Documente Academic

Documente Profesional

Documente Cultură

Screw

Încărcat de

ameybarveDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Screw

Încărcat de

ameybarveDrepturi de autor:

Formate disponibile

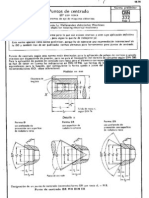

A screw, or bolt, is a type of fastener characterized by a helical ridge, known as an external thread or just thread, wrapped around a cylinder.

Some screw threads are designed to mate with a complementary thread, known as an internal thread, often in the form of a nut or an object that has the internal thread formed into it. Other screw threads are designed to cut a helical groove in a softer material as the screw is inserted. he most common uses of screws are to hold objects together and to position objects. Often screws have a head, which is a specially formed section on one end of the screw that allows it to be turned, or driven. !ommon tools for driving screws include screwdrivers and wrenches. he head is usually larger than the body of the screw, which keeps the screw from being driven deeper than the length of the screw and to provide a bearing surface. here are exceptions" for instance, carriage bolts have a domed head that is not designed to be driven" set screws have a head smaller than the outer diameter of the screw" #$bolts have a #$shaped head which is not designed to be driven, but rather is usually sunk into concrete allowing it to be used as an anchor bolt. he cylindrical portion of the screw from the underside of the head to the tip is known as the shank" it may be fully threaded or partially threaded. he majority of screws are tightened by clockwise rotation, which is termed a right$hand thread. Screws with left$hand threads are used in exceptional cases. %or example, when the screw will be subject to anticlockwise forces &which would work to undo a right$hand thread', a left$hand$threaded screw would be an appropriate choice. A bolt is an externally threaded fastener designed for insertion through holes in assembled parts, and is normally intended to be tightened or released by tor(uing a nut. A screw is an externally threaded fastener capable of being inserted into holes in assembled parts, of mating with a preformed internal thread or forming its own thread, and of being tightened or released by tor(uing the head. An externally threaded fastener which is prevented from being turned during assembly and which can be tightened or released only by tor(uing a nut is a bolt. &)xample* round head bolts, track bolts, plow bolts.' An externally threaded fastener that has thread form which prohibits assembly with a nut having a straight thread of multiple pitch length is a screw. &)xample* wood screws, tapping screws.' his distinction is consistent with AS+) ,-../.- and some dictionary definitions for screw and bolt. he issue of what is a screw and what is a bolt is not completely resolved with +achinery0s 1andbook distinction, however, because of confounding terms, the ambiguous nature of some parts of the distinction, and usage variations. Some of these issues are discussed below*

Machine screws AS+) standards specify a variety of 2+achine Screws2 in diameters ranging up to 3.45 in. hese fasteners are often used with nuts and they are often driven into tapped holes. hey might be considered a screw or a bolt based on the +achinery0s 1andbook distinction. 6n practice, they tend to be mostly available in smaller sizes and the smaller sizes are referred to as screws or less ambiguously as machine screws, although some kinds of machine screws can be referred to as stove bolts. Hex cap screws AS+) standard ,-../.- $-778 specifies 1ex !ap Screws that range in size from 3./59: in in diameter. hese fasteners are very similar to hex bolts. hey differ mostly in that they are manufactured to tighter tolerances than the corresponding bolts. he +achinery0s 1andbook refers parenthetically to these fasteners as 2%inished 1ex ,olts2. ;easonably, these fasteners might be referred to as bolts but based on the <S government document" =istinguishing ,olts from Screws, the <S government might classify them as screws because of the tighter tolerance. 6n -77- responding to an influx of counterfeit fasteners !ongress passed >? -3-$57/ 2%astener @uality Act2 his resulted in the rewriting of specifications by the AS+) ,-. committee. ,-../.- was re$written and as a result they eliminated the 2%inished 1ex ,olts2 and renamed them the 21ex !ap Screw2. Lug bolts & head bolts hese terms refer to fasteners that are designed to be threaded into a tapped hole that is in part of the assembly and so based on the +achinery0s 1andbook distinction they would be screws. 1ere common terms are at variance with +achinery0s 1andbook distinction. Lag bolt hese are clearly screws based on the +achinery0s 1andbook distinction. he term has been replaced by 2?ag Screw2 in the +achinery0s 1andbook Government standards he <S government made an effort to formalize the difference between a bolt and a screw because different tariffs apply to each. he document seems to have no significant effect on common usage and does not eliminate the ambiguous nature of the distinction between screws and bolts for some threaded fasteners.A Historical issue Old <SS and SA) standards defined cap screws as fasteners with shanks that were threaded to the head and bolts as fasteners with shanks that were partially unthreaded. his is now an obsolete distinction. Controlled vocabulary versus natural language he distinctions delineated above are enforced in the controlled vocabulary of standards organizations. Bevertheless, there are sometimes differences between the controlled vocabulary and the natural$language usage of the words among machinists, auto mechanics, and other workers. hese differences reflect linguistic evolution shaped by the changing of technology over centuries. he words bolt and screw have both existed since before

today0s modern mix of fastener types existed, and the natural usage of those words has evolved retronymously in response to the technological change. & hat is, the use of words as names for objects changes as the objects themselves change.' Bonthreaded fasteners predominated in fastening technology until the advent of practical, inexpensive screw$cutting in the early -7th century. he basic meaning of the word screw has long involved the idea of a helical screw thread, but the Archimedes screw and the screw gimlet &like a corkscrew' preceded the fastener. he word bolt is also a very old word, and it was used for centuries to refer to metal rods that passed through the substrate to be fastened on the other side, often via nonthreaded means &clinching, forge welding, pinning, wedging, etc.'. he connection of this sense to the sense of a door bolt or the crossbow bolt is apparent. 6n the -7th century, bolts fastened via screw threads were often called screw bolts in contradistinction to clench bolts. 6n common usage, the distinction is often that screws are smaller than bolts, and that screws are generally tapered and bolts are not. his distinction is not rigorous. Other distinctions ,olts have been defined as headed fasteners having external threads that meet an exacting, uniform bolt thread specification &such as +, +#, <B, <B;, and <B#' such that they can accept a nontapered nut. Screws are then defined as headed, externally threaded fasteners that do not meet the above definition of bolts. hese definitions of screw and bolt eliminate the ambiguity of the +achinery0s handbook distinction. And it is for that reason, perhaps, that some people favor them. 1owever, they are neither compliant with common usage of the two words nor are they compliant with formal specifications. ypes of screws and bolts hreaded fasteners either have a tapered shank or a non$tapered shank. %asteners with tapered shanks are designed to either be driven into a substrate directly or into a pilot hole in a substrate. +ating threads are formed in the substrate as these fasteners are driven in. %asteners with a non$ tapered shank are designed to mate with a nut or to be driven into a tapped hole.

Fasteners with a tapered shank sel!"threading screws#

A >hillips wood screw being driven into a board with a driver. $ood screw Cenerally has an unthreaded shank below the head. 6t is designed to attach two pieces of wood together. %win!ast screw A type of wood screw with two threads &i.e. a lead of /', so that it can be driven twice as fast. Coach screw &'# or lag screw(bolt &)#

Similar to a wood screw except that it is generally much larger running to lengths up to -5 in &:.- mm' with diameters from 3./593.5 in &8.:59-/.43 mm' in commonly available &hardware store' sizes ¬ counting larger mining and civil engineering lags and lag bolts' and it generally has a hexagonal drive head. ?ag bolts are designed for securely fastening heavy timbers &post and beams, timber railway trestles and bridges' to one another, or to fasten wood to masonry or concrete. ?ag bolts are usually used with an expanding insert called a lag in masonry or concrete walls, the lag manufactured with a hard metal jacket that bites into the sides of the drilled hole, and the inner metal in the lag being a softer alloy of lead, or zinc alloyed with soft iron. he coarse thread of a lag bolt and lag mesh and deform slightly making a secure near water tight anti$corroding mechanically strong fastening. )heet metal screw sel!"tapping screw* thread cutting screws# 1as sharp threads that cut into a material such as sheet metal, plastic or wood. hey are sometimes notched at the tip to aid in chip removal during thread cutting. he shank is usually threaded up to the head. Sheet metal screws make excellent fasteners for attaching metal hardware to wood because the fully threaded shank provides good retention in wood. Concrete screw A stainless or carbon steel screw for fastening wood, metal, or other materials into concrete or masonry. !oncrete screws are commonly blue in color, with or without corrosion coating. hey may either have a >hillips flat head or a slotted hex washer head. 1eads sizes range from 3.-.45 to 3.:45 in &D.48: to 7.5/5 mm' and lengths from -./5 to 5 in &:/ to -/4 mm'. ypically an installer uses a hammer drill to make a pilot hole for each concrete screw. 6n the <nited States, concrete screws are commonly called apcons which refers to the brand name created from the definition of 2an anchor that taps its own threads into concrete.2 Other commercial names for the fastener are masonry screw, confast screw, blue screw, self$tapping screw, and iten. )el!"drilling screw %eks screw# Similar to a sheet metal screw, but it has a drill$shaped point to cut through the substrate to eliminate the need for drilling a pilot hole. =esigned for use in soft steel or other metals. he points are numbered from - through 5, the larger the number, the thicker metal it can go through without a pilot hole. A 5 point can drill a 3.5 in &-/.4 mm' of steel, for example. +rywall screw Specialized screw with a bugle head that is designed to attach drywall to wood or metal studs, however it is a versatile construction fastener with many uses. he diameter of drywall screw threads is larger than the shaft diameter. ,article board screw chipboard screw# Similar to a drywall screw except that it has a thinner shaft and provides better resistance to pull$out in particle board, while offset against a lower shear strength. he threads on particle board screws are asymmetrical. +eck screw

Similar to drywall screw except that it has improved corrosion resistance and is generally supplied in a larger gauge. +ost deck screws have a type$-4 &auger type' thread cutting tip for installation into decking materials. +ouble ended screw dowel screw# Similar to a wood screw but with two pointed ends and no head, used for making hidden joints between two pieces of wood. )crew eye eye screw# Screw with a looped head. ?arger ones are sometimes call lag eye screws. =esigned to be used as attachment point, particularly for something that is hung from it. %hread rolling screws hese have a lobed &usually triangular' cross$section. hey form threads in a pre$drilled hole in the mating workpiece by pushing the material outward during installation. Mirror screws hese are flat head wood screws with a tapped hole in the head, which is designed to receive a separate screw$in chrome$plated cover. hey are usually used to mount mirrors.

Fasteners with a non"tapered shank

-reakaway bolt A bolt with a hollow threaded shank, which is designed to break away upon impact. ypically used to fasten fire hydrants, so they will break away when hit by a car. Also used in aircraft to reduce weight. Cap screw he term cap screw refers to many different things at different times and places. !urrently, it most narrowly refers to a style of head &see the gallery below'. +ore broadly, and more commonly, it refers to the group of screws* shoulder screws, hex heads, counter$sunk heads, button heads, and fillister heads. 6n the <S, cap screws are defined by AS+) ,-..8./ and AS+) ,-..:. 6n the past, the term cap screw, in general, referred to screws that were supposed to be used in applications where a nut was not used, however the characteristics that differentiated it from a bolt vary over time. 6n -7-3, Anthony defined it as screw with a hex head that was thicker than a bolt head, but the distance across the flats was less than a bolt0s. 6n -7-:, Eoolley and +eredith defined them like Anthony, but gave the following dimensions* hex head cap screws up to and including 4F-8 in have a head that is :F-8 in larger than the shank diameter" screws greater than -F/ in in diameter have a head that is -FD larger than the shank. S(uare head cap screws up to and including : FD in have a head -F. in larger than the shank" screws larger than :FD in have a head -FD in larger than the shank. 6n -7-7, =yke defined them as screws that are threaded all the way to the head. Hex cap screw !ap screw with a hexagonal head, designed to be driven by a wrench &spanner'. An AS+) ,-../.- compliant cap screw has somewhat tighter

tolerances than a hex bolt for the head height and the shank length. he nature of the tolerance difference allows an AS+) ,-../.- hex cap screw to always fit where a hex bolt is installed but a hex bolt could be slightly too large to be used where a hex cap screw is designed in. Hex bolt At times the term is used interchangeably with hex cap screw. An AS+) ,-../.- compliant hex bolt is built to different tolerances than a hex cap screw. )ocket cap screw Also known as a socket head cap screw, socket screw or Allen bolt, this is a type of cap screw with a hexagonal recessed drive. he most common types in use have a cylindrical head whose diameter is nominally -.5 times &-783 series design' that of the screw shank &major' diameter. !ounterbored holes in parts allow the screw head to be flush with the surface or recessed. Other head designs include button head and flat head, the latter designed to be seated into countersunk holes. A hex key &sometimes referred to as an Allen wrench or Allen key' or hex driver is re(uired to tighten or loosen a socket screw. Socket screws are commonly used in assemblies that do not provide sufficient clearance for a conventional wrench or socket. Machine screw Cenerally a smaller fastener &less than -FD inch in diameter' threaded the entire length of its shank that usually has a recessed drive type &slotted, >hillips, etc.'. +achine screws are also made with socket heads &see above', in which case they may be referred to as socket head machine screws. )el!"tapping machine screw Similar to a machine screw except the lower part of the shank is designed to cut threads as the screw is driven into an untapped hole. he advantage of this screw type over a self$tapping screw is that, if the screw is reinstalled, new threads are not cut as the screw is driven. )et screw grub screw# Cenerally a headless screw but can be any screw used to fix a rotating part to a shaft. he set screw is driven through a threaded hole in the rotating part until it is tight against the shaft. he most often used type is the socket set screw, which is tightened or loosened with a hex key. )et -olt &tap bolt' A bolt that is threaded all the way to the head. An AS+) ,-../.compliant setGtap bolt has the same tolerances as an AS+) ,-../.compliant hex cap screw. )tud(threaded rod Studs are head$less screws. hey may be threaded at both ends and unthreaded in the middle or completely threaded" the latter is usually referred to as a threaded rod, especially when it has a large aspect ratio &that is, (uite long compared to diameter'. !ompletely threaded round stock is available in bar stock form and is then usually referred to as 2all$thread2. .ye bolt A bolt with a looped head.

%oggle bolt A bolt with a special nut known as a wing. 6t is designed to be used where there is no access to side of the material where the nut is located. <sually the wing is spring loaded and expands after being inserted into the hole. Carriage bolt coach bolt# 1as a domed or countersunk head, and the shank is topped by a short s(uare section under the head. he s(uare section grips into the part being fixed &typically wood', preventing the bolt from turning when the nut is tightened. A rib neck carriage bolt has several longitudinal ribs instead of the s(uare section, to grip into a metal part being fixed. .levator bolt A bolt similar to a carriage bolt, except the head is thin and flat. here are many variations. Some do not have a s(uare base, but rather triangular sections of the flat head are folded down to form 2fangs2 that cut into wood and hold it secure. )tove bolt A type of machine screw that has a round or flat head and is threaded to the head. hey are usually made of low grade steel, have a slot or >hillips drive, and are used to join sheet metal parts using a hex or s(uare nut. )houlder screw stripper bolt# A shoulder screw differs from machine screws in that the shank is ground to a precise diameter, known as the shoulder, and the threaded portion is smaller in diameter than the shoulder. Shoulder bolt specifications call out the shoulder diameter, shoulder length, and threaded diameter" the threaded length is fixed, based on the threaded diameter, and usually (uite short. 6t is usually used for revolving joints in mechanisms and linkages" when used as a guide for the stripper plate in a die set its called a stripper bolt. %humb screw A threaded fastener designed to be twisted into a tapped hole by hand without the use of tools. )ecurity screw similar to a standard screw except that once inserted it cannot be easily removed. ension control bolt & ! bolt' 1eavy duty bolt used in steel frame construction. he head is usually domed and is not designed to be driven. he end of the shank has a spline on it which is engaged by a special power wrench which prevents the bolt from turning while the nut is tightened. Ehen the appropriate tor(ue is reached the spline shears off. ,low bolt A bolt similar to a carriage bolt, except the head is flat or concave, and the underside of the head is cone designed to fit in a countersunk recess. here are many variations, with some not using a s(uare base, but rather a key, a locking slot, or other means. he recess in the mating part must be designed to accept the particular plow bolt. )pring bolt

A bolt which must be pulled back and which is brought back into place by the spring when the pressure is released. Spring bolts are used in ;ubik0s Snakes, for example, the wedges of which are pulled apart slightly when twisted and are pulled back together by the spring bolt when shifted back into position. Materials Screws and bolts are made from a wide range of materials, with steel being perhaps the most common, in many varieties. Ehere great resistance to weather or corrosion is re(uired, stainless steel, titanium, brass &steel screws can discolor oak and other woods', bronze, monel or silicon bronze may be used, or a coating such as brass, zinc or chromium applied. )lectrolytic action from dissimilar metals can be prevented with aluminium screws for double$ glazing tracks, for example. Some types of plastic, such as nylon or polytetrafluoroethylene &> %)', can be threaded and used for fastening re(uiring moderate strength and great resistance to corrosion or for the purpose of electrical insulation. he American 6nstitute of Steel !onstruction &A6S!' -:th )dition Steel =esign +anual section -8.- chapter #$: specifies the re(uirements for bolted structural connections. Structural bolts replaced rivets due to decreasing cost and increasing strength of structural bolts in the /3th century. !onnections are formed with two types of joints* slip$critical connections and bearing connections. 6n slip$critical connections, movement of the connected parts is a serviceability condition and bolts are tightened to a minimum re(uired pretension. Slip is prevented through friction of the 2faying2 surface, that is the plane of shear for the bolt and where two members make contact. ,ecause friction is proportional to the normal force, connections must be sized with bolts numerous and large enough to provide the re(uired load capacity. 1owever, this greatly decreases the shear capacity of each bolt in the connection. he second type and more common connection is a bearing connection. 6n this type of connection the bolts carry the load through shear and are only tightened to a 2snug$fit.2 hese connections re(uire fewer bolts than slip$critical connections and therefore are a less expensive alternative. Slip$critical connections are more common on flange plates for beam and column splices and moment critical connections. ,earing type connections are used in light weight structures and in member connections where slip is not important and prevention of structural failure is the design constraint. !ommon bearing type connections include* shear tabs, beam supports, gusset plates in trusses. Mechanical classi!ications he numbers stamped on the head of the bolt are referred to the grade of the bolt used in certain application with the strength of a bolt. 1igh$strength steel bolts usually have a hexagonal head with an 6SO strength rating &called property class' stamped on the head. And the absence of markingGnumber indicates a lower grade bolt with low strength. he property classes most

often used are 5.., ..., and -3.7. he number before the point is the tensile ultimate strength in +>a divided by -33. he number after the point is -3 times the ratio of tensile yield strength to tensile ultimate strength. %or example, a property class 5.. bolt has a nominal &minimum' tensile ultimate strength of 533 +>a, and a tensile yield strength of 3.. times tensile ultimate strength or 3..&533' H D33 +>a. ensile ultimate strength is the stress at which the bolt fails. ensile yield strength is the stress at which the bolt will receive a permanent set &an elongation from which it will not recover when the force is removed' of 3./ I offset strain. Ehen elongating a fastener prior to reaching the yield point, the fastener is said to be operating in the elastic region" whereas elongation beyond the yield point is referred to as operating in the plastic region, since the fastener has suffered permanent plastic deformation. +ild steel bolts have property class D.8. 1igh$strength steel bolts have property class ... or above. he same type of screw or bolt can be made in many different grades of material. %or critical high$tensile$strength applications, low$grade bolts may fail, resulting in damage or injury. On SA)$standard bolts, a distinctive pattern of marking is impressed on the heads to allow inspection and validation of the strength of the bolt. 1owever, low$cost counterfeit fasteners may be found with actual strength far less than indicated by the markings. Such inferior fasteners are a danger to life and property when used in aircraft, automobiles, heavy trucks, and similar critical applications. 6nch SA) #D/7 defines the bolt grades for inch$system sized bolts and screws. 6t defines them by grade, which ranges from 3 to ., with . being the strongest. 1igher grades do not exist within the specification. SA) grades 5 and . are the most common. +etric he international standard for metric screws is defined by 6SO .7., specifically 6SO .7.$-. SA) #--77 and AS + %58.+ are two Borth American metric standards that closely mimic the 6SO standard. 6n case of inch sizes the grade is dictated by the number of radial shapes plus a value of two. 6nch$ system bolts use integer values to indicate grades but metric bolts use numbers with one decimal. he two Borth American standards use the same property class markings as defined by 6SO .7.. he AS + standard only includes the following property classes from the 6SO standard* D.8, D.., 5.., ..., 7.., -3.7, and -/.7" it also includes two extra property classes* ....: and -3.7.:. AS + property classes are to be stamped on the top of screws and it is preferred that the marking is raised. Screw head shapes

&a'

pan, &b' button, &c' round, &d' truss, &e' flat &countersunk', &f' oval ,an head A low disc with chamfered outer edge -utton or dome head !ylindrical with a rounded top /ound head A dome$shaped head used for decoration. %russ head ?ower$profile dome designed to prevent tampering Countersunk or !lat head !onical, with flat outer face and tapering inner face allowing it to sink into the material. he angle of the screw is measured as the full angle of the cone. Oval or raised head A decorative screw head with a countersunk bottom and rounded top. -ugle head Similar to countersunk, but there is a smooth progression from the shank to the angle of the head, similar to the bell of a bugle Cheese head =isc with cylindrical outer edge, height approximately half the head diameter Fillister head !ylindrical, but with a slightly convex top surface. 1eight to diameter ratio is larger than cheese head. Flanged head A flanged head can be any of the above head styles with the addition of an integrated flange at the base of the head. his eliminates the need for a flat washer. Some varieties of screw are manufactured with a break$away head, which snaps off when ade(uate tor(ue is applied. his prevents tampering and also provides an easily inspectable joint to guarantee proper assembly. An example of this is the shear bolts used on vehicle steering columns, to secure the ignition switch. %hread standards here are many systems for specifying the dimensions of screws, but in much of the world the 6SO metric screw thread preferred series has displaced the many older systems. Other relatively common systems include the ,ritish Standard Ehitworth, ,A system &,ritish Association', and the <nified hread Standard.

0)O metric screw thread

he basic principles of the 6SO metric screw thread are defined in international standard 6SO 8.$- and preferred combinations of diameter and pitch are listed in 6SO /8-. he smaller subset of diameter and pitch combinations commonly used in screws, nuts and bolts is given in 6SO /8/. he most commonly used pitch value for each diameter is the coarse pitch. %or some diameters, one or two additional fine pitch variants are also specified, for special applications such as threads in thin$walled pipes. 6SO metric screw threads are designated by the letter M followed by the major diameter of the thread in millimeters &e.g., +.'. 6f the thread does not use the normal coarse pitch &e.g., -./5 mm in the case of +.', then the pitch in millimeters is also appended with a multiplication sign &e.g. 2+.J-2 if the screw thread has an outer diameter of . mm and advances by - mm per :83K rotation'. he nominal diameter of a metric screw is the outer diameter of the thread. he tapped hole &or nut' into which the screw fits, has an internal diameter which is the size of the screw minus the pitch of the thread. hus, an +8 screw, which has a pitch of - mm, is made by threading a 8 mm shank, and the nut or threaded hole is made by tapping threads into a hole of 5 mm diameter &8 mm $ - mm'. +etric hexagon bolts, screws and nuts are specified, for example, in ,ritish Standard ,S D-73 &general purpose screws' and ,S :87/ &precision screws'. he following table lists the relationship given in these standards between the thread size and the maximal width across the hexagonal flats &wrench size'* 0 ) O m et ri c t h r e a d $ r e n c

+ + + - + / + + + + + . / . : D 5 8 . 3 8 5

+ /

+ 8

+ / 3

+ / D

+ : 3

+ : 8

+ D /

+ D .

+ 5 8

+ 8 D

: . /

5 . 5

/ D

: 3

: 8

D 8

5 5

8 5

4 5

. 5

7 5

h si 1 e m m # 6n addition, the following non$preferred intermediate sizes are specified* 0)O metri c threa d $ren ch si1e mm#

+ 4

+ -D

+ -.

+ //

+ /4

+ ::

+ :7

+ D5

+ 5/

+ 83

+8 .

//

/4

:/

D-

53

83

43

.3

73

-3 3

$hitworth

he first person to create a standard &in about -.D-' was the )nglish engineer Sir #oseph Ehitworth. Ehitworth screw sizes are still used, both for repairing old machinery and where a coarser thread than the metric fastener thread is re(uired. Ehitworth became ,ritish Standard Ehitworth, abbreviated to ,SE &,S .D*-758' and the ,ritish Standard %ine &,S%' thread was introduced in -73. because the Ehitworth thread was too coarse for some applications. he thread angle was 55K and a depth and pitch of thread that varied with the diameter of the thread &i.e., the bigger the bolt, the coarser the thread'. he spanner size is determined by the size of the bolt, not the distance between the flats. he most common use of a Ehitworth pitch nowadays is in all <L scaffolding. Additionally, the standard photographic tripod thread, which for small cameras is -GD2 Ehitworth &/3 tpi' and for mediumGlarge format cameras is :G.2 Ehitworth &-8 tpi'. 6t is also used for microphone stands and their appropriate clips, again in both sizes, along with 2thread adapters2 to allow the smaller size to attach to items re(uiring the larger thread.

-ritish 2ssociation screw thread

A later standard established in the <nited Lingdom was the ,ritish Association &,A' screw threads, named after the ,ritish Association for Advancement of Science. Screws were described as 2/,A2, 2D,A2 etc., the

odd numbers being rarely used, except in e(uipment made prior to the -743s for telephone exchanges in the <L. his e(uipment made extensive use of odd$numbered ,A screws, in orderMit may be suspectedMto reduce theft. ,A threads are specified by ,ritish Standard ,S 7:*-75- 2Specification for ,ritish Association &,.A.' screw threads with tolerances for sizes 3 ,.A. to -8 ,.A.2 Ehile not related to 6SO metric screws, the sizes were actually defined in metric terms, a 3,A thread having a 8 mm diameter and - mm pitch. Other threads in the ,A series are related to 3,A in a geometric series with the common factors 3.7 and -./. %or example, a D,A thread has pitch mm &3.85mm' and diameter mm &:.8/mm'. Although 3,A has the same diameter and pitch as 6SO +8, the threads have different forms and are not compatible. ,A threads are still common in some niche applications. !ertain types of fine machinery, such as moving$coil meters and clocks, tend to have ,A threads wherever they are manufactured. ,A sizes were also used extensively in aircraft, especially those manufactured in the <nited Lingdom. ,A sizing is still used in railway signalling, mainly for the termination of electrical e(uipment and cabling. ,A threads are extensively used in +odel )ngineering where the smaller hex head sizes make scale fastenings easier to represent. As a result many <L +odel )ngineering suppliers still carry stocks of ,A fasteners up to typically .,A and -3,A. 5,A is also commonly used as it can be threaded onto -G. rod.

&ni!ied %hread )tandard

he <nified hread Standard &< S' is most commonly used in the <nited States of America, but is also extensively used in !anada and occasionally in other countries. he size of a < S screw is described using the following format* 3"4, where 3 is the nominal size &the hole or slot size in standard manufacturing practice through which the shaft of the screw can easily be pushed' and 4 is the threads per inch & >6'. %or sizes -FD inch and larger the size is given as a fraction" for sizes less than this an integer is used, ranging from 3 to -8. %or most size screws there are multiple >6 available, with the most common being designated a <nified !oarse hread &<B! or <B' and <nified %ine hread &<B% or <%'. Manu!acture

here are three steps in manufacturing a screw* heading, thread rolling, and coating. Screws are normally made from wire, which is supplied in large coils, or round bar stock for larger screws. he wire or rod is then cut to the proper length for the type of screw being made" this workpiece is known as a blank. 6t is then cold headed, which is a cold working process. 1eading produces the head of the screw. he shape of the die in the machine dictates what features are pressed into the screw head" for example a flat head screw uses a flat die. %or more complicated shapes two heading processes are re(uired to get all of the features into the screw head. Slotted head screws re(uire an extra step to cut the slot in the head" this is done on a slotting machine. hese machines are essentially stripped down milling machines designed to process as many blanks as possible. he blanks are then polished again prior to threading. he threads are usually produced via thread rolling, however some are cut. he workpiece is then tumble finished with wood and leather media to do final cleaning and polishing. %or most screws a coating, such as hot$dip galvanizing or blackening, is applied to prevent corrosion.

=ifferent bolt sections

Heading

he first step in the overall process is heading, which is a cold working forging process. his process produces a near net shape workpiece, which means the final product is almost finished. An important consideration in heading is the tendency for the bar to buckle if its unsupported length to diameter ratio is too high. his ratio usually is limited to less than :*- but with appropriate dies, it can be higher. herefore, heading is the most likely production method because bolts have a large head$to$shank ratio, they are longer than -N times their diameter, bolts have multiple diameters and finally re(uire a geometrical shape &i.e. the rounded head'. %urthermore, this production method is probably used because cold heading has a very high production rate, and produces virtually no waste material. he process works as follows* the bar stock is fed into a machine, called a 2former2. he bar stock is stopped, and then gripped by a gripping die. he gripping die is shaped in such a way that it forms a carriage along the neck of the stock when its full gripping force is applied. An indented punch, the shape of a rounded head, will then proceed to move forward, colliding with the stock and causing the metal to flow at right angles to the ram force provided by the punch, increasing the diameter of the workpiece, and reducing its overall length, thus forming a 2rounded2 head. he work billet is then sheared to the desired length.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Lifting MethodsDocument10 paginiLifting Methodsselva1965Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Module 5 PDFDocument93 paginiModule 5 PDFVishal Shanmuga SundramÎncă nu există evaluări

- Stack Design CalculationDocument27 paginiStack Design Calculationrupam dey100% (6)

- Session 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowDocument48 paginiSession 5-Thermal Spray Coatings For Corrosion Protection-What You Need To KnowBala SingamÎncă nu există evaluări

- Fundamentals of Metal FormingDocument9 paginiFundamentals of Metal FormingGeorge CamachoÎncă nu există evaluări

- ISO 10816-1 Normativa VibracionesDocument10 paginiISO 10816-1 Normativa Vibracionesumendibil100% (1)

- Astm C 618 02 1Document4 paginiAstm C 618 02 1Ciro Arnold Gonzales PauccarÎncă nu există evaluări

- Diaphragm WallsDocument15 paginiDiaphragm WallsWan Eira100% (1)

- ViscosityDocument20 paginiViscosityOnur CelikkanÎncă nu există evaluări

- Analysis of Project Success Factors in Construction IndustryDocument14 paginiAnalysis of Project Success Factors in Construction IndustryJuan AlayoÎncă nu există evaluări

- Din 332-1Document1 paginăDin 332-1AdrianopoÎncă nu există evaluări

- Arranjos Amca PDFDocument8 paginiArranjos Amca PDFfabio_persoliÎncă nu există evaluări

- List of StandardsDocument16 paginiList of StandardsameybarveÎncă nu există evaluări

- Blower SilencersDocument2 paginiBlower SilencersameybarveÎncă nu există evaluări

- Cast Heat-Resistant AlloyDocument8 paginiCast Heat-Resistant Alloywangchao821Încă nu există evaluări

- Type of ThreadDocument13 paginiType of ThreadVils ArabadzhievaÎncă nu există evaluări

- Orifice Plate Formula DerivationDocument5 paginiOrifice Plate Formula DerivationameybarveÎncă nu există evaluări

- Fan Laws: Reference InformationDocument1 paginăFan Laws: Reference InformationBMÎncă nu există evaluări

- Catalogo Flanges Awwa PDFDocument7 paginiCatalogo Flanges Awwa PDFhosman_australÎncă nu există evaluări

- Helical strakes reduce vortex shedding forcesDocument1 paginăHelical strakes reduce vortex shedding forcesameybarveÎncă nu există evaluări

- 3 Moment EqnDocument18 pagini3 Moment EqnRahul GaikwadÎncă nu există evaluări

- Ibr CalculationsDocument9 paginiIbr CalculationsoperationmanagerÎncă nu există evaluări

- Basic Engg DataDocument19 paginiBasic Engg DataameybarveÎncă nu există evaluări

- Air Pollutant ConcentrationsDocument6 paginiAir Pollutant ConcentrationsameybarveÎncă nu există evaluări

- Typical Head TypesDocument1 paginăTypical Head TypesameybarveÎncă nu există evaluări

- Valve HandbookDocument296 paginiValve HandbookameybarveÎncă nu există evaluări

- Simplex Basket Type Offset Conn. Simplex Basket Type Inline Conn. Simplex Basket Type Inline Conn. With Weld Neck FlangesDocument2 paginiSimplex Basket Type Offset Conn. Simplex Basket Type Inline Conn. Simplex Basket Type Inline Conn. With Weld Neck FlangesameybarveÎncă nu există evaluări

- Density of Mix GasDocument3 paginiDensity of Mix GasameybarveÎncă nu există evaluări

- Straddle Principle For FlangesDocument1 paginăStraddle Principle For Flangesameybarve67% (3)

- Anti Vibration PadDocument4 paginiAnti Vibration PadameybarveÎncă nu există evaluări

- Expansion JointDocument4 paginiExpansion JointameybarveÎncă nu există evaluări

- Calorific Value of FuelsDocument3 paginiCalorific Value of FuelsameybarveÎncă nu există evaluări

- Pipe and Types According To ProcessDocument3 paginiPipe and Types According To ProcessameybarveÎncă nu există evaluări

- Grating Design DataDocument2 paginiGrating Design DataericastorgalucoÎncă nu există evaluări

- Understanding The Basics of GreaseDocument3 paginiUnderstanding The Basics of Greasemusleparrain1Încă nu există evaluări

- Bridge Concrete Approach Slab and Embankment SettlementDocument152 paginiBridge Concrete Approach Slab and Embankment SettlementwalaywanÎncă nu există evaluări

- Boiler ManualDocument68 paginiBoiler ManualAnwar AliÎncă nu există evaluări

- ASTMC Actual S-Curve Erwin 01-20-15Document69 paginiASTMC Actual S-Curve Erwin 01-20-15Dick Anthony MabaoÎncă nu există evaluări

- Pahu Schedule For MPHDocument1 paginăPahu Schedule For MPHsachinsaklani23Încă nu există evaluări

- The Fire Resistant Solution For Steel Conduit: Cable DescriptionDocument10 paginiThe Fire Resistant Solution For Steel Conduit: Cable DescriptionBhagoo HatheyÎncă nu există evaluări

- DEAP Manual Version 4.2.3 FinalDocument212 paginiDEAP Manual Version 4.2.3 FinalSean WalshÎncă nu există evaluări

- Torques FagDocument52 paginiTorques FagAlain Gonzalo Larama CastroÎncă nu există evaluări

- ContentDocument29 paginiContentys bdÎncă nu există evaluări

- Chapter 4 - Plasticity of SoilDocument15 paginiChapter 4 - Plasticity of SoilHussein EssaÎncă nu există evaluări

- Regleta 6700 Liquid Level IndicatorDocument4 paginiRegleta 6700 Liquid Level IndicatorJulio PCÎncă nu există evaluări

- 21-50-007 AVK Resilient Seated Gate Valve DN50-400Document2 pagini21-50-007 AVK Resilient Seated Gate Valve DN50-400Ferdi SagalaÎncă nu există evaluări

- A Texas Home Is Designed To Authentically Represent Hacienda StyleDocument5 paginiA Texas Home Is Designed To Authentically Represent Hacienda StyleJulieta Perez GomezÎncă nu există evaluări

- Kss Cable TieDocument32 paginiKss Cable Tieismail alwainiÎncă nu există evaluări

- Petronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelDocument27 paginiPetronas Technical Standards: Passive Fire and Cryogenic Protection For Structural SteelvinothÎncă nu există evaluări

- Áfico de Correlación Del Martillo Schmidt Miller 1965 PDFDocument1 paginăÁfico de Correlación Del Martillo Schmidt Miller 1965 PDFalexanderÎncă nu există evaluări

- BR Enclosures Ilinq CatalogueDocument64 paginiBR Enclosures Ilinq CatalogueEng Yasser FoudahÎncă nu există evaluări

- Windmason Technical SpecificationDocument8 paginiWindmason Technical Specificationowais mirÎncă nu există evaluări

- DSI-Products and Systems of MiningDocument12 paginiDSI-Products and Systems of MiningJustin CorbettÎncă nu există evaluări

- Precast Concrete Girder BridgesDocument30 paginiPrecast Concrete Girder BridgesPacha Khan KhogyaniÎncă nu există evaluări

- Ep61412.PDF - Piping Classes 600#Document10 paginiEp61412.PDF - Piping Classes 600#eke23Încă nu există evaluări

- JPPJ Calcs for Raft Foundation DesignDocument1 paginăJPPJ Calcs for Raft Foundation DesignHimura_100% (1)

- TunnellingDocument37 paginiTunnellingrockyminÎncă nu există evaluări

- Live Loads On Bridge Superstructures: BelowDocument8 paginiLive Loads On Bridge Superstructures: BelowMark Angelo FloresÎncă nu există evaluări