Documente Academic

Documente Profesional

Documente Cultură

Ammonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGH

Încărcat de

R Kibik Sht100%(1)100% au considerat acest document util (1 vot)

105 vizualizări22 paginiwdgfvbcnas lkjlidfjs lfjdsjf ldsjf lskdhshgjklsh fweoiuufdispojlkxzc zxc sclksjflkhdfgiueir djsdlkfjlksdjflk v jioeodi csdfkjcv esn d vhoiudsfn xcv xcv cxvfdxv dfg fdbvcbrth6u ko s gh fgh fghgfhsg g f fg gf

Titlu original

Ammonia Slide Blok Diagram

cv nghjyujkm bnmc ndfhg nvbnbmgh

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentwdgfvbcnas lkjlidfjs lfjdsjf ldsjf lskdhshgjklsh fweoiuufdispojlkxzc zxc sclksjflkhdfgiueir djsdlkfjlksdjflk v jioeodi csdfkjcv esn d vhoiudsfn xcv xcv cxvfdxv dfg fdbvcbrth6u ko s gh fgh fghgfhsg g f fg gf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

105 vizualizări22 paginiAmmonia Slide Blok Diagram CV Nghjyujkm BNMC NDFHG NVBNBMGH

Încărcat de

R Kibik Shtwdgfvbcnas lkjlidfjs lfjdsjf ldsjf lskdhshgjklsh fweoiuufdispojlkxzc zxc sclksjflkhdfgiueir djsdlkfjlksdjflk v jioeodi csdfkjcv esn d vhoiudsfn xcv xcv cxvfdxv dfg fdbvcbrth6u ko s gh fgh fghgfhsg g f fg gf

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 22

Ammonia

Basic Flowsheet Elements

Chemistry of the Ammonia Process

Simplified Block Diagram of a Typical

1000 t/d Ammonia Plant

Simplified Block Diagram of a 2000

MTPD Methanol Flowsheet

Methanol

Purification

Reforming

Compression Distillation

Synthesis

Steam Raising

Feedstock

(CH )

4

Water

VHT-S103

20 m

VSG-EZ200

VSG-Z101

40 m

VSG-Z101

40 m

VSG-A101

200 m

Simplified Block Diagram of a

Hydrogen Flowsheet

Desulfurization

Primary Reforming

High Temperature

CO Shift

VHT-S101

VSG-

Cl101

VSG-

EZ200

VSG-

Z101

VSG-

F101

PSA

etc

Steam Natural Gas Feed

Hydrogen

Simplified Flowsheet for a Typical

Ammonia Plant

Natural

Gas

Steam

superheater

Air

Steam

30

bar

Steam

Steam

raising

350 C

200 C

Heat

Recovery

Steam

raising

Cooling

Cooling

Reboiler

CO

Cooling

Preheater

Heat

Recovery

Steam

Boiler

Process

Condensate

Quench

Quench

Liquid Ammonia

H

Hydrodesulphuriser Primary

Reformer

Secondary

Reformer

High

Temperature

Shift

Low

Temperature

Shift

Ammonia Synthesis Methanator

Carbon Dioxide

Purge Gas

Cooling

400 C

o

390 C

o

2

790 C

o

550 C

o

1000 C

o

o

420 C

o

150 C

o

400 C

o

470 C

o

o

220 C

o

290 C

o

330 C

o

2

CO Removal

2

220 bar

Refrigeration

Condensate

Cooling

Ammonia

Catchpot

Modern Conventional Flowsheets

Main process steps are the same for all plants

Main differences in equipment design

Uhde

Top fired reformer

Proprietary exit header design

Secondary reformer has a riser

HP loop with radial flow converter

Modern Conventional Flowsheets

HKBR

Primary reformer with manifold/riser

Haldor Topse

Side fired reformer

Radial flow converter

S-200

S-250

Other Flowsheet Options

Braun Purifier

ICI AMV

ICI LCA

Dual Pressure Uhde Process

HKBR KAAP (with/without purifier)

Linde LAC

H2 Recovery is used on most

modern plants

Braun Purifier Process

Primary reformer exit temperature is 700C

Excess air is added to the secondary reformer

Methane slip typically around 2-2.5 mol %

Excess nitrogen (and methane) cryogenically

removed downstream of methanator

Also removes water - ammonia synthesis catalyst

poison

Improved synthesis lives

Can reduce SC ratio to 2.7-3.0

Small primary

Braun Purifier Process

Cold Box

Purified Syn Gas

Waste Gas

Raw Syn Gas

Feed Effluent Exchangers

ICI AMV Process

As with Braun - utilizes excess air to secondary

Excess nitrogen is passed to the loop

Loop runs at low pressure (80-110 bara)

Use ICI LP Catalyst (74- Series)

Uses a saturator to saturate feed gas

This raises around 50% of the required steam

Can use SC ratio of 2.8

H

2

Recovery in loop at loop pressure

ICI LCA Process

Aim at small plant capacities (500 mtpd)

Uses the GHR-Secondary concept

Excess air is utilized to close heat balance

Utilizes an ITS rather than HTS and LTS

A saturator for steam raising

A PSA system to remove the CO

2

and excess N

2

A low pressure loop (80 bara)

A tube cooled converter or Casale converter

No longer actively marketing

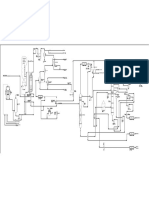

Dual Pressure Uhde Process

PGR Unit

Make upgas

fromfrontend

H

2

O

Ammonia from once throughconversion

HP-

steam

C.W.

NH

3

NH

3

C.W.

C.W.

C.W.

HP-

steam

NH

3

NH

3

Off-Gas

Ammonia

from

HP loop

HP

casing

LP

casing

First

ammonia

converter

Second

ammonia

converter

Once

through

ammonia

converter

HP-

steam

Note: Molecular

Sievesnot shown

Dual Pressure Uhde Process

Benefits of such a scheme realised at 3,000

mtpd +

Although this is large capacity - all equipment is

proven

Note the low pressure converter between stages

of synthesis gas machine

Makes machine smaller

Makes loop pipework 24

Uses Comp. J catalyst

HKBR Purifier and KAAP

Primary

Reformer

Secondary

Reformer

Shift &

CO

2

Removal

Purifier

Compression KAAP

Methn

Dryers

Recycle Purge

To Fuel

Feed

Linde LAC

Key features are

No secondary reformer

Nitrogen is generated cryogenically and

added after a PSA unit

No HTS/LTS - only Isothermal (ITS) shift

No methanation

Linde LAC

Desulfurization

Primary Reformer

Isothermal Shift

PSA

Nitrogen Unit

Ammonia Synthesis

Other Flowsheet Options

Use Gas Turbine to drive process air

compressor

Can use effluent as combustion air

Has 16-17% O

2

and is at 500C

Braun plants

Install pre reformer

HT Retrofit

Many other reasons

Remove heat from duct

Uprate plant

Other Flowsheet Options

Synthesis Gas driers

Reduces H

2

O in syn gas

H

2

O is a poison

Activity increases

Ammonia Wash

As per Syn Gas driers

Booster converters

Drop load on loop and allow overall output

increase

Quenches in Shifts

Ammonia Flowsheet Data Analysis

Tool - VULCAN CERES

Looks at all catalytic unit operations

Highlights potential issues/in-correct data

items

Functionality to address flowsheet options

Kellogg risers

Differential flowsheet conditions (Braun)

Use as a basis for

Predictions of future performance

Predictions of new catalyst options

Uprates

S-ar putea să vă placă și

- US Navy Course NAVEDTRA 14009 - Aviation Electrician's Mate 3 & 2Document452 paginiUS Navy Course NAVEDTRA 14009 - Aviation Electrician's Mate 3 & 2Georges100% (3)

- Calculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Document11 paginiCalculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Malouk CheniouniÎncă nu există evaluări

- Annex 1 - Hystat-10 IndoorDocument15 paginiAnnex 1 - Hystat-10 Indoorc108Încă nu există evaluări

- TEWI AnalysisDocument63 paginiTEWI Analysismirali74Încă nu există evaluări

- The Uhde Ammonia ProcessesDocument2 paginiThe Uhde Ammonia ProcessesMohamed R BeialyÎncă nu există evaluări

- Auto Thermal Reactor:: Secondary ReformerDocument6 paginiAuto Thermal Reactor:: Secondary ReformerAtif MehfoozÎncă nu există evaluări

- Ammonia Plant: Kribhco Shyam Fertilisers LTDDocument51 paginiAmmonia Plant: Kribhco Shyam Fertilisers LTDSabeeh Faruqui100% (1)

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationDe la EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosÎncă nu există evaluări

- Natural Gas Processing from Midstream to DownstreamDe la EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirÎncă nu există evaluări

- Magnesium HydrideDocument16 paginiMagnesium Hydridefraniq2007Încă nu există evaluări

- Large Scale Industrial Ammonia Cracking PlantDocument4 paginiLarge Scale Industrial Ammonia Cracking PlantZ AÎncă nu există evaluări

- Electric Heaters For Safe Startup ofDocument9 paginiElectric Heaters For Safe Startup ofSteve WanÎncă nu există evaluări

- 5 L1 Aspen TutorialDocument28 pagini5 L1 Aspen TutorialJustin DeVitoÎncă nu există evaluări

- White Paper Blue Ammonia Fueling The Future Today 1705324080Document18 paginiWhite Paper Blue Ammonia Fueling The Future Today 1705324080Muhammad IlyasÎncă nu există evaluări

- Cooling Tower Lewis FactorDocument6 paginiCooling Tower Lewis Factorshivajireturns100% (1)

- Handling HydrogenDocument51 paginiHandling HydrogenShabin Shabi100% (1)

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDocument1 paginăBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaÎncă nu există evaluări

- Uses and Applications of AmmoniaDocument5 paginiUses and Applications of AmmoniaSohail Asghar100% (2)

- Pressure Relief Valves Transcritical Co2Document2 paginiPressure Relief Valves Transcritical Co2Edita SzuketiováÎncă nu există evaluări

- PSA O2 Generator ReportDocument36 paginiPSA O2 Generator ReportPrasoon TaylorÎncă nu există evaluări

- Ben FieldDocument10 paginiBen FieldashmitharajaÎncă nu există evaluări

- MSDS Ar-301 GB CLP enDocument11 paginiMSDS Ar-301 GB CLP enA RÎncă nu există evaluări

- Liquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessDocument8 paginiLiquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessHaru MasaÎncă nu există evaluări

- O2 PSA Design NotesDocument3 paginiO2 PSA Design NotesTushar AgarwalÎncă nu există evaluări

- Simulation of Ammonia Production From Synthesis GaDocument12 paginiSimulation of Ammonia Production From Synthesis Gasagar dasguptaÎncă nu există evaluări

- JAQUET Greenline EDocument12 paginiJAQUET Greenline Eseriousguy2Încă nu există evaluări

- Hyoffwind Power To Gas End ReportDocument68 paginiHyoffwind Power To Gas End Reportapi-267204600Încă nu există evaluări

- Reciprocating CompressorsDocument5 paginiReciprocating CompressorsthirumalaiÎncă nu există evaluări

- Xebec Hydrogen BrochureDocument24 paginiXebec Hydrogen BrochureJoshÎncă nu există evaluări

- Coal ChemicalDocument71 paginiCoal ChemicalKiran KumarÎncă nu există evaluări

- PDF Refrigeration Compressor Driver SelectionDocument27 paginiPDF Refrigeration Compressor Driver SelectionDjamel EeddinÎncă nu există evaluări

- Trim Heater PDFDocument2 paginiTrim Heater PDFsaadashfaq100% (1)

- Oxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery UnitDocument22 paginiOxy Enrich Process For Capacity Enhancement of Claus Based Sulfur Recovery Unitsara25dec689288Încă nu există evaluări

- Equilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DDocument5 paginiEquilibria in The Ammonium Carbamate Urea-Water System: K. G. Clark, L. C. DjcortezcÎncă nu există evaluări

- Igcc UnitsDocument40 paginiIgcc UnitsEverton CollingÎncă nu există evaluări

- Main Combustion ChamberDocument31 paginiMain Combustion Chambershaliq28Încă nu există evaluări

- Pipephase 9.1: User's GuideDocument104 paginiPipephase 9.1: User's GuideGabi AraujoÎncă nu există evaluări

- KSFL ReportDocument56 paginiKSFL ReportAbhishek KumarÎncă nu există evaluări

- PH Measurement in Tail Gas Clean-Up: Petroleum Refining IndustryDocument2 paginiPH Measurement in Tail Gas Clean-Up: Petroleum Refining IndustryachillesntroyÎncă nu există evaluări

- Guidelines For Diesel Storage and TransportDocument11 paginiGuidelines For Diesel Storage and TransportErwinApriandiÎncă nu există evaluări

- Tech Memo - y FactorDocument4 paginiTech Memo - y FactorsumitrochakrabortiÎncă nu există evaluări

- Ammonia Based DesulferizationDocument36 paginiAmmonia Based Desulferizationlibid_rajÎncă nu există evaluări

- Process Design ParametersDocument6 paginiProcess Design ParametersDeden SobirinÎncă nu există evaluări

- 12Document16 pagini12Anonymous kBjvdERRQÎncă nu există evaluări

- HYSYS For Ammonia Plants Using Johnson Matthey Catalysts TechnologyDocument1 paginăHYSYS For Ammonia Plants Using Johnson Matthey Catalysts TechnologyAhmed Ali0% (2)

- Converting Mass Flow RateDocument3 paginiConverting Mass Flow RateAgung PriambodhoÎncă nu există evaluări

- VmgsimDocument65 paginiVmgsimObatarhe Ogra100% (1)

- 6 Types of Hydrogen ElectrolyzersDocument26 pagini6 Types of Hydrogen ElectrolyzersVishnuVarthan ImayavarambanÎncă nu există evaluări

- Design and Application of Ammonia Heat PumpDocument8 paginiDesign and Application of Ammonia Heat PumptasysatÎncă nu există evaluări

- Dynamic Energy and Mass Balance Model For An Industrial Alkaline Water Electrolyzer Plant ProcessDocument18 paginiDynamic Energy and Mass Balance Model For An Industrial Alkaline Water Electrolyzer Plant ProcessLucas Vander MeyÎncă nu există evaluări

- Predicting Dewpoints of Acid GasesDocument6 paginiPredicting Dewpoints of Acid GasesShreyasGadkariÎncă nu există evaluări

- Amine Sweetening With DEADocument14 paginiAmine Sweetening With DEARoza SavitriÎncă nu există evaluări

- Kres KBRDocument33 paginiKres KBRrenitadyahÎncă nu există evaluări

- The Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEODocument0 paginiThe Theory and Practice of Steam Reforming: By: Gerard B. Hawkins Managing Director, CEOBalaji RamanÎncă nu există evaluări

- P&id HydrocrackerDocument1 paginăP&id HydrocrackerchintanÎncă nu există evaluări

- RG Integrally Geared Compressors PDFDocument6 paginiRG Integrally Geared Compressors PDFJaswindersingh BhatiaÎncă nu există evaluări

- Cryogenic Air Separation UnitDocument13 paginiCryogenic Air Separation UnitMehran IsgandarliÎncă nu există evaluări

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)De la EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)Încă nu există evaluări

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectDe la EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectÎncă nu există evaluări

- Soft Drink/ Soda ProductionDocument20 paginiSoft Drink/ Soda ProductionD.W.W.Sewwandi100% (1)

- Algae Into AlkanesDocument230 paginiAlgae Into AlkanesFoong Shiuh HaurÎncă nu există evaluări

- Submerged Arc FurnaceDocument11 paginiSubmerged Arc FurnaceArooshbabu BabuÎncă nu există evaluări

- Combustion of LPG 1710831517Document75 paginiCombustion of LPG 1710831517Safwan MohammedÎncă nu există evaluări

- MSDS Suganate 160Document3 paginiMSDS Suganate 160mndmatt100% (2)

- Respiratory NCLEX Practice Test Part 1: Guillain-Barré SyndromeDocument20 paginiRespiratory NCLEX Practice Test Part 1: Guillain-Barré SyndromeHasan A AsFour100% (2)

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsDocument8 paginiEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaÎncă nu există evaluări

- 4 Toc Special Applications 18aDocument19 pagini4 Toc Special Applications 18aAnonymous 1oWzM3Încă nu există evaluări

- DNA Affirmative - MSDI 2015Document146 paginiDNA Affirmative - MSDI 2015Michael TangÎncă nu există evaluări

- Microcirculation Monitoring - LOCAL GhalebDocument46 paginiMicrocirculation Monitoring - LOCAL GhalebGHALEB A. AlmekhlafiÎncă nu există evaluări

- AQIS Methyl Bromide Fumigation StandardDocument61 paginiAQIS Methyl Bromide Fumigation StandardMiguel CornejoÎncă nu există evaluări

- Refrigeração GUIDELINESDocument40 paginiRefrigeração GUIDELINESHyan GontijoÎncă nu există evaluări

- DlcoDocument49 paginiDlcoCristina RaduleaÎncă nu există evaluări

- Chapter - 8 - Chemical - Reactions - and - Equations 2Document13 paginiChapter - 8 - Chemical - Reactions - and - Equations 2b4398385Încă nu există evaluări

- Condensate Part 1 NotesDocument46 paginiCondensate Part 1 NotesAtifÎncă nu există evaluări

- MEDIA 8468 Grade+9+Sample+Essays WatermarkDocument18 paginiMEDIA 8468 Grade+9+Sample+Essays Watermarkleen mortadaÎncă nu există evaluări

- Factors Affecting The Production of Biomass by A NDocument12 paginiFactors Affecting The Production of Biomass by A Ndhanalakshmi k sÎncă nu există evaluări

- Answers To Questions About PaperDocument21 paginiAnswers To Questions About PaperArdita rizki FauziÎncă nu există evaluări

- Data Sheet GCEM40 SeriesDocument6 paginiData Sheet GCEM40 SerieskaicyemÎncă nu există evaluări

- Arneg CO2 Technologies - TechnicalkDocument41 paginiArneg CO2 Technologies - TechnicalkArlindo CrispimÎncă nu există evaluări

- F2 IS Exam1 (04-05)Document9 paginiF2 IS Exam1 (04-05)羅天佑Încă nu există evaluări

- Photosynthesis, Food Chains and CyclesDocument6 paginiPhotosynthesis, Food Chains and CyclesOsmany MadrigalÎncă nu există evaluări

- Mobility of Included Soda in SodaliteDocument4 paginiMobility of Included Soda in SodaliteRogerio CannoniÎncă nu există evaluări

- Research in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDocument13 paginiResearch in International Business and Finance: Huizheng Liu, Zhe Zong, Kate Hynes, Karolien de Bruyne TDessy ParamitaÎncă nu există evaluări

- Dry Ice Pelletizer A30P D3Document4 paginiDry Ice Pelletizer A30P D3Zoran TatarevicÎncă nu există evaluări

- Exploring The Future Role of Hydrogen in Power Generation White Paper Burns McDonnell 22115Document6 paginiExploring The Future Role of Hydrogen in Power Generation White Paper Burns McDonnell 22115Vikas SareenÎncă nu există evaluări

- L4-Basic Components and BaselineDocument35 paginiL4-Basic Components and BaselineHimank SoniÎncă nu există evaluări

- Viper (E) 2 Flavor, Viper (E) 3 Flavor & Viper (E) 4 Flavor: Installation ManualDocument45 paginiViper (E) 2 Flavor, Viper (E) 3 Flavor & Viper (E) 4 Flavor: Installation ManualAndrewÎncă nu există evaluări

- Interior Design and LandscapeDocument37 paginiInterior Design and LandscapeYoha PriyaÎncă nu există evaluări