Documente Academic

Documente Profesional

Documente Cultură

Daerator - Sizing - Vacuum Breakers

Încărcat de

cirius_coolTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Daerator - Sizing - Vacuum Breakers

Încărcat de

cirius_coolDrepturi de autor:

Formate disponibile

Issue Date: 9/06

GESTRA Steam Systems

GESTRA Information A 2.4

Sizing of Vacuum Breakers

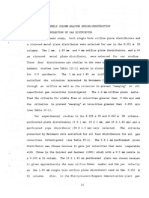

Vacuum breakers (air-inlet valves) are used to protect vessels or heat exchangers against vacuum. The causes leading to the formation of vacuum depend on the specic plant conditions, but the basic considerations required to determine the size of a vacuum breaker are in many cases similar. We want to take a feedwater tank with deaerator dome as an example for demonstrating the method of calculating the size of a vacuum breaker. Sizing of vacuum breakers for feedwater deaerators Vacuum in feedwater deaerators is formed if the heatingsteam supply fails and if, at the same time, cold water is added resulting in condensation of the remaining steam. To prevent the formation of a vacuum an adequate system must be provided to ensure that air can enter the deaerator to provide a pressure balance as soon as vacuum starts to form. A vacuum breaker for example a GESTRA DISCO non-return valve fulls this purpose. The basis for the calculation may be assumed to be the condition prevailing when the vacuum breaker starts to open. As the exact opening pressure of a non-return valve depends on the installation position, we shall base our calculation on a mean opening pressure of 20 mbar. At an average ambient pressure of 1 bar absolute this corresponds to an opening point of 0.98 bar a. We furthermore suppose that the cold make-up water is heated to no more than 99 C (boiling temperature at 0.98 bara). The following facts are not considered or may be neglected:

Heat transfer by heating steam to the inowing air

C D E F

(when vacuum breaker is open)

Ambient heat loss of the deaerator Revaporization (ashing) when pressure drops Increase in water volume from condensation of

What is the amount of water required to condense the total heating-steam volume, i.e. to absorb the complete heat of evaporation of the heating steam? What is the time required by the cold make-up water to condense the total heating-steam amount? The corresponding air volume must ow in at the sametime to prevent the formation of vacuum. What is the volume of the required air ow? What is the resulting nominal size?

heating steam and added make-up water.

Method of Calculation

General The heating steam in the deaerator transfers its heat to the cold make-up water. If the steam supply is interrupted, that part of the steam which is lost by condensation has to be compensated for by the admission of air to prevent the formation of a vacuum. To be able to determine the air volume that should enter the deaerator in a given time to prevent vacuum formation, i.e. to calculate the nominal size of the vacuum breaker, the following questions have to be answered:

To be able to establish a formula for the calculation of the air volume ow, the calculation is carried out in individual steps.

Determination of the heat of evaporation available in the deaerator if the steam supply fails at a pressure of 0.98 bar a.

At 0.98 bara the heat of evaporaton is r = 2259.6 kJ/kg (in acc. with steam tables). The total amount of heat of evaporation (R) is then

A B

What is the total heat of evaporation (latent heat content) available in the deaerator at the opening point of the vacuum breaker (0.98 bar a)? What is the maximum amount of heat that can be absorbed by the cold make-up water?

1 2

R = m1 r [kJ]

and the heating-steam mass (m1) m1 = V [kg] V" R = V r [kJ] V"

2 in 1 = 3

Gas outlet / Flash steam Heating steam Make-up water

Vacuum breaker

Feedwater outlet

Fig. 1

Feedwater tank with deaerator

Determination of the maximum amount of heat that can be absorbed by the cold make-up water (Q)

The equivalent water volume ow is calculated as follows:

R m1 V v" Q hE

Complete heat of evaporation available in deaerator at a pressure of 0.98 bar a [kJ] Heating-steam amount available in deaerator at 0.98 bar a [kg] Volume of heating steam at 0.98 bar a [m3] Specic volume of heating steam at 0.98 bar a [m3/kg] (= 1.7272 m3/kg) Max. amount of heat that can be absorbed by the cold make-up water [kJ/kg] Heat content (enthalpy) of cold make-up water [kJ/kg]

As the cold make-up water can be heated to no more than 99 C (boiling temperature at 0.98 bara), the amount of heat absorbed (Q) is the difference between the enthalpy of the cold makeup water (hE) and the maximum possible enthalpy (hmax) of the make-up water heated by heat transfer from the heating steam.

"

. Vw = VL

1000 [m h ]

L 3

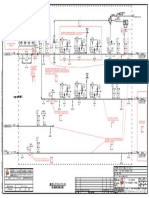

Refer to the pressure drop chart of the RK valve and choose the size whose pressure-drop curve is intersected by the equivalent water volume ow in the linear range. If ! is inserted in ", the result is . . L m3 V w = v" (hmax hE) m r 1000 h

Q = hmax hE

kJ [ kg ]

[ ] [ ]

Determination of the amount of water required to condense the total heating-steam amount (m2)

For this purpose the complete heat of evaporation available in the deaerator (at p = 0.98 bar a) is divided by the maximum amount of heat that can be absorbed by the cold make-up water.

If, in addition, the values already known are inserted, there results . . m3 V w = 1.7272 (hmax hE) m 1.19 2259.6 1000 h

hmax Max. heat content (enthalpy) of heated make-up water [kJ/kg] m2 t . VL . m . Vw L Amount of water required for condensing the total heating-steam amount [kg] Time required for condensing the total heatingsteam amount [h] Air ow required to prevent a vacuum [m3/h] Cold make-up water [kg/h] Equivalent water volume ow [m3/h] Density of air at 1 bar a and 20 C (ambient values) (= 1.19) [kg/m3] Heat of evaporaton of heating steam at 0.98 bar a (2259.6 kJ/kg)

m2 = R [kg] Q m2 = Vr

v" (hmax hE)

Vw = 2.63 10-5 m (hmax hE)

[ mh ]

3

Dimensional analysis for [kg] m3 kJ kJ kg . kg kg kg h Vw = kJ kg

3 and 4 in 5 = 6

kg/m3 kg/m3

[ ]

m3 h

1000 Densitiy of water [kg/m3] r

Determination of the time required to condense the total heating-steam amount (t)

If the amount of water (mass) required for condens ing the total heating-steam amount is divided by the cold make-up water amount (mass ow), the time is obtained.

t= m . 2 [h] m t =

v" (hmax hE) m

6 in 7 = 8

Vr . [h]

Determination of the air ow . required to prevent the formation of vacuum (V)

If the volume of the heating steam (at 0.98 bar a) is divided by the time required for the total heatingsteam amount to condense, the volume of the air that must ow into the deaerator in the same period to prevent the formation of vacuum is obtained. . 3 9 VL = V m t h

[ ]

8 in 9 = 0

. . VL = V v" (hmax hE) m Vr

[ mh ]

3

As V can be cancelled from the equation, the result is: . . 3 ! VL = v" (hmax hE) m m r h

Fig. 2

[ ]

Determination of the nominal size of the vacuum breaker

The pressure drop charts of the GESTRA DISCO non-return valves are based on water as the ow medium. To determine the nominal size of the vacuum breaker the air volume ow has therefore to be converted to the equivalent water volume ow.

GESTRA AG

P. O. Box 10 54 60, D28054 Bremen Mnchener Str. 77 , D28215 Bremen Telephone +49 (0) 421 35 03 0, Fax +49 (0) 421 35 03393 EMail gestra.ag@owserve.com, Internet www.gestra.de

810670-02/906cm 1981 GESTRA AG Bremen Printed in Germany

S-ar putea să vă placă și

- Reference For Sizing of Vacuum Breaker Valve PDFDocument2 paginiReference For Sizing of Vacuum Breaker Valve PDFLcm Tnl50% (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringDe la EverandFlow Analysis for Hydrocarbon Pipeline EngineeringÎncă nu există evaluări

- HRSG Water Chemistry Control OverviewDocument5 paginiHRSG Water Chemistry Control OverviewRahul ChoubeyÎncă nu există evaluări

- Deaerator Volume Calculation ReportDocument1 paginăDeaerator Volume Calculation Reportpsk.pranesh5520Încă nu există evaluări

- Evaporative Cooling Technical Handbook - MuntersDocument20 paginiEvaporative Cooling Technical Handbook - MuntersradiopascalgeÎncă nu există evaluări

- BR Turbulent Tech BrochureDocument19 paginiBR Turbulent Tech BrochureGrover Marcelo Monasterios SardónÎncă nu există evaluări

- What Is The Difference Between Nm3 and Sm3Document1 paginăWhat Is The Difference Between Nm3 and Sm3jimx_101Încă nu există evaluări

- Let Down StationDocument5 paginiLet Down StationSabeeh AhmedÎncă nu există evaluări

- Boiler Performance & Technical Data JT-K13467-E01-0Document15 paginiBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Air Cooled CondenserDocument3 paginiAir Cooled CondenserJonathan Buenaobra100% (1)

- Forced Draft Fan Sizing For Fired HeatersDocument5 paginiForced Draft Fan Sizing For Fired Heatersdlalameen4471Încă nu există evaluări

- Barry Dooley Introducton-to-ACC-FAC-and-Cycle-ChemistryDocument37 paginiBarry Dooley Introducton-to-ACC-FAC-and-Cycle-Chemistrychemicalchouhan9303Încă nu există evaluări

- Boil Out ProcedureDocument2 paginiBoil Out Proceduremrizalygani99100% (1)

- Orifice Sizing PrinciplesDocument12 paginiOrifice Sizing Principlesjlcheefei9258100% (1)

- Graham - Lessons From The Field - Ejector SystemDocument5 paginiGraham - Lessons From The Field - Ejector SystemAnonymous DJrec2Încă nu există evaluări

- Air Cooled Condenser ACC PDFDocument3 paginiAir Cooled Condenser ACC PDFHoney TiwariÎncă nu există evaluări

- Vibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwareDocument5 paginiVibration Analysis of Aes Type Shell and Tube Heat Exchanger by Htri SoftwarevikramÎncă nu există evaluări

- DEAERATORDocument26 paginiDEAERATORSai Swaroop100% (2)

- Alpema Standerd For Brazed Aluminium Plate-Fin Heat ExchDocument78 paginiAlpema Standerd For Brazed Aluminium Plate-Fin Heat ExchBilal NazirÎncă nu există evaluări

- Eyectors PDFDocument110 paginiEyectors PDFDiego RinconÎncă nu există evaluări

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pagini9.1 Overview: 9 Wiped Film EvaporatorNoman AslamÎncă nu există evaluări

- DAM DesuperheaterDocument4 paginiDAM DesuperheaterangeloÎncă nu există evaluări

- Vertical Thermosyphon ReboilersDocument9 paginiVertical Thermosyphon ReboilersLucianoÎncă nu există evaluări

- Improved Analysis of External Loads On Flanged JointsDocument1 paginăImproved Analysis of External Loads On Flanged JointsTiHoRÎncă nu există evaluări

- EDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFDocument33 paginiEDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFErol DAĞ100% (1)

- 4.16 Flanged Joints v6 PDFDocument44 pagini4.16 Flanged Joints v6 PDFaprabhakar15Încă nu există evaluări

- Bell Delaware Math Cad ExampleDocument8 paginiBell Delaware Math Cad ExampleMohammed A IsaÎncă nu există evaluări

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 paginiOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- The GPSA 13th Edition Major ChangesDocument2 paginiThe GPSA 13th Edition Major Changespatrickandreas77Încă nu există evaluări

- Air Cooled Heat Exchanger !Document17 paginiAir Cooled Heat Exchanger !RehinaÎncă nu există evaluări

- Shell - DEP - 31.22.20.31 PRESSURE VESSELS Table VIII-1Document1 paginăShell - DEP - 31.22.20.31 PRESSURE VESSELS Table VIII-1Sulist N Wahyudie100% (1)

- Steam Turbines: PartaDocument52 paginiSteam Turbines: PartaSheetal JadhavÎncă nu există evaluări

- Thermal Power Plant PDFDocument16 paginiThermal Power Plant PDFMoustafa MahmoudÎncă nu există evaluări

- Long Weld Necks 300 PDFDocument1 paginăLong Weld Necks 300 PDFPedro Montes MarinÎncă nu există evaluări

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocument14 paginiSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiÎncă nu există evaluări

- Drum Internal1Document12 paginiDrum Internal1mayurpatare100% (1)

- Presentation For API 934FDocument22 paginiPresentation For API 934FandreahankÎncă nu există evaluări

- Boiler Design and Operation PDFDocument8 paginiBoiler Design and Operation PDFChungNguyenÎncă nu există evaluări

- Boiler Drum Level Control Pid ControlDocument10 paginiBoiler Drum Level Control Pid ControlrajishrrrÎncă nu există evaluări

- Gas Distributor DesignDocument9 paginiGas Distributor DesignHuzefa CalcuttawalaÎncă nu există evaluări

- Process Heat Transfer - D. Q. KernDocument273 paginiProcess Heat Transfer - D. Q. KernMuhammad Andrifar Empatpuluhlima0% (1)

- Steam JacketsDocument1 paginăSteam Jacketsomar.moradi3707Încă nu există evaluări

- Asme Section I Int Vol 57Document25 paginiAsme Section I Int Vol 57dalvarezÎncă nu există evaluări

- Increasing Efficiency of Boiler Using ScaphDocument11 paginiIncreasing Efficiency of Boiler Using ScaphInternational Journal of Innovative Science and Research Technology100% (1)

- Flash TanksDocument8 paginiFlash TanksOwen HizriawanÎncă nu există evaluări

- Nm3 To M3Document4 paginiNm3 To M3Aniket royÎncă nu există evaluări

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 paginiControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımÎncă nu există evaluări

- Standard Design Manual For Steam Drum InternalsDocument17 paginiStandard Design Manual For Steam Drum Internalsahmed sobhyÎncă nu există evaluări

- Turbine Bypass ValvesDocument6 paginiTurbine Bypass ValvesadehriyaÎncă nu există evaluări

- Basic Desuperheater Types PDFDocument17 paginiBasic Desuperheater Types PDFLiège CostaÎncă nu există evaluări

- Fuel Gas Skid Train PDFDocument1 paginăFuel Gas Skid Train PDFhadÎncă nu există evaluări

- Dry Wet Cooling Systems and Flue Gas System ENEXIODocument55 paginiDry Wet Cooling Systems and Flue Gas System ENEXIOAmir AbbaszadehÎncă nu există evaluări

- Level Control Valve - LCVDocument2 paginiLevel Control Valve - LCVLaxman Singh SankhlaÎncă nu există evaluări

- Engro Fertilizer ReportDocument46 paginiEngro Fertilizer ReportSher Muhammad100% (1)

- Boiler Design Step 2Document2 paginiBoiler Design Step 2Amad TaupiqÎncă nu există evaluări

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4De la EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Evaluare: 5 din 5 stele5/5 (1)

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7De la EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Încă nu există evaluări

- PDFDocument2 paginiPDFak_thimiriÎncă nu există evaluări

- Handling Hot and Corrosive Gases: Gas AbsorptionDocument17 paginiHandling Hot and Corrosive Gases: Gas AbsorptionKrishnendu GhoshÎncă nu există evaluări

- Chimney SL - No. Name of The Supplier/ Erecting Agency No. of Orders Placed (No. of Chimneys RemarksDocument3 paginiChimney SL - No. Name of The Supplier/ Erecting Agency No. of Orders Placed (No. of Chimneys Remarkscirius_cool0% (1)

- Drinking Water Irrigation Fire Agricultural Chemical Food Preparation Water Plastics Polyethylene Polypropylene Fiberglass Concrete Stone SteelDocument1 paginăDrinking Water Irrigation Fire Agricultural Chemical Food Preparation Water Plastics Polyethylene Polypropylene Fiberglass Concrete Stone Steelcirius_coolÎncă nu există evaluări

- Statuscrusher HouseDocument2 paginiStatuscrusher Housecirius_coolÎncă nu există evaluări

- AnkurDocument2 paginiAnkurcirius_coolÎncă nu există evaluări

- Prefabricated Factory ShedsDocument3 paginiPrefabricated Factory Shedscirius_coolÎncă nu există evaluări

- Existing Plant Engineering ServicesDocument1 paginăExisting Plant Engineering Servicescirius_coolÎncă nu există evaluări

- Statuscrusher HouseDocument2 paginiStatuscrusher Housecirius_coolÎncă nu există evaluări

- Erection Steps-STG 57.5 MWDocument27 paginiErection Steps-STG 57.5 MWcirius_coolÎncă nu există evaluări

- Excel Product Info PDFDocument1 paginăExcel Product Info PDFcirius_coolÎncă nu există evaluări

- Motor Duty Cycles-IEC - S1... EtcDocument1 paginăMotor Duty Cycles-IEC - S1... Etccirius_coolÎncă nu există evaluări

- List of Beneficiaries - MSMS & NMCP SchemesDocument17 paginiList of Beneficiaries - MSMS & NMCP Schemescirius_coolÎncă nu există evaluări

- Chapter - Steam Distribution and UtilizationDocument68 paginiChapter - Steam Distribution and UtilizationIbrahim YalginÎncă nu există evaluări

- Basics of ThermodynamicsDocument51 paginiBasics of ThermodynamicsRajib ChatterjeeÎncă nu există evaluări

- BethelDocument40 paginiBethelcirius_coolÎncă nu există evaluări

- Plates and Shts-Diff.Document1 paginăPlates and Shts-Diff.cirius_coolÎncă nu există evaluări

- Sbi Internet Banking FormDocument3 paginiSbi Internet Banking Formrajandtu93Încă nu există evaluări

- Extract - ASME B16.5 (2009) - Flanges and Flanged FittingsDocument1 paginăExtract - ASME B16.5 (2009) - Flanges and Flanged Fittingscirius_coolÎncă nu există evaluări

- Boiler Heaters DescriptionDocument12 paginiBoiler Heaters Descriptioncirius_coolÎncă nu există evaluări

- Is 808-1989 Steel TableDocument24 paginiIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- Sbi Internet Banking FormDocument3 paginiSbi Internet Banking Formrajandtu93Încă nu există evaluări

- Extract - ASME B16.5 (2009) - Flanges and Flanged FittingsDocument1 paginăExtract - ASME B16.5 (2009) - Flanges and Flanged Fittingscirius_coolÎncă nu există evaluări

- Plates and Shts-Diff.Document1 paginăPlates and Shts-Diff.cirius_coolÎncă nu există evaluări

- Trent 60 - REolls Royse - 60 MWDocument1 paginăTrent 60 - REolls Royse - 60 MWcirius_coolÎncă nu există evaluări

- Plates and Shts-Diff.Document1 paginăPlates and Shts-Diff.cirius_coolÎncă nu există evaluări

- Standard Pipe Sizes ME303-4.1.1Document5 paginiStandard Pipe Sizes ME303-4.1.1manashbdÎncă nu există evaluări

- Ingress ProtectionDocument1 paginăIngress Protectioncirius_coolÎncă nu există evaluări

- IBRDocument1 paginăIBRcirius_coolÎncă nu există evaluări

- IBRDocument5 paginiIBRcirius_coolÎncă nu există evaluări

- C Language Tutorial by Gordon Drodrill (1999)Document124 paginiC Language Tutorial by Gordon Drodrill (1999)felixandy101100% (1)

- Hype Cycle For Data Center P 263280Document66 paginiHype Cycle For Data Center P 263280Hai Le HoangÎncă nu există evaluări

- Ensayo Medio AmbienteDocument2 paginiEnsayo Medio Ambientemrisel76Încă nu există evaluări

- DRRR Reviewer: A Comprehensive Plan ShouldDocument3 paginiDRRR Reviewer: A Comprehensive Plan ShouldJames BastesÎncă nu există evaluări

- Physical Science QTR4 Week 1 4Document8 paginiPhysical Science QTR4 Week 1 4Marrianne ShaneÎncă nu există evaluări

- Proposal "Air Pollution by PT. Wilmar Nabati Gresik East Java"Document4 paginiProposal "Air Pollution by PT. Wilmar Nabati Gresik East Java"Imtikhana KhofifahÎncă nu există evaluări

- Fundamentals of Heat Exchanger DesignDocument972 paginiFundamentals of Heat Exchanger DesignNgô Linh Đan80% (5)

- TE. Toefl Reading 2Document5 paginiTE. Toefl Reading 2beatriceÎncă nu există evaluări

- Safe Operation of Reboilers/Condensers in Air Separation UnitsDocument30 paginiSafe Operation of Reboilers/Condensers in Air Separation UnitsAmit BiswasÎncă nu există evaluări

- DroughtDocument4 paginiDroughtSarvesh JaiswalÎncă nu există evaluări

- OceanographyDocument24 paginiOceanographyAnkit Sundriyal100% (1)

- Chapter 9Document29 paginiChapter 9Danny TÎncă nu există evaluări

- Flow in Open Channel: Prepared By: Amalina Amirah Abu BakarDocument121 paginiFlow in Open Channel: Prepared By: Amalina Amirah Abu BakarnurulselangorÎncă nu există evaluări

- Core BooksDocument3 paginiCore Booksemmanuelsimati49Încă nu există evaluări

- Raw MealDocument48 paginiRaw Mealrashmiranjan1110Încă nu există evaluări

- Research Overview Context Guillen.Document3 paginiResearch Overview Context Guillen.andreagassiÎncă nu există evaluări

- Seminar Report On SolarmobilechargerDocument25 paginiSeminar Report On SolarmobilechargerSujana Suji100% (1)

- Chapter 1 - ExerciseDocument15 paginiChapter 1 - Exerciseحسن كميت hassankomeit lÎncă nu există evaluări

- Lowenthal (1999)Document6 paginiLowenthal (1999)CristobalMartinezÎncă nu există evaluări

- Solar Hybrid Chimney Final ReportDocument51 paginiSolar Hybrid Chimney Final ReportInder Mankotia50% (2)

- 2022.08.30-GE Series SpecDocument4 pagini2022.08.30-GE Series SpecEniola FaladeÎncă nu există evaluări

- UNIT-5 Phase EquilibriaDocument13 paginiUNIT-5 Phase EquilibriaALOK KUMARÎncă nu există evaluări

- MerDocument264 paginiMerkoloÎncă nu există evaluări

- Kumpulan Soal Latihan UTS IKGM 2011 FKG UADocument20 paginiKumpulan Soal Latihan UTS IKGM 2011 FKG UAaderiskapradinaÎncă nu există evaluări

- Priyanshu LLB 301Document8 paginiPriyanshu LLB 301Priyanshu RanjanÎncă nu există evaluări

- WavesDocument8 paginiWavesMuneeb AnsariÎncă nu există evaluări

- Taiga PDFDocument1 paginăTaiga PDFMaria TavioÎncă nu există evaluări

- Chemical Bonding Shobhit NirwanDocument17 paginiChemical Bonding Shobhit NirwanBhavya Goyal XI Non medÎncă nu există evaluări

- M. Cuney and K. Kayser - 2008, Recent and Not-So-Recent Developments in Uranium Deposits and Implications For ExplorationDocument259 paginiM. Cuney and K. Kayser - 2008, Recent and Not-So-Recent Developments in Uranium Deposits and Implications For ExplorationDomenik Elizabeth Calderon VÎncă nu există evaluări

- Category 3 GuidebookDocument23 paginiCategory 3 GuidebookWorking GuyÎncă nu există evaluări