3F-GEN-11-07-0002

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 1 OF 2

CALCULATION FOR SUMP TANK T-2Y40

SKETCH

42.6 t/d 3 1612.73 Am /h

Inlet Minimum Inlet nozzle ID 88 mm Length T/T= 3050 mm

Minimum Gas Outlet Nozzle ID =

Gas = 99 mm

GAS

I. D. =

1130 mm

Height HLSD HLL NLL LLL LLSD

650 mm 600 mm 550 mm 425 mm 350 mm

Vol. (m3) 1.24 0.40 0.01 0.5 0.28 0.89

(Gas) (HLL-HLSD) (NLL-HLL) (NLL-LLL) (LLL-LLSD) (LLSD-Btm)

LIQUID

Note : Working Condition Volume (LAL-LAH) = 3.8 m3

Minimum Mixed Liquid Outlet 50 mm Nozzle ID =

Mixed Liquid =

0.1 0.00

t/d m3/h

NOMENCLATURE LLL LLSD NLL HLL HLSD Btm rl rv Low Liquid Level Low Level Shut Down Normal Liquid Level High Liquid Level High Level Shut Down Bottom Liquid density kg/m 3 Vapour density kg/m 3 Dp m Vt VMAX K KCR g Dmax Droplet diameter m Gas viscosity Cp Settling Velocity m/s Maximum vapour velocity m/s Design vapour velocity factor m/s Proportionality constant, dimensionless. Gas constant Upper Particle Size Limit

13

27.11.07

16.03.07 29.09.06 23.08.06 DATE

APPROVED FOR DESIGN APPROVED FOR DESIGN APPROVED FOR DESIGN ISSUED FOR COMMENTS DESCRIPTION

9-Apr-14 9:15 AM

TITLE

12

11 10 Rev.

AUT SUP SUP

BY

SKP PJ PJ

CHECK APPR.

CALCULATION FOR SUMP TANK (T-2Y40)

PROJ. BONGKOT 3F

THAI NIPPON STEEL ENGINEERING & CONSTUCTION CO., LTD

DOCUMENT NUMBER THAI-3F-GEN-11-07-0002

DATE AND TIME PRINTED:

PAGE 2 OF 2

VERTICAL SEPARATOR (2 phase)

INPUT PRODUCTION SEPARATOR

GAS 11401 57.02 0.01

OUTPUT

LIQUID

17.6 1051.0 1.796 300 0.10 5000 3750 1.00

Feed Flow (t/d) Density (kg/m3) Viscosity (cP) Droplet Size, (m) Oil in Gas K Value (m/s) from mist extractor data GPSA fig.7.9 r.v2 max for inlet nozzle (kg/m.s2) r.v2 max for gas outlet nozzle (kg/m.s2) Max vel. in Oil outlet nozzle (m/s) Mixture density (kg/m3)

RESIDENCE TIMES HLL-HLSD NLL-HLL NLL-LLL LLL-LLSD LLSD to bottom SETTLING VELOCITY CRITERION K Factor Gas Velocity (m/s) Gas Velocity (m/s) - calculated Oil Droplet Velocity (m/s) Gravity Settling Method

Specified (mins) 1.0 1.5 1.5 1.0 1.0

Actual (mins) 56.8 56.8 56.8 56.8 113.5

** WARNINGS ** OK OK OK OK OK

57.10

Choose Dished end shape by clicking on arrow.

See note 6

0.42 0.35 0.39

OK OK

CALCULATIONS LIQUID / VAPOUR SEPARATION K Value Method

(Note 2)

K Value Max allow. Velocity (Vmax) Gas Velocity Minimum Vessel Diameter Actual Gas Velocity OK Stoke's Law (Kcr = 0.025) Vt = 1488 g Dp2 (rl - rv) 18m

0.10 0.42 0.35 2656

m/s m/s m/s mm

Dmax is the upper particle size limit for each of the laws. Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the settling velocity in m/s.

Oil from Gas (Gravity Settling Laws method) Particle / droplet size calc for determination of appropriate law Settling Velocity Settling Law Used Law Used: Stoke's Law Intermediate Law Newton's Law Kcr 0.03 0.33 18.13 0.39 m/s Newton's Law Vt (m/s) 3.69 0.40 0.39 Dp max (m) 22 296 16049

Intermediate Law (Kcr = 0.334) Vt = 3.54*g0.71 Dp1.14 (rl - rv)0.71 rv

0.29

Newton's Law (Kcr = 18.13) Vt = 1.74 * SQRT(g Dp (rl-rv) / rv )

*m

0.43

TITLE

SEPARATOR SIZING SPREADSHEET

PRODUCTION SEPARATOR

PROJ.

CALCULATION SHEET

RELIANCE'S KGD6 FIELD DEVELOPMENT

BY

DATE

CHECKED

DATE

CALC.NO 2001 - KGD6 - D1 - PF - B - PRR - 402

SV

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 2 OF 4

VERTICAL SEPARATOR (2 phase)

SKETCH

Min Gas Outlet Nozz. Size =

Gas = 603 mm

11400.84 8331.02

t/d Am3/h

Calculated Total T/T Height: 4012 mm consider 4000 mm

300 mm with L/D of approx 1.4

100 mm ID=2900mm

Wire Mesh Demister

1740 mm Inlet

1122 mm

(Note 4)

GAS

(Note 5) (Note 2)

600 mm 500 mm

Min Inlet Nozzle Size =

561 mm

150 mm

NOMENCLATURE

LLSD LLL NLL HLL HLSD g Dmax rL rV Dp m Vt VMAX K KCR Low Level Shut Down Low Liquid Level Normal Liquid Level High Liquid Level High Level Shut Down Gas constant Upper Particle Size Limit Liquid density (kg/m3) Vapour density (kg/m3) Droplet diameter (m) Gas viscosity Cp Settling Velocity (m/s) Maximum vapour velocity (m/s) Design vapour velocity factor (m/s) Proportionality constant, dimensionless.

HLSD HLL

Volume increment 0.66 m3 0.66 m3

NLL

400 mm

OIL

LLL LLSD

300 mm 200 mm

0.66 m3

(Note 3) Volume to LLSD including dished end =

0.66 m3 4.51 m3

Min Liquid Outlet Nozz. Size =

TITLE

Oil = 50 mm

17.61 0.70

t/d m3/h

SEPARATOR SIZING SPREADSHEET

PRODUCTION SEPARATOR

PROJ. CALCULATION SHEET RELIANCE'S KGD6 FIELD DEVELOPMENT DATE CALC.NO 2001 - KGD6 - D1 - PF - B - PRR - 402

BY SV

DATE

CHECKED

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 3 OF 4

VERTICAL SEPARATOR (2 phase)

CALCULATIONS Cont'd

AREA & VOLUME INFORMATION

Area (m )

2

Cylinder Volume (m3)

Volume + Dished end (m3)

Volume Increment (m3)

GAS Cross Sectional Area STORAGE (Volume from Bottom) Oil HLSD Oil HLL Oil NLL Oil LLL Oil LLSD

6.605

6.605 6.605 6.605 6.605 6.605

3.963 3.303 2.642 1.982 1.321 3.193

7.156 6.495 5.835 5.174 4.514

0.661 0.661 0.661 0.661 1.321

Dished End Type

Dished End Volume

(m^3) 3.193 6.385

semi-ellipsoidal hemispherical

NOTES

1. Maximum allowable vapour velocity is calculated from the equation: VMAX 2. 150 mm minimum. 3. Space for instrument nozzles and/or emergency liquid capacity - minimum 150 mm. 4. 60% of vessel diameter or 750mm whichever is greater. 5. twice inlet nozzle diameter.

3 6 .Semi-ellipsoidal end-volume is calculated using the formula V = ( P x (ID) )/24 which applies to one end only of the separator (ie. the bottom). Hemispherical end-volume for one dished end is calculated using the formula: V = (P x (ID) 3 )/12 Information taken from GPSA handbook Sections SI - 6, and in particular, figs. 6.21&6.22

K [ (rL - rV) / rV ] 0.5

TITLE

SEPARATOR SIZING SPREADSHEET

PRODUCTION SEPARATOR

PROJ. CALCULATION SHEET RELIANCE'S KGD6 FIELD DEVELOPMENT DATE CALC.NO 2001 - KGD6 - D1 - PF - B - PRR - 402

BY SV

DATE

CHECKED

DATE AND TIME PRINTED:

9-Apr-14

9:15 AM

PAGE 4 OF 4

S-ar putea să vă placă și

- Separator (1) Sizing Spread SheetsDocument21 paginiSeparator (1) Sizing Spread SheetsSteve WanÎncă nu există evaluări

- Rumus Calculation SeparatorDocument21 paginiRumus Calculation SeparatorAffian WidjanarkoÎncă nu există evaluări

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design SeparatorsreninbabaskiÎncă nu există evaluări

- Separator Sizing SpreadsheetDocument22 paginiSeparator Sizing SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- All Sep CalcDocument22 paginiAll Sep Calcbharathscds100% (3)

- Liquid Line SizingDocument12 paginiLiquid Line Sizinglolofm25Încă nu există evaluări

- Separator Sizing SpreadsheetDocument40 paginiSeparator Sizing SpreadsheetWalid Ben Husein100% (2)

- Vertical Separator SizingDocument4 paginiVertical Separator SizingSyed Waqas HaiderÎncă nu există evaluări

- Master - Three Phase Horizontal Separator Rev 0Document6 paginiMaster - Three Phase Horizontal Separator Rev 0Naeem HussainÎncă nu există evaluări

- Separator DesignDocument3 paginiSeparator Designsondung4ver80% (5)

- Separator SpeadsheetDocument8 paginiSeparator SpeadsheetShabrina GhassaniÎncă nu există evaluări

- Horizontal Three Phase Separator vap-IPDocument5 paginiHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Thermosyphon Reboiler (Horizontal) GPSADocument6 paginiThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006Încă nu există evaluări

- Horizontal 3 Phase Separator With Boot SizingDocument16 paginiHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- 2phase Separator Size 2010 VerAADocument22 pagini2phase Separator Size 2010 VerAAAnonymous a4Jwz14WÎncă nu există evaluări

- Horizontal Vessel Sizing ProgramDocument8 paginiHorizontal Vessel Sizing ProgramsegunoyesÎncă nu există evaluări

- Heater Treater CalculationDocument12 paginiHeater Treater Calculationwahyu100% (1)

- Vertical Knock Out Drum With Wire Mesh For NDocument1 paginăVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- Sizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesDocument5 paginiSizing of The Feed Nozzles For Gas-Liquid Separator - Industrial Professionals - CheresourcesJavierÎncă nu există evaluări

- 2 Phase Vertical Separator Sizing Calculation-AUHDocument26 pagini2 Phase Vertical Separator Sizing Calculation-AUHMike Dukas100% (1)

- Two Phase Separator SizingDocument5 paginiTwo Phase Separator SizingNoman Abu-FarhaÎncă nu există evaluări

- Seperator Sizing v3Document5 paginiSeperator Sizing v3camasa2011Încă nu există evaluări

- Liquid Hold Up Change and Slug Catcher SizingDocument2 paginiLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Validation Report On The 2-Phase Line SizingDocument18 paginiValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- 3Ph Horiz Sep 2010 Weir VerA SIDocument5 pagini3Ph Horiz Sep 2010 Weir VerA SIBrenda DavisÎncă nu există evaluări

- Vertical Drum Separator Calculation SheetDocument2 paginiVertical Drum Separator Calculation Sheeteka resmana100% (2)

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 paginiNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnÎncă nu există evaluări

- Three Phase Separator Sizing (Double Weir 2)Document3 paginiThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- 2-Phase Vertical SeparatorDocument9 pagini2-Phase Vertical SeparatorTolstoy LeoÎncă nu există evaluări

- Line Sizing - 2PHASEDocument11 paginiLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Guide For Vessel Sizing PDFDocument24 paginiGuide For Vessel Sizing PDFManish542Încă nu există evaluări

- Stage 1 pipe sizing dataDocument21 paginiStage 1 pipe sizing datasj_scribdÎncă nu există evaluări

- Vapor Liquid Vertical SeparatorDocument4 paginiVapor Liquid Vertical SeparatorIoana Popescu100% (1)

- API 521 Separator SizingDocument6 paginiAPI 521 Separator SizingFraz RizviÎncă nu există evaluări

- API 12j SizingDocument8 paginiAPI 12j SizingIRVINGÎncă nu există evaluări

- Gas Coalescer SizingDocument6 paginiGas Coalescer SizingAde IskandarÎncă nu există evaluări

- Flare Knock Out Drum Sizing ReportDocument4 paginiFlare Knock Out Drum Sizing ReportSaid Ahmed Salem100% (1)

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pagini11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaÎncă nu există evaluări

- Calculation Sheet for 3-Phase Separator SizingDocument6 paginiCalculation Sheet for 3-Phase Separator SizingHani KirmaniÎncă nu există evaluări

- How To Use Vertical Thermosyphon Reboiler CalculatorDocument2 paginiHow To Use Vertical Thermosyphon Reboiler CalculatorMahesh KumarÎncă nu există evaluări

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechDocument31 paginiEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- PACKED COLUMN DESIGN FOR HCL SCRUBBERDocument11 paginiPACKED COLUMN DESIGN FOR HCL SCRUBBERsoreksatuÎncă nu există evaluări

- HYSYS Excel Link Manipulate Oil ManagerDocument19 paginiHYSYS Excel Link Manipulate Oil ManagerEbby OnyekweÎncă nu există evaluări

- How To Calculate The Flowrate of Motive Fluid in An EjectorDocument3 paginiHow To Calculate The Flowrate of Motive Fluid in An EjectorRajesh Krishnamoorthy100% (3)

- 2-TWO Phase Separator Design Guide by Manish ShahDocument62 pagini2-TWO Phase Separator Design Guide by Manish Shahdennis_ugarteÎncă nu există evaluări

- Gas-Liquid Line SizingDocument1 paginăGas-Liquid Line Sizingagusnnn100% (1)

- Equipment - Sizing (Update) - Pacf2-Rev. ADocument52 paginiEquipment - Sizing (Update) - Pacf2-Rev. AAnonymous AtAGVssJÎncă nu există evaluări

- SeparatorDocument23 paginiSeparatorLeonardo Ramirez GuzmanÎncă nu există evaluări

- Separator Sizing Spreadsheet Main Menu: File Separp1Document23 paginiSeparator Sizing Spreadsheet Main Menu: File Separp1Amiruddin Kubik100% (1)

- Separator 1 Sizing Spread SheetsDocument21 paginiSeparator 1 Sizing Spread SheetsYustianÎncă nu există evaluări

- Separator 1 Sizing Spread Sheets PDF FreeDocument21 paginiSeparator 1 Sizing Spread Sheets PDF FreeHenry WicaksanaÎncă nu există evaluări

- Separator Calculation For MedcoDocument25 paginiSeparator Calculation For MedcoTifano Khristiyanto100% (1)

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorssemarasik_651536604Încă nu există evaluări

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorssemarasik_651536604Încă nu există evaluări

- Guide To CADREFlow SamplesDocument20 paginiGuide To CADREFlow SamplesWashington RodriguesÎncă nu există evaluări

- Tutorial 2Document7 paginiTutorial 2Jaime HernandezÎncă nu există evaluări

- Gas Line Sizing Rev1Document11 paginiGas Line Sizing Rev1Sermsak LimpadapunÎncă nu există evaluări

- Horizontal separator sizing calculation noteDocument6 paginiHorizontal separator sizing calculation noteAnonymous AtAGVssJÎncă nu există evaluări

- Instrucal IIIDocument46 paginiInstrucal IIINorberto Soto100% (1)

- Optimizing Gas/Liquid Separator PerformanceDocument14 paginiOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankÎncă nu există evaluări

- Joint Category UW-3Document1 paginăJoint Category UW-3grabettyÎncă nu există evaluări

- Welding Joint For Storage TankDocument1 paginăWelding Joint For Storage TankgrabettyÎncă nu există evaluări

- Circunferential and Longitudinal StressDocument2 paginiCircunferential and Longitudinal StressgrabettyÎncă nu există evaluări

- Approximate RT Calculation For API 650 TankDocument2 paginiApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Design Data: 2" Threadolet CalculationDocument2 paginiDesign Data: 2" Threadolet Calculationgrabetty50% (2)

- Cristaline Structure Fe-CDocument1 paginăCristaline Structure Fe-CgrabettyÎncă nu există evaluări

- Design Data: 4" Weldolet CalculationDocument2 paginiDesign Data: 4" Weldolet Calculationgrabetty100% (2)

- Scrubber Design (Packed Column)Document10 paginiScrubber Design (Packed Column)alinaveed198367% (3)

- Pipe Span ChartDocument8 paginiPipe Span ChartgrabettyÎncă nu există evaluări

- Pressure Drop and Pipeline Flow CalculatorDocument1 paginăPressure Drop and Pipeline Flow CalculatorgrabettyÎncă nu există evaluări

- Drain A Tank CalculationDocument251 paginiDrain A Tank CalculationAnonymous oVRvsdWzfBÎncă nu există evaluări

- Control Valve Data SheetDocument3 paginiControl Valve Data SheetgrabettyÎncă nu există evaluări

- Reducer Resistance Coefficient CalculationDocument7 paginiReducer Resistance Coefficient CalculationAbdul ShanavasÎncă nu există evaluări

- Casing and Drill Pipe DataDocument1 paginăCasing and Drill Pipe DatagrabettyÎncă nu există evaluări

- Dispersed Phase Surface Area As A Function of Drop SizeDocument3 paginiDispersed Phase Surface Area As A Function of Drop SizegrabettyÎncă nu există evaluări

- Appendix A - Tank Calculations - A4L0L6Document19 paginiAppendix A - Tank Calculations - A4L0L6Ignacio OñateÎncă nu există evaluări

- Knockout DrumDocument9 paginiKnockout Drumgautam_96948069Încă nu există evaluări

- Fatigue of Drillpipe: 391047887.xlsx Mitchell Engineering ProgramsDocument1 paginăFatigue of Drillpipe: 391047887.xlsx Mitchell Engineering ProgramsgrabettyÎncă nu există evaluări

- Hydrocarbon Conversion Table GuideDocument1 paginăHydrocarbon Conversion Table GuidehypermekoolÎncă nu există evaluări

- Design of Cooling - TowerDocument6 paginiDesign of Cooling - TowergrabettyÎncă nu există evaluări

- Pump Specific Speed and Inertia EstimateDocument2 paginiPump Specific Speed and Inertia EstimategrabettyÎncă nu există evaluări

- Centrifugal Compresor CalculationDocument2 paginiCentrifugal Compresor CalculationgrabettyÎncă nu există evaluări

- Distillation Theoretical Stages CalculatorDocument687 paginiDistillation Theoretical Stages CalculatorgrabettyÎncă nu există evaluări

- Gas Velocity CalculatorDocument5 paginiGas Velocity CalculatoresutjiadiÎncă nu există evaluări

- Weld Defect Wall ChartDocument6 paginiWeld Defect Wall ChartMuhammad Attaulla KhanÎncă nu există evaluări

- Distillation Theoretical Stages CalculatorDocument687 paginiDistillation Theoretical Stages CalculatorgrabettyÎncă nu există evaluări

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 paginăEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersgrabettyÎncă nu există evaluări

- Reactor Particle SizingDocument4 paginiReactor Particle SizinggrabettyÎncă nu există evaluări

- Weld Defect Wall ChartDocument6 paginiWeld Defect Wall ChartMuhammad Attaulla KhanÎncă nu există evaluări

- Table For Sieve DataDocument10 paginiTable For Sieve DatagrabettyÎncă nu există evaluări

- Kinetic Investigation On Thermal Tar Cracking During Biomass Gasification ProcessDocument1 paginăKinetic Investigation On Thermal Tar Cracking During Biomass Gasification ProcessDavid AntonioÎncă nu există evaluări

- SPE 169444 Method To Size Gas-Liquid Horizontal Separators Handling Nonstable Multiphase StreamsDocument11 paginiSPE 169444 Method To Size Gas-Liquid Horizontal Separators Handling Nonstable Multiphase StreamskrvishwaÎncă nu există evaluări

- Axial Transport and Residence Time of MSW in Rotary KilnsDocument11 paginiAxial Transport and Residence Time of MSW in Rotary Kilnsjimmy_burgos_11Încă nu există evaluări

- Chemical RXN Eng I - (1) Exercises (B&W)Document23 paginiChemical RXN Eng I - (1) Exercises (B&W)Carolina AlvaÎncă nu există evaluări

- TFR ExperimentDocument25 paginiTFR ExperimentSiti Norbaya100% (1)

- Lab Report CSTR 40LDocument26 paginiLab Report CSTR 40LAnonymous NyvKBW33% (3)

- High-Temperature Kinetics of The Homogeneous Reverse Water-Gas Shift ReactionDocument14 paginiHigh-Temperature Kinetics of The Homogeneous Reverse Water-Gas Shift ReactionUmesh Kumar Sharma RamamoorthiÎncă nu există evaluări

- Liquid-Liquid Extraction Techniques and ApplicationsDocument76 paginiLiquid-Liquid Extraction Techniques and Applicationsbakhtyar21Încă nu există evaluări

- Saponification Kinetics in Batch and CSTR ReactorsDocument28 paginiSaponification Kinetics in Batch and CSTR ReactorsjY-ren100% (1)

- Chapter 3 - Equipment Design Part 3 (R-101)Document37 paginiChapter 3 - Equipment Design Part 3 (R-101)aimanrsln0% (1)

- Lab6-Tubular Flow ReactorDocument11 paginiLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- 5.2 Steady-State Mixed Flow Reactor: Ideal Reactors For A Single ReactionDocument40 pagini5.2 Steady-State Mixed Flow Reactor: Ideal Reactors For A Single ReactionGUNJANS93100% (2)

- Reactor TechnologyDocument11 paginiReactor TechnologyChandraSekaranBmÎncă nu există evaluări

- CBB2074 Reaction EngineeringDocument22 paginiCBB2074 Reaction EngineeringSrinivasan SivaramanÎncă nu există evaluări

- Catalytic Dehydration of Isopropyl Alcohol: AcetoneDocument6 paginiCatalytic Dehydration of Isopropyl Alcohol: AcetoneKharkhodaÎncă nu există evaluări

- PFR Lab ReportDocument16 paginiPFR Lab Reportcog0812Încă nu există evaluări

- Dispersion ModelDocument9 paginiDispersion ModelBrahma Teja LbÎncă nu există evaluări

- Miniaturization of Hvdrowocessina Catalvst Testing System Sie 1996 AIChE Journal PDFDocument10 paginiMiniaturization of Hvdrowocessina Catalvst Testing System Sie 1996 AIChE Journal PDFBrenda Rubí Hdz BetancourtÎncă nu există evaluări

- Modeling Chemical Kinetics and Mixing Times for Reactor Scale-UpDocument14 paginiModeling Chemical Kinetics and Mixing Times for Reactor Scale-Upnurul9535Încă nu există evaluări

- Design of SRU Thermal Reactor and Waste Heat BoilerDocument8 paginiDesign of SRU Thermal Reactor and Waste Heat Boilerfujiman35Încă nu există evaluări

- KMPS Extraction 1Document76 paginiKMPS Extraction 1Adila AnbreenÎncă nu există evaluări

- Residence Time Distribution Functions for Chemical ReactorsDocument71 paginiResidence Time Distribution Functions for Chemical ReactorsSavitha SadhasivamÎncă nu există evaluări

- Cinética Química UDocument16 paginiCinética Química UJesus Manuel Yallerco VenegasÎncă nu există evaluări

- A Review of Rapid Gas-Solid Separation Techniques, Int J Chem Reactor Eng 2010Document75 paginiA Review of Rapid Gas-Solid Separation Techniques, Int J Chem Reactor Eng 2010ejhnoram0% (1)

- Chemical Engineering - 1999 Section A (75 Marks) ExamDocument13 paginiChemical Engineering - 1999 Section A (75 Marks) ExamAnonymous 8pCXXsÎncă nu există evaluări

- Shah Et AlDocument27 paginiShah Et AlEby OkvaleyÎncă nu există evaluări

- Ideal Plug Flow ReactorDocument6 paginiIdeal Plug Flow ReactorMaque Cimafranca GabianaÎncă nu există evaluări

- Reactor Design BasicsDocument22 paginiReactor Design BasicsBatool Ali50% (2)

- CSTR 40LDocument17 paginiCSTR 40LMuhammad Affifudin100% (1)