Documente Academic

Documente Profesional

Documente Cultură

HPLC Quantitative Analysis Method For The Determination of A - Mangostin in Mangosteen Fruit Rind Extract

Încărcat de

Yunus HidayatDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HPLC Quantitative Analysis Method For The Determination of A - Mangostin in Mangosteen Fruit Rind Extract

Încărcat de

Yunus HidayatDrepturi de autor:

Formate disponibile

www.thaiagj.

org

Thai Journal of Agricultural Science 2009, 42(1): 7-12

HPLC Quantitative Analysis Method for the Determination of -Mangostin in Mangosteen Fruit Rind Extract

W. Pothitirat and W. Gritsanapan* Department of Pharmacognosy, Faculty of Pharmacy, Mahidol University Bangkok, 10400 Thailand *Corresponding author. Email: pywgs@mahidol.ac.th

Abstract The fruit rind extract of mangosteen (Garcinia mangostana Linn.) of which a major active component is -mangostin, has been popularly used in food supplements and herbal cosmetic preparations. -Mangostin is used as a marker quantitative analysis and standardization of the raw materials and preparation from this plant. The precise method for analysis of plant constituents is normally a reverse-phase high performance liquid chromatographic (RP-HPLC). The aims of this study were to develop and validate a RP-HPLC method for determination of -mangostin content in the extracts of mangosteen fruit rind. Chromatographic separation was carried out on a Hypersil BDS C-18 column (4.6 x 250 mm, 5 m) at room temperature using a gradient mobile phase consisting of 70-80 % acetonitrile in 0.1 %v/v ortho phosphoric acid at the flow rate of 1 mL min-1 with a UV detection at 320 nm. The method was validated for linearity, precision, accuracy, limit of detection (LOD), and limit of quantitation (LOQ). The linearity of the proposed method was found in the range of 10200 g mL-1 with regression coefficient 0.9999. Intraday and interday precision studies showed the relative standard deviation less than 2 %. Accuracy of the method was determined by a recovery study conducted at 3 different levels, and the average recovery was 100.01 %. The LOD and LOQ were 0.06 and 0.17 g mL-1, respectively. Two samples of mangosteen fruit rind were separately extracted and analyzed using validated HPLC method. The contents of -mangostin in the crude extracts and dried powder were within the ranges of 8.36 10.04 and 1.84 2.47 %w/w, respectively. This developed HPLC method was proven to be precise, specific, sensitive, and accurate for routine quality assessment of raw material of mangosteen fruit rind, its extract, and products. Keywords: Garcinia mangostana, high performance liquid chromatography, mangostin, quality control, validation method

Introduction At present, medicinal plants are employed throughout the industrialized and developing world as home remedies and ingredients for the pharmaceutical products. The lack of standardization and quality control for medicinal plants is still being problem. It seems to be necessary to determine the phytochemical constituents of herbal products in order to ensure the reliability and repeatability of pharmacological

and clinical research to understand their bioactivities and possible side effects of active compounds and to enhance product quality control (Liang et al., 2004). For quality control of herbal products, high performance liquid chromatography (HPLC) is a popular method for the analysis of herbal medicines because it is accurate, precise and not limited by the volatility or stability of the sample compounds (Jandera et al., 2005; Holcapek et al., 2005; Klejdus et al., 2007; Hellstrm and Mattila, 2008; Lee et al., 2008).

W. Pothitirat and W. Gritsanapan

Thai Journal of Agricultural Science

Mangosteen or Garcinia mangostana Linn. belongs to the family Guttiferae and it is widely cultivated throughout Southeast Asian countries, especially in eastern and southern parts of Thailand. The fruit rind of this plant has long been used as a traditional medicine for treatment of abdominal pain, diarrhea, dysentery, infected wound, suppuration, and chronic ulcer (Mahabusarakam et al., 1987; Martin, 1980; Morton, 1987). It has been shown to contain a variety of phenolic compounds such as condensed tannins, anthocyanins, xanthones and their derivatives (Fu et al., 2007; Chin et al., 2008; Maisuthisakul et al., 2007). Several studies have reported that xanthones particularly mangostin (Figure 1), which is a major xanthone, exhibits antioxidant, antitumoral, antiinflammatory, anti-allergic, antibacterial and antifungal activities (Jung et al., 2006; Chen et al., 2008; Chomnawang et al., 2007; Chomnawang et al., 2005; Gopalakrishnan et al., 1997; Chairungsrilerd et al., 1996; Iinuma et al., 1996; Ee et al., 2008; Nabandith et al., 2004). Due to its pharmacological activities, it is popularly applied to herbal cosmetics and pharmaceutical products. However, there is limited information for quality and quantity determination of -mangostin in mangosteen extract. So, analytical methods play an important role in the quality control of its raw materials and products. From our previous study, we reported quantitative analytical methods of mangostin by UV-spectrophotometry and TLCdensitometry (Pothitirat and Gritsanapan, 2008a; Pothitirat and Gritsanapan, 2008b). These two methods are carried low cost in terms of solvents, number of samples and time consuming, but less in accuracy and precision. Therefore, the aims of this study were to develop and validate HPLC method for quantitative analysis of -mangostin content in the mangosteen fruit rind extracts. HPLC fingerprints of the extract were also performed. Materials and Methods Chemicals and Reagents -Mangostin was purchased from Chroma Dex Inc. (Santa Ana, CA). The other chemicals and solvents used in this experiment were analytical grade which were purchased from Labscan Asia (Thailand) and M&B Chemical Laboratory (England), except for

Figure 1 Chemical structure of -mangostin.

95 % ethanol which was obtained from the Excise Department, Bangkok, Thailand. Plant Materials The ripe fruits of G. mangostana were purchased from two local markets in Bangkok, Thailand in June 2006. The samples were identified by Dr. Wandee Gritsanapan, Faculty of Pharmacy, Mahidol University. The voucher specimens (WGM0614 and WGM0615) were deposited at the Department of Pharmacognosy, Faculty of Pharmacy, Mahidol University, Bangkok, Thailand. The fruits were cleaned and the edible aril part was removed. The fruit rinds were cut into small pieces and dried in a hot oven at 50 C for 72 h. The dried samples were ground into powder, passed through a sieve (20 meshs). The samples were separately kept in air tight container and protected from light until used. Instrumentation and Chromatographic Condition HPLC method was performed on a Shimadzu SCL-10A HPLC system, equipped with a model LC-10AD pump, UV-vis detector SPD-10A, Rheodyne injector fitted with a 20 L loop and auto injector SIL-10A. A Hypersil BDS C-18 column (4.6 250 mm, 5 m size) with a C-18 guard column was used. The elution was carried out with gradient solvent systems with a flow rate of 1 mL min-1 at ambient temperature (25-28C). The mobile phase was consisted of 0.1 %v/v ortho phosphoric acid (solvent A) and acetonitrile (solvent B). The mobile phase was prepared daily,

Vol. 42, No.1, 2009

HPLC analysis of -mangostin in mangosteen

filtered through a 0.45 m and sonicated before use. Total running time was 37 min and the gradient programme was as follows: 70 % B for 015 min, 70 % B to 75 % B for 3 min, 75 % B to 80 % B for 1 min, constant at 80 % B for 6 min, 80 % B to 70 % B for 1 min. There was 11 min of postrun for reconditioning. The sample injection volume was 10 L while the wavelength of the UV-vis detector was set at 320 nm. The compounds were quantified using CLASS VP software. Preparation of Standard Solutions A stock solution of -mangostin reference standard (purity 97 %) was prepared by dissolving an accurately weighed 10 mg of -mangostin in 10 mL of methanol in a volumetric flask. Various concentrations of the standard solution were diluted to obtain final concentrations at 200, 100, 50, 25, and 10 g mL-1 with methanol. Preparation of Sample Solutions Each sample (10 g) was separately placed into a thimble and was extracted with 400 mL of 95% ethanol in a soxhlet apparatus for 15 h with 5 cycles h-1. Each extract was filtered through a Whatman no. 1 filter paper by suction. The filtrate was concentrated under reduced pressured at 50C using a rotary vacuum evaporator. The final weight of the crude extract was weighed and calculated for the yield. The extraction of each sample was done in triplicate. Each dried extract (10 mg) was accurately weighed and transferred to a 10 mL volumetric flask. Methanol was added to volume (final concentration 1,000 g mL-1). Aliquot of the solution (2.5 mL) was diluted with methanol in a 10 mL volumetric flask to make a concentration of 250 g mL-1. Prior to analysis, the solutions were filtered through 0.45 m membrane filters. Quantitative Analysis of -Mangostin Content Determination of -mangostin content was carried out by HPLC under the same condition as the proposed method. -Mangostin content in the extract was calculated using its calibration curve with regarding to the dilution factor. The contents of -mangostin in the extract and the fruit rind were expressed as gram per 100 grams of the

extract and of the dried powder, respectively. Each determination was carried out in triplicate. Validation of the Method Validation of the analytical method was done according to the International Conference on Harmonization guideline (ICH, 1996). The method was validated for linearity, precision, accuracy, limit of detection (LOD) and limit of quantitation (LOQ). Linearity Linearity was determined by using -mangostin standard solution of 1000 g mL-1 in methanol. Ten to 200 g mL-1 of the standard solution was prepared (n = 3). The calibration graphs were obtained by plotting the peak area versus the concentration of the standard solutions. Precision The precision was determined by analyzing 10, 25, and 50 g mL-1 of standard solution of mangostin (n = 3) on the same day for intraday precision and on 3 different days for interday precision by the propose method. The precision was expressed as relative standard deviation (RSD). Accuracy The accuracy of the method was tested by performing recovery studies at 3 levels of mangostin reference standard added to the samples. Three different volumes (0.5, 1, and 1.5 mL) of the standard solution (containing 200 g mL-1 of mangostin in methanol) were added to the sample solution (150 g mL-1) and analyzed by the proposed HPLC method. The recovery and average recovery were calculated. Three determinations were performed for each concentration level. Limit of Detection (LOD) and Limit of Quantitation (LOQ) According to the International Conference on Harmonization of Technical Requirements for the Registration of Pharmaceuticals for Human Use recommendations, the approach based on SD of the response and the slope were used for determining the detection and quantitation limits.

10

W. Pothitirat and W. Gritsanapan

Thai Journal of Agricultural Science

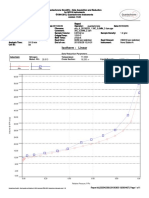

Results and Discussion HPLC method with gradient elution was developed for the quantification of -mangostin in G. mangostana fruit rind extracts. The mixture of 0.1 % ortho phosphoric acid and acetonitrile gave optimum chromatographic separation of mangostin with the other peaks in the extract (Figure 2). It was found that the resolution was very good (resolution value > 1.5). The wavelength at 320 nm was used for all measurements due to its maximum absorption. The method was validated for its linearity, precision, accuracy, LOD, and LOQ. The calibration graph for -mangostin was within the concentration range of 10 200 g mL-1, with a correlation coefficient (r2) of 0.9999 (Table 1). The interday and intraday precisions of -mangostin are presented in Table 2. The results showed acceptable precision of the method, with RSD values lower than 2%. The recovery at 3 different levels of mangostin was 105.10, 95.00, and 99.93 %, with an average of 100.01% (Table 3).These values indicate the accuracy of the method. The LOD and LOQ for -mangostin were found to be 0.06 and 0.17 g mL-1, respectively, which indicate a high sensitivity of the method (Table 1).

Table 1 Method validation parameters for the quantification of -mangostin by the proposed HPLC method. Parameters Linear range (g mL-1) Regression equation LOQ (g mL ) LOD (g mL )

1/

Results 10-200 y = 33674x - 7244.7

2 1/

Correlation coefficient (r )

-1 -1

0.9999 0.17 0.06

x is the concentration of -mangostin in g mL-1, y is the peak area at 320 nm

Table 2 Intraday and interday precision of mangostin determination by the proposed HPLC method. Concentration (g mL-1) 10 25 50 Intraday precision 1.97 0.61 1.21 Interday precision 0.77 1.65 1.63

(---------- % RSD---------)

Table 3 Recovery study of -mangostin by the proposed HPLC method. Serial no. Amount present in the extract 0.26 0.26 0.26 Average

1/

Amount added

Amount found1/

Recovery1/ (%) 105.10 1.21 95.00 1.81 99.93 1.51 100.01

(------------------------- g mL-1 -----------------------) 1 2 3 10 20 30 10.77 0.07 19.26 0.34 30.26 1.58

Expressed as mean standard deviation (SD; n = 3).

Figure 2 HPLC fingerprint of G. mangostana fruit rind extract.

Vol. 42, No.1, 2009

HPLC analysis of -mangostin in mangosteen

11

Table 4 Yield of crude extract and the content of -mangostin in the extracts and dried powder of G. mangostana fruit rinds by the proposed HPLC method. Yield of crude extract1/ (% w/w of dried powder) Local market A Local market B

1/

Sample

-Mangostin content1/ In dried powder 2.47 0.08 1.82 0.04 In extract 10.04 0.33 8.36 0.17 (--------------- % w/w-----------------)

24.41 0.21 22.46 0.95

Expressed as mean standard deviation (SD; n = 3).

-Mangostin content in the samples of G. mangostana fruit rind which obtained from different local markets in Bangkok during June 2006 determined by the developed HPLC method is given in Table 4. The contents of -mangostin in the ethanolic extracts of Sample A and Sample B were 10.04 0.33 and 8.36 0.17 % w/w, while in the dried powder were 2.47 0.08 and 1.82 0.04%w/w, respectively (Table 4). HPLC chromatograms of both extracts showed similar pattern with a major peak of -mangostin at retention time of 16.32 min (Figure 2). The identity of the peak of -mangostin in the sample chromatograms was confirmed by spiking with its standard and determination of retention time. Yodhnu et al. (2009) reported that the isocratic RP-HPLC method can be used for quantitative determination of -mangostin in the extract from G. mangostana. In our work, we used gradient RPHPLC which offers advantages over isocratic RPHPLC for separation a wide range of compounds with high resolution. Comparing with other analytical methods such as TLC-densitometric and UV- spectrophotometric methods, HPLC promotes higher precision, accuracy and sensitivity. Although a UV spectrophotometry is a rapid and economical method but it does not give information of each component of mangostins, i.e., -mangostin, while HPLC can be used for separation, identification and quantification of individual mangostin. TLCdensitometry is appropriate when a lot of samples are needed to be analyzed routinely, and not high accuracy is required.

Conclusions The proposed HPLC method promoted high precision, sensitivity and accuracy for quality control of raw materials of G. mangostana fruit rind and its extract. It should be useful for quantitative analysis of -mangostin content in the products derived from G. mangostana fruit rind extracts such as anti-acne mangosteen gel which is now carried out in our laboratory. -Mangostin is recommended for using as a marker for mangosteen analysis due to its majority and biological activities. This proposed method will be useful for quantitative analysis in standardization and quality assessment of G. mangostana fruit rind extracts for pharmaceutical and cosmetic uses. Acknowledgments This study is a part of a Ph.D. thesis of Mahidol University, Bangkok, Thailand and was granted by the University Research Fund. References

Chairungsrilerd, N., K. Furukawa, T. Ohta, S. Nozoe and Y. Ohizumi. 1996. Histaminergic and serotonergic receptor blocking substances from the medicinal plant Garcinia mangostana. Planta Med. 62: 471-472. Chen, L.G., L.L. Yang and C.C. Wang. 2008. Antiinflammatory activity of mangostins from Garcinia mangostana. Food Chem. Toxicol. 46: 688-693. Chin, Y.W., H.A. Jung, H. Chai, W.J. Keller and A.D. Kinghorn. 2008. Xanthones with quinone reductaseinducing activity from the fruits of Garcinia mangostana (Mangosteen). Phytochemistry 69: 754-758.

12

W. Pothitirat and W. Gritsanapan

Thai Journal of Agricultural Science

Chomnawang, M. T., S. Surassmo, V.S. Nukoolkarn and W. Gritsanapan. 2005. Antimicrobial effects of Thai medicinal plants against acne-inducing bacteria. J. Ethnopharmacol. 101: 330-3. Chomnawang, M. T., S. Surassmo, V.S. Nukoolkarn and W. Gritsanapan. 2007. Effect of Garcinia mangostana on inflammation caused by Propionibacterium acnes. Fitoterapia 78: 401-408. Ee, G.C., S. Daud, S.A. Izzaddin and M. Rahmani. 2008. Garcinia mangostana: a source of potential anti-cancer lead compounds against CEM-SS cell line. J. Asian Nat. Prod. Res. 10: 481-485. Fu, C., A.E.K. Loo, P.P. Chia and D. Huang. 2007. Oligomeric proanthocyanidins from mangosteen pericarps. J. Agric. Food Chem. 55: 7689-7694. Gopalakrishnan, G., B. Banumathi and G. Suresh. 1997. Evaluation of the antifungal activity of natural xanthones from Garcinia mangostana and their synthetic derivatives. J. Nat. Prod. 60: 519-524. Hellstrm, J.K. and P.H. Mattila. 2008. HPLC determination of extractable and unextractable proanthocyanidins in plant materials. J. Agric. Food Chem. 56: 7617-7624. Holcapek, M., M. Lsa, P. Jandera and N. Kabtov. 2005. Quantitation of triacylglycerols in plant oils using HPLC with APCI-MS, evaporative light-scattering, and UV detection. J. Sep. Sci. 28: 1315-1333. ICH Steering Committee. 1996. International Conference on Harmonization of Technical Requirements for the Registration of Pharmaceuticals for Human Use. Validation of analytical procedure: Methodology. Iinuma, M., H. Tosa, T. Tanaka, F. Asai, Y. Kobayashi, R. Shimano and K. Miyauchi. 1996. Antibacterial activity of xanthones from guttiferaeous plants against methicillin-resistant Staphylococcus aureus. J. Pharm. Pharmacol. 48: 861-865. Jandera, P., V. Skeifkov, L. Rehov, T. Hjek, L. Baldrinov, G. Skopov , V. Kellner, V and Horna, A. 2005. RP-HPLC analysis of phenolic compounds and flavonoids in beverages and plant extracts using a CoulArray detector. J. Sep. Sci. 28: 1005-1022. Jung, H.A., B.N. Su, W.J. Keller, R.G. Mehta and D. Kinghorn. 2006. Antioxidant xanthones from the pericarp of Garcinia mangostana (mangosteen). J. Agric. Food Chem. 54: 2077-2082.

Klejdus, B., J. Vacek, L. Benesov, J. Kopeck, O. Lapck and V. Kubn. 2007. Rapid-resolution HPLC with spectrometric detection for the determination and identification of isoflavones in soy preparations and plant extracts. Anal. Bioanal. Chem. 389: 2277-2285 Lee, S.T., D.R. Gardner, C.W. Chang, K.E. Panter and R.J. Molyneux . 2008. Separation and measurement of plant alkaloid enantiomers by RP-HPLC analysis of their Fmoc-Alanine analogs. Phytochem. Anal. 19: 395-402. Liang, Y.Z., P. Xie and K. Chan. 2004. Quality control of herbal medicines. J. Chromatogr. B. 812: 53-70. Mahabusarakam, W., P. Iriyachitra and W.C. Taylor. 1987. Chemical constituents of Garcinia mangostana. J. Nat. Prod. 50: 474-478. Maisuthisakul, P., M. Suttajit and R. Pongsawatmanit. 2007. Assessment of phenolic content and free radicalscavenging capacity of some Thai indigenous plants. Food Chem. 100: 1409-1418. Martin, F.W. 1980. Durian and mangosteen, pp. 407414. In S. Nagy and D.S. Shaw, eds., Tropical and Subtropical Fruits: Composition, Properties and Uses. Morton, J. 1987. Mangosteen: Garcinia mangostana L., pp. 301-304. In F. Julia, ed., Fruits in Warm Climates. Nabandith, V., M. Suzui, T. Morioka, T. Kaneshiro, T. Kinjo, K. Matsumoto, Y. Akao, M. Iinuma and N. Yoshimi. 2004. Inhibitory effects of crude alphamangostin, a xanthone derivative, on two different categories of colon preneoplastic lesions induced by 1, 2 dimethylhydrazine in the rat. Asian Pac. J. Cancer Prev. 5: 433-438. Pothitirat, W. and W. Gritsanapan. 2008a. Thin layer chromatography densitometric analysis of -mangostin content in Garcinia mangostana fruit rind extracts. J. AOAC Int. 91: 1145-1148. Pothitirat, W. and W. Gritsanapan. 2008b. Quantitative analysis of total mangostins in Garcinia mangostana fruit rind. J. Health Res. 22: 161-166. Yodhnu, S., A. Sirikatitham, and C. Wattanapiromsakul. 2009. Validation of LC for the determination of mangostin in mangosteen peel extract: A tool for quality assessment of Garcinia mangostana L. J. Chromatogr. Sci. 47: 185-189.

Manuscript received 5 March 2009, accepted 3 June 2009

Now online at http://www.thaiagj.org

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- MD HOW TO InfoDocument4 paginiMD HOW TO InfoMotherboardTV92% (13)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Drug Study - SalbutamolDocument2 paginiDrug Study - SalbutamolryanÎncă nu există evaluări

- Annotated Bibliography 2Document6 paginiAnnotated Bibliography 2api-292066378Încă nu există evaluări

- SanofiDocument17 paginiSanofiyishun44Încă nu există evaluări

- Jadwal TrainingDocument14 paginiJadwal TrainingAnonymous xCSrahÎncă nu există evaluări

- LicenseDocument7 paginiLicenseharrazÎncă nu există evaluări

- Reset PrefsDocument1 paginăReset PrefsYunus HidayatÎncă nu există evaluări

- StarburnDocument1 paginăStarburnFieda AliÎncă nu există evaluări

- GraphIsotherm Linear STTN - A - 20150226 - 1 30C - 0,5MM - 3 JamDocument1 paginăGraphIsotherm Linear STTN - A - 20150226 - 1 30C - 0,5MM - 3 JamYunus HidayatÎncă nu există evaluări

- BicarbAnalysis PDFDocument11 paginiBicarbAnalysis PDFYunus HidayatÎncă nu există evaluări

- Benzopyrene GC MSDocument6 paginiBenzopyrene GC MSYunus HidayatÎncă nu există evaluări

- Benzopyrene GC MSDocument6 paginiBenzopyrene GC MSYunus HidayatÎncă nu există evaluări

- To Study The Effect of Various Tranquilizers and Sedatives On Motor Co-Ordination by Rotarod Test in Mice PDFDocument2 paginiTo Study The Effect of Various Tranquilizers and Sedatives On Motor Co-Ordination by Rotarod Test in Mice PDFSuman DahalÎncă nu există evaluări

- Medicinal Plants of Assam, India: A Mini ReviewDocument7 paginiMedicinal Plants of Assam, India: A Mini Reviewanita laddhaÎncă nu există evaluări

- Enzymes: Biological CatalystsDocument9 paginiEnzymes: Biological CatalystsChamzelleÎncă nu există evaluări

- PARKINSONDocument59 paginiPARKINSONvannyÎncă nu există evaluări

- ReviewDocument19 paginiReviewfebyan yohanesÎncă nu există evaluări

- Ototoxic BrochureDocument6 paginiOtotoxic BrochureWindaÎncă nu există evaluări

- Adams4e Tif Ch47Document19 paginiAdams4e Tif Ch47fbernis1480_11022046100% (1)

- Herbalife 1 - Slimming at All Costs: HerbalifeÒ-induced Liver InjuryDocument3 paginiHerbalife 1 - Slimming at All Costs: HerbalifeÒ-induced Liver InjuryMohammed AyubÎncă nu există evaluări

- Ready Pack Information SheetDocument2 paginiReady Pack Information SheetSatish HiremathÎncă nu există evaluări

- Prescribing Information: 1. Name of The Medicinal ProductDocument5 paginiPrescribing Information: 1. Name of The Medicinal Productddandan_20% (1)

- Analytical Review of The Modern Range of Suppository BasesDocument6 paginiAnalytical Review of The Modern Range of Suppository BaseskurniilaihiÎncă nu există evaluări

- Articaine Vs LidocaineDocument25 paginiArticaine Vs LidocainecjoybensondmdÎncă nu există evaluări

- 429-743-1-SM (2) OJS Hermanto Jurnal Metris Unika AtmaJaya Jakarta PDFDocument8 pagini429-743-1-SM (2) OJS Hermanto Jurnal Metris Unika AtmaJaya Jakarta PDFHermanto RuslanÎncă nu există evaluări

- AmphetaminesDocument11 paginiAmphetaminesMatt CrossÎncă nu există evaluări

- Adverse Drug ReactionsDocument34 paginiAdverse Drug ReactionsYanaÎncă nu există evaluări

- Side-Effects Quinolone Antibiotics Toxicity. July 2005QUINOLONE ANTIBIOTICS TOXICITY. July 2005Document82 paginiSide-Effects Quinolone Antibiotics Toxicity. July 2005QUINOLONE ANTIBIOTICS TOXICITY. July 2005Avelox FloxÎncă nu există evaluări

- Affliated To Gautam Buddh Technicaluniversity Lucknow,: AcknowledgementDocument41 paginiAffliated To Gautam Buddh Technicaluniversity Lucknow,: AcknowledgementGaurav JaiswalÎncă nu există evaluări

- FDA OverviewDocument32 paginiFDA OverviewRamya KonaÎncă nu există evaluări

- Clinical Pathway: Perhimpunan Dokter Spesialis Anestesiologi Dan Terapi Intensif Indonesia 2013Document43 paginiClinical Pathway: Perhimpunan Dokter Spesialis Anestesiologi Dan Terapi Intensif Indonesia 2013tar1195Încă nu există evaluări

- Pharmaceutical Care Practice: The Clinician's GuideDocument4 paginiPharmaceutical Care Practice: The Clinician's Guidekoeya7Încă nu există evaluări

- GLP TrainerDocument268 paginiGLP TrainerAsep RÎncă nu există evaluări

- HPLC Column Selection GuideDocument2 paginiHPLC Column Selection GuideMilena SegatoÎncă nu există evaluări

- Journal Terapi Dermatitis SeboroikDocument4 paginiJournal Terapi Dermatitis SeboroikMohd Faie RamliÎncă nu există evaluări

- Blue Ocean Strategy: Create Uncontested Market Space & Make The Competition IrrelevantDocument21 paginiBlue Ocean Strategy: Create Uncontested Market Space & Make The Competition IrrelevantKadir Yıldırım100% (2)

- Pharmacy 1 Year Pharmaceutics 1 2111 Dec 2019Document2 paginiPharmacy 1 Year Pharmaceutics 1 2111 Dec 2019Sachin NagarÎncă nu există evaluări

- Pharmaceutical and Food Safety Bureau, Ministry of Health, Labour and Welfare Translated by Office of Safety I, Pharmaceuticals and Medical Devices AgencyDocument19 paginiPharmaceutical and Food Safety Bureau, Ministry of Health, Labour and Welfare Translated by Office of Safety I, Pharmaceuticals and Medical Devices Agencyعبدالعزيز بدرÎncă nu există evaluări