Documente Academic

Documente Profesional

Documente Cultură

PLAN11

Încărcat de

vijaysatawDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PLAN11

Încărcat de

vijaysatawDrepturi de autor:

Formate disponibile

API Piping Plan 11

REV 1 Definition:

A primary product seal flush plan that originates at the discharge, or a pressure point on the pump higher than that of the stuffing box pressure, of the pump and is piped to the flush port on the primary seal flange or stuffingbox tap.

Objective:

To lubricate the primary product seal and dissipate heat generated by this seal. This plan can also be used to raise the pressure in the stuffing box when the required product vapor suppression margin is not present (suction pressure is at or near the vapor presssure of the liquid).

Line Up Procedure:

The following steps outline the checks required before, during and after start-up of the equipment. 1) Check to make sure any valves in the seal flush line are open. These lines should be free of valves, if possible. Otherwise, any valves in this line must remain open until the pump is pulled for repair. 2) Proceed with opening all valves for service. 3) Check for leaks around valves and orifice unions in the seal flush line. 4) Start pump per normal procedures. 5) Once running, check to make sure the seal flush line is the same temperature from its origin to the primary seal flush port on the primary seal flange. It should be the same temperature as the pump case. [Caution: Use caution if the pumping temperature is above 150F.]

Preventive Maintenance and Troubleshooting:

The primary seal flush line should be checked on normal operator rounds. This can be done by using a temperature indicator, and making sure it is the same temperature as the pump case from its origin to the flush port on the primary seal flange. [Caution: Use caution if the pumping temperature is above 150F.] The typical mode of failure in this flush plan is a clogged orifice or a closed valve in the seal flush line. During this mode, you will find the following when you check the seal flush line on a particular piece of equipment.

A Hot Service (seal flush line clogged)

When the seal flush line is clogged in a hot service, you will find the line cold. It may be hot at the origin and also at the flush port connection, but it will become cold as you move away from the connections.

A Cold Service (seal flush line clogged)

When the seal flush line is clogged in a cold service, you will find the line hotter at the seal flush port connection on the primary seal flange. The line will cool as you slide the temperature indicator toward the origin of the seal flush line (i.e.. discharge of pump, etc..). The heat that is radiating up the seal flush line and is generated by the mechanical seal. In other words, there is no flow in this line and therefore, heat is backing up through the line.

Solution

Upon finding the above situation, you should check for closed valves in the seal flush line. If no valves are present or they are open, tap on the orifice union in this line to see if it will open and flow properly. If the above attempts are unsuccessful, begin procedures to shut the equipment down in an orderly manner.

Shut Down Procedure:

Once the equipment has been prepared for maintenance, remove the seal flush line and check for foreign matter clogging the line. This matter will usually be found in the union housing the orifice that regulates flow in the seal flush line. In the event you cannot find a problem, contact your maintenance or BW/IP personnel for further assistance.

S-ar putea să vă placă și

- CAT Hydraulic SystemsDocument4 paginiCAT Hydraulic Systemsjimmy gomezÎncă nu există evaluări

- Hydraulic System Troubleshooting GuideDocument27 paginiHydraulic System Troubleshooting Guidekhumiso100% (1)

- Motor Load and Efficiency PDFDocument16 paginiMotor Load and Efficiency PDFwfjerrÎncă nu există evaluări

- Aircraft Steel Data SheetDocument4 paginiAircraft Steel Data Sheetrodryguo74Încă nu există evaluări

- Method Statement For Hydrostatic Pressure Testing of Chilled Water PipeworkDocument3 paginiMethod Statement For Hydrostatic Pressure Testing of Chilled Water Pipeworkamg007100% (3)

- Vacuum Leakage TestDocument11 paginiVacuum Leakage Testsambhu100% (1)

- Aluminium GMAW GuideDocument32 paginiAluminium GMAW GuideDaniel Salinas100% (2)

- Everything You Need To Know About TX ValvesDocument6 paginiEverything You Need To Know About TX Valvescalishe1Încă nu există evaluări

- Well Maintenance ProcedureDocument14 paginiWell Maintenance ProcedureVlassis Sarantinos100% (1)

- SI0219 Flash Tank and Low SuctionDocument12 paginiSI0219 Flash Tank and Low SuctionEEstebanGiron73% (11)

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 paginiGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowDe la EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Factors Affecting SolubilityDocument2 paginiFactors Affecting SolubilityTerence FocasanÎncă nu există evaluări

- Single Core & Multicore Flexible CablesDocument12 paginiSingle Core & Multicore Flexible Cablesdh24992499Încă nu există evaluări

- Troubleshoooting Hydraulic System71742 - 10Document7 paginiTroubleshoooting Hydraulic System71742 - 10honeyvish92Încă nu există evaluări

- CO2 Capture Using Monoethanolamine (MEA) Aqueous SolutionDocument18 paginiCO2 Capture Using Monoethanolamine (MEA) Aqueous SolutionChia-YiiÎncă nu există evaluări

- Coc Oral Exam Preparation (Part - 17) : Boiler Safety ValveDocument3 paginiCoc Oral Exam Preparation (Part - 17) : Boiler Safety ValveshashankrawatÎncă nu există evaluări

- Book-Fractography and Failure Analysis 2018Document61 paginiBook-Fractography and Failure Analysis 2018claradwisÎncă nu există evaluări

- Inspections and Survey Procedures in Auxiliary BoilerDocument16 paginiInspections and Survey Procedures in Auxiliary BoilerkrishnaÎncă nu există evaluări

- Volvo Penta Overheat DiagnosisDocument15 paginiVolvo Penta Overheat DiagnosisJohn Morgan100% (1)

- API Plans FlowserveDocument56 paginiAPI Plans Flowservewwast72100% (5)

- Understanding Electricity and CurrentDocument104 paginiUnderstanding Electricity and CurrentJamil MaslanÎncă nu există evaluări

- Mechanical Seal Piping PlansDocument56 paginiMechanical Seal Piping Plansaltieri1100% (2)

- Many Body ApproachDocument596 paginiMany Body Approachchvar80Încă nu există evaluări

- Pump Seal PlansDocument56 paginiPump Seal PlansKwang Je LeeÎncă nu există evaluări

- Background To Rock Roughness EquationDocument8 paginiBackground To Rock Roughness EquationMuhammad Sya FiqÎncă nu există evaluări

- 4 PumpsDocument26 pagini4 PumpsdhasdjÎncă nu există evaluări

- Safety Valves For Power PlantDocument56 paginiSafety Valves For Power Planttek_surinder100% (1)

- GAS LIFT TROUBLESHOOTING GUIDE Oilproduction PDFDocument20 paginiGAS LIFT TROUBLESHOOTING GUIDE Oilproduction PDFSteve MarfissiÎncă nu există evaluări

- Power Transformer Testing ProcedureDocument4 paginiPower Transformer Testing ProcedureJustin Taylor100% (4)

- Power Transformer Testing ProcedureDocument4 paginiPower Transformer Testing ProcedureJustin Taylor100% (4)

- Solution Manual Mechanics For Engineers Statics 13th Chapter 8 RC HibbelerDocument144 paginiSolution Manual Mechanics For Engineers Statics 13th Chapter 8 RC HibbelerArteezy Babaev50% (2)

- Process Engineering: Facts, Fiction and FablesDe la EverandProcess Engineering: Facts, Fiction and FablesEvaluare: 3 din 5 stele3/5 (2)

- Valves Gate DamperDocument54 paginiValves Gate DamperLalit MeenaÎncă nu există evaluări

- Hydrotest Pressure Vs Design PressureDocument122 paginiHydrotest Pressure Vs Design PressureHenryOdohÎncă nu există evaluări

- Deluge SystemDocument13 paginiDeluge SystemAnuj GuptaÎncă nu există evaluări

- API Piping Plan 13: REV 2.0 DefinitionDocument3 paginiAPI Piping Plan 13: REV 2.0 DefinitionvijaysatawÎncă nu există evaluări

- API Plan21-Seal PipingDocument3 paginiAPI Plan21-Seal Pipingkrishna_pipingÎncă nu există evaluări

- API 682 Short Guide Most Common Plans and Operational InformationDocument40 paginiAPI 682 Short Guide Most Common Plans and Operational InformationFarhan TalibÎncă nu există evaluări

- Hydraulic Troubleshooting GuideDocument3 paginiHydraulic Troubleshooting GuideRamon PeyegrinÎncă nu există evaluări

- 2006FC 174R1TXVre ArticleDocument4 pagini2006FC 174R1TXVre Articleremwel_Încă nu există evaluări

- Troubleshooting: System Shuts Down During OperationDocument8 paginiTroubleshooting: System Shuts Down During Operationdollahyong69Încă nu există evaluări

- Automatic Isolation Valves Test ProceduresDocument4 paginiAutomatic Isolation Valves Test ProceduresRahul ChandrawarÎncă nu există evaluări

- Tech Sheet 128Document1 paginăTech Sheet 128Sriram RamanujamÎncă nu există evaluări

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsDocument51 paginiW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanÎncă nu există evaluări

- Chase Method Statement Dry Riser TestingDocument6 paginiChase Method Statement Dry Riser Testingarmagan55Încă nu există evaluări

- Operation: Service PortsDocument17 paginiOperation: Service PortsJulietina PerezÎncă nu există evaluări

- Manual Pump Down On An Air ConditioningDocument5 paginiManual Pump Down On An Air ConditioningRay RavelÎncă nu există evaluări

- Tip Card 04Document2 paginiTip Card 04Ola_Adel_Încă nu există evaluări

- Install and Operate Seal Flushing SystemDocument11 paginiInstall and Operate Seal Flushing SystemAnonymous AS1lUJLÎncă nu există evaluări

- KTM512 Extended Guide ENDocument12 paginiKTM512 Extended Guide ENFilip SerafimovÎncă nu există evaluări

- Bam 800 T004 - Nozzle Flow Testing GuidelinesDocument11 paginiBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Fire Sprinkler Alarm Valve Technical DataDocument16 paginiFire Sprinkler Alarm Valve Technical DataAjjuParmarÎncă nu există evaluări

- Norman Kronowitz - Hydraulic TroubleshootingDocument25 paginiNorman Kronowitz - Hydraulic TroubleshootingStarchyLittleOleMeÎncă nu există evaluări

- 1 System Description LP3-RLU - 13.02.2006 New NHP5Document9 pagini1 System Description LP3-RLU - 13.02.2006 New NHP5Andrei ZahaÎncă nu există evaluări

- Adp TXV PDFDocument7 paginiAdp TXV PDFhilariolussaÎncă nu există evaluări

- Collin Test and Commissioning ProcedureDocument7 paginiCollin Test and Commissioning ProcedureSamuelJrManatadÎncă nu există evaluări

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDocument40 paginiSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangÎncă nu există evaluări

- Tempe Fire Department Policies and Procedures Hose Maintenance and Testing 405.03D Rev 3-12-97Document3 paginiTempe Fire Department Policies and Procedures Hose Maintenance and Testing 405.03D Rev 3-12-97Muhammad FerialÎncă nu există evaluări

- Deluge Valve Technical Data SheetDocument14 paginiDeluge Valve Technical Data SheetSiddharth GupteÎncă nu există evaluări

- Hydraulic Reliability Preventive Maintenance ReportDocument5 paginiHydraulic Reliability Preventive Maintenance ReportLeonardo DíazÎncă nu există evaluări

- Flash Tank Heat Recovery Operating and Maintenance ManualDocument2 paginiFlash Tank Heat Recovery Operating and Maintenance ManualCastoriadisÎncă nu există evaluări

- Troubleshooting HintsDocument10 paginiTroubleshooting HintsRubyAsHwinÎncă nu există evaluări

- TroubleshootingDocument11 paginiTroubleshootingMaxwell Carrasco SantiÎncă nu există evaluări

- Installation & Maintenance Instructions for Mark 57 Pressure RegulatorsDocument4 paginiInstallation & Maintenance Instructions for Mark 57 Pressure Regulatorsbenzerga karimÎncă nu există evaluări

- Heat Pumps 2nd Edition Silberstein Solutions ManualDocument35 paginiHeat Pumps 2nd Edition Silberstein Solutions Manualapostolicembetterxrymjn100% (16)

- Dwnload Full Heat Pumps 2nd Edition Silberstein Solutions Manual PDFDocument32 paginiDwnload Full Heat Pumps 2nd Edition Silberstein Solutions Manual PDFtreen.whiles.2kz51t100% (11)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- Grade Chart:: Subject Grade Grade Point Marks Range PercentageDocument1 paginăGrade Chart:: Subject Grade Grade Point Marks Range PercentagevijaysatawÎncă nu există evaluări

- En 1431515330Document35 paginiEn 1431515330vijaysatawÎncă nu există evaluări

- MM2Document85 paginiMM2vijaysatawÎncă nu există evaluări

- En 1431515330Document35 paginiEn 1431515330vijaysatawÎncă nu există evaluări

- C&S-Industrial Motor Starter PDFDocument8 paginiC&S-Industrial Motor Starter PDFvijaysatawÎncă nu există evaluări

- Sr. No. Full Line Description Unit QTY Supply Rate Installation RateDocument1 paginăSr. No. Full Line Description Unit QTY Supply Rate Installation RatevijaysatawÎncă nu există evaluări

- Indian Cables & Electricals PVT - LTD.: Price List W.E.F. 25.07.2014Document1 paginăIndian Cables & Electricals PVT - LTD.: Price List W.E.F. 25.07.2014vijaysatawÎncă nu există evaluări

- Thermal Black in Butyl Curing BladdersDocument7 paginiThermal Black in Butyl Curing BladdersvijaysatawÎncă nu există evaluări

- Delivering Power to the Nation with Flame Retardant WiresDocument25 paginiDelivering Power to the Nation with Flame Retardant WiresvijaysatawÎncă nu există evaluări

- Ec1269 - Microprocessors ApplicationsDocument31 paginiEc1269 - Microprocessors ApplicationsNamrata SinghÎncă nu există evaluări

- CG RomDocument14 paginiCG RomvijaysatawÎncă nu există evaluări

- Load Cell 2Document2 paginiLoad Cell 2vijaysatawÎncă nu există evaluări

- Stationery Request-Project OfficeDocument3 paginiStationery Request-Project OfficevijaysatawÎncă nu există evaluări

- PLAN53GDocument4 paginiPLAN53GvijaysatawÎncă nu există evaluări

- BJM CORP ALL-TEST™ Tech Note: Trans01: Theme: Transformer Testing - 3 Phase TransformersDocument2 paginiBJM CORP ALL-TEST™ Tech Note: Trans01: Theme: Transformer Testing - 3 Phase TransformersvijaysatawÎncă nu există evaluări

- Section - Iv: Erection, Testing and Commissioning 4.1Document14 paginiSection - Iv: Erection, Testing and Commissioning 4.1Vinod ViparÎncă nu există evaluări

- PLAN32Document3 paginiPLAN32vijaysatawÎncă nu există evaluări

- PLAN61Document2 paginiPLAN61vijaysatawÎncă nu există evaluări

- PLAN31Document3 paginiPLAN31vijaysatawÎncă nu există evaluări

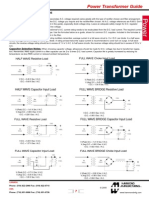

- Power Transformer GuideDocument1 paginăPower Transformer Guidenmg_babuÎncă nu există evaluări

- Electrical: Section - V Technical SpecificationsDocument6 paginiElectrical: Section - V Technical SpecificationsvijaysatawÎncă nu există evaluări

- Group - B Sl. No. - 1) 11 KV Distribution Class Lighting ArrestorsDocument6 paginiGroup - B Sl. No. - 1) 11 KV Distribution Class Lighting ArrestorsKhánh RòmÎncă nu există evaluări

- Group - C: Sl. No. - 1) G.I. Flat (25 X 6 MM)Document1 paginăGroup - C: Sl. No. - 1) G.I. Flat (25 X 6 MM)vijaysatawÎncă nu există evaluări

- Managers Vs LeadersDocument48 paginiManagers Vs LeadersvijaysatawÎncă nu există evaluări

- CIV 442 Hydrology: Lecture 4D: Idf TheoryDocument25 paginiCIV 442 Hydrology: Lecture 4D: Idf TheoryMohammed ZiadÎncă nu există evaluări

- AUDI OptimizationDocument37 paginiAUDI OptimizationKiran DamaÎncă nu există evaluări

- Chapter 9Document29 paginiChapter 9Danny TÎncă nu există evaluări

- 4.0 Radiometry PhotometryDocument25 pagini4.0 Radiometry PhotometrynidharshanÎncă nu există evaluări

- Telescope Equations Guide for Exploring the Night SkyDocument97 paginiTelescope Equations Guide for Exploring the Night SkyAnimalesProtegidosAhora100% (1)

- Nanocomposix Guidelines For Zeta Potential Analysis of Nanoparticles PDFDocument6 paginiNanocomposix Guidelines For Zeta Potential Analysis of Nanoparticles PDFGOWTHAM GUPTHAÎncă nu există evaluări

- The Optimal Design of Pressure Swing Adsorption SystemsDocument27 paginiThe Optimal Design of Pressure Swing Adsorption SystemsBich Lien PhamÎncă nu există evaluări

- ASA - Temperature Sensor - ILLZTT5069K - enDocument1 paginăASA - Temperature Sensor - ILLZTT5069K - enKrum KashavarovÎncă nu există evaluări

- Final Year Project Presentation: Lokmanya Tilak College of EngineeringDocument20 paginiFinal Year Project Presentation: Lokmanya Tilak College of EngineeringOnkar BhosaleÎncă nu există evaluări

- Cavecool Wine Cooler Service ManualDocument27 paginiCavecool Wine Cooler Service ManualCristian CecconelloÎncă nu există evaluări

- Topic 4. Binary DistillationDocument123 paginiTopic 4. Binary DistillationAngela Lorena DíazÎncă nu există evaluări

- High Performance Fiber Reinforced Concrete - OverviewDocument14 paginiHigh Performance Fiber Reinforced Concrete - Overviewhaoude9Încă nu există evaluări

- Universitatea Transilvania Din Brasov Facultatea de Alimentatie Si Turism Specializarea: Controlul Si Expertiza Produselor AlimentareDocument17 paginiUniversitatea Transilvania Din Brasov Facultatea de Alimentatie Si Turism Specializarea: Controlul Si Expertiza Produselor AlimentareadiamariÎncă nu există evaluări

- Soil Cheatsheet (Updated)Document3 paginiSoil Cheatsheet (Updated)AOS100% (1)

- Phase DiagramDocument13 paginiPhase DiagramJayzl Lastrella CastanedaÎncă nu există evaluări

- 44 3 KarakanDocument6 pagini44 3 KarakanVitória SalazarÎncă nu există evaluări

- BiosensorsDocument60 paginiBiosensorsRahul SinghÎncă nu există evaluări

- Plastistrength™: Acrylic Process Aids For PVC ApplicationsDocument28 paginiPlastistrength™: Acrylic Process Aids For PVC ApplicationsJaved Iqbal100% (1)

- Electrical ProperitiesDocument66 paginiElectrical ProperitiesGabito EssienÎncă nu există evaluări

- UntitledDocument344 paginiUntitledSanjay PrasadÎncă nu există evaluări

- Sulfur Dioxide Absorption Column DesignDocument9 paginiSulfur Dioxide Absorption Column DesignGODWIN ANYIMAHÎncă nu există evaluări