Documente Academic

Documente Profesional

Documente Cultură

Chemical Handling and Blending Process

Încărcat de

Arun KumarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chemical Handling and Blending Process

Încărcat de

Arun KumarDrepturi de autor:

Formate disponibile

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD)

Risk Compendium for the Chemical Industry Chemical Handling and Blending Process

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 1 1b. Work Activity Receiving bulk chemicals 1c. Hazard Moving vehicles 1d. Possible Accident / IllHealth Injuries or deaths from traffic accident 2a. or 3a. Possible Risk Control Attend and complete forklift driver training Abide by speed limit Designate loading/unloading bay Install warning alarms Install gas/vapour detection systems Place drum/containers on spill control pallets Build bund walls Implement emergency plans Conduct regular drills Install gas/vapour detection systems Install ventilation system in storage area Provide well-ventilated, non-air-conditioned work area Engage competent person in charge to manage hazardous substances Segregate incompatibles Provide well-ventilated, non-air-conditioned work area Label chemicals Obtain and use information in MSDSs Provide hazard communication training Implement safe work procedures Segregate incompatibles Prohibit ignition, heat sources, smoking and open flames Provide well-ventilated, non-air-conditioned work area Label chemicals Obtain and use information in MSDSs Provide hazard communication training Implement safe work procedures Install deluge / fixed water systems Implement emergency plans Conduct regular drills

Leaking drums / containers

Chemical spill, excessive inhalation / skin absorption of chemicals

Inhalation of fugitive chemical emissions Inhalation of hazardous products from undesirable reactions upon incompatible mixing

Ill-health from chemical overexposure Ill-health from chemical overexposure

Fire and explosions from excessive heat produced and flammable vapours

Injuries / deaths

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 2 1b. Work Activity Weighing of raw materials 1c. Hazard Fire and explosions 1d. Possible Accident / IllHealth Injuries / deaths 2a. or 3a. Possible Risk Control Install local exhaust ventilation system Install dilution ventilation Provide well-ventilated work area Prohibit ignition, heat sources, smoking and open flames Implement safe work procedures Provide and attend training on fire and explosion safety Install deluge / fixed water systems Implement emergency plans Conduct regular drills Install local exhaust ventilation system Build enclosure around weighing scale Automate weighing system Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Practice good housekeeping Provide and attend training on solvent hazards and control measures Provide, use and maintain respiratory protection Automate washing/cleaning system Implement safe work procedures Provide and attend training on solvent hazards and control measures Provide, use and maintain eye, body and hand protection Install local exhaust ventilation system Build enclosure around weighing scale Automate weighing system Implement safe work procedures Practice good housekeeping Provide and attend training on dust hazards and dust control measures Provide, use and maintain respiratory, eye, face, body and hand protection

Excessive inhalation of solvent vapours

Ill-health due to chemical overexposure

Excessive skin absorption of solvents

Dermatitis, ill-health due to chemical overexposure

Excessive inhalation of dust (from raw materials in powder or solid form)

Ill-health due to chemical overexposure

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 1b. Work Activity 1c. Hazard Burnt by corrosive solutions (e.g. acids, alkalis etc) 1d. Possible Accident / IllHealth Eye / skin burns 2a. or 3a. Possible Risk Control Splashes by chemicals during agitation / mixing / blending Eye / skin irritation, dermatitis Install local exhaust ventilation system Build enclosure around weighing scale Automate weighing system Implement safe work procedures Provide eye wash, emergency shower Practice good housekeeping Provide and attend training on corrosive hazards and their control measures Provide, use and maintain eye, face, body and hand protection Install covers on mixer/blender Build enclosures around mixer/blender Implement safe work procedures Provide and attend training Provide, use and maintain eye and face protection Install machine guarding Install sensors Install warning alarms Implement safe work procedures Provide and attend training on machine guarding Install local exhaust ventilation Build covers on mixer/blender Build enclosures around mixer/blender Install dilution ventilation in work area Prohibit ignition, heat sources and open flames Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Provide and attend training on fire and explosion safety Install deluge / fixed water systems Implement emergency plans Conduct regular drills

Mixing/Blending

Limbs caught in moving mechanical parts of mixer / blender

Amputations, fractures, sprains

Fire & explosions

Injuries / deaths

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 1b. Work Activity 1c. Hazard Excessive inhalation of solvent vapours produced by agitation, mixing or blending 1d. Possible Accident / IllHealth Ill-health due to chemical overexposure 2a. or 3a. Possible Risk Control Install local exhaust ventilation Build covers on mixer/blender Build enclosures around mixer/blender Install dilution ventilation in work area Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Provide and attend training on solvent hazards and control measures Provide, use and maintain respiratory protection Substitute noisy mechanical parts with quieter ones Build enclosures padded with noise-absorbing materials around mixer/blender Maintain mechanical parts regularly Provide and attend hearing conservation training Implement safe work procedures Put up warning signs Provide, use and maintain hearing protection Install covers on mixer/blender Build enclosures around mixer/blender Implement safe work procedures Provide and attend training Provide, use and maintain eye and face protection Automate packing system Install local exhaust ventilation system Install dilution ventilation in work area Prohibit ignition, heat sources and open flames Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Provide and attend training on fire and explosion safety Install deluge / fixed water systems Implement emergency plans Conduct regular drills

Excessive noise exposure from moving mechanical parts of mixer / blender

Noise induced deafness

Splashed by chemicals during agitation / mixing / blending

Eye / skin irritation, dermatitis

Packing into smaller containers / drums

Fire & explosions

Injuries / deaths

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 1b. Work Activity 1c. Hazard Excessive inhalation of solvent vapours produced during packing 1d. Possible Accident / IllHealth Ill-health due to chemical overexposure 2a. or 3a. Possible Risk Control Automate packing system Install local exhaust ventilation system Install dilution ventilation in work area Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Provide and attend training Provide, use and maintain respiratory protection Automate packing system Build enclosures around packing system Implement safe work procedures Provide and attend training Provide, use and maintain eye and face protection Automate packing system Use pallets with adjustable heights that respond to weight of packed containers/drums Provide mechanical lifting aids Implement safe work procedures Provide and attend ergonomics training Use proper lifting posture Provide adequate breaks Implement log out/tag out Implement safe work procedures Provide and attend training Put up warning signs Implement log out/tag out Implement safe work procedures Provide and attend training on machine guarding Put up warning signs Implement log out/tag out Implement safe work procedures Provide and attend training Put up warning signs

Splashed by chemicals during packing

Eye / skin irritation, dermatitis

Repeated lifting of packed containers / drums

Back aches, strains

Maintenance of mixer/blender

Electrocution

Electric shock, deaths

Limbs caught in moving mechanical parts of mixer / blender 6 Cleaning/washing of mixer/blending Electrocution

Amputations, fractures, sprains

Electric shock, deaths

Ministry of Manpower (MOM) Occupational Safety and Health Division (OSHD) 1a. No. 1b. Work Activity 1c. Hazard Limbs caught in moving mechanical parts of mixer/blender Excessive skin absorption of solvents 1d. Possible Accident / IllHealth Amputations, fractures, sprains 2a. or 3a. Possible Risk Control Implement log out/tag out Implement safe work procedures Provide and attend training on machine guarding Put up warning signs Automate washing/cleaning system Implement safe work procedures Provide and attend training Provide, use and maintain eye, body and hand protection Install local exhaust ventilation Install dilution ventilation in work area Provide well-ventilated, non-air-conditioned work area Implement safe work procedures Provide and attend training on solvent hazards and control measures Provide, use and maintain respiratory protection

Dermatitis

Excessive inhalation of solvent vapours

Ill-health due to chemical overexposure

This material is not intended to be an exhaustive list of hazards and control measures for the above activities. Companies are to conduct risk assessment on the work activities specific to their workplaces by identifying the hazards, evaluating the risk and determining suitable control measures where appropriate. References should be made to the relevant regulations and code of practices when in doubt.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Fluid Mechanics Chapter 1-5Document32 paginiFluid Mechanics Chapter 1-5Kristine Ann Reclosado38% (8)

- Hazen - William Coeficiente FBEDocument10 paginiHazen - William Coeficiente FBEOrlandoÎncă nu există evaluări

- Non Veg DishesDocument99 paginiNon Veg DishesArun KumarÎncă nu există evaluări

- Veg DishesDocument45 paginiVeg DishesArun KumarÎncă nu există evaluări

- Ehandbook Process Safety 1309 PDFDocument15 paginiEhandbook Process Safety 1309 PDFArun KumarÎncă nu există evaluări

- Pug Mills / Paddle Mixers: Design & Principles of OperationDocument1 paginăPug Mills / Paddle Mixers: Design & Principles of OperationArun KumarÎncă nu există evaluări

- Melting Points of MetalsDocument1 paginăMelting Points of MetalsArun KumarÎncă nu există evaluări

- Safety Is Money in The BankDocument3 paginiSafety Is Money in The BankArun KumarÎncă nu există evaluări

- Industrial Pipe Marking GuideDocument2 paginiIndustrial Pipe Marking GuideArun KumarÎncă nu există evaluări

- Ims Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageDocument9 paginiIms Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageArun KumarÎncă nu există evaluări

- Glass GlossaryDocument3 paginiGlass GlossaryArun Kumar100% (1)

- Seko Dosing DiaDocument12 paginiSeko Dosing DiaSeptriani LaoliÎncă nu există evaluări

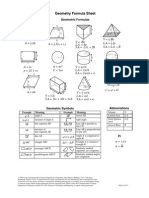

- Geometry Formula SheetDocument1 paginăGeometry Formula SheetArun KumarÎncă nu există evaluări

- Safety Management SystemDocument17 paginiSafety Management SystemPradeep NegiÎncă nu există evaluări

- Corrective and Preventive Actions: "A Five Step Approach"Document41 paginiCorrective and Preventive Actions: "A Five Step Approach"Arun KumarÎncă nu există evaluări

- Bearing Shaft Fits and Tolerances 1Document9 paginiBearing Shaft Fits and Tolerances 1Arun KumarÎncă nu există evaluări

- Safety Management SystemDocument17 paginiSafety Management SystemPradeep NegiÎncă nu există evaluări

- Double Paddle MixerDocument118 paginiDouble Paddle MixerArun Kumar80% (5)

- List of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaDocument4 paginiList of Youtube Video Clips For Kataline Infraproducts PVT Ltd-IndiaArun KumarÎncă nu există evaluări

- The Explosives Rules, 1983: Preliminary 1. Short Title and CommencementDocument2 paginiThe Explosives Rules, 1983: Preliminary 1. Short Title and CommencementArun KumarÎncă nu există evaluări

- Dust Control in TunnelsDocument27 paginiDust Control in TunnelsrockyminÎncă nu există evaluări

- Iso 9001 2008 StandardDocument90 paginiIso 9001 2008 StandardArun KumarÎncă nu există evaluări

- CapaDocument24 paginiCapaArun KumarÎncă nu există evaluări

- OISD Standard 244 DraftDocument94 paginiOISD Standard 244 DraftSuresh GanesanÎncă nu există evaluări

- Basf Masterflow 649 TdsDocument4 paginiBasf Masterflow 649 Tdsgazwang478Încă nu există evaluări

- 905 3SDocument4 pagini905 3SyasafyÎncă nu există evaluări

- Sum11 Pharma PDFDocument29 paginiSum11 Pharma PDFMostofa RubalÎncă nu există evaluări

- Assignment - CEP-534 - Team 04 PDFDocument16 paginiAssignment - CEP-534 - Team 04 PDFshowravÎncă nu există evaluări

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasDocument41 paginiCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoÎncă nu există evaluări

- Semester/Concrete Technology (9021) /experiment-02 PDFDocument14 paginiSemester/Concrete Technology (9021) /experiment-02 PDFjestinvthomasÎncă nu există evaluări

- YLAA InstallationDocument62 paginiYLAA InstallationJoe YoungÎncă nu există evaluări

- Nanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsDocument19 paginiNanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsPRAVEEN MÎncă nu există evaluări

- Cleaning Bones: General GuidelinesDocument4 paginiCleaning Bones: General GuidelinesSaira SepulvidaÎncă nu există evaluări

- Tugas 1 PPADocument29 paginiTugas 1 PPAlulalalaÎncă nu există evaluări

- Procedures For Hvac System Design and InstallationDocument5 paginiProcedures For Hvac System Design and Installationrawadsultan100% (1)

- Zhang 2022Document10 paginiZhang 2022Statistics LearningÎncă nu există evaluări

- Coke Gujranawala DD 27 12Document25 paginiCoke Gujranawala DD 27 12Muhammad AmmarÎncă nu există evaluări

- Rework Procedure For Bga ModulesDocument8 paginiRework Procedure For Bga ModulesexwilliamÎncă nu există evaluări

- DNA-protein Interactions: Methods For Detection and AnalysisDocument31 paginiDNA-protein Interactions: Methods For Detection and AnalysisAhsan Arshad BSIT-F16-LC-008Încă nu există evaluări

- Article WJPR 1467266667Document10 paginiArticle WJPR 1467266667Atthapu ThirupathaiahÎncă nu există evaluări

- Reference Only: I Pus Pond StreetDocument132 paginiReference Only: I Pus Pond StreetJagdish ShindeÎncă nu există evaluări

- Book by MontogomeryDocument10 paginiBook by MontogomerySubba PappuÎncă nu există evaluări

- ASTM D 3364-99 - Flow Rates For Poly (Vinyl Chloride) With Molecular Structural ImplicationsDocument4 paginiASTM D 3364-99 - Flow Rates For Poly (Vinyl Chloride) With Molecular Structural Implicationszeqs9Încă nu există evaluări

- 0653 - w12 - QP - 11 (Combined)Document20 pagini0653 - w12 - QP - 11 (Combined)MCHÎncă nu există evaluări

- Donaldon General Brochure WideDocument20 paginiDonaldon General Brochure WidecivodulÎncă nu există evaluări

- 1.1 Verbal Reasoning Pre-TestDocument6 pagini1.1 Verbal Reasoning Pre-TestAshlie JaneÎncă nu există evaluări

- En 10263-1Document30 paginiEn 10263-1Mogos PaulÎncă nu există evaluări

- Praxis GuideDocument43 paginiPraxis GuideRyan NegadÎncă nu există evaluări

- Stainless EnstainlessDocument27 paginiStainless EnstainlessVinaya Almane DattathreyaÎncă nu există evaluări

- WasherDocument80 paginiWasherbugdapugÎncă nu există evaluări

- Hot Work PermitDocument2 paginiHot Work PermitRex UrbiztondoÎncă nu există evaluări