Documente Academic

Documente Profesional

Documente Cultură

Drilling Engineering

Încărcat de

karanx16Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drilling Engineering

Încărcat de

karanx16Drepturi de autor:

Formate disponibile

1431/11/07

Drilling Engineering (I)

Prepared by: M.Mostofi

Marking System and References

References: 1.Applied Drilling Engineering 2.Drilling Engineering, A complete well planning approach, by Adams N. J. 3. Oil Well Drilling Engineering, Principles and Practice, by Rabia H.

1431/11/07

Course Summery

Drilling Engineering

General Drilling

Special Drilling Topics

Drilling Mechanisms

Power

Hoisting

Circulating

Rotating

Controlling

Monitoring

Drilling Fluid

Cementing

Casing Fundamentals

Casing Design

Additional Topics maybe Directional Drilling and Hydraulic of Drilling Fluids and ROP Models

Introduction

� Source Rock � Migration g (p (primary, y, secondary) y) � First Oil wells in the worlds and in Iran � Reservoir Rock � Cap Rock � How to find Hydrocarbon Reservoirs

� Oil Seepage � Geology and Geophysics � And Finally Drilling (Wildcat wells, Exploration wells, Development wells, Injection Wells)

SPE and IADC

1431/11/07

Importance of Drilling

� Maturity of an oil industry is in Drilling Engineering � Some aspects p of drilling g engineering g g

� Multilateral Wells � Directional Wells � Horizontal Wells � Stimulation of Wells � Relief Wells � Casing Drillings � LWD and MWD � Geomechanical Analysis and Wellbore stability � Geomechanical Analysis and Sand Productions � Geomechanical Analysis and best drilling paths

Drilling Mechanisms

� Different Drilling Mechanisms:

I. II.

Precaution Drilling Rotary Drilling System

I.

Precaution Drilling Mechanism

1431/11/07

- Precaution Drilling

� Precautions Drilling Components:

� Driving mechanism � Drill String() � Bailer

Application of Precaution Drilling

1. 2. 3.

Sampling of Formations Drilling Shallow Reservoirs Water wells

1431/11/07

Questions:

� Drill String Components � Bailer Applications in Precaution Drilling � Application of Precaution Drilling

This session quiz

� Please compare the porosity and permeability of source rock,

reservoir rock, migration path rocks and cap rock .

� Please write two application of precaution drilling method � Please explain about SPE in two sentences

50% is the passing mark.

1431/11/07

Rotary Mechanism

Drilling Rigs

Rigs Marine Bottom Support Barge Jack Up Land

Floating

Conventional

Mobile

Drill Ship Semi submersible

Platform Self Contained Tendered

Jacknife

Portable mast

1431/11/07

Different Rig Types

Rig Systems

� Power � Hoisting � Rotating � Circulating � Well Control System � Monitoring

The Function of each of them

1431/11/07

Power Systems

� Two main power consuming systems:

� Hoisting � Circulating

They are not simultaneously

� Power by combustion diesel engines:

� Diesel-Electric rigs � Direct Derive Rigs

Advantages and Disadvantages??

Hoisting System

� Function: Raising and Lowering casing, drill pipes , in and

out of the well � Main Components of this system:

� Drawwork � Block and tackle � Derrick and substructure

1431/11/07

Hoisting System

� Two routine drilling operation:

� Making g a connection � Making a trip

Rate hole and Mouse hole!

Making a connection

� Mouse Hole � Air Hoist � Slips � Kelly � Pipe rack � V door

1431/11/07

Making a trip

The question

� Braking systems � Crown block � Travelling block � Fast line � Dead Line � Dead line anchor � Drilling ll l line

Probe Slip and cutting program Pick Point and Lap Point Drum Pulley or Sheaves The diameter of the drilling line? Hook

10

1431/11/07

The question

� Elevator � Motion Compensator, p , Where? How?

Lets have the movie: � E:\Technical Information\Drilling Movies\Hoisting\start.exe

Ton-Mile Calculation for Drilling line

� Three main factors affecting on drilling line wear:

1. 2 2. 3.

Trip C i S Casing Setting tti Drilling

� Tone during a Round Trip:

Tr Tone miles during the trip D Depth, ft Ls Length of drill pipe stand WM Drill pipe weight per foot, foot lb/ft M Travelling Block-Elevator Weight, lb C Weight of drill collar minus weight of drill pipe with same length lb/ft

TR =

D( Ls + D)WM D ( M + 1 / 2C ) + 10560000 2640000

11

1431/11/07

Block and Tackle

Block and Tackle System

� Mechanical advantage

� When no friction, then M=2*number of pulleys=number of lines

M=

W Ff

12

1431/11/07

Derrick Load, Derrick Efficiency

� Block and Tackle Efficiency y (E) ( )

� Number of Lines, Friction Mechanical Advantage

E = (0.98) n

More Information about E in Direct Drive Rigs Chains, Ch i T Torque convertors and db belts l i in Direct D Drive Rigs please refer to: Drilling Engineering, A complete Well Planning Approach, A. J. Adams

13

1431/11/07

Load Distribution

� Derrick Load:

Derrick Efficiency (Ed )

14

1431/11/07

Quiz

The relation between Fast line and hook load (1 mark)The relation between fast line and hook velocity (1mark) 2. What happens on derrick efficiency and block and tackle efficiency when n increases (2marks) 3. Which leg of the derrick undergo the maximum force? (1 mark)which leg has the minimum force on it? (1mark)

1.

Answer two of them and 3 marks is the passing mark

Today Program

� Solution of last quiz � Example of Hoisting problems � Providing new HWs � Circulation System

15

1431/11/07

Questions

300,000 . 500 . 4 8 ).( Fast Line ).( )( )( Derrick )( Derrick efficiency factor . 1 hp = 33000 ft.lbf/min ft lbf/min ) (E 8 0.841

Question In English

16

1431/11/07

Solution

W=300,000lbf p = 165 *107 lbf.ft/min Pin = 500 hp n=8 and therefore E=0.841 (a) Fast line tension=? (b) Maximum Hook Horse Power? (c) Maximum Hoisting Speed? (d)Derrick Load? (e)Derrick Efficiency (Ed )

E= Pout Pin

P in =V f *F f

Solution (continue)

17

1431/11/07

Solution (continue)

HW1

18

1431/11/07

HW 2

Hw 3

19

1431/11/07

HW 4

Additional mark (HW5)

20

1431/11/07

Circulating System

� � � � � � � �

Mud Tanks Mud Pumps Pulsation Dampener Stand Pipe Rotary Hose Swivel Return Mud Line Mud Removal Equipments

Another View of Circulation System

21

1431/11/07

Mud Pumps

Mud Pumps p

� Application of Each Pumps � Pump Factors

Centrifugal

Reciprocate

Duplex Pumps

Triplex Pumps

Centrifugal Pumps

� Application: � Supercharging Mud Pumps

Reciprocating Pumps and Centrifugal Pumps Combination

� Fluid Supplement for Mud mixing equipment � Fluid Supplement for solid controlling equipment � Tank Cleaning � � Characteristics � Low pressure pump high h h flow fl rate � Cheap � To some how solid dependent

22

1431/11/07

Reciprocating Pumps

� Application

()

� Pump p High g Pressure Mud into the hole to reach hole cleaning, g

cutting removal and other goals.

Characteristics:

� Pump High Solid Content Fluid � Ease Operation and Maintenance � Ability to Operate in Large Range of Flow Rate and Pressure

How?

Number of Pumps on the Well

� Two Mud Pumps are AVAILABLE on the site � WHY TWO?

Top Hole Application

Deep Hole Application

� Triplex or Duplex Pump? (Advantages and Disadvantages)

23

1431/11/07

Duplex and Triplex Pumps

Duplex(Two-way acting) and Triplex (One way acting) Pumps

Two-way acting Pump

One-way acting Pump

What is Pump Factor????

24

1431/11/07

Pump Factor

� Pump Factor for Triplex Pumps

� Pump Factor for Duplex Pumps

Here is the home work for you to derive above formulas

Pump Efficiency Factor

� Mechanical Efficiency (90%) � Volumetric Efficiency y (up ( p to 100%) )

Et = Em * Ev

25

1431/11/07

Example

Pulsation Dampener

� How does it operate? � Where can it be placed? � Characteristics:

� Removing the surging � Stabilizing the suction Pressure � Increasing the Pump Life

26

1431/11/07

Hooper Component

� What is it for? � What is the mechanism?

What about Caustic Soda?

Animation of Circulating System

� Lets have the animation:

E:\Technical Information\Drilling Movies\Circulating System\start.exe

27

1431/11/07

These are the things to remember

� Contaminant removal systems � Shale shaker � Hydro cyclones � Degassers � Mud tanks � Chemical Tank � Slug Tank � Reserve Tanks, Reserve Pit � Settling Tank � Mud disposal methods � Stand Pipe � Rotary Hose � Swivel � Suction Line � Suction Tank � Bulk lk Tanks T k � Mud House � Number of Mud Tanks???

These are the things to remember

� Pulsation Dampener � Suction Dampener p � Supercharging Mud pumps � Piston and Liners � Relief Valve � Discharge Line � Agitator � Centrifuge � PVT(Pit volume totalizer) � Hooper

28

1431/11/07

Rotary System

� Rotary Table � Swivel � Kelly Choke � Kelly � Lower Kelly Choke � Kelly Saver Sub � Drill Pipe � BHA(Bottom Hole l Assemble) bl � Kelly Bushing � Kelly Master Bushing

How to rotate the drill string

Kelly K ll Kelly Saver Sub Kelly Drive Bushing Master M t Bushing B hi Rotary Table

29

1431/11/07

Other Components

Animations of Rotary System

� E:\Technical Information\Drilling Movies\Rotating

equipment and mast structure\start.exe

30

1431/11/07

The question.

� Kelly � Kelly Bushing � Slips � Air Hoist � Air Wrentch � Mouse Hole � Rat Hole l

Monkey Board Stabbing Board Walkaround Board Fingers Stand and Single (pipe) Kell Bushing Kelly Bushing, Master Bushing Draw Work

Application of Each Components

� Swivel � Upper Kelly Chock � Kelly � Lower Kelly Chock � Kelly Saver Sub

31

1431/11/07

Example from applied drilling

32

1431/11/07

Solution Continue

Solution Continue

33

1431/11/07

Home Work 6

HW6 continue

34

1431/11/07

HW6 continue

Homework7

35

1431/11/07

HW7 Continue

Well Control System

� What is Kick and How Harmful is it? � What is Fluid Loss and How Harmful is it? � What is Blow out? � Have you seem a blow out? lets see one.

36

1431/11/07

Blow out

Causes of Kick

� Failure to keep the well full � Swabbing the formation fluid into the well � Insufficient mud density � Poor well planning (Casing and Mud weight) � Lost Circulation and Formation Fracturing

SURGE PRESSURE VS SWAB PRESSURE

37

1431/11/07

Kick Detection

� Drilling Fluid Volume increase. (Pit Volume indicator or

di i i ) digitizer)

� Comparison of flow in and flow out of the well � Drilling Brake, sudden increase in the rate of penetration � Comparison of mud weight in and out of the well. � Change in ion concentration (occasionally) � Volume change while tripping in trip tank

What is Trip Tank

What do you do when you get a kick?

� Static Scenario: Closing the well and taking the time for

making decision

� Flowing Scenario without well controlling consideration � Using Well Controlling Methods

Or alternatively, run and go home and take a rest?

38

1431/11/07

Primary Well Control GOAL

Mud in Mud Window No Kick Entry No Blow Out

What is Mud Window?

Secondary Well Control GOAL

Circulate the kick while BHP is constant and no kick inter the wells and finally shift to primary well control.

Shift to Primary Well Control!!? What does it mean? ?

39

1431/11/07

Well Control

� Primary Well Control � Secondary Well Control

BOP Drilling Fluid

Overbalanced Drilling Principle Advantage, Disadvantage

BOP Equipments

� Blow Out Preventers:

� � � � �

Ram Preventers Annular(Bag type) BOP Blind Ram Shear Ram Rotating Head

� Accumulator � Chock Line and Manifold � Casing Head � Control Panel � Internal BOPs

40

1431/11/07

Annular Preventer

� Provides Striping � 2000, 5000, 10,000 psi

Why Striping?

� Bag g type yp BOP=Annular Preventer= Hydrill(the y ( brand name) )

Pipe Ram Type BOP

� Seals around the pipe at 2000, 5000, 10000 and 15000 psi

41

1431/11/07

Blind and Shear Ram

� Blind Ram for closing the well when no string in the well � Shear ram to cut the drilling g string g and closing g the well in

emergency occasion. � Blind ram can seal when string in well, only collapse the string!

Casing Spool and Casing Head

� BOP Stag is fixed on Casing Head or casing spools. � Lets have the casing g running g steps p

to have the casing spool functions 1. Surface casing and then casing head 2. Intermediate spool on casing head and BOP on the Intermediate spool 3. Production spool p on Intermediate spool p and BOP on the Intermediate spool 4. Tubing spool on Production spool and X-mas tree on tubing spool.

Casing Head

42

1431/11/07

A schematic of casing sequences

X-mas Tree

43

1431/11/07

Well head schematic

Casing spool and pp g stripping

Do not forget Conductor pipe

Chock, Chock line, Kill Line, Chock manifold and Back Pressure

Choke valve

Hydraulic controlling valve on choke flow line

Application of Kill line

44

1431/11/07

Accumulator

� N2 gas capsules to hydraulically close and open:

� Pipe, Blind, Shear ram � Adjust annular BOP � Adjust Hydraulic chokes

� N2 pushes an inert oil to close and open the valves � A pump is used to charge the N2 capsules

Control Panel and Drilling Consol

� Control Panel, one on the rig floor, one

out one out of the rig g floor

45

1431/11/07

Internal BOPs

� Float Valve � Upper pp kelly y cock � Lower kelly cock (drill stem valve) � Internal BOPs (ball type, dart type)

Mud Gas separator

To T clean l the h contaminated i d mud. d Distinguish it from DEGASER

Well Control Methods

o Well Control Methods

� Driller Method � Wait and Weight Method � Volumetric Method

o Drillers method:

Circulate the kick with old contaminated drilling fluid and then replace the old drilling fluid with heavier drilling fluid.

o Wait W it and d Weight W i ht method: th d

Circulate the kick with heavier drilling fluid. One circulation then the well is in primary well control system.

46

1431/11/07

Two Important Rules in all well Circulating methods

P C

P C

Means constant BHP and no new flux entry

P frac

Means maximum annulus pressure at the casing shoe should be lower than fracture pressure.

P m P f

Why Casing shoe is critical point in the annulus? When should the kick flux be to have maximum pressure on the casing shoe? PC + PM < PFracture

PM + PC + PK > PF

Well Monitoring System

� It is all about mud logger system which provides MUD

LOGS � The data we see on mud logging system:

WOB and Hook Load Rotary Speed What important III. Flow Rate in and out information are available IV. ROP from each mentioned V. MW in and MW out parameters ? p VI. Well Head Pressure VII. Torque of well string VIII. Temperature in and out IX. Gas composition on the shale shaker

I. II.

47

1431/11/07

Geologist and Well Monitoring System

� Geologist is the eyes of the Driller, because:

Analysis y the cutting g from drilling g fluid circulation 2. According to thin section analysis, he finds where we are exactly. 3. How much drill to reach the casing depth. 4. Is there any fault and help to improve geological model of the well (if exists any!!) � What is lag time and how it can be calculated?

1.

Do you have some corns?

Drilling Fluid

� To cool and Lubricate the bit and drill string � Primary y well controlling g system y � Prevent the fluid loss zone by mud cake formation � Provide the hydraulic power to enhance the drilling � Transport and suspend the cuttings � Check the lithology (Well Monitoring System) � Well bore stability � Cementing and Completion

48

1431/11/07

Drilling Fluid Types

Special BOP g ( g head) ) stage(Rotating

Drilling Fluid

Overbalanced Drilling Fluids

Underbalanced Drilling Fluids

Water Based Drilling Fluid

Oil Based Drilling Fluids

Foam

Air

Mist

Flow Regimes

� Plug Flow

� Low Velocities and high viscosity � Flat Fl Velocity Vl i P Profile fil � Velocity at the wall is the same as middle

Do you remember Fluid Mechanics?

Laminar Flow

� After Plug flow

Definition of laminar flow in fluid mechanics

� Parallel of layers and bullet shape velocity profile � Velocity is zero at the walls and maximum in the middle

Transition Flow ( (after Laminar and before Turbulent) ) Turbulent Flow

� Eddies and turbulences � No parallel of layers

49

1431/11/07

Fluid First Law of Newton in Mechanic

=

Viscosity, Important Drilling fluid characteristics

F u u = A x t

1. Pressure Drop 2. Hydraulic Impact Force 3. Displacing Different Fl id Fluids 4. Mud Weight and Viscosity 5. Permeability Calculation 6. Fracture Pressure Estimation

Fluid Models

� Newtonian Fluid � Bingham Fluid � Power Law

What is Thixotropic Behavior? What is Dilatant ?

u = x

= YP + p

= K n

50

1431/11/07

How to measure the Viscosity?

� Marsh Funnel � Rotary y Viscometer

51

S-ar putea să vă placă și

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDocument8 paginiDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinÎncă nu există evaluări

- Drilling 1Document37 paginiDrilling 1Samarth Patel100% (1)

- Drilling Problems and SolutionsDocument60 paginiDrilling Problems and SolutionsMuhd EizadÎncă nu există evaluări

- Drilling Basic 2001 ManualDocument286 paginiDrilling Basic 2001 Manualasset_kulmagambetov86% (7)

- Surface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFDocument14 paginiSurface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFKaleem UllahÎncă nu există evaluări

- 10 - Bottom Hole AssembliesDocument25 pagini10 - Bottom Hole AssembliesManuel GómezÎncă nu există evaluări

- Well Drilling DesignDocument26 paginiWell Drilling DesignMajedur Rahman100% (1)

- Stuck Pipe Prevention - Rev1Document83 paginiStuck Pipe Prevention - Rev1Arijit Ray100% (1)

- Maximizing Hydraulics PerformanceDocument36 paginiMaximizing Hydraulics PerformancedohlalaÎncă nu există evaluări

- Drilling OfficeDocument2 paginiDrilling OfficeLuisA.HarCór0% (1)

- Drilling OperationDocument25 paginiDrilling OperationMohammed Mushtaq Abu OmarÎncă nu există evaluări

- Casing Setting Depth DesignDocument26 paginiCasing Setting Depth Designehsan100% (1)

- Buckling Analysis in Deviated Wells A Practical MethodDocument10 paginiBuckling Analysis in Deviated Wells A Practical Methodsabilco13Încă nu există evaluări

- Drilling application evaluate design bit hydraulicsDocument1 paginăDrilling application evaluate design bit hydraulicsstevebeardsleyÎncă nu există evaluări

- Drill String Design 4.11Document23 paginiDrill String Design 4.11Ryan Tan Ping YiÎncă nu există evaluări

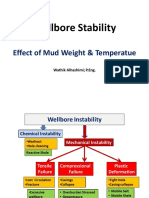

- Wellbore Stability Effect of Mud Weight 1645782860Document27 paginiWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzÎncă nu există evaluări

- SABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteDocument26 paginiSABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteMr. Moses Imagoro100% (1)

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 paginiA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadÎncă nu există evaluări

- Well Control Leak-Off Test & Kick Circulation MethodsDocument45 paginiWell Control Leak-Off Test & Kick Circulation MethodsLaxmi Kant PrasadÎncă nu există evaluări

- Drilling Fluid BasicsDocument12 paginiDrilling Fluid BasicstharmarajÎncă nu există evaluări

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDocument6 paginiFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalÎncă nu există evaluări

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDe la EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersÎncă nu există evaluări

- Drillpipe FailuresDocument9 paginiDrillpipe FailuresRobert KochÎncă nu există evaluări

- 28 - IWCF Study GuideDocument7 pagini28 - IWCF Study GuideBabi LakhdariÎncă nu există evaluări

- WITSML - Lithology - Object - Usage - Guide - 1.1revisions Version 2 PDFDocument41 paginiWITSML - Lithology - Object - Usage - Guide - 1.1revisions Version 2 PDFBarrett BoucherÎncă nu există evaluări

- Well Problems GoodDocument27 paginiWell Problems Gooddeyaa Sadoon100% (1)

- Applied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesDe la EverandApplied Gaseous Fluid Drilling Engineering: Design and Field Case StudiesÎncă nu există evaluări

- Chapter Managed Pressure Drilling OperationsDocument106 paginiChapter Managed Pressure Drilling OperationsCarlos Perea0% (1)

- Barrier (Well Control) 1Document13 paginiBarrier (Well Control) 1Zahraa AliÎncă nu există evaluări

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- Bolts - SlidesDocument133 paginiBolts - SlidesImran BabarÎncă nu există evaluări

- SAP 2000 Manual Water Tank DesignDocument20 paginiSAP 2000 Manual Water Tank DesignSyner Qxz100% (1)

- DAY 6 - Loss Circulation & Stuck Pipe Sharing SessionDocument27 paginiDAY 6 - Loss Circulation & Stuck Pipe Sharing SessionReza Syahputra MulyanaÎncă nu există evaluări

- Circulation and Well ControlDocument16 paginiCirculation and Well ControlAmirhosseinÎncă nu există evaluări

- Anti CollisionDocument13 paginiAnti Collision44ali100% (1)

- Convential Drilling Vs MPD StodleDocument83 paginiConvential Drilling Vs MPD StodleSyed Irtaza100% (1)

- Drilling Programme - ChecklistDocument5 paginiDrilling Programme - ChecklistFill Jose100% (1)

- Casing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouDocument6 paginiCasing Setting Depth Optimisation Based On Well Control Considerations by Lek Chun HouLek Chun Hou100% (1)

- Project vs Fixed Term EmploymentDocument3 paginiProject vs Fixed Term EmploymentJechel TanÎncă nu există evaluări

- Stuck PipeDocument71 paginiStuck Pipemosli_Încă nu există evaluări

- 56r 08Document21 pagini56r 08manojsingh4allÎncă nu există evaluări

- ROP Optimization and Modelling in Directional Drilling ProcessDocument122 paginiROP Optimization and Modelling in Directional Drilling ProcessM. Fadhli Cesar KÎncă nu există evaluări

- Segmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFDocument6 paginiSegmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFTarek HareedyÎncă nu există evaluări

- Mechanical and Differential Pressure Pipe Sticking Causes and PreventionDocument21 paginiMechanical and Differential Pressure Pipe Sticking Causes and PreventionMarco100% (1)

- Chapter 2 - Hole Problem March 2018 PDFDocument60 paginiChapter 2 - Hole Problem March 2018 PDFMohd RafiqÎncă nu există evaluări

- 3 Well ProblemsDocument47 pagini3 Well ProblemsKarwan DilmanyÎncă nu există evaluări

- Special Problems During DrillingDocument60 paginiSpecial Problems During DrillingDanian PrimasatryaÎncă nu există evaluări

- Torque and Drag CalculationsDocument78 paginiTorque and Drag CalculationsMilad Ebrahimi Dastgerdi100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDe la EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsÎncă nu există evaluări

- Real Time Drilling OptimizationDocument3 paginiReal Time Drilling OptimizationSergio RamirezÎncă nu există evaluări

- Offshore Drilling IntroductionDocument56 paginiOffshore Drilling IntroductionnaefmubarakÎncă nu există evaluări

- 07 Well ProblemsDocument47 pagini07 Well ProblemsMustafa010891Încă nu există evaluări

- Directional Drilling CalcuationsDocument43 paginiDirectional Drilling CalcuationsNourden Al100% (1)

- Kill MethodsDocument12 paginiKill Methodsnabi100% (1)

- Hydraulics PresentationDocument29 paginiHydraulics PresentationUsama Bin Sabir100% (2)

- Cameron U2 BOP, Data SheetDocument4 paginiCameron U2 BOP, Data SheetIhonghong HongÎncă nu există evaluări

- WELLCAT Data SheetDocument8 paginiWELLCAT Data SheetErik Rodriguez100% (1)

- Hole Cleaning Techniques and FactorsDocument59 paginiHole Cleaning Techniques and FactorsSaranya Yellela100% (1)

- Drilling ProblemsDocument25 paginiDrilling ProblemsMohamed Ahmed AlyÎncă nu există evaluări

- Chapter 7 Hole ProblemsDocument23 paginiChapter 7 Hole ProblemsAmine MimoÎncă nu există evaluări

- Well ProblemsDocument15 paginiWell ProblemsAngel NgoÎncă nu există evaluări

- Drilling Fluid QuestionsDocument2 paginiDrilling Fluid QuestionsMunsef AL-juroshyÎncă nu există evaluări

- Underbalanced DrillingDocument2 paginiUnderbalanced DrillingWilson WanÎncă nu există evaluări

- Pressure Regimes Drilling Process Formation Evaluation 1645995935Document34 paginiPressure Regimes Drilling Process Formation Evaluation 1645995935Muhammad Husein MahfudzÎncă nu există evaluări

- Oil Well DesigningDocument15 paginiOil Well DesigningShashank SacamuriÎncă nu există evaluări

- Remedial Cementing TechniquesDocument4 paginiRemedial Cementing TechniquesColor RougeÎncă nu există evaluări

- Andarko Petroleum UBS 2013 Global O&G Conference PresentationDocument22 paginiAndarko Petroleum UBS 2013 Global O&G Conference Presentationkaranx16Încă nu există evaluări

- Air Flow Calculation For Reverse Circulation DrillingDocument6 paginiAir Flow Calculation For Reverse Circulation Drillingkaranx16100% (1)

- BXPDocument53 paginiBXPkaranx16Încă nu există evaluări

- Concrete Mix Design Methods, Verification StudyDocument26 paginiConcrete Mix Design Methods, Verification StudyAhmed M AminÎncă nu există evaluări

- Staad Training Day 1Document116 paginiStaad Training Day 1Bee AnquilianoÎncă nu există evaluări

- Engineering Data Book for Heat Recovery and Heat Pump SystemsDocument196 paginiEngineering Data Book for Heat Recovery and Heat Pump SystemstowiwaÎncă nu există evaluări

- Scully U31766uDocument2 paginiScully U31766unumonveÎncă nu există evaluări

- 8015-0151-SC03-00-000-Cl-RP-00050 - A - Geotechnical Report Template - Pipeline From CPF To WP 11-WQ (II)Document79 pagini8015-0151-SC03-00-000-Cl-RP-00050 - A - Geotechnical Report Template - Pipeline From CPF To WP 11-WQ (II)Fabrizio MansuetoÎncă nu există evaluări

- Under Floor Insulation System: CompliesDocument4 paginiUnder Floor Insulation System: CompliesJohn LiebermanÎncă nu există evaluări

- Procurement 2023Document11 paginiProcurement 2023Roi Andrei GalangÎncă nu există evaluări

- Sheikh Abdullah Al Salem Cultural Centre Case StudyDocument7 paginiSheikh Abdullah Al Salem Cultural Centre Case StudyAnudeep ChandraÎncă nu există evaluări

- Tyco - Mokri Sprinkler VentilDocument20 paginiTyco - Mokri Sprinkler VentilMuhidin KozicaÎncă nu există evaluări

- ASCAR Report 1906Document138 paginiASCAR Report 1906Thilanka SiriwardanaÎncă nu există evaluări

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 paginăStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilÎncă nu există evaluări

- Tube StructureDocument27 paginiTube StructureI Gede Arta RismawanÎncă nu există evaluări

- Daewoo FR 330Document13 paginiDaewoo FR 330Jorge MosqueraÎncă nu există evaluări

- 002JTGT B02-01-2008-EnDocument75 pagini002JTGT B02-01-2008-Enziming liÎncă nu există evaluări

- CONSEAL 300 Pure Bitumen WaterproofingDocument2 paginiCONSEAL 300 Pure Bitumen WaterproofingGodwin IwekaÎncă nu există evaluări

- Cobi Spec GuideDocument10 paginiCobi Spec Guideharry HendersonÎncă nu există evaluări

- Barriers to Quality Management in Small Building ConstructionDocument16 paginiBarriers to Quality Management in Small Building ConstructionAcharya RabinÎncă nu există evaluări

- Colphenebswh 1816Document2 paginiColphenebswh 1816vinoth kumar SanthanamÎncă nu există evaluări

- 4190 HPRVDocument12 pagini4190 HPRVvadivel415Încă nu există evaluări

- Catalogo NovumDocument72 paginiCatalogo NovumrodgutieÎncă nu există evaluări

- Chapter8 - Design Theory & Procedure PDFDocument407 paginiChapter8 - Design Theory & Procedure PDFJunwhan KimÎncă nu există evaluări

- High Performance Louvers For Curtain Wall SystemsDocument8 paginiHigh Performance Louvers For Curtain Wall Systemszeynepuzunoglu6Încă nu există evaluări

- DNV RU YACHT Pt3Ch5Document68 paginiDNV RU YACHT Pt3Ch5Ante KezicÎncă nu există evaluări

- 2 NDDocument3 pagini2 NDAgnes AsilÎncă nu există evaluări