Documente Academic

Documente Profesional

Documente Cultură

Under Water Welding and Cutting

Încărcat de

Vijo JoseDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Under Water Welding and Cutting

Încărcat de

Vijo JoseDrepturi de autor:

Formate disponibile

Our experience runs deep

10868 Bell Court Rancho Cucamonga, CA 91730 Experts available at Phone: +1.909.483.3222 FAX: +1.909.483.3233 www.brocoinc.com sales@brocoinc.com

2010 Broco, Inc.

CAUTION: This equipment is potentially dangerous to operate and must be used in strict accordance with the instructions provided. Underwater cutting and welding should only be performed by trained professional commercial divers and in accordance to industry accepted safe diving practices.

Developed by Divers for Divers

Innovation has always been at the core of Broco. Our first products were developed by working divers in 1975. Brocos success in the underwater frontier is based on that foundationa deep understanding of the requirements of the working diver. Today we continue to work with divers and world-class engineers to refine and develop products that set the standard for underwater operations. Brocos expertise is trusted by professional divers and underwater service companies. Our experience runs deep and so does our commitment to superior product performance and total customer satisfaction.

Ultimate Underwater Cutting

The Broco Underwater Ultrathermic Cutting System is the most widely used and highly recommended underwater cutting tool. The Broco system provides the fastest, most efficient and cost effective means of completing underwater jobs involving cutting and piercing.

Proven Performance

The Ultrathermic cutting rod produces a temperature in excess of 10,000F hot enough to quickly melt almost anything including cast iron, stainless steel, brass and other ferrous and non-ferrous metals, as well as concrete. Divers can cut sheet pile, remove tubular supports and trim damaged props.

Safer, Easier Use

The Broco Underwater Ultrathermic Cutting System uses only oxygen and a maximum of 150 amps to cut (compared to 300 - 500 amps for other systems). The Ultrathermic cutting rod ignites readily from a 12 to 24 volt auto or marine battery. The rod will continue to burn with electrical current removed until the flow of oxygen is stopped or the rod is consumed. The need for expensive support equipment is reduced and a safer diving environment is maintained.

Approved for Navy Use

Approved for Navy Use (ANU) designated and featured in the U.S. Navys Underwater Welding and Cutting manual, the Broco Underwater Ultrathermic Cutting System is used by navies and commercial customers around the world. More offshore cutting is done with Broco than with all competitors combined. Broco Ultrathermic is the ultimate cutting system.

More offshore cutting is done with Broco than all competitors combined.

Broco Underwater Products

BR-22 PLUS Cutting Torch

The BR-22 PLUS features 21 design improvements, including the removal of all rubber from direct oxygen pathway, a PTFE lined fiberglass reinforced coupler hose, improved flash arrestor with higher oxygen flow rate and better flash back protection, non-return valve to prevent back flow, and improved collet and collet washer design.

BR-22 Cutting Torch

Ultrathermic Cutting Rods

The BR-22 Cutting Torch is ergonomically designed for diver comfort and reducing forearm fatigue. The torch is constructed from durable high-impact and corrosion resistant materials. All metal parts are brass. The BR-22s engineered safety features are unique and found only in the Broco torch design. All connections are threaded for maintenance ease. The solid brass flash arrestor with internal filter protects the diver and torch without restricting oxygen flow. The large collet nut is knurled to assure the diver a solid grasp. Acme threads prevent binding from mud or other debris insuring quick, reliable rod insertion and retention. Interchangeable collets accommodate 3/8 inch, 5/16 inch or 1/4 inch diameter cutting rods. The BR-22 can also be used as a welding electrode holder and in that use will accommodate 1/8 inch, 5/32 inch, and 3/16 inch diameters. The BR-22 Cutting Torch is built to deliver years of trouble-free performance at minimum cost. Spare parts kits are available.

Burning in excess of 10,000F at the tip, Broco Underwater Ultrathermic Cutting Rods cut or melt virtually any known material. Brocos rod design features alloy core wires retained by circular crimps. A safety design prevents burnback into the torch, making Broco Underwater Ultrathermic Cutting Rods the safest on the market. Ultrathermic Cutting Rods can be bent 90 degrees or more to access hard to reach places without restricting oxygen flow or causing insulation to split or flake off. Ultrathermic Cutting Rods may be used with a maximum of 150 amps to assist in the burning process but have no electrical requirement. Once ignited, they continue to burn as long as oxygen is supplied or until the rod is consumed. Broco Underwater Ultrathermic Cutting Rods are available in 1/4 inch and 3/8 inch diameters. Standard length is 18 inches. Broco offers 36 inch Ultrathermic Cutting Rods for heavier jobs allowing more burn time between rod changes.

HVR-4401 Oxygen Regulator

The Broco Underwater High-Volume Oxygen Regulator is a multi-stage unit delivering the constant flow and high volume required for underwater burning. Brocos research demonstrates cutting efficiency depends more on oxygen flow than oxygen pressure. Brocos High-Volume Regulator is offered to meet this basic requirement. Designed and manufactured for ease of operation, maximum efficiency, and years of rugged use, the Broco Underwater High-Volume Oxygen Regulator is Underwriters Laboratories Listed.

Broco Underwater makes cutting and welding jobs safer, faster, and more economical.

Broco recommends using a flashback suppresor and a pressure relief valve to protect the umbilical hose system and deck personnel from a regulator failure.

5

The Wet Welding Standard

Broco Underwater welding electrodes set the standard for commercially available mild and stainless steel wet welding electrodes, and more recently, nickel based wet welding electrodes have been added to our line. SofTouch, EasyTouch, Ni-Touch and specialty stainless electrodes assure engineers, diving companies and clients that Broco offers the right electrodes for their jobs criteria.

Easier Certifiable Welds

Use BR-20 and BR-21 welding stingers with SofTouch and wet welding is easier and safer. Whether using the manipulative or self-consuming technique, these smooth running electrodes require little or no pressure. SofTouch electrodes produce a hotter arc, better flow, correct penetration and a higher deposition rate. Brocos flux coating effectively reduces hydrogen cracking. EasyTouch wet welding electrodes have been formulated with performance and value in mind offering both superior strength and good weld integrity.

BR-20 Welding Stinger

Superior Maintenance and Repair

Since 1986 SofTouch has been listed as ANU (Approved for Navy Use). U.S Navy commands and Navy shipyards have been using SofTouch for repair and maintenance on vessels worldwide. Welding assignments on structures, vessels, in nuclear power plants and other applications require the proven performance of Broco Underwater wet welding products.

The BR-20 welding stinger is designed to hold the electrode at the optimum angle to the work piece delivering quality welds while reducing operator fatigue. The movable jaw design accepts a wide range of electrode diameters. The BR-20 Welding Stinger meets Mil-H-865D and is Approved for Navy Use (ANU). All-brass parts last longer under extreme conditions.

BR-21 Welding Stinger

This new generation compression welding stinger is engineered with superior features. The BR-21 is lightweight, durable and designed to hold the electrode at the optimum angle to reduce diver fatigue. Selected features of the BR-21 include an index notch on the head to help divers find the hole which improves rod insertion even in a low-visibility environment. The beveled seat keeps the electrode at the ideal angle and the groove eliminates electrode wiggle. The over-sized head is easier to hold and the handle and head are from hexagonal stock for sure gripping by a gloved hand. The BR-21 also includes a resistance O-ring on the shoulder to ensure tension when the head is tightened and increase head life.

Broco stands for quality wet welds done right the first time in all positions.

6 7

Ni-Touch Electrodes

Brocos Ni-Touch nickel wet welding electrode was developed to allow underwater wet welding of higher carbon and high tensile steels which would normally require the use of more expensive dry chamber welding. Ni-Touch electrodes produce welds with less porosity, while allowing deeper welding in the overhead position than similar electrodes. They are appropriate for all position groove and fillet welds. Test results exceed the requirements of the American Welding Society (AWS) Specification D3.699 for Class B underwater wet welds. Yield strengths typically exceeding 70 ksi and tensile strengths exceeding 80 ksi can be expected from the nickel weld metal in the as-welded condition. Ni-Touch is presently qualified at a water depth of 33 feet. With Ni-Touch the nickel electrode mitigates the effect of hydrogen. This results in successful underwater wet welds involving a broad range of high carbon equivalent steels, including HY-80 quenched, and tempered steel used in Naval ships with carbon equivalents exceeding 0.50 percent. Ni-Touch meets the more stringent requirements of the Navys Naval Ship Technical Manual NSTM 074.

SofTouch Brocos proprietary flux enhancing formulation, BroCote, makes this electrode particularly impervious to water penetration and denigration and ensures consistent certifiable underwater weld quality eliminating costly rework.

SofTouch electrodes are used for wet welding repairs in many applications where steel must be joined underwater according to code specifications. SofTouch welds consistently meet or exceed AWS D3.6-99 specifications for Class B welds in all positions (flat, horizontal, vertical and overhead). SofTouch is designed to pass all AWS test requirements, including radiograph, tensiles, bends and hardness. Since 1989, SofTouch electrodes have been specified in the U.S. Navys Ships Husbandry Manual Chapter 11, Underwater Wet and Dry Chamber Welding. SofTouch electrodes are lot certified and available in various sizes and mild steel and stainless alloys. Available diameters include 1/8 inch, 5/32 inch, and 3/16 inch. Stainless electrodes are sold in 1/8 inch and 5/32 inch sizes. Broco Underwater wet welding electrodes are sealed in a Mil-Spec foil pouch to prevent contamination and then inserted in a rigid resealable plastic tube which provides maximum protection. The color-coded end cap denotes mild or stainless steel electrodes type. Operating guidelines are printed on the label.

EasyTouch For many repairs the resultant weld is allowed more leeway in terms of porosity, inclusions, integrity and appearance. To fill the void between to-code work and economy, Broco applied its experience and knowledge to the design of a quality electrode specifically for the economy market. The result is EasyTouch, a moderately priced electrode yielding excellent results. It is easy to start, easy to run (a controllable puddle with rippled bead appearance) and easy to clean. EasyTouch is a high deposition all-position electrode.

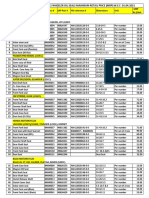

Broco Underwater Products List

in underwater welding, Ultrathermic cutting products, and customer satisfaction.

Broco sets the world standard

Underwater Cutting

P R O D. N U M B E R DESCRIPTION UNIT

Spare Parts

P R O D. N U M B E R DESCRIPTION UNIT

BR-22 PLUS BR-22 3818UW-25 3818UW-20/QP 3836UW-25 1418UW-25 TA22XX SPK-C SPK-M HVR-4401 HVR-FBS UW/KS

Upgraded Underwater Oxy-Arc Cutting Torch Underwater Oxy-Arc Cutting Torch Broco Ultrathermic Cutting Rods 3/8x18, 25lb. box (66rods) QuiverPak with 50 Broco Ultrathermic Cutting Rods, 3/8x18 Broco Ultrathermic Cutting Rods 3/8x36, 25lb. box (31rods) Broco Ultrathermic Cutting Rods 1/4x18, 25 lb. box (131 rods) Collet and Washer Kit. Order by size Complete Spare Parts Kit (For BR-22) Mini Spare Parts Kit (For BR-22) High Volume Oxygen Regulator Flash Back Suppressor w/ Pressure Relief Valve 400 amp Single Pole Knife Switch

Ea Ea Bx Bx Bx Bx Ea Ea Ea Ea Ea Ea

UW101/102 UW103/112 UW104 UW105 UW107 UW108 UW109 UW110 UW111 UW113 UW114 UW115 UW116 UW117 UW118 UW119/120 UW121/122 UW123

Handle Set, Left & Right Torch Head & Cable Assembly Collet Nut Neoprene Compression Washer Flash Arrestor Monel Flash Arrestor Screen Lever Valve Stem (includes O-Ring) Coupler Assembly Control Valve Body Valve Stem Spring Control Valve Nut Valve Stem O-Ring Neoprene Valve Stem Washer Valve Nut Gasket Brass Screw & Locknut Nylon Screws & Nuts (Four Each) Collet Washer Control Valve Assembly Replacement Handle Set w/Screw, Nuts & O-Ring Torch Head & Cable Assembly Collet Nut Flash Arrestor Check Valve Assembly Coupler Hose Assembly Control Valve Assembly Valve Letter Set w/ Screw & Nut Dash 014 Neoprene O-Ring Collet to Head Seal Dash 123 Neoprene O-Ring Nut to Handle Seal Replacement Handle Set w/Nuts Control Valve Repair Kit Replacement O-Ring Set Complete Spare Parts Kit Silicone Rubber Collet Washer for 3/8 Collet Silicone Rubber Collet Washer for 1/4 Collet Silicone Rubber Collet Washer for 5/16 Collet Silicone Rubber Collet Washer for Welding Collets 3/8 UW Collet Kit w/O-Ring & Washers 1/4 UW Collet Kit w/O-Ring & Washers 5/16 UW Collet Kit w/O-Ring & Washers 1/8 UW Collet Kit w/O-Ring & Washers 5/32 UW Collet Kit w/O-Ring & Washers 3/16 UW Collet Kit w/O-Ring & Washers

Set Set Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Set Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea Ea

Underwater Welding

P R O D. N U M B E R DESCRIPTION UNIT

UW7A UWBR22A01 UWBR22A03 UWBR22A04 UWBR22A05 UWBR22A06 UWBR22A07 UWBR22A08 UWBR22A09 UWBR22N014 UWBR22N123 UWBR22R02K UWBR22R08K UWBR22ROSK UWBR22RCSK UWBR22W38 UWBR22W14 UWBR22W516 UWBR22W00 UWBR22C38K UWBR22C14K UWBR22C516K UWBR22C18K UWBR22C532K UWBR22316K

BR-20 BR-21 UW/CS-1

Underwater Welding Stinger Underwater Welding Stinger SofTouch Wet Welding Electrodes AWS E7014 Mild Steel, 1/8(3.20mm) 8-lb. Tube Approx. 95 Electrodes SofTouch Wet Welding Electrodes AWS E7014 Mild Steel, 5/32(3.97mm) 8-lb. Tube Approx. 69 Electrodes SofTouch Wet Welding Electrodes AWS E7014 Mild Steel, 3/16(4.76mm) 8-lb. Tube Approx. 48 Electrodes SofTouch Wet Welding Electrodes AWS E312-16 Stainless Steel, 1/8(3.20mm) 8-lb. Tube Approx. 95 Electrodes SofTouch Wet Welding Electrodes AWS E312-16 Stainless Steel, 5/32(3.97mm) 8-lb. Tube Approx. 69 Electrodes EasyTouch Wet Welding Electrodes AWS E7014 Mild Steel, 1/8(3.20mm) 8-lb. Tube Approx. 95 Electrodes EasyTouch Wet Welding Electrodes AWS E7014 Mild Steel, 5/32(3.97mm) 8-lb. Tube Approx. 69 Electrodes EasyTouch Wet Welding Electrodes AWS E7014 Mild Steel, 3/16(4.76mm) 8-lb. Tube Approx. 48 Electrodes High Nickel Electrodes, 3/32 ( 2.38mm) 5lb. Tube Approx. 75 Electrodes

Ea Ea Tb

UW/CS-2

Tb

UW/CS-3

Tb

UW/SS-1

Tb

UW/SS-2

Tb

UW/EZ-1

Tb

UW/EZ-2

Tb

UW/EZ-3

Tb

UW/HN332

Tb

S-ar putea să vă placă și

- Underwater Welding EssayDocument11 paginiUnderwater Welding Essayapi-248835946Încă nu există evaluări

- Diving BellDocument11 paginiDiving BellAnonymous UCveMQÎncă nu există evaluări

- Wet WeldingDocument13 paginiWet WeldingViktor ŽganecÎncă nu există evaluări

- Underwater Repair WeldingDocument11 paginiUnderwater Repair WeldingmariusÎncă nu există evaluări

- Pipeline Connection & Repair Systems (PCRS)Document12 paginiPipeline Connection & Repair Systems (PCRS)Yang Gul Lee100% (2)

- ESVAGT Safe Personnel Basket RevDocument15 paginiESVAGT Safe Personnel Basket RevilikecrayonsÎncă nu există evaluări

- List of Diving Hazards and Precautions: The Aquatic Environment Use of Breathing Equipment in An Underwater EnvironmentDocument40 paginiList of Diving Hazards and Precautions: The Aquatic Environment Use of Breathing Equipment in An Underwater EnvironmentEric FranckÎncă nu există evaluări

- Diving O&g411Document52 paginiDiving O&g411phsemÎncă nu există evaluări

- IMCA D060 Publication 254 Guidelines For Lifting OperationsDocument70 paginiIMCA D060 Publication 254 Guidelines For Lifting OperationsAnonymous VqTus7QAwÎncă nu există evaluări

- Greater Noida Institute of Technology: Under-Water WeldingDocument12 paginiGreater Noida Institute of Technology: Under-Water WeldingEr Raghvendra SinghÎncă nu există evaluări

- Underwater Cutting and Welding ManualDocument2 paginiUnderwater Cutting and Welding Manualapi-3723333Încă nu există evaluări

- HSE Diving Health and Safety Strategy To 2010: ContentsDocument4 paginiHSE Diving Health and Safety Strategy To 2010: ContentsYoga PratamaÎncă nu există evaluări

- QP-75-12 Diving Operations at NBEHPPDocument10 paginiQP-75-12 Diving Operations at NBEHPPSamsudin AhmadÎncă nu există evaluări

- S0300-BB-MAN-010 - Underwater CuttingDocument200 paginiS0300-BB-MAN-010 - Underwater Cuttingsandeep5Încă nu există evaluări

- Delta P in Diving - Risks and Prevention PDFDocument87 paginiDelta P in Diving - Risks and Prevention PDFfrgonzalezÎncă nu există evaluări

- Underwater WeldingDocument5 paginiUnderwater WeldingGourang PaulÎncă nu există evaluări

- Underwater Welding - Underwater Welding Dangers - Hyperbaric Welding - Mechanical EngineeringDocument10 paginiUnderwater Welding - Underwater Welding Dangers - Hyperbaric Welding - Mechanical EngineeringVitorHugoÎncă nu există evaluări

- Underwater WeldingDocument4 paginiUnderwater WeldingdhmbasÎncă nu există evaluări

- Maersk Tender Fatal Diving Accident On 24 July 2 0 1 0Document52 paginiMaersk Tender Fatal Diving Accident On 24 July 2 0 1 0Fernando Cadena DuqueÎncă nu există evaluări

- Cable Burying in Vung Tau Project - FniDocument36 paginiCable Burying in Vung Tau Project - Fnilenghiemckt07Încă nu există evaluări

- Neptune Subsea Stabilisation - Products and Services (V10) PDFDocument56 paginiNeptune Subsea Stabilisation - Products and Services (V10) PDFPablo Ignacio Cortés AguileraÎncă nu există evaluări

- OMAE2008-57082: A New Wind and Wave Atlas of The Hellenic SeasDocument9 paginiOMAE2008-57082: A New Wind and Wave Atlas of The Hellenic SeaspanÎncă nu există evaluări

- HSE L103 - 2014 - Commercial Diving Projects Offshore. Diving at Work Regulations 1997. Approved Code of PracticeDocument53 paginiHSE L103 - 2014 - Commercial Diving Projects Offshore. Diving at Work Regulations 1997. Approved Code of PracticeKris WilochÎncă nu există evaluări

- Permanent Underwater Wet Weld RepairsDocument14 paginiPermanent Underwater Wet Weld RepairsMubeenÎncă nu există evaluări

- Underwater Cutting & Welding Manual - U.S. NavyDocument200 paginiUnderwater Cutting & Welding Manual - U.S. NavyJ.R.T100% (2)

- The Development and Installation of Mechanically Connected Risers and PipelinesDocument20 paginiThe Development and Installation of Mechanically Connected Risers and PipelinesalbertofgvÎncă nu există evaluări

- Underwater Welding PDFDocument5 paginiUnderwater Welding PDFrock_xxx567879Încă nu există evaluări

- OGP 471 Underwater Cutting - Burning ReportDocument46 paginiOGP 471 Underwater Cutting - Burning Reportullwn100% (1)

- Material Safety DatasheetDocument12 paginiMaterial Safety Datasheetrangarajan1989Încă nu există evaluări

- Cement Lining of PipesDocument28 paginiCement Lining of PipesvenkyÎncă nu există evaluări

- Ocupational DivingDocument5 paginiOcupational Divingfirst last0% (1)

- 2.1) Technical Data Sheet - SS-COAT 909-Silver Zinc CoatDocument3 pagini2.1) Technical Data Sheet - SS-COAT 909-Silver Zinc CoathaharameshÎncă nu există evaluări

- ALDIVE Dive Plan and Proceduree ARMADA STERLING IIIDocument11 paginiALDIVE Dive Plan and Proceduree ARMADA STERLING IIIdudi hidayatÎncă nu există evaluări

- Cswip Div 7 95 Underwater Diver Inspectors Part 1 6th Edition April 2019 1Document18 paginiCswip Div 7 95 Underwater Diver Inspectors Part 1 6th Edition April 2019 1Satendra kumarÎncă nu există evaluări

- Integrity Management and Life Extension For A CALM Buoy Oil Export TerminalDocument11 paginiIntegrity Management and Life Extension For A CALM Buoy Oil Export TerminalArun Kumar Pancharaj100% (1)

- EEMUA Online Learning and Publications CatalogueDocument6 paginiEEMUA Online Learning and Publications CatalogueT. LimÎncă nu există evaluări

- Catalogue 2014 en HDDocument58 paginiCatalogue 2014 en HDBrad BarnesÎncă nu există evaluări

- Norsok - Marine OperationsDocument27 paginiNorsok - Marine OperationsbeegmacÎncă nu există evaluări

- Broco ExplaningDocument3 paginiBroco Explaningsequeiradiver1Încă nu există evaluări

- Corte Debajo Del AguaDocument1 paginăCorte Debajo Del AguageorgeÎncă nu există evaluări

- Broco Cutting TorchDocument1 paginăBroco Cutting TorchLee BalayoÎncă nu există evaluări

- Sharkbite® Metal Push-Fit Plumbing Solution: Technical InformationDocument36 paginiSharkbite® Metal Push-Fit Plumbing Solution: Technical InformationPubcrawlÎncă nu există evaluări

- Omsco Drillpipe CatalogueDocument24 paginiOmsco Drillpipe Cataloguerwinmill100% (3)

- StartaboxDocument8 paginiStartaboxmeanbadeggÎncă nu există evaluări

- ABB - Composite Hollow Core InsulatorDocument8 paginiABB - Composite Hollow Core InsulatorAnu SunÎncă nu există evaluări

- Bridon Construction ProductsDocument16 paginiBridon Construction ProductsAnonymous UebIaD8A8CÎncă nu există evaluări

- OhioBrass - 27-International Suspension InsulatorsDocument8 paginiOhioBrass - 27-International Suspension Insulatorslduong4Încă nu există evaluări

- En - Ineos Bichlor ElectrolyserDocument8 paginiEn - Ineos Bichlor Electrolyserbarun1977Încă nu există evaluări

- CP Rotork Actuator - Catalogue PDFDocument8 paginiCP Rotork Actuator - Catalogue PDFLai HuynhÎncă nu există evaluări

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pagini3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaÎncă nu există evaluări

- Medium Voltage Composite InsulatorsDocument14 paginiMedium Voltage Composite Insulatorsdeepthik27Încă nu există evaluări

- BA5139 Bellows PDFDocument1 paginăBA5139 Bellows PDFMuhammad ZuhairizÎncă nu există evaluări

- Bollhoff Armstrong HeliCoilDocument28 paginiBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- Fittings DK LOK Pipe Fitting BrochureDocument11 paginiFittings DK LOK Pipe Fitting BrochureHafiz KamalÎncă nu există evaluări

- Heavy Duty Track Chains: The Complete ChoiceDocument8 paginiHeavy Duty Track Chains: The Complete ChoiceNanang Al MunawarÎncă nu există evaluări

- Carrileria Berco CATDocument8 paginiCarrileria Berco CATEiser Vasquez Vargas100% (3)

- Hydraulic Tube Fittings enDocument16 paginiHydraulic Tube Fittings enAlex PeñaÎncă nu există evaluări

- BossBro Q4Document12 paginiBossBro Q4mahotkatÎncă nu există evaluări

- Ductile PipesDocument33 paginiDuctile Pipesanirbanpwd76Încă nu există evaluări

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesDe la EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesEvaluare: 4.5 din 5 stele4.5/5 (5)

- Taining Materials 2021, HobartDocument28 paginiTaining Materials 2021, HobartVijo JoseÎncă nu există evaluări

- Recommendation On Pipepro Parameters Technique 2019Document2 paginiRecommendation On Pipepro Parameters Technique 2019Vijo JoseÎncă nu există evaluări

- AlumaFeed™ Synergic Aluminium Welding System PDFDocument8 paginiAlumaFeed™ Synergic Aluminium Welding System PDFVijo JoseÎncă nu există evaluări

- M655 ArcReach Wire Feeders PDFDocument8 paginiM655 ArcReach Wire Feeders PDFVijo JoseÎncă nu există evaluări

- Ad4 81 PDFDocument8 paginiAd4 81 PDFГуставо Аранда МендосаÎncă nu există evaluări

- Product Selector Guide: XMT 350 Fieldpro WeldersDocument1 paginăProduct Selector Guide: XMT 350 Fieldpro WeldersVijo JoseÎncă nu există evaluări

- Element Brochure E71uDocument8 paginiElement Brochure E71uVijo JoseÎncă nu există evaluări

- Load Banks: 350 Amp and 750 Amp PortableDocument2 paginiLoad Banks: 350 Amp and 750 Amp PortablelauguicoÎncă nu există evaluări

- RHS Furnaces PDFDocument1 paginăRHS Furnaces PDFVijo JoseÎncă nu există evaluări

- 4 Inverters 250 Amps PDFDocument2 pagini4 Inverters 250 Amps PDFVijo JoseÎncă nu există evaluări

- DC1259 Mulitmatic 215 English PDFDocument4 paginiDC1259 Mulitmatic 215 English PDFVijo JoseÎncă nu există evaluări

- KHM 500 Ps - CC/CV: Service ManualDocument56 paginiKHM 500 Ps - CC/CV: Service ManualVijo JoseÎncă nu există evaluări

- Continuum Systems PDFDocument12 paginiContinuum Systems PDFVijo JoseÎncă nu există evaluări

- Esab BrochureDocument82 paginiEsab BrochureMahmud MaherÎncă nu există evaluări

- Paper PDFDocument2 paginiPaper PDFVijo JoseÎncă nu există evaluări

- HNG Multi XA00141620 PDFDocument4 paginiHNG Multi XA00141620 PDFVijo JoseÎncă nu există evaluări

- Svetsaren 2002-2 PDFDocument55 paginiSvetsaren 2002-2 PDFVijo JoseÎncă nu există evaluări

- TB Welding-English PDFDocument20 paginiTB Welding-English PDFdanghpÎncă nu există evaluări

- Pro Ox100 Oxygen Monitor PDFDocument4 paginiPro Ox100 Oxygen Monitor PDFVijo JoseÎncă nu există evaluări

- 2004Document64 pagini2004Chema Rodriguez HernandezÎncă nu există evaluări

- (SamdiLab) 37 PDFDocument36 pagini(SamdiLab) 37 PDFAndika Pandu VidiantoÎncă nu există evaluări

- SoluShim Brochure - SS.B1.0910.R1 PDFDocument2 paginiSoluShim Brochure - SS.B1.0910.R1 PDFVijo JoseÎncă nu există evaluări

- XMT 350 Series PDFDocument8 paginiXMT 350 Series PDFVijo JoseÎncă nu există evaluări

- SoluGap Brochure - SG.B1.0609.R1 PDFDocument2 paginiSoluGap Brochure - SG.B1.0609.R1 PDFVijo JoseÎncă nu există evaluări

- Liquifilm PDFDocument2 paginiLiquifilm PDFVijo JoseÎncă nu există evaluări

- I PurgeX Brochure IPX.B1.1112.R1 PDFDocument2 paginiI PurgeX Brochure IPX.B1.1112.R1 PDFVijo JoseÎncă nu există evaluări

- Ox-100x Kit Brochure - Ox.b1.0611.r.4Document2 paginiOx-100x Kit Brochure - Ox.b1.0611.r.4Vijo JoseÎncă nu există evaluări

- Paper PDFDocument2 paginiPaper PDFVijo JoseÎncă nu există evaluări

- Liquifilm PDFDocument2 paginiLiquifilm PDFVijo JoseÎncă nu există evaluări

- I Purge Brochure IP.B3.1012.r1 PDFDocument4 paginiI Purge Brochure IP.B3.1012.r1 PDFVijo JoseÎncă nu există evaluări

- 2016 US Seal Catalog - NOLINKSDocument865 pagini2016 US Seal Catalog - NOLINKSMIGUELÎncă nu există evaluări

- Belimo NVF24Document36 paginiBelimo NVF24Jamile_P_NÎncă nu există evaluări

- HF DIT-Katalog 2016 EN - Technische InformationDocument30 paginiHF DIT-Katalog 2016 EN - Technische InformationDejan KostadinovicÎncă nu există evaluări

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document24 paginiOperating Manual: Eagleburgmann Mechanical Seal (M.S.)Morteza ShakerienÎncă nu există evaluări

- Operation and Maint.70000056 - A4-P - 2.0 - enDocument53 paginiOperation and Maint.70000056 - A4-P - 2.0 - enmkpq100% (2)

- Ut Pump Part ListDocument38 paginiUt Pump Part Listranjan shiveshÎncă nu există evaluări

- SWING MOTOR (W - MECHA BRAKE W - ANTI-RVS V) (Part# KSC10070) - 001 PISTONDocument3 paginiSWING MOTOR (W - MECHA BRAKE W - ANTI-RVS V) (Part# KSC10070) - 001 PISTONjavier muñozÎncă nu există evaluări

- Seal Selection For Valve Design and RetrofittingDocument6 paginiSeal Selection For Valve Design and RetrofittingshahganÎncă nu există evaluări

- Cat AXCATDocument80 paginiCat AXCATgazwang478Încă nu există evaluări

- John Blue - DP 139 Diaphragm Pump - Parts and Instruction Manual - 7 M 17 - 0622Document12 paginiJohn Blue - DP 139 Diaphragm Pump - Parts and Instruction Manual - 7 M 17 - 0622Dung PhamÎncă nu există evaluări

- Bomba Hidráulica (Ppal) Serie A.55 Serie H1P250 Parts Manual (H1P250R E8 C3 N D6 C G2 NN L40 K38 R L 24 PN NNN NNN)Document96 paginiBomba Hidráulica (Ppal) Serie A.55 Serie H1P250 Parts Manual (H1P250R E8 C3 N D6 C G2 NN L40 K38 R L 24 PN NNN NNN)IngenieriaÎncă nu există evaluări

- WSA 109-2011 Flange GasketsDocument39 paginiWSA 109-2011 Flange GasketsTon Phichit100% (1)

- VNE Valves CatalogsDocument45 paginiVNE Valves CatalogsSANDRA TORRESÎncă nu există evaluări

- Flange Spreader: Parts List and Operating Instructions ForDocument6 paginiFlange Spreader: Parts List and Operating Instructions ForTitanplyÎncă nu există evaluări

- ERIKS - Viton Fluoroelastomers An OverviewDocument32 paginiERIKS - Viton Fluoroelastomers An OverviewNano MaxÎncă nu există evaluări

- Nok Two Wheeler MRP List Wef 1.4.2021Document4 paginiNok Two Wheeler MRP List Wef 1.4.2021Senthil KumarÎncă nu există evaluări

- SB-F2000EX EASy-413 PDFDocument19 paginiSB-F2000EX EASy-413 PDFSorina CtinÎncă nu există evaluări

- Terex Backhoe Loader 2008 Workshop ManualDocument20 paginiTerex Backhoe Loader 2008 Workshop Manualjuan98% (44)

- AppendicesDocument69 paginiAppendicesIvan CanoÎncă nu există evaluări

- EN Industrial-Sealing-Solutions PDFDocument12 paginiEN Industrial-Sealing-Solutions PDFAbd Al-Rahmman Al-qatananiÎncă nu există evaluări

- Eaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFDocument405 paginiEaton Hydraulic Lubrication Oil Filters Technical Data Catalog PDFjithanÎncă nu există evaluări

- D 100017 X 012Document24 paginiD 100017 X 012ErnestoÎncă nu există evaluări

- Advanced Mechanical Sealing of PumpsDocument17 paginiAdvanced Mechanical Sealing of PumpsHmidaÎncă nu există evaluări

- DILO Couplings DN20 C3105Document14 paginiDILO Couplings DN20 C3105lgaungÎncă nu există evaluări

- ZF 2Document49 paginiZF 2Silvio Roman100% (2)

- PfeifferDuo35 65 Operating InstructionsDocument34 paginiPfeifferDuo35 65 Operating Instructions80autobotsÎncă nu există evaluări

- Catalogo de AcumuladoresDocument65 paginiCatalogo de Acumuladoresingenioso23Încă nu există evaluări

- 6991 5013 01 Diamec 232 KIts de Peças PDFDocument38 pagini6991 5013 01 Diamec 232 KIts de Peças PDFAdãodaLuz100% (2)

- Desmontaje y Montaje D 379398 y 399Document137 paginiDesmontaje y Montaje D 379398 y 399Yuriy Senyk100% (6)

- Catalogo EC35CDocument486 paginiCatalogo EC35CAntonio Moro100% (2)