Documente Academic

Documente Profesional

Documente Cultură

Copyright 2004 Martian Auctions

Încărcat de

humayunkk20020 evaluări0% au considerat acest document util (0 voturi)

431 vizualizări9 paginiBuild a lightweight frame that's the exact size of the shed, then use the frame to mark the site. Drive stakes into the ground to mark each corner, then remove the frame. Use a straight 2 x 4 and level to check that the corner blocks are installed at the same height.

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBuild a lightweight frame that's the exact size of the shed, then use the frame to mark the site. Drive stakes into the ground to mark each corner, then remove the frame. Use a straight 2 x 4 and level to check that the corner blocks are installed at the same height.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

431 vizualizări9 paginiCopyright 2004 Martian Auctions

Încărcat de

humayunkk2002Build a lightweight frame that's the exact size of the shed, then use the frame to mark the site. Drive stakes into the ground to mark each corner, then remove the frame. Use a straight 2 x 4 and level to check that the corner blocks are installed at the same height.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 9

36

SHED

Copyright 2004 Martian Auctions 154

Copyright 2004 Martian Auctions 155

Site Work

Begin by marking out the building’s location in

your yard. For a structure of this size, it’s

simplest to build a lightweight frame that’s the

exact size of the shed, then use the frame to

mark the site.

Use 3/4-in.-thick pine to build your frame. Cut the

sides to the exact dimensions of the floor, and

use one screw in each corner to fasten the sides

into a rectangle. Screw a diagonal brace

between two sides of the frame to hold it square.

Clear the building site and level any obvious high

Use a wooden frame to find the best spot

spots. Place the frame in the site and adjust its for your shed. Drive a stake at each

position until you’re happy with the location of corner and use string to delineate the site.

the shed. Drive stakes into the ground to mark

each corner, stretch string between them (Photo

1) and then remove the frame.

Find the highest corner of the site and excavate

for the first foundation corner block. Plan on

having 3 to 4 in. of block exposed above grade.

Dig out an area several inches wider than the

block. Spread 2 or 3 in. of crushed stone in the

hole to form a stable base for the block.

Dig a hole for the first block at the highest

Now you’re ready to position the first block, point in the grade. Add gravel, install the

aligning its edges with the layout string. Check block, align it with the string, and level it

that the block is level across its length and width

(Photo 2), and adjust the crushed stone as .

required.

Use a long, straight 2 x 4 and level to check the

relative height of the second corner, then

excavate the site for the block. Check that the

second block is level with the first (Photo 3), and

add the remaining corner blocks in the same

way.

Use a straight 2 x 4 and a 4-ft. level to check

that the corner blocks are installed at the

same height.

Copyright 2004 Martian Auctions 156

Building The Floor

It’s a good idea to use pressure-treated lumber

for the floor joists. Cut 2 x 6 stock to length for

the front and back rim joists, and then lay out

the locations of the floor joists on 16-in. centers.

Nail joist hangers to the inside surface of each

inner joist using 1-1/2-in. joist hanger nails

(Photo 4). Next, place the inner front and back

joists between the corner blocks, and then cut

and position the floor joists (Photo 5). Nail the

floor joists in place, then attach the outer rim

joists to the front and back of the floor frame.

Compare opposite diagonal measurements of

After marking joist locations on long front

and rear rim joists, install metal hangers

the floor assembly to check that it’s square. Nail

with 1-1/2-in. joist hanger nails. 3/4-in.-thick plywood to the joists for the shed

floor (Photo 6).

Lay the front and rear joists on the corner

blocks. Then, cut the joists, position them

in the joist hangers and secure with nails.

After doubling the front and rear joists,

add the 3/4-in. plywood floor. Nail it in

place with 8d nails spaced about 6 in.

apart.

Copyright 2004 Martian Auctions 157

Wall Construction

Cut 2 x 6 stock to size for the door

and window headers. Use pieces of

1/2-in. plywood as spacers between

the 2 x 6s to bring the header

assemblies to 3-1/2 in. thick. Nail

together the header pieces with 16d

common nails.

Cut 2 x 4 stock to length for the wall

studs and window and door jack

studs. Nail each jack stud to a wall

stud with 8d common nails. Build the

four corner posts by nailing three 2 x

With the back wall framing members cut

4 spacers between two studs as to length and headers assembled, lay out

Show on the diagram the pieces on the shed floor and join with

nails.

Begin framing the back wall by laying

out the stud locations on the top and

bottom plates. Then, lay out the

framing members on the deck (Photo

7). Nail through the top plate and into

the wall members, then secure the

bottom plate. Frame the window

opening, and nail the second top

plate to the wall, keeping its ends

back 3-1/2 in. from each end of the

wall.

Install 1/2-in. plywood wall sheathing on

Now compare the opposite diagonal the framed back wall. Then, raise the

measurements of the wall and adjust assembly and secure it with diagonal

the assembly until it’s square. Then, braces.

apply 1/2-in. plywood sheathing,

using 6d common nails spaced about

6 in. apart.

Stand the rear wall, bracing it with 2 x

4s nailed between the wall and the

outside floor joists (Photo 8). Nail the

bottom plate to the deck so the

plywood sheathing is flush with the

edge of the deck.

Frame the front wall, but don’t apply

the sheathing yet. Instead, stand the

framed wall and brace it. Position the

wall 1/2 in. from the deck edges to Frame and raise the remaining walls

allow for the thickness of the without sheathing. After nailing together

sheathing. Then frame the side walls, the corner studs, add the top plates.

one at a time, and stand them. Leave

the second top plate off the side

walls until they are raised. Nail the

walls together at the corners, and

then cut Copyright

and install2004 Martian

the side Auctions

wall top 158

plates (Photo 9). Use a level to check

that the corners of the building are

plumb, and nail temporary diagonal

braces to the inside surface of each

wall.

Apply the remaining plywood

sheathing (Photo 10). At the side

walls, keep the plywood 1-1/2 in.

down from the top to provide room to

nail the gable-end sheathing.

When the framing is in place and the

assembly is square and plumb, add the

remaining plywood sheathing.

Framing The Roof

Use a framing square to lay out the 5-in. pitch on

the first roof rafter (Photo 11). Cut out the rafter

and use it as a pattern to make the second rafter.

Test the first two for proper fit, then trace and cut

the remaining rafters.

Cut a gusset for each truss from 1/2-in.-thick

plywood as shown in the plans. Use a sheet of

3/4-in. plywood as an assembly table, and draw

the outline of the roof truss directly on the

To find the rafter cutting angle, align the

5- and 12-in. marks on the framing

plywood surface. Align two rafters over the

square’s legs with the edge of the rafter pattern and nail the gusset to the rafters with 1-

stock. 1/2-in. roofing nails (Photo 12).

Toenail the trusses to the front and rear walls with

8d common nails (Photo 13). At the gable ends

keep the gussets on the inside faces of the

trusses.

Cut 2 x 6 stock to length for the subfascia, and

nail the boards to the rafter ends with 16d

common nails. Cut and install the gable-end

sheathing, and then nail 1 x 6 pine furring over

the gable rafters.

Set up a worktable with the outline of the

rafter assembly marked. Then, join each Rip cedar stock to width for the front and back

pair of rafters with a plywood gusset. soffits and cut it to length. Use 6d galvanized

finishing nails to fasten the soffit boards to the

rafters and subfascia. Then, install the cedar

fascia and rake trim.

Install the plywood roof deck, allowing it to

overhang the fascia by 1/2 in. along the eaves.

Copyright 2004 Martian Auctions Nail aluminum drip edge to the eaves, and apply 159

roofing felt. Then, install the drip edge along the

ragke edes.

With all the rafters assembled in pairs,

position each pair on the wall top plates

and secure by toenailing.

Roofing And Siding

Follow the manufacturer’s directions for

installing the roof shingles (Photo 14).

Since the tongue-and-groove siding is installed

vertically, add 2 x 4 nailing blocks between the

studs, about halfway up the wall. Cut and install

these nailers by toenailing them between

adjacent studs.

If you plan to stain or paint the trim a different

color than the shed siding, it’s a good idea to

finish the roof trim before applying the siding.

Cut siding boards to length and begin installing

Use 1/2-in. plywood for the roof deck and

them at a corner of the building. Use galvanized cover it with roofing felt. Install shingles

finishing nails to fasten the boards—8d nails for following the manufacturer’s instructions.

fastening to the 2 x 4 framing and 6d nails for

the plywood sheathing (Photo 15). Face nail the

first board, but fasten succeeding boards with

nails driven diagonally through the tongue so

the heads will be hidden. Set the nailheads

slightly below the wood surface.

Copyright 2004 Martian Auctions 160

Nail 1 x 6 tongue-and-groove cedar siding

in place. Use 8d nails over wall framing

and 6d nails when nailing into plywood

alone.

Windows And Doors

After staining or painting the siding, install the

door and window jambs (Photo 16). Nail the

jambs directly to the framing, with the outside

edge of each jamb flush to the face of the

siding. At the windows, slope the sill pieces

about 5° toward the outside of the building, add

the top jambs, and then cut the side jambs to

fit.

Cut stops for the windows from 1 x cedar stock,

and install the outer stops with 6d galvanized

finishing nails. Then, place a window in each

opening and add the inner stops.

Cut stock for doorjambs and nail in place.

At a window, install the angled sill piece

first, then the top jamb, then side jambs. Rip door and window trim and shed corner

boards from rough-sawn cedar. Cut each piece

to length and nail in place.

Cut siding boards to length for the shed door.

Use clamps to pull the boards together, but

don’t use glue on the joints. Cut the battens for

the door, and screw them to the inside surface

of the boards.

Hold the door hinges in place and mark the

mounting-hole locations. Bore pilot holes and

fasten the hinges to the shed. Position the door

Position the door in its opening with a 1/4- with a 1/4-in. space on the sides and top, and

in. space at the top and sides. Bore pilot mark the hinge holes. Bore pilot holes and

holes for the hinge screws and secure the

hinges.

mount the hinges (Photo 17). Install the door

pull and hasp. Cut the doorstops and nail them

in place on the top and open-side jamb. Then,

stain or paint the windows, door and remaining

Copyright 2004 Martian Auctionstrim. 161

We built a ramp from pressure-treated stock to

make it easier to wheel a mower or

snowthrower into the shed. To build a ramp,

use 2 x 6 material spaced about 1/2 in. apart for

the ramp deck, and 2 x 4 stock for battens

underneath.

Copyright 2004 Martian Auctions 162

S-ar putea să vă placă și

- How to Build A Laminate Square Edge CountertopDe la EverandHow to Build A Laminate Square Edge CountertopEvaluare: 2 din 5 stele2/5 (1)

- The Princess PlayhouseDocument33 paginiThe Princess PlayhouseEvandroÎncă nu există evaluări

- Minwax Advanced Project Adirondack ChairDocument9 paginiMinwax Advanced Project Adirondack ChairPetrus Cassu Menck100% (1)

- Domino Zigzag ChairDocument6 paginiDomino Zigzag ChairAlex Johnston0% (1)

- How To Build A Double Chair Bench With TableDocument27 paginiHow To Build A Double Chair Bench With TablebearyuyuÎncă nu există evaluări

- Adirondack Chair PlansDocument9 paginiAdirondack Chair PlansBEA18Încă nu există evaluări

- First Look: Guerilla FurnitureDocument15 paginiFirst Look: Guerilla FurnitureStorey Publishing50% (4)

- All American TreehouseDocument50 paginiAll American Treehousecompulsorylogin50% (2)

- How To Build An Outdoor Storage Bench (DIY) - Family HandymanDocument18 paginiHow To Build An Outdoor Storage Bench (DIY) - Family Handymanmiengrong anhÎncă nu există evaluări

- Adirondack Chair: ModerateDocument15 paginiAdirondack Chair: ModeratealexnmÎncă nu există evaluări

- Bee Hotel PlansDocument7 paginiBee Hotel PlansAdam WintersÎncă nu există evaluări

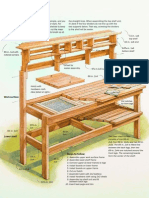

- DIY PottingBench 1110Document2 paginiDIY PottingBench 1110TheOwlReadsÎncă nu există evaluări

- Cardboard LumberDocument15 paginiCardboard Lumberpastel1977Încă nu există evaluări

- WB31238 Diy-WorkbenchDocument8 paginiWB31238 Diy-WorkbenchFrancois VaaltynÎncă nu există evaluări

- Installing A Pre-Hung DoorDocument3 paginiInstalling A Pre-Hung DoorEng_20140% (1)

- 2202 Duo 75 PDFDocument1 pagină2202 Duo 75 PDFWilson Medes AndrinÎncă nu există evaluări

- U-Bild: Animal ArkDocument8 paginiU-Bild: Animal ArkEmilian BalutaÎncă nu există evaluări

- Make A Plaid Cutting Board: InstructablesDocument8 paginiMake A Plaid Cutting Board: InstructablesRod Hyatt100% (1)

- Achitecture For Farmers - RollAwayNestBox - RichardPerkinsDocument21 paginiAchitecture For Farmers - RollAwayNestBox - RichardPerkinsFV100% (1)

- What Do U Dream About WEBDocument46 paginiWhat Do U Dream About WEBCato Arce100% (1)

- The Lutyens Garden BenchDocument8 paginiThe Lutyens Garden BenchAdrian CocisÎncă nu există evaluări

- Folding Stool: I Can Do ThatDocument3 paginiFolding Stool: I Can Do ThatSergio PazÎncă nu există evaluări

- Carpentry III - Specialized CarpentryDocument66 paginiCarpentry III - Specialized CarpentryChuck Achberger100% (1)

- Gabions Install GuideDocument2 paginiGabions Install GuideTele2 Phone2100% (1)

- How To Make A Meat SafeDocument5 paginiHow To Make A Meat SafeChristian Theriault100% (1)

- Adirondack ChairDocument5 paginiAdirondack ChairCristian Liviu CiovicaÎncă nu există evaluări

- Stone Building - How To Construct Your Own Walls, Patios, Walkways, Fire Pits, and MoreDocument178 paginiStone Building - How To Construct Your Own Walls, Patios, Walkways, Fire Pits, and MoreMalek HedhlyÎncă nu există evaluări

- Adirondack Rocking Chair PlansDocument19 paginiAdirondack Rocking Chair PlansMoises BarbosaÎncă nu există evaluări

- Bluebird Nesting Box Project Plan: Materials List MountingDocument1 paginăBluebird Nesting Box Project Plan: Materials List MountingTim SawyerÎncă nu există evaluări

- WJC178 Roaring 20s Sports CarDocument0 paginiWJC178 Roaring 20s Sports Carroose1Încă nu există evaluări

- Folding Sun LoungerDocument14 paginiFolding Sun LoungerKrespov100% (1)

- DIY Arena Kits: Build Your Own Riding ArenaDocument4 paginiDIY Arena Kits: Build Your Own Riding ArenaAli Kemal ArkunÎncă nu există evaluări

- Horrible Mistakes You're Making With Shoe CabinetDocument2 paginiHorrible Mistakes You're Making With Shoe CabinetcalvinhmtaÎncă nu există evaluări

- Making The Most of Small SpacesDocument42 paginiMaking The Most of Small SpacesArnav DasaurÎncă nu există evaluări

- Rășină Epoxidică Pentru Bijuterii Artresin Epoxy Resin - Clear - Non-Toxic - 1 Gal (3.78 L)Document6 paginiRășină Epoxidică Pentru Bijuterii Artresin Epoxy Resin - Clear - Non-Toxic - 1 Gal (3.78 L)Maria MeșinăÎncă nu există evaluări

- Manual de Torno MaderaDocument40 paginiManual de Torno MaderaJuan Palaci Alonso100% (1)

- Homegrown Wood, Handmade Furniture, New Scandinavian Design (PDFDrive)Document70 paginiHomegrown Wood, Handmade Furniture, New Scandinavian Design (PDFDrive)Fulu NemasetoniÎncă nu există evaluări

- ArtofWoodworking WorkbenchDocument4 paginiArtofWoodworking Workbenchsalulai100% (1)

- How To Make A Sawhorse: The PlansDocument4 paginiHow To Make A Sawhorse: The Plansztmp1Încă nu există evaluări

- Building Curved Decks: Templates and Flexible Synthetic Lumber Make The Job EasierDocument7 paginiBuilding Curved Decks: Templates and Flexible Synthetic Lumber Make The Job EasierEdwin GeeqÎncă nu există evaluări

- Visit For More DIY ProjectsDocument13 paginiVisit For More DIY ProjectsCarlos puentesÎncă nu există evaluări

- LP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedDocument10 paginiLP® Shed Assembly Instructions Hawthorne Place 10'X12' Gable Roof ShedMinuteman ModelworksÎncă nu există evaluări

- Diy PVC Grow Light StandDocument7 paginiDiy PVC Grow Light StandRichard MussioÎncă nu există evaluări

- DIY Kitchen Island: Tools ListDocument14 paginiDIY Kitchen Island: Tools ListDanÎncă nu există evaluări

- How To Make A Japanese PlaneDocument4 paginiHow To Make A Japanese PlaneRod HyattÎncă nu există evaluări

- German Ring TurningDocument7 paginiGerman Ring TurningInform7105Încă nu există evaluări

- Interstate PVC Fence Brochure - Sunrise Custom Fence East Inc.Document20 paginiInterstate PVC Fence Brochure - Sunrise Custom Fence East Inc.Sunrise Custom Fence East IncÎncă nu există evaluări

- Digital Patterns: Designed by Steve GoodDocument12 paginiDigital Patterns: Designed by Steve Goodanon_763769249Încă nu există evaluări

- Easy DIY Adirondack Chair and Table PlansDocument11 paginiEasy DIY Adirondack Chair and Table PlansMoises Martins RochaÎncă nu există evaluări

- Rear Elevation Loft PlanDocument1 paginăRear Elevation Loft PlanPatrick BostickÎncă nu există evaluări

- Wanna Bee. A WoodworkerDocument14 paginiWanna Bee. A WoodworkerJake YetoÎncă nu există evaluări

- Building A Potting Bench: Top Shelf UnitDocument2 paginiBuilding A Potting Bench: Top Shelf UnitjteamÎncă nu există evaluări

- The Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Document2 paginiThe Cutting List Where To Drill The Holes: Item Id Description Stock Size Length Pieces (A) (B) (C) (D) (E) (F)Exartis GeorgeÎncă nu există evaluări

- Log Cabin TechnologyDocument1 paginăLog Cabin TechnologyRoger BryantÎncă nu există evaluări

- A Classic CaseDocument6 paginiA Classic CaseTarek YoussefÎncă nu există evaluări

- Condor TailsDocument6 paginiCondor TailsEnrique CoronelÎncă nu există evaluări

- Yurt DoorsDocument1 paginăYurt DoorsAnthony GreenÎncă nu există evaluări

- Bow Top Conestoga Gypsy Vardo: InstructablesDocument28 paginiBow Top Conestoga Gypsy Vardo: InstructablesRod HyattÎncă nu există evaluări

- Woodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)De la EverandWoodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)Încă nu există evaluări

- Konica Minolta DiMAGE Z5Document132 paginiKonica Minolta DiMAGE Z5humayunkk2002Încă nu există evaluări

- Copyright 2004 Martian AuctionsDocument6 paginiCopyright 2004 Martian Auctionshumayunkk2002Încă nu există evaluări

- Play HouseDocument9 paginiPlay Househumayunkk2002Încă nu există evaluări

- Bedside TableDocument3 paginiBedside Table- yAy3e -Încă nu există evaluări

- Bird House2Document3 paginiBird House2khunchaiyai100% (1)

- Metric and US Customary ConversionsDocument3 paginiMetric and US Customary ConversionsYounes BarakaÎncă nu există evaluări

- Uf 1002 FDocument3 paginiUf 1002 FJose M PeresÎncă nu există evaluări

- Distribution TransformerDocument5 paginiDistribution TransformerRahul RoyÎncă nu există evaluări

- Laurie BakerDocument82 paginiLaurie Bakersarath sarathÎncă nu există evaluări

- Pre Assessment in MTB Mle 3 KapampanganDocument8 paginiPre Assessment in MTB Mle 3 KapampanganNicko David DaagÎncă nu există evaluări

- DSR 2007Document80 paginiDSR 2007shiv_am19Încă nu există evaluări

- Sylvania Twist-Pak Post Top Decorator Models Spec SheetDocument2 paginiSylvania Twist-Pak Post Top Decorator Models Spec SheetAlan MastersÎncă nu există evaluări

- Presentation of Electric MotorDocument20 paginiPresentation of Electric MotorRicky Raj100% (2)

- Desert Eagle Semi-Automatic Pistol ManualDocument40 paginiDesert Eagle Semi-Automatic Pistol ManualMeor Amri100% (6)

- Circuit BreakerDocument12 paginiCircuit BreakerJintoKJames100% (1)

- Fire Escape RouteDocument27 paginiFire Escape RouteNitesh SasidharanÎncă nu există evaluări

- EDEN PreivewDocument27 paginiEDEN PreivewAnonymous OV8FmmÎncă nu există evaluări

- Vav Sdainstallsheetsltbt Vsda InstDocument2 paginiVav Sdainstallsheetsltbt Vsda InstdimaomarÎncă nu există evaluări

- Vocabulary Regular - Irregular Verbs PDFDocument12 paginiVocabulary Regular - Irregular Verbs PDFGerardo RiveraÎncă nu există evaluări

- FXB-A15007 User ManualDocument11 paginiFXB-A15007 User Manualivan andres rios guiralesÎncă nu există evaluări

- C-Type EstimateDocument68 paginiC-Type EstimateSurajit KalitaÎncă nu există evaluări

- Argus For Asia Sae Ue Ms Cu WeDocument2 paginiArgus For Asia Sae Ue Ms Cu WeAAÎncă nu există evaluări

- Electrical Design Construction of Skate ParkDocument5 paginiElectrical Design Construction of Skate ParkJorge Dela PeñaÎncă nu există evaluări

- CCTV Project Price 2020!5!11Document10 paginiCCTV Project Price 2020!5!11Salman FayyazÎncă nu există evaluări

- 074bel348 EMD AssignmentDocument11 pagini074bel348 EMD Assignmentkeshav raj sharma100% (1)

- Honeywell Sensing Switch 5000 Series ProductsheetDocument2 paginiHoneywell Sensing Switch 5000 Series ProductsheetAdam SamyÎncă nu există evaluări

- SodapdfDocument27 paginiSodapdfsaravananÎncă nu există evaluări

- SM 89Document36 paginiSM 89Camilo RamosÎncă nu există evaluări

- Harga Lantai Kayu ParketDocument4 paginiHarga Lantai Kayu ParketAliÎncă nu există evaluări

- Swylite LST700 Instruction SheetDocument2 paginiSwylite LST700 Instruction Sheetgreen8019Încă nu există evaluări

- Schneider CatalogueDocument7 paginiSchneider Cataloguesheikh nasseruddienÎncă nu există evaluări

- Such As Long Nosed and Side-: Tools and Materials Needed in Making Simple Electrical GadgetsDocument23 paginiSuch As Long Nosed and Side-: Tools and Materials Needed in Making Simple Electrical GadgetsCjan Malahay GeconcilloÎncă nu există evaluări

- Relay Selection Guide R0 81105Document27 paginiRelay Selection Guide R0 81105jjcanoolivaresÎncă nu există evaluări

- DatasheetDocument3 paginiDatasheetMaysum AbbasÎncă nu există evaluări

- Parts Catalog: Browning .50 M2 Machine Gun, AssemblyDocument32 paginiParts Catalog: Browning .50 M2 Machine Gun, AssemblyJay Mason100% (1)