Documente Academic

Documente Profesional

Documente Cultură

ESSAY (100 Marks) : Pages 2 of 8

Încărcat de

Iskandar IbrahimTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ESSAY (100 Marks) : Pages 2 of 8

Încărcat de

Iskandar IbrahimDrepturi de autor:

Formate disponibile

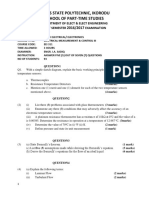

ESSAY (100 marks) Instruction: This section consists of SIX (6) essay questions.

Answer only FOUR (4) questions. QUESTION 1

(a)

Give the definitions for quality and zero defect. (3 marks)

(b)

Inspection of products is important to ensure the products quality level. State and elaborate TWO (2) types of products inspection. (6 marks)

(c)

In a manufacturing steel industry, steel rods are produced through the pultrusion process. The average of steel rod diameter is 3.20 cm and standard deviation is 0.05 cm. The acceptance level is 3.200.06 cm. Based on this case, sketch and label a normal curve. (4 marks)

Calculate: i. The percentage of rejected rods. (4 marks)

ii.

The percentage of the rods reworked.

(4 marks)

iii.

The percentage of accepted rods.

(4 marks)

Pages 2 of 8

QUESTION 2

(a)

Define the following terms:

i. ii. iii.

Control Charts for Variables Assignable causes variation Random variation

(3 marks) (3 marks) (3 marks)

(b)

Define process capability (Cp) and illustrate cases where process variability exceeds specifications. (4 marks)

(c)

Table 1 shows some sampling data. By using the table,

i. ii. iii.

Determine the mean and range (X and R). Determine the upper and lower control limit (UCL and LCL). Draw a control chart from the data.

(4 marks) (4 marks) (4 marks)

TABLE 1 Sample number 1 2 3 4 5 6 7 8 9 10 28.28 26.92 28.46 32.43 28.84 30.75 31.26 31.25 31.42 32.20 Observations (mm) 33.95 27.66 28.30 26.10 30.52 33.00 24.29 28.58 35.80 32.02 30.47 31.47 29.00 29.84 32.24 28.08 35.46 35.01 33.61 32.71 28.87 29.67 31.14 37.20 30.47 26.20 28.41 31.24 27.82 29.38

Pages 3 of 8

QUESTION 3

(a)

Differentiate between defect and defective and briefly describe types of attributes control charts related to each of them. (10 marks)

(b)

Define the word attributes by giving suitable examples. (5 marks)

(c)

Table 2 represents the observed number of defects from an inspection of 30 successive chocolate wafers, each containing 100 chips. determine : i. The average number of defects (c) (4 marks) ii. The upper and lower control limits ( UCL and LCL) (6 marks) Number of Chocolate Wafers 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 TABLE 2 Number of defects Number of Chocolate Wafers 19 16 17 17 14 18 16 19 15 20 13 21 14 22 16 23 11 24 20 25 15 26 13 27 10 28 15 29 16 30 Number of defects 16 14 28 16 12 20 10 12 10 17 10 12 13 18 11

Pages 4 of 8

QUESTION 4

(a)

Give TWO (2) types of Control Chart. (2 marks)

(b)

Explain how to choose a control chart suitable for a specific data. (4 marks)

(c)

Table 3 is a data compilation of the length of steel bars. TABLE 3

Date

Time 9.00 10.00 11.00 12.00 1.00 2.00 3.00 9.00 10.00 11.00 12.00 1.00 2.00 3.00 9.00 10.00 11.00 12.00 1.00 2.00 3.00

1/8/05

No. of Inspected Bars (mm) B1 B2 B3 B4 5.85 5.65 5.65 5.70 5.75 5.85 5.75 5.85 5.80 5.80 5.75 5.70 5.65 5.75 5.60 5.70 5.75 5.70 5.65 5.80 5.60 5.75 5.65 5.70 5.65 5.80 5.60 5.60 5.80 5.75 5.80 5.65 5.85 5.60 5.70 5.80 5.75 5.80 5.65 5.85 5.80 5.60 5.75 5.85 5.80 5.65 5.75 5.60 5.80 5.80 5.75 5.80 5.65 5.85 5.60 5.70 5.85 5.75 5.80 5.65 5.85 5.70 5.60 5.80 5.75 5.80 5.65 5.85 5.60 5.65 5.65 5.75 5.80 5.65 5.75 5.60 5.70 5.80 5.75 5.80 5.65 5.85 5.80 5.60

Mean

Range

2/8/05

3/8/05

Pages 5 of 8

i. ii. iii. iv.

Determine the mean and range (X and R). Determine the central line and control limits. Plot the points of the chart. Analyze the plotted points to determine if the process is in control. Give a reason for your answer.

(4 marks) (6 marks) (5 marks)

(4 marks)

Pages 6 of 8

QUESTION 5

(a)

Differentiate producers risk and consumers risk. (4 marks)

(b)

In sampling inspection products that do not meet specifications would be rejected. Explain in detail THREE (3) actions that are usually taken against the rejected lot. (9 marks)

(c)

Using Table 4, inspector needs to determine the Single Sampling Plans for the following information: TABLE 4 INSPECTION LEVEL i) II ii) I iii) III INSPECTION Tightened Normal Reduced AQL 1.5% 65% 0.40% LOT SIZE 1,400 115 160,000 (9 marks)

(d)

Explain the sampling plan determined in QUESTION 5 (c) iii. if 6 nonconforming units are found in the sample. (3 marks)

Pages 7 of 8

QUESTION 6

(a)

i.

State FOUR (4) types of quality cost.

(4 marks)

ii.

Explain TWO (2) types of quality cost.

(4 marks)

iii.

Draw and label the curve of quality cost.

(2 marks)

(b)

i. iii.

State the uses of Pareto Diagram. Using Table 5, construct the Pareto Diagram and discuss the results. TABLE 5 Types of defections Scratch Broken Color not uniform Short mould Flashing Pin hole etc

(2 marks)

(10 marks)

Number of nonconforming units 42 20 108 10 35 15 5

(c)

Give the terms for ISO 9000:2000 listed below. i. ii. iii. ISO 9000 ISO 9001 ISO 9004 ( 3 marks)

Pages 8 of 8

S-ar putea să vă placă și

- Fuather, That Smid Govern-: Such Time As It May Deem Proper: TeDocument18 paginiFuather, That Smid Govern-: Such Time As It May Deem Proper: Tencwazzy100% (1)

- Marriage Gift PolicyDocument4 paginiMarriage Gift PolicyGanesh Gaikwad100% (3)

- Engineering CLDocument1 paginăEngineering CLUmer Iftikhar AhmedÎncă nu există evaluări

- 001 Gace Early Childhood TestDocument3 pagini001 Gace Early Childhood Testapi-265795386Încă nu există evaluări

- PLJ-8LED Manual Translation enDocument13 paginiPLJ-8LED Manual Translation enandrey100% (2)

- p2 - Guerrero Ch13Document40 paginip2 - Guerrero Ch13JerichoPedragosa88% (17)

- Popular Tools CatalogDocument24 paginiPopular Tools CatalogCarbide Processors IncÎncă nu există evaluări

- BWT Septron Line 31-61 Rev01!08!05-18 Opm enDocument56 paginiBWT Septron Line 31-61 Rev01!08!05-18 Opm enDavide Grioni100% (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Shell Omala S2 G150 DatasheetDocument3 paginiShell Omala S2 G150 Datasheetphankhoa83-1Încă nu există evaluări

- 2019 ASME Section V ChangesDocument61 pagini2019 ASME Section V Changesmanisami7036100% (4)

- Industrial Engineering and Quality Control MSBTEDocument5 paginiIndustrial Engineering and Quality Control MSBTEJaydip Jadhav100% (2)

- ME-mit Admission FormDocument1.057 paginiME-mit Admission FormBittu50% (2)

- 4th Summative Test Science 6Document5 pagini4th Summative Test Science 6ANNALIZA FIECASÎncă nu există evaluări

- GARCH Models: Structure, Statistical Inference and Financial ApplicationsDe la EverandGARCH Models: Structure, Statistical Inference and Financial ApplicationsEvaluare: 5 din 5 stele5/5 (1)

- STRUCTURED/ESSAY (100 Marks) : Page 2 of 10Document9 paginiSTRUCTURED/ESSAY (100 Marks) : Page 2 of 10Iskandar IbrahimÎncă nu există evaluări

- Sem Pendek QCDocument6 paginiSem Pendek QCIskandar IbrahimÎncă nu există evaluări

- Business Statistics L3 Past Paper Series 2 2011Document7 paginiBusiness Statistics L3 Past Paper Series 2 2011Haznetta HowellÎncă nu există evaluări

- T.E. (Production S/W) (Semester II) Examination, 2009 Process Planning and Industrial StatisticsDocument54 paginiT.E. (Production S/W) (Semester II) Examination, 2009 Process Planning and Industrial StatisticsShahzeb NusratÎncă nu există evaluări

- Emg 3212 Metrology Exam Draft[1]Document4 paginiEmg 3212 Metrology Exam Draft[1]kiokocurtisÎncă nu există evaluări

- Measuring Quality Data and Statistical Process Control ChartsDocument5 paginiMeasuring Quality Data and Statistical Process Control ChartsIskandar Ibrahim100% (1)

- rr312002 Metrology and Quality ControlDocument8 paginirr312002 Metrology and Quality ControlSRINIVASA RAO GANTAÎncă nu există evaluări

- Advanced Manufacturing ProcessDocument2 paginiAdvanced Manufacturing Processmukesh3021Încă nu există evaluări

- 10me848qpset Design For Manufacturing and AssemblyDocument13 pagini10me848qpset Design For Manufacturing and AssemblyDr. N. S. Sriram100% (1)

- Manufacturing Final Exam GuideDocument17 paginiManufacturing Final Exam GuideShah MalikÎncă nu există evaluări

- Bda 30502 Sem 2 1213Document5 paginiBda 30502 Sem 2 1213Iskandar BellÎncă nu există evaluări

- Quality Engineering Statistical ToolsDocument16 paginiQuality Engineering Statistical ToolsNilankan KumarÎncă nu există evaluări

- Mech3002y 3 2007 2 PDFDocument6 paginiMech3002y 3 2007 2 PDFKeshav GopaulÎncă nu există evaluări

- 11496-132239-Mqp - Metrology and Quality ControlDocument2 pagini11496-132239-Mqp - Metrology and Quality ControlRuby SmithÎncă nu există evaluări

- PR 2303Document4 paginiPR 2303Karthik Srinivas0% (1)

- Mech3002y 3 2010 2 PDFDocument5 paginiMech3002y 3 2010 2 PDFKeshav GopaulÎncă nu există evaluări

- 2017 Winter Question PaperDocument5 pagini2017 Winter Question PaperMahesh SelokarÎncă nu există evaluări

- Emg 3212 Metrology Supp[1]Document4 paginiEmg 3212 Metrology Supp[1]kiokocurtisÎncă nu există evaluări

- UHU033Document2 paginiUHU033Kshitij GulatiÎncă nu există evaluări

- CHT206-FDocument3 paginiCHT206-FAkshay A BijuÎncă nu există evaluări

- WWW - Manaresults.Co - In: Set No. 1Document4 paginiWWW - Manaresults.Co - In: Set No. 1Chanumolu DushyanthÎncă nu există evaluări

- Pages From Harris - Quantitative Chemical Analysis - 8th EditionDocument2 paginiPages From Harris - Quantitative Chemical Analysis - 8th EditionJorge LunaaÎncă nu există evaluări

- Set No. 1Document8 paginiSet No. 1ajay7892Încă nu există evaluări

- Final Exame of Statoistics PDFDocument9 paginiFinal Exame of Statoistics PDFandersonÎncă nu există evaluări

- BTME 2nd Year AssignmentDocument15 paginiBTME 2nd Year AssignmentshishunalÎncă nu există evaluări

- Examination,: Degree NoyemberDocument2 paginiExamination,: Degree NoyemberDeepak MisraÎncă nu există evaluări

- Metrology QPDocument3 paginiMetrology QPFaizur RahmanÎncă nu există evaluări

- r05320302 Metrology and Surface EngineeringDocument4 paginir05320302 Metrology and Surface EngineeringSRINIVASA RAO GANTAÎncă nu există evaluări

- University of Mauritius Faculty of EngineeringDocument4 paginiUniversity of Mauritius Faculty of EngineeringKeshav GopaulÎncă nu există evaluări

- 2023 June CHT206-EDocument3 pagini2023 June CHT206-EGouri K SÎncă nu există evaluări

- SQC Final Exam June 2010Document4 paginiSQC Final Exam June 2010endu wesenÎncă nu există evaluări

- Bit2201 Bbit308 Simulation and ModelingDocument3 paginiBit2201 Bbit308 Simulation and ModelingMark Joe AburÎncă nu există evaluări

- M&SE Dec 2011Document4 paginiM&SE Dec 2011simalaraviÎncă nu există evaluări

- ME2Document478 paginiME2आकाश संगीता प्रकाश पवारÎncă nu există evaluări

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 paginiE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RÎncă nu există evaluări

- Metrology and Surface Engineering Questions and AnswersDocument4 paginiMetrology and Surface Engineering Questions and AnswersSurendra Babu Koganti0% (1)

- STASTICS PP 1Document3 paginiSTASTICS PP 1Getrude HioÎncă nu există evaluări

- 141210-141901-Mechanical Measurement and MetrologyDocument2 pagini141210-141901-Mechanical Measurement and Metrologysameer_m_daniÎncă nu există evaluări

- HND 1 Electrical Measurement and Control EEI 311 2016Document2 paginiHND 1 Electrical Measurement and Control EEI 311 2016iskeel75% (4)

- Manufacturing Process 2 Jan 2014Document2 paginiManufacturing Process 2 Jan 2014Prasad C MÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityVraj ShahÎncă nu există evaluări

- 2019 Winter Question Paper (Msbte Study Resources)Document4 pagini2019 Winter Question Paper (Msbte Study Resources)1042 Arun NagariyaÎncă nu există evaluări

- Universiti Teknologi Malaysia Fakulti Kejuruteraan Mekanikal Final Examination Semester Ii, Session 2008/2009Document14 paginiUniversiti Teknologi Malaysia Fakulti Kejuruteraan Mekanikal Final Examination Semester Ii, Session 2008/2009Shah MalikÎncă nu există evaluări

- Metrologyand Surface EngineeringDocument4 paginiMetrologyand Surface EngineeringshivkrnÎncă nu există evaluări

- 22342 2023 Winter Question Paper[Msbte Study Resources]Document4 pagini22342 2023 Winter Question Paper[Msbte Study Resources]Rohan ChavanÎncă nu există evaluări

- Metalwork: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 paginiMetalwork: Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Încă nu există evaluări

- Measuring tools and techniquesDocument4 paginiMeasuring tools and techniquesbathinsreenivasÎncă nu există evaluări

- Exercise 1 Sem 2 201718Document6 paginiExercise 1 Sem 2 201718Ahmad MunawirÎncă nu există evaluări

- Tema1 EjerciciosDocument21 paginiTema1 EjerciciosJust SomebodyÎncă nu există evaluări

- University of Mauritius 2011 Manufacturing Processes & Metrology ExamDocument5 paginiUniversity of Mauritius 2011 Manufacturing Processes & Metrology ExamKeshav GopaulÎncă nu există evaluări

- An Introduction to Discrete-Valued Time SeriesDe la EverandAn Introduction to Discrete-Valued Time SeriesÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghÎncă nu există evaluări

- Attainable Region Theory: An Introduction to Choosing an Optimal ReactorDe la EverandAttainable Region Theory: An Introduction to Choosing an Optimal ReactorÎncă nu există evaluări

- 3D Printer Brochure OdysseyX2Document2 pagini3D Printer Brochure OdysseyX2Iskandar IbrahimÎncă nu există evaluări

- End of Cahpter 1Document2 paginiEnd of Cahpter 1Kelvin YipÎncă nu există evaluări

- (") (B) I. Ii. Iii.: Ffit. (.QDocument1 pagină(") (B) I. Ii. Iii.: Ffit. (.QIskandar IbrahimÎncă nu există evaluări

- Huraikan (2) Kos Kualiti. Quality Cosfs (4Document1 paginăHuraikan (2) Kos Kualiti. Quality Cosfs (4Iskandar IbrahimÎncă nu există evaluări

- Measuring Quality Data and Statistical Process Control ChartsDocument5 paginiMeasuring Quality Data and Statistical Process Control ChartsIskandar Ibrahim100% (1)

- Cover Page 1Document1 paginăCover Page 1Iskandar IbrahimÎncă nu există evaluări

- Department of Mechanical EngineeringDocument1 paginăDepartment of Mechanical EngineeringIskandar IbrahimÎncă nu există evaluări

- Ary RyeDocument4 paginiAry RyeIskandar IbrahimÎncă nu există evaluări

- 10CV54 Unit 05 PDFDocument21 pagini10CV54 Unit 05 PDFvinodh159Încă nu există evaluări

- EGMM - Training Partner MOUDocument32 paginiEGMM - Training Partner MOUShaik HussainÎncă nu există evaluări

- After EffectsDocument56 paginiAfter EffectsRodrigo ArgentoÎncă nu există evaluări

- 114 ArDocument254 pagini114 ArJothishÎncă nu există evaluări

- UK Commutator Maintenance CatalogueDocument9 paginiUK Commutator Maintenance CatalogueCarlosÎncă nu există evaluări

- C++ Programmierung (Benjamin Buch, Wikibooks - Org)Document257 paginiC++ Programmierung (Benjamin Buch, Wikibooks - Org)stefano rossiÎncă nu există evaluări

- Heads of Departments - 13102021Document2 paginiHeads of Departments - 13102021Indian LawyerÎncă nu există evaluări

- A Development of The Test For Mathematical Creative Problem Solving AbilityDocument27 paginiA Development of The Test For Mathematical Creative Problem Solving AbilityanwarÎncă nu există evaluări

- Pic Attack1Document13 paginiPic Attack1celiaescaÎncă nu există evaluări

- Illegal FishingDocument1 paginăIllegal FishingDita DwynÎncă nu există evaluări

- Raptor SQ2804 Users Manual English v2.12Document68 paginiRaptor SQ2804 Users Manual English v2.12JaimeÎncă nu există evaluări

- Homer Christensen ResumeDocument4 paginiHomer Christensen ResumeR. N. Homer Christensen - Inish Icaro KiÎncă nu există evaluări

- Data Validation and Verification - BBC BitsizeDocument56 paginiData Validation and Verification - BBC BitsizeluciferothegoatÎncă nu există evaluări

- Yamaha RX-A3000 - V3067Document197 paginiYamaha RX-A3000 - V3067jaysonÎncă nu există evaluări

- Offshore Wind Turbine 6mw Robust Simple EfficientDocument4 paginiOffshore Wind Turbine 6mw Robust Simple EfficientCristian Jhair PerezÎncă nu există evaluări

- Roll Covering Letter LathiaDocument6 paginiRoll Covering Letter LathiaPankaj PandeyÎncă nu există evaluări

- APLI - Annual Report - 2016Document122 paginiAPLI - Annual Report - 2016tugas noviaindraÎncă nu există evaluări

- Imp RssDocument8 paginiImp RssPriya SharmaÎncă nu există evaluări

- EasyLogic PM2000 Series - METSEPM2130Document4 paginiEasyLogic PM2000 Series - METSEPM2130ٍJordan SportÎncă nu există evaluări

- Speech TravellingDocument4 paginiSpeech Travellingshafidah ZainiÎncă nu există evaluări

![Emg 3212 Metrology Exam Draft[1]](https://imgv2-2-f.scribdassets.com/img/document/722472828/149x198/ddbb07e1f3/1712947938?v=1)

![Emg 3212 Metrology Supp[1]](https://imgv2-1-f.scribdassets.com/img/document/722472804/149x198/2805680717/1712947934?v=1)

![22342 2023 Winter Question Paper[Msbte Study Resources]](https://imgv2-2-f.scribdassets.com/img/document/721031440/149x198/192855f07d/1712548606?v=1)