Documente Academic

Documente Profesional

Documente Cultură

Material Balance Enrgy Balance

Încărcat de

Gunjan SolankiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Material Balance Enrgy Balance

Încărcat de

Gunjan SolankiDrepturi de autor:

Formate disponibile

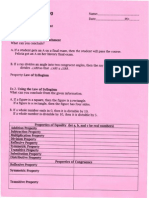

AIM:

To design carbon disulfide plant of 100 TPD

Assuming loses

1) 2) 3)

Reactor Absorber Stripper

0.5 % of COS 1 % of COS 1 % of CS2

carbonyl sulfide carbonyl sulfide carbon disulfide

Molecular weight of compounds used in the process: 1 Carbon monoxide CO 28.01 kg/kmol CO2 2 Carbon dioxide 44.01 kg/kmol 3 Sulphur Dioxide 4 Carbon disulfide 5 Carbonyl sulfide SO2 CS2 COS 64.066 kg/kmol 76.139 kg/kmol 60.075 kg/kmol

Unit 1:

shell and tube reactor Reaction: Feed: CO 3CO + SO2 COS + 2CO2

373.0715779 kmol/hr 10449.7349 kg/hr kmol/hr kg/hr

124.3571926 7967.067902 Conversion rate = 95 % Product: COS 118.139333 7097.220429 CO2

SO2

CO

COS CO2

kmol/hr kg/hr

SO2

236.278666 kmol/hr 10398.62409 kg/hr

Shell and tube reactor

CO2 output after loss

235.0973 kmol/hr 10346.63 kg/hr 117.5486 kmol/hr 7061.734 kg/hr

COS output after loss

Second unit:

Reactor cum absorber: Reaction: 2COS CS2 + CO2

Feed:

1)

CO2

235.0973 kmol/hr 10346.63 kg/hr 117.5486 kmol/hr 7061.734 kg/hr

2)

COS

Note:

Conv

95%

factor(Mole ):

0.5

Product

1)

CS2

55.8356 kmol/hr 4251.267 kg/hr 55.8356 kmol/hr 2457.325 kg/hr Carbon disulfide 55.27724623 kmol/hr 4208.754251 kg/hr

2)

CO2

Product after loss

1)

Third Unit: Stripping section() Stripping Section(No reaction takes place here)

Feed:

Carbon Monoxide

CO

5% more then required in first reactor 391.7252 kmol/hr 10972.22 kg/hr

carbon disulfide

CS2

55.27725 kmol/hr 4208.754 kg/hr

Final CS2 After Losses

CS2

54.72447 kmol/hr 4166.667 kg/hr

Considering plant operation of 24 HR 24 Total production of CS2 1313.38737 100000.001 100.000001

hr kmol/day kg/day TPD

Energy Balance Across UNIT 1: Shell and tube Reactor. 1) Temperature of reactor 200 Celsius 473.15 Kelvin

2)

log Kp

22.58819

1 log Kp 15509( ) 10.19 T

Heat of formation at 25 Degree 1 CO -110.53 KJ/mol 2 CO2 -393.5 KJ/mol 3 COS -141.5 KJ/mol 4 CS2 -116.9 KJ/mol 5 SO2 -296.81 KJ/mol Heat Capacity datas at constant pressure Cp 1 2 3 4 5 6 3) CO CO2 COS CS2 SO2 Ethylene Energy require to take CO and SO2 from 25 C to 200C m(CO) 373.0716 Kmol/hr Cp(CO) 0.0292 KJ/Kmol C m(SO2) 124.3572 Kmol/hr CP(SO2) 0.042 KJ/Kmol C temp T1 T2 25 C 200 C m*Cp*T 298.15 K 473.15 K

29.2 KJ/kmol C 42 KJ/kmol C

Heat required

2820421 KJ/hr 67690107 KJ/day

4)

Heat of reaction for first reaction in catalytic reactor: Reaction: 3CO + SO2 COS + 2CO2

Hr

-48.1 KJ/mol -5654.08941 KJ/hr -135698.146 KJ/day

-48100 KJ/Kmol

-5682501.92 KJ/hr -136380046 KJ/day

4.1)

Heat removed to get 100C T1 T2 200 100 energy needed Cp(CO2) Cp(COS) If we use ethylene glycol in our HE 39.94 71.25 Cp(Ethylen gylcol) flowrate Inlet temp Outlet Temp Energy 150.6 235.9246 0 50 1776513 1776512.541 KJ/hr

5)

Reaction:

2COS

CS2 + CO2

Hr

-227.4 KJ/mol -12570.0458 KJ/hr -301681.099 KJ/day

-227400 KJ/Kmol

5.1)

Energy to heat the CO from 25 to 100 T1 T2 energy required

25 100 857878.1 flowrate T1 113.928 Kmol/hr 0C

Taking ethylene glycol as a cooling agent in HE

T2

50 C 857878

6)

Heat balance around the condensor Temperature required T2 T1 heat Taking ethylene gycol in heat exchanger 25 C 100 C 1173000 KJ/hr Cp(ethylene glycol) 150.6 KJ/Kmol C 155.7769 0 50 1173000 Cp(CS2) Cp(CO) 76.01 29.2

flowrate required to achieve cooling inlet temp outlet temp

Total Energy requirement

-214249 KJ/hr

CS2 + CO2

Solvent back to absrober

CO (For stripping)

COS absorbed in Solvent

Stripper

CO2

Solvent(From Stripper)

Dissolved COS to stripper COS + CO2

Reactor cum absorber

first reactor

CO

373.0716 kmol/hr COS 118.1393 kmol/hr

CO2 SO2 124.3572 kmol/hr

236.2787 kmol/hr

KJ/kmol C kmol/hr C C

KJ/Kmol C KJ/Kmol C

kmol/hr C C KJ/hr

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 6 0LDies PDFDocument101 pagini6 0LDies PDFscodavnx100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- KA Chemistry Notes PartialDocument146 paginiKA Chemistry Notes PartialAnjali PradhanÎncă nu există evaluări

- Design Aspects of Cathodic ProtectionDocument24 paginiDesign Aspects of Cathodic ProtectionRahul AdityaÎncă nu există evaluări

- Salary Slip Sept 2014 PDFDocument2 paginiSalary Slip Sept 2014 PDFGunjan SolankiÎncă nu există evaluări

- Phy Interface Pci Express Sata Usb31 Architectures Ver43 PDFDocument99 paginiPhy Interface Pci Express Sata Usb31 Architectures Ver43 PDFRaj Shekhar ReddyÎncă nu există evaluări

- Digital Control Engineering 2nd Edition Fadali Solution Manual - Doc254405506Document23 paginiDigital Control Engineering 2nd Edition Fadali Solution Manual - Doc254405506chyntia50% (4)

- Chapter 2 - FIR Filters - Digital Filter Design - Mikroelektronika PDFDocument114 paginiChapter 2 - FIR Filters - Digital Filter Design - Mikroelektronika PDFAnimesh NagrareÎncă nu există evaluări

- Case 6-7 Questions For Advance Preparation and Group Submission On Campus 360Document1 paginăCase 6-7 Questions For Advance Preparation and Group Submission On Campus 360Gunjan SolankiÎncă nu există evaluări

- Project WorkDocument3 paginiProject WorkGunjan SolankiÎncă nu există evaluări

- Floor Pricing of "Plasto Cover" Floor Cover: 140 Price of "Plasto Cover" For Time of 5 Year in Case of Optimistic SellingDocument4 paginiFloor Pricing of "Plasto Cover" Floor Cover: 140 Price of "Plasto Cover" For Time of 5 Year in Case of Optimistic SellingGunjan SolankiÎncă nu există evaluări

- R 1Document11 paginiR 1Gunjan SolankiÎncă nu există evaluări

- Product MixDocument191 paginiProduct MixGunjan SolankiÎncă nu există evaluări

- CASE 6: Hanover Bates Chemical Corporation: Group 5Document1 paginăCASE 6: Hanover Bates Chemical Corporation: Group 5Gunjan SolankiÎncă nu există evaluări

- SDM - 2016-18 - Course OutlineDocument22 paginiSDM - 2016-18 - Course OutlineGunjan SolankiÎncă nu există evaluări

- 507419143 (1)Document2 pagini507419143 (1)Gunjan Solanki0% (1)

- Raghuram Rajan in 3 YearsDocument4 paginiRaghuram Rajan in 3 YearsGunjan SolankiÎncă nu există evaluări

- IntroductionDocument1 paginăIntroductionGunjan SolankiÎncă nu există evaluări

- 17th August 9 PMDocument1 pagină17th August 9 PMGunjan SolankiÎncă nu există evaluări

- IntroductionDocument1 paginăIntroductionGunjan SolankiÎncă nu există evaluări

- Mont BlancDocument1 paginăMont BlancGunjan SolankiÎncă nu există evaluări

- Farewell LetterDocument1 paginăFarewell LetterGunjan SolankiÎncă nu există evaluări

- Body BoiloutDocument1 paginăBody BoiloutGunjan SolankiÎncă nu există evaluări

- Incoming IlluminationsDocument1 paginăIncoming IlluminationsGunjan SolankiÎncă nu există evaluări

- Online Admissions 2016-2018 IIFTDocument2 paginiOnline Admissions 2016-2018 IIFTGunjan SolankiÎncă nu există evaluări

- Nmat 2015-16Document2 paginiNmat 2015-16Gunjan SolankiÎncă nu există evaluări

- XLRi InterviewDocument6 paginiXLRi InterviewGunjan SolankiÎncă nu există evaluări

- Work ExDocument2 paginiWork ExGunjan SolankiÎncă nu există evaluări

- Receipt 888915766442Document1 paginăReceipt 888915766442Gunjan SolankiÎncă nu există evaluări

- Gunjan Solanki ResumeDocument3 paginiGunjan Solanki ResumeGunjan SolankiÎncă nu există evaluări

- State Bank of India ReciptDocument1 paginăState Bank of India ReciptGunjan SolankiÎncă nu există evaluări

- Evaporator 1st Effect Body Change Over - Rev01Document3 paginiEvaporator 1st Effect Body Change Over - Rev01Gunjan SolankiÎncă nu există evaluări

- Recovery Boiler 2 Cold ShutDocument5 paginiRecovery Boiler 2 Cold ShutGunjan SolankiÎncă nu există evaluări

- XlriDocument1 paginăXlriGunjan SolankiÎncă nu există evaluări

- MomentDocument1 paginăMomentGunjan SolankiÎncă nu există evaluări

- ESP Internal Cleaning & CheckingDocument2 paginiESP Internal Cleaning & CheckingGunjan SolankiÎncă nu există evaluări

- Recovery Boiler 2 Cold ShutDocument5 paginiRecovery Boiler 2 Cold ShutGunjan SolankiÎncă nu există evaluări

- 6 DZM 24Document1 pagină6 DZM 24Wai Phyoe AungÎncă nu există evaluări

- Test 5C A P Statistics NameDocument4 paginiTest 5C A P Statistics NameShaunn Diesto CabertoÎncă nu există evaluări

- Nicira - It Is Time To Virtualize The NetworkDocument9 paginiNicira - It Is Time To Virtualize The Networkcsp_675491Încă nu există evaluări

- S1&2-Basic Electrical Engineering: MGU B.TECH SyllabusDocument1 paginăS1&2-Basic Electrical Engineering: MGU B.TECH SyllabusshonmlrÎncă nu există evaluări

- BookSellerFlyer 9781484241660Document1 paginăBookSellerFlyer 9781484241660超揚林Încă nu există evaluări

- Computer GraphicsDocument14 paginiComputer GraphicsNitish SandÎncă nu există evaluări

- Hyperlogic Heavy Metal 120x60 Skid System Quick Start Installation InstructionsDocument17 paginiHyperlogic Heavy Metal 120x60 Skid System Quick Start Installation Instructionsapi-247828287Încă nu există evaluări

- Gen Nav WeOneDocument272 paginiGen Nav WeOnecaptvivekÎncă nu există evaluări

- Day 4 and 5 - Deductive Reasoning and Two Column Proofs AnswersDocument4 paginiDay 4 and 5 - Deductive Reasoning and Two Column Proofs Answersapi-253195113Încă nu există evaluări

- Penlon-Paragon AV-S-Ventilator - User ManualDocument72 paginiPenlon-Paragon AV-S-Ventilator - User Manualrkillian44Încă nu există evaluări

- Hvac - Iec 60840Document1 paginăHvac - Iec 60840NirmalKumarSelvarajÎncă nu există evaluări

- Lecture 2 - Inverse Laplace TransformsDocument3 paginiLecture 2 - Inverse Laplace TransformsAmirah MapandiÎncă nu există evaluări

- LAMIGAS - BSN2H-Laboratory No. 2Document3 paginiLAMIGAS - BSN2H-Laboratory No. 2Juliemae LamigasÎncă nu există evaluări

- Video Display DevicesDocument66 paginiVideo Display DevicesshabanaÎncă nu există evaluări

- LSMW Carga SapDocument7 paginiLSMW Carga SapMario A. AvilaÎncă nu există evaluări

- Chapter 1-Part 1: Half-Wave RectifiersDocument50 paginiChapter 1-Part 1: Half-Wave RectifiersWeehao SiowÎncă nu există evaluări

- Psychological, Social and Environmental BarriersDocument12 paginiPsychological, Social and Environmental BarrierssaifÎncă nu există evaluări

- TacheometryDocument6 paginiTacheometryregieÎncă nu există evaluări

- ET4117 Electrical Machines and Drives Lecture5Document31 paginiET4117 Electrical Machines and Drives Lecture5farhan beighÎncă nu există evaluări

- Serto Up To Date 33Document7 paginiSerto Up To Date 33Teesing BVÎncă nu există evaluări

- Lasal: Laser Cutting SolutionsDocument4 paginiLasal: Laser Cutting SolutionsGeorge ZiovasÎncă nu există evaluări

- AN000042 SERCOS Troubleshooting Guide - ApplicationNote - En-Us - Revision1Document14 paginiAN000042 SERCOS Troubleshooting Guide - ApplicationNote - En-Us - Revision1uongquocvuÎncă nu există evaluări

- UNIT 5 Matrices and System of EquationsDocument8 paginiUNIT 5 Matrices and System of EquationsrishiÎncă nu există evaluări

- Service Factors BaldorDocument1 paginăService Factors BaldornautelÎncă nu există evaluări