Documente Academic

Documente Profesional

Documente Cultură

Speedmaster: Than Just A Motor Company

Încărcat de

Flores CesarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Speedmaster: Than Just A Motor Company

Încărcat de

Flores CesarDrepturi de autor:

Formate disponibile

SPEEDMASTER

AC ADJUSTABLE SPEED DRIVES

Bulletin 1400

A REGAL-BELOIT COMPANY

Than Just a Motor Company

More

As the demand for tighter process control and greater operating

efficiency grows, customers increasingly look to LEESON for easy-to-

use, cost-effective inverters and complete motor and drives solutions.

Our two distinct families of inverters offer specific benefits in many

adjustable speed applications.

Micro Series: 1/2 through 60 HP

Full metal NEMA 1 or NEMA 4/12 enclosures. Intuitive alphanumeric

display for programming and set-up. Built-in thermal overload

protection and heavy-duty wiring terminals. With these industrial-duty

features, and many others, SPEEDMASTER

Micro Series inverters

set the standard for out-of-the-box functionality. Plus, their modular

design reduces manufacturing cost and enhances reliability, making

our Micros among the most cost-effective full-featured drives. Best of

all, LEESONs customer-friendly inventory approach allows the flexi-

bility to purchase quantities large or small to meet immediate needs.

SM Plus Series: 1/4 through 25 HP

Ideal for OEM or multi-drive applications, the ultra-compact SM Plus

inverter offers a removable Electronic Programming Module for off-line

set-up and program replication. Over 50 programmable functions, 18

isolated I/O terminals and other software-intensive features mean

unlimited versatility. No other Sub-Micro class drive offers a greater

range of performance enhancements. Its advanced design makes

the SM Plus cost-competitive with DC drives, two-speed motors,

adjustable pulleys, soft starterseven, in many cases, with fixed

speed AC systems.

SM Series: 1/2 through 5 HP

The right drive for simple speed control applications not requiring the

advanced functionality of the SM Plus Series. The SM drive, applied

with a LEESON motor now offers a cost advantage over most PMDC

motor/drive combinations; and is a superior alternative to reversing

devices, soft-starters, or instead of multi-speed motors. Like all

LEESON Sub-Micro Drives, the SM utilizes the innovative Electronic

Programming Module for fast, error free drive configuration. Also with

over 50 programmable functions, the SM has 11 isolated I/O terminals

and a programmable Form A relay for status indication.

SM Vector Series: 1/2 through 10 HP

This is an ideal control if you are needing full torque down to 1Hz.

This control also offers 200% starting torque. The SM Series Vector

control is designed for easy installation into your control panel. The

compact size of this control, along with its contactor style design,

takes up little room in your control panel and makes it easy to wire to.

This control is easy to program and has auto tuning to make sure you

get all the performance you need. It is designed for either Vector or

V/Hz mode.

For complete ordering information, please

refer to LEESON Stock Catalog 1050.

SM Plus

1/4 - 25 HP

Micro Series

1/2 - 60 HP

SM

1/2 - 5 HP

SPEEDMASTER

INVERTER DRIVES

SM Vector

1/2 - 10 HP

1/2 - 60 HP

Food-safe epoxy finish or 300

grade stainless steel

All steel construction provides

complete protection, fully gasketed,

water and dust-tight enclosure

Fully enclosed with no cooling fans

Ideal for use with LEESONs

IRISprotected WASHGUARD washdown-duty motors

Higher HP require cooling fans and are NEMA 12 only

NEMA 4/12 Micro Series

WASHGUARD Inverters

WASHGUARD

NEMA 4X

IP65 Enclosure

NEMA

4/12

Standard Micro Series Features

Intelligent Power ModuleIGBTs with a 16-bit Intel

motor control

microprocessor

Back-lit 16 character plain-English display

User choice programming with speed dial:

Choice of Quick Start factory presets

Built-in English programmable options, 52 parameters, accessible

via build-in touch-pad

Serial communication port for RS485 interface with MODBUS

protocol

Speed reference signal. Choice of potentiometer, 0-10VDC or

4-20mA inputs

Analog output signal 0-10VDC, speed or load

Three preset speeds

Two auxiliary contacts: One from C relay and one open collector

output

Slip compensation

Adjustable carrier frequency

Adjustable acceleration and deceleration times

Forward/reverse

DC braking time and voltage adjustable

Password protected

Constant torque with adjustable current limit

150% overload capacity for one minute based on nominal output

rating of the control

Rugged, heavy-gauge steel enclosures with barrier type terminal

strips

UL listed

Optional features available as kits or as modifications:

Remote keypad

Dynamic braking

NEMA 1, IP31 Enclosures

Micro Series compact inverters offer big drive features for adapting

standard or premium efficiency three-phase motors to adjustable

speed operation. Utilizing the latest microprocessor and advanced

IGBT power conversion devices, these high performance controls

program and read-out in plain English terms, eliminating the frustration

and time involved in looking up confusing coded symbols. Complete,

rugged steel enclosures for NEMA 1 (IP31) or NEMA 4/12 (IP65)

service do not require additional enclosure protection as with many

plastic-housed compact drives. Built-in thermal overload protection

reduces additional costs. Heavy-duty wiring terminals, accessible

via three conduit openings on the bottom of the housing, speed

installation and cut costs. Available in single-phase and three-phase

input models.

MICRO SERIES

No language barrier, plain-English programming and operational

read-outs

Back-lit LCD displays for easy readability. 1 line x 16 characters

Eight-button keypad with choice of scrolling or speed dial access to

programming, monitoring or operational functions

Quick Start factory presets

Plain-English Display Examples

RUN > 1728 RPM

48.72 < 60.00 HZ

FAULT : OVERLOAD

Full Features, Ultra-Friendly Set-Up and Operation

No Drive Is Easier To Use

Removable electronic programming module allows off-line setup and

program replication.

Input line voltage calibration optimizes over and under voltage trip

levels.

Current limit to 180% with frequency foldback

Adjustable carrier frequency (4 to 10 kHz)

Adjustable V/Hz

Output frequency to 240 Hz

Seven preset speeds

Automatic restart after fault

Control via drive face, terminal strip or optional remote keypad

Coast or ramp to stop

Independent Accel and Decel adjustment

Forward only or forward and reverse direction

Adjustable DC injection braking

Speed reference: Keypad, 1-10

VDC, or 4-20 mA

Speed reference calibration

I2t motor thermal overload protec-

tion; meets UL requirements for

motor protection in single motor

applications.

Fixed boost for high starting torque

Accel boost for high torque accelerating at any speed

Three-digit LED display

Password protection

Fault history: Stores eight previous trips

Terminal status indication

Default parameter reset

IP20 enclosure with finger safe terminals

Key SM Plus Features

Input line voltage calibrationoptimizes over and under voltage trip

levels

Current limit to 180% with frequency foldback

Adjustable carrier frequency

Adjustable V/Hz

Output frequency to 120 Hz

Seven preset speeds

Three programmable terminals for speed reference and control

activation

Two open collector auxiliary outputs

Automatic restart after fault

Control via terminal strip or optional remote keypad

Coast or ramp to stop

Independent accel and decel adjustment

Forward only or forward and reverse direction

Adjustable DC injection braking

Speed reference: Keypad, 0-10 VDC, or 4-20 mA

Speed reference calibration

Speed & load indicating output signal selection: 0-10 VDC or 4-20mA

Output signal calibration

I2t motor thermal overload protection

Torque and accel boost

Slip compensation

Activation or disabling of serial communications

Assignment of serial addresses

Modbus

Serial Communication Protocol

Password protection

Fault history: Stores eight previous trips

Terminal status indication

Default parameter reset

SM PLUS SERIES

IP20 Enclosures

Big Value in a Sub-Micro Package

Key SM Features

SM SERIES

3.64 in.

5.75 in.

Big Performance in a Sub-Micro Package

The SM Vector drive is designed for operation with vector duty rated

induction motors rated for 200, 230, 400, 460, or 590VAC from 0 to

240Hz.

IP20 enclosure with finger safe terminals

Easy setup and operation program the SM Vector drive one of four

different ways:

From the front of the drive

The optional remote keypad

A PC using the TechLink Software

The EPM Programmer

Modes of operation:

Constant Torque V/Hz

Variable Torque V/Hz

Sensorless Vector speed mode

Sensorless Vector torque mode

Auto Tuning determines key performance values based on the motor

and installation variables. Required for operation in vector modes,

but can be used to enhance

performance in V/Hz mode.

The SM Vector drive is an approved

thermal overload protection device for

single motor applications

18 isolated terminals provide 5 logic

inputs and two logic outputs

Two reference inputs allow for 4-20mA and either 0-10V or bipolar

10 to +10V

Two analog outputs indicate speed and load

Two wire RS485 serial communication

Output frequency 0-240Hz

Adjustable carrier frequency 2kHz to 8kHz

Seven preset speeds

Jog function forward and reverse

SM VECTOR SUB-MICRO INVERTER DRIVES

Electronic Programming Unit

Optional SM Plus Electronic Programming Unit

allows off-line set-up and replication of the drives

plug-in electronic programming module. Excellent

for multi-drive applications. RS-232 serial port

allows downloading of configuration files from

personal computer.

Remote Keypad

Optional remote keypad kit for SM Plus, SM

Series and SM Vector drives includes eight-foot

connecting cable and gasket. Mounted in proper

enclosure, the keypad kit will provide up to

NEMA 4 protection. Micro Series Cables

available in 2.5 foot, 5 foot, or 10 foot lengths.

Programming Modules

Plug-in electronic programming modules

(EPM) for SM Plus drives. Allow off-line set-

up and replication of program using Electronic

Programming Unit.

Dynamic Braking Modules & Resistors

Expand the capabilities of any sub-micro drive with

panel or DIN rail mountable modules. Braking

resistors are built-in for units up through 10HP.

Accessories for SM, SM Plus and Vector Series Drives

Input Line Voltages:

Micro Series: 120/240, 200-240 400-480, 480-590 VAC, +10%, -15%

SM Plus: 115/230, 200-230, 460-480, 550-575 VAC, +10%,-15%

SM: 110-120, 200-240, 400-480 VAC, +10%,-15%

Input Frequency: 50/60 Hz, tolerance of 48 to 62 Hz

Output Wave Form: Sine coded, pulse width modulated

Output Frequency: 0-120 Hz

Carrier Frequency:

Micro Series: 2.5 kHz to 14 kHz

SM & SM Plus: 4 kHz to 10 kHz

SM Vector: 2 kHz to 8 kHz

Service Factor: 1.0

Overload Current Capacity:

Micro Series, SM & SM Plus: 150% for 60 sec., 180% for 20 sec.

SM Vector: 150% for 60 sec., 200% for 25 sec.

Speed Reference Follower: 0-10 VDC, 4-20 mA

Control Voltage: 15 VDC

Analog Outputs: 0-10 VDC or 2-10 VDC: Proportional to frequency

or load

Digital Outputs: Open-collector: 40 mA at 30 VDC

Power Supply for Aux. Relays: 40 mA at 12 VDC

Ambient Operating Temperature:

Micro Series: NEMA 1, 0 to 50C

NEMA 4/12, 0 to 40C

SM Plus: 0 to 50C

SM: 0 to 40C

SM Vector: 0 to 50C

Ambient Humidity: <95% (non-condensing)

Maximum Altitude: 3300 ft (1000m)

above sea level

Storage Temperature: -20 to 70 C

Key SM Vector Features

Condensed Inverter Specifications

Delivering More Low End Torque in a Sub-Micro Package

Standard at no extra cost on all LEESON

stock NEMA three-phase motors,

1 HP and larger, is the exclusive

Inverter Rated Insulation System

(IRIS). This provides superior

protection against voltage spikes

induced by variable frequency drives.

With LEESON, you dont have to wonder whether your motor is

suitable for use with an inverter. Thats because all LEESON

SPEEDMASTER

Inverter-Duty motors, WATTSAVER

premium

efficiency motors, and WASHGUARD washdown-duty motors, as well

as general-purpose three-phase motors 1HP and larger include our

exclusive IRISInverter-Rated Insulation System at no extra cost.

IRISis a multi-level system that results in a motor truly hardened for

inverter service. Careful placement of wire within the stator, well

thought-out winding and lamination design, and precise insulation

practices (including phase insulation, sleeving, connection insulation

and varnish) all play critical roles. Second-generation spike-resistant

magnet wire, specially coated to resist corona inception, completes

the system offering service life well beyond conventional double,

triple or even quad-build wire in inverter-fed applications.

For true inverter-duty performance, meeting NEMA MG1 parts 30 &

31, LEESONs SPEEDMASTER

motor is readily available from stock

in either TENV or TEBC designs. LEESONs WATTSAVER

line offers

NEMA Premiumefficiency levels and an inverter-rated design. With

the addition of a constant speed blower kit, Wattsaver

motors are

capable of full torque to zero speed. Encoder kits for closed loop

control are available for both SPEEDMASTER

and WATTSAVER

motors, making them excellent for use with vector drives. Both

SPEEDMASTER

and WATTSAVER

carry a three-year

warrantyeven in inverter service!

Premium efficiency WATTSAVER

motors are built with greater

copper and steel mass, which results in additional tolerance to

heat rise in inverter-fed applications. As with all LEESON

motors, WATTSAVER

efficiencies are verified to IEEE 112B

test standards.

INVERTER-CAPABLE MOTORS

See chart (opposite page)

of inverter motor capabilities.

Constant-speed blower kits convert LEESON cast iron TEFC

motors to NEMA MG1.6 (IC46) standard for inverter and vec-

tor drive applications where continuous cooling is required.

Installation requires no shaft modification. Available for NEMA

frame sizes 182-4T through 324-6T.

Encoder kits are available for LEESON cast iron TEFC

motors from NEMA 182-4T through 284-6T frame size. The

encoder slips over the motors fan-end shaft to provide

speed-reference signals for closed-loop control systems.

Industrial-duty encoders are isolated from shaft currents, and

electrical noise immunity exceeds international standards.

Available From Stock

IRIS

PROTECTED MOTOR INVERTER CAPABILITIES

STEEL FRAME MOTORS

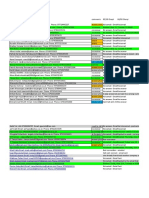

NEMA Variable Constant Constant

Frame Torque** Torque** HP** Notes

Standard General Purpose

TEFC 56-210 frame 6-60 Hz 6-60 Hz to 90 Hz*

ODP 56-210 frame 6-60 Hz 20-60 Hz to 90 Hz*

WATTSAVER

Premium Efficiency

TEFC 56-210 frame 6-60 Hz 6-60 Hz to 90 Hz*

ODP 56-210 frame 6-60 Hz 6-60 Hz to 90 Hz*

Special Purpose Motors

WASHGUARD MOTORS

TENV 56-140 frame 6-60 Hz 6-60 Hz to 90 Hz*

TEFC 56-210 frame 6-60 Hz 6-60 Hz to 90 Hz*

CAST IRON MOTORS

NEMA Variable Constant Constant

Frame Torque** Torque** HP** Notes

Standard General Purpose

TEFC 180-440 frame 6-60 Hz 6-60 Hz to 90 Hz*

ODP 180-440 frame 6-60 Hz 6-60 Hz to 90 Hz*

TEFC with blower kit 180-320 frame 5-60 Hz 5-60 Hz to 90 Hz* full torque at low speed with vector drive

WATTSAVER

Inverter Duty, Premium Efficiency

TEFC 180-280 frame 6-60 Hz 6-60 Hz to 90 Hz*

320-440 frame 6-60 Hz 6-60 Hz to 90 Hz*

ODP 180-280 frame 6-60 Hz 6-60 Hz to 90 Hz*

320-440 frame 6-60 Hz 6-60 Hz to 90 Hz*

TEFC with blower kit 180-320 frame 0-60 Hz 0-60 Hz to 90 Hz* full torque at zero speed with vector drive

SPEEDMASTER

Extreme-Duty Inverter Motors

TENV 143TC-256TC 0-120 Hz 0-120 Hz

TEBC 284T-449T 0-90 Hz 0-90 Hz

* The maximum recommended frequency (speed) for 2 pole (3600 rpm) motors, without application analysis, is Hz=75, rather than 90 Hz. Contact factory for details.

** Operation for variable or constant torque is up to a base frequency of 60 Hz only. Operation above 60 Hz to the maximum frequency listed is constant horsepower (horse-

power equal to motor rated horsepower).

NOTES:

1. All motors are class F insulated, 40C ambient, 3300 ft.

and 1.0 service factor when used with an inverter.

2. Optimized voltage boost is required for continuous

operation throughout the frequency range specified. (See

operating curves.)

3. Motors with blower kits have continuous cooling and are

capable of full rated torque at 0 speed with properly tuned

vector drive.

4. Maximum recommended cable length for IGBT inverters is

250 ft. (longer cable lengths may require noise or voltage

suppression).

5. All motors have LEESONs IRISinsulation system, which

is designed to meet the NEMA requirements for peak

voltages up to 1600 volts, and pulse rise time greater than

or equal to 0.1 microseconds.

6. Operating curves are available for WATTSAVER

motors.

Refer to curves for more details about frequency ranges.

DC Adjustable Speed Drives

SPEEDMASTER

DC drives range from sub-fractional-

horsepower through 3 HP. SCR and PWM versions

are offered, in reversing or non-reversing options.

Four-quadrant regenerative drives are also available.

NEMA 1, NEMA 4X or open chassis styles. For more

information, request Catalog 1050.

Bulletin 1400 LEESON ELECTRIC, 2006 PRINTED IN U.S.A.

Specifications subject to change without notice.

5260S-NP/12-05/7500/WD

LEESON Electric offers a variety of Inverter Rated Motors and Gear+Motor packages to compliment our family of

SPEEDMASTER

AC Adjustable Speed Drive products.

A REGAL-BELOIT COMPANY

PACKAGED SOLUTIONS

Than Just a Motor Company More

Vector Duty Motors

2000:1 Constant Torque

High Efficiency

WATTSAVER

Motors F2 Mount 3-Phase Motors

NEMA Efficient 3-Phase Motors

Stainless Steel JM Pump

Shaft Motors

Stainless Steel General

Purpose Motors

JP Pump Motors

IP55 WASHGUARD Duty

White Epoxy Motors

Blower Kits Available for 56T

thru 326T Frame Motors

WATTSAVER

C-Face Motors IEC Metric Motors

Available Gearbox/Motor

Combinations

S-ar putea să vă placă și

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- Aconis 2000 eDocument8 paginiAconis 2000 etranquangluong86Încă nu există evaluări

- Supply Chain Risk Management: Resilience and Business ContinuityDocument27 paginiSupply Chain Risk Management: Resilience and Business ContinuityHope VillonÎncă nu există evaluări

- 3G3JXDocument8 pagini3G3JXrwciriloÎncă nu există evaluări

- Ss1169 - Telecom Frameworx l1TMFDocument65 paginiSs1169 - Telecom Frameworx l1TMFPrince SinghÎncă nu există evaluări

- Infineon - Brochure - Motor ControlDocument42 paginiInfineon - Brochure - Motor ControlRyan AngelesÎncă nu există evaluări

- 200 KVA Perkins Diesel Generator SetDocument5 pagini200 KVA Perkins Diesel Generator SetPopa AurelÎncă nu există evaluări

- Spa ClaimsDocument1 paginăSpa ClaimsJosephine Berces100% (1)

- Jaquet FT 1400 eDocument4 paginiJaquet FT 1400 eAnonymous AeIfk4RKnÎncă nu există evaluări

- Tsurumi 3013 CatalogDocument32 paginiTsurumi 3013 CatalogFlores Cesar0% (1)

- Catalogo Industrial SKFDocument209 paginiCatalogo Industrial SKFOfelia DiazÎncă nu există evaluări

- Financial StatementDocument8 paginiFinancial StatementDarwin Dionisio ClementeÎncă nu există evaluări

- Networked Control System: Fundamentals and ApplicationsDe la EverandNetworked Control System: Fundamentals and ApplicationsÎncă nu există evaluări

- MVControllers 1500 Sg001 en PDocument48 paginiMVControllers 1500 Sg001 en PricardoqqÎncă nu există evaluări

- 454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesDocument12 pagini454 GT Series: ID-PWM AC Low Voltage Variable Frequency DrivesVicente Orbegoso RodriguezÎncă nu există evaluări

- HA030092 Issue 2Document12 paginiHA030092 Issue 2Germán GonzálezÎncă nu există evaluări

- International Network: The LEROY-SOMER OfferDocument10 paginiInternational Network: The LEROY-SOMER OfferTibor DanielÎncă nu există evaluări

- Flex Pak 3000Document24 paginiFlex Pak 3000Maitry ShahÎncă nu există evaluări

- Yaskawa P7 Drives PDFDocument2 paginiYaskawa P7 Drives PDFMukti AwanÎncă nu există evaluări

- Versa MaxDocument34 paginiVersa MaxSenthil KumarÎncă nu există evaluări

- Controller FIS134 19-22 EN PDFDocument4 paginiController FIS134 19-22 EN PDFrimce77Încă nu există evaluări

- Kollmorgen Servostar CD Series2 CatalogDocument20 paginiKollmorgen Servostar CD Series2 CatalogElectromateÎncă nu există evaluări

- Product Profile: Provide Optimized SimplicityDocument4 paginiProduct Profile: Provide Optimized SimplicitySudipta Kumar GarnayakÎncă nu există evaluări

- VSI-Prospekt E Rev01Document11 paginiVSI-Prospekt E Rev01اسلام الجرفÎncă nu există evaluări

- Smd23e Ethernet Stepper Controller Drive MotorDocument2 paginiSmd23e Ethernet Stepper Controller Drive MotorJairo FontesÎncă nu există evaluări

- Modular, Configurable, Compact: SVX9000 Adjustable Frequency DrivesDocument6 paginiModular, Configurable, Compact: SVX9000 Adjustable Frequency DrivesagroelizabethÎncă nu există evaluări

- Isel ControlerDocument18 paginiIsel Controlermihail91smÎncă nu există evaluări

- Yaskawa V7 VFD DrivesDocument2 paginiYaskawa V7 VFD DrivesMukti AwanÎncă nu există evaluări

- Integrator Series AC DrivesDocument9 paginiIntegrator Series AC Drivesjohxav10Încă nu există evaluări

- Catalogo Controlador CD 600Document8 paginiCatalogo Controlador CD 600robertocarlosroa100% (1)

- VLT® Soft Starter MCD 500: PerfectDocument2 paginiVLT® Soft Starter MCD 500: PerfectserginÎncă nu există evaluări

- FC51Document8 paginiFC51Nguyễn Minh TríÎncă nu există evaluări

- Industrial Load ManagementDocument7 paginiIndustrial Load ManagementMuhammad Naveed SultanÎncă nu există evaluări

- Kollmorgen Servostar600 With GoldLine BHMH TB CatalogDocument28 paginiKollmorgen Servostar600 With GoldLine BHMH TB CatalogElectromateÎncă nu există evaluări

- P26-33 wBAL501A-2007Document8 paginiP26-33 wBAL501A-2007circlelineÎncă nu există evaluări

- De DriveDocument6 paginiDe DriveEdgar RdzÎncă nu există evaluări

- Hc900 ControllerDocument19 paginiHc900 ControllercarlosoalvarezcÎncă nu există evaluări

- Ti MotorDocument25 paginiTi MotorBruno SilvaÎncă nu există evaluări

- Simatic s7-200: New ProductsDocument6 paginiSimatic s7-200: New ProductsHoa Lưu LyÎncă nu există evaluări

- TM GE Load Commuted InverterDocument12 paginiTM GE Load Commuted InverterTufan MaityÎncă nu există evaluări

- CMMS-ST enDocument12 paginiCMMS-ST enJacpro Automation SacÎncă nu există evaluări

- InteliDrive Mobile - Datasheet PDFDocument2 paginiInteliDrive Mobile - Datasheet PDFdeeparunÎncă nu există evaluări

- 13 389 390 392 enDocument3 pagini13 389 390 392 enJuan Manuel Barrera FdzÎncă nu există evaluări

- Digital DC Drives & Systems Upto 5000 KWDocument12 paginiDigital DC Drives & Systems Upto 5000 KWGemco ControlsÎncă nu există evaluări

- IGEL MV Soft Starter Catalogue To ArgenDocument4 paginiIGEL MV Soft Starter Catalogue To ArgenanksyeteÎncă nu există evaluări

- MCS350S 1Document7 paginiMCS350S 1Pedro SepúlvedaÎncă nu există evaluări

- s7 1500 CatalogueDocument54 paginis7 1500 CatalogueBenjamín Cares ZalazarÎncă nu există evaluări

- Sec-Ac EnusDocument10 paginiSec-Ac EnusJohan JorezÎncă nu există evaluări

- 635215952379094386498Document128 pagini635215952379094386498bajricaÎncă nu există evaluări

- All Motion EZ Stepper Model EZ4AXISDocument60 paginiAll Motion EZ Stepper Model EZ4AXISJohn Melanathy IIÎncă nu există evaluări

- Emms-St CMMS-ST Psi141 3 en PDFDocument2 paginiEmms-St CMMS-ST Psi141 3 en PDFrimce77Încă nu există evaluări

- Compax3Brochure Sept2010Document20 paginiCompax3Brochure Sept2010cartunesÎncă nu există evaluări

- 1207A RevDDocument2 pagini1207A RevDEduardo Martinez VazquezÎncă nu există evaluări

- Commander SK: Compact, Easy To Use AC DriveDocument2 paginiCommander SK: Compact, Easy To Use AC DriveCharitha RanwalaÎncă nu există evaluări

- D11 SinamicsG110 KatalogDocument20 paginiD11 SinamicsG110 Katalogiyilmaz1Încă nu există evaluări

- Brochure S7-200 (En)Document6 paginiBrochure S7-200 (En)Jorge_Andril_5370Încă nu există evaluări

- Curtis PDFDocument3 paginiCurtis PDFmax_6744Încă nu există evaluări

- Base Drive Operation: Stan Ar Ontrol Mo EsDocument52 paginiBase Drive Operation: Stan Ar Ontrol Mo EsDuvel AragoÎncă nu există evaluări

- Drive Emerson DatasheetDocument12 paginiDrive Emerson DatasheetArmando JuarezÎncă nu există evaluări

- Selection Guide: Fixed Speed ControlDocument32 paginiSelection Guide: Fixed Speed Controlav_86Încă nu există evaluări

- Advanced Motion Controls Dpeaniu-C060a400Document11 paginiAdvanced Motion Controls Dpeaniu-C060a400ElectromateÎncă nu există evaluări

- Infinity S Flex, CPB-NESFlex 10-29-15Document16 paginiInfinity S Flex, CPB-NESFlex 10-29-15Anonymous z631suOmÎncă nu există evaluări

- TEC2000 Electronic Valve Actuators: Engineering and Controls ManualDocument44 paginiTEC2000 Electronic Valve Actuators: Engineering and Controls ManualjoseaibarraÎncă nu există evaluări

- Sales Memo ATV71Document2 paginiSales Memo ATV71chahbounnabilÎncă nu există evaluări

- Valve Clarkson KgaDocument6 paginiValve Clarkson KgaFlores CesarÎncă nu există evaluări

- Ingles Vi: Lic. Elva Cirilo ChapiDocument15 paginiIngles Vi: Lic. Elva Cirilo ChapiFlores CesarÎncă nu există evaluări

- F-Modelo de Examen Final Inglés VDocument3 paginiF-Modelo de Examen Final Inglés VFlores CesarÎncă nu există evaluări

- Manual de Instalacion Se, CompletoDocument16 paginiManual de Instalacion Se, CompletoFlores CesarÎncă nu există evaluări

- SAGSim RecycleDocument162 paginiSAGSim RecycleFlores CesarÎncă nu există evaluări

- Ingles Vi: Lic. Elva Cirilo ChapiDocument11 paginiIngles Vi: Lic. Elva Cirilo ChapiFlores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Document10 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Flores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 10-Jul-2014 20:53:58Document31 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 10-Jul-2014 20:53:58Flores CesarÎncă nu există evaluări

- Reduct orDocument20 paginiReduct orFlores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 01-Jul-2014 19:52:22Document72 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 01-Jul-2014 19:52:22Flores CesarÎncă nu există evaluări

- 15 07 2014.pdfeDocument29 pagini15 07 2014.pdfeFlores CesarÎncă nu există evaluări

- FLENDER Supplies: Oil-Supply SystemsDocument34 paginiFLENDER Supplies: Oil-Supply SystemsFlores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 05-Ago-2014 19:56:46Document8 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 05-Ago-2014 19:56:46Flores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Document10 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 17-Jul-2014 20:51:19Flores CesarÎncă nu există evaluări

- Turbine Mixers 4Document27 paginiTurbine Mixers 4Flores CesarÎncă nu există evaluări

- 03 07 2014ba - PDFNDocument8 pagini03 07 2014ba - PDFNFlores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMDocument8 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMJhon Arias FloresÎncă nu există evaluări

- SLM SeriesDocument4 paginiSLM SeriesFlores CesarÎncă nu există evaluări

- Rodamientos ToleranciaDocument32 paginiRodamientos ToleranciaFlores CesarÎncă nu există evaluări

- 301-100 - Falk Ram Mixer Drives - BrochureDocument4 pagini301-100 - Falk Ram Mixer Drives - BrochureFlores CesarÎncă nu există evaluări

- 001 Rotex en PDFDocument34 pagini001 Rotex en PDFFlores CesarÎncă nu există evaluări

- Teco MaxDocument40 paginiTeco MaxFlores CesarÎncă nu există evaluări

- pl1021 UsDocument7 paginipl1021 UsFlores CesarÎncă nu există evaluări

- Blackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMDocument8 paginiBlackboard Collaborate ?? SALA TERMODINAMICA (1703-17302) SEC 02-1 SEM 05 MOD 2 U.A.P. LIMA DUED 2014-1 DUED LIMA 24/06/2014 07:58:27 PMJhon Arias FloresÎncă nu există evaluări

- Eta SeriesDocument4 paginiEta SeriesFlores CesarÎncă nu există evaluări

- Eta SeriesDocument4 paginiEta SeriesFlores CesarÎncă nu există evaluări

- Fsd166eng SLMDocument4 paginiFsd166eng SLMFlores CesarÎncă nu există evaluări

- DevelopersDocument88 paginiDevelopersdiegoesÎncă nu există evaluări

- Press Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFDocument6 paginiPress Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFJay ShahÎncă nu există evaluări

- The Website Design Partnership FranchiseDocument5 paginiThe Website Design Partnership FranchiseCheryl MountainclearÎncă nu există evaluări

- CENT - Company Presentation Q1 2020 PDFDocument22 paginiCENT - Company Presentation Q1 2020 PDFsabrina rahmawatiÎncă nu există evaluări

- MNO Manuale Centrifughe IngleseDocument52 paginiMNO Manuale Centrifughe IngleseChrist Rodney MAKANAÎncă nu există evaluări

- 1 Ton Per Hour Electrode Production LineDocument7 pagini1 Ton Per Hour Electrode Production LineMohamed AdelÎncă nu există evaluări

- Carry Trade Calculator 1.54Document3 paginiCarry Trade Calculator 1.54Gabriel RomanÎncă nu există evaluări

- Key Features of A Company 1. Artificial PersonDocument19 paginiKey Features of A Company 1. Artificial PersonVijayaragavan MÎncă nu există evaluări

- Land Use Paln in La Trinidad BenguetDocument19 paginiLand Use Paln in La Trinidad BenguetErin FontanillaÎncă nu există evaluări

- Computer System Sevicing NC Ii: SectorDocument44 paginiComputer System Sevicing NC Ii: SectorJess QuizzaganÎncă nu există evaluări

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 paginiKit 2: Essential COVID-19 WASH in SchooltamanimoÎncă nu există evaluări

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 paginiEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandÎncă nu există evaluări

- QP 4Document4 paginiQP 4Yusra RaoufÎncă nu există evaluări

- scx4521f SeriesDocument173 paginiscx4521f SeriesVuleticJovanÎncă nu există evaluări

- Is 10719 (Iso 1302) - 1Document1 paginăIs 10719 (Iso 1302) - 1Svapnesh ParikhÎncă nu există evaluări

- Contemp World Module 2 Topics 1 4Document95 paginiContemp World Module 2 Topics 1 4Miguel EderÎncă nu există evaluări

- Database Management System and SQL CommandsDocument3 paginiDatabase Management System and SQL Commandsdev guptaÎncă nu există evaluări

- Salva v. MakalintalDocument2 paginiSalva v. MakalintalGain DeeÎncă nu există evaluări

- Jainithesh - Docx CorrectedDocument54 paginiJainithesh - Docx CorrectedBala MuruganÎncă nu există evaluări

- Brazilian Mineral Bottled WaterDocument11 paginiBrazilian Mineral Bottled WaterEdison OchiengÎncă nu există evaluări

- S200 For Sumber RezekiDocument2 paginiS200 For Sumber RezekiIfan JayusdianÎncă nu există evaluări

- Corporation Law Review Test Midterms 2019Document4 paginiCorporation Law Review Test Midterms 2019Van NessaÎncă nu există evaluări

- Certification DSWD Educational AssistanceDocument3 paginiCertification DSWD Educational AssistancePatoc Stand Alone Senior High School (Region VIII - Leyte)Încă nu există evaluări

- Comparative Analysis of Mutual Fund SchemesDocument29 paginiComparative Analysis of Mutual Fund SchemesAvinash JamiÎncă nu există evaluări

- Ewellery Ndustry: Presentation OnDocument26 paginiEwellery Ndustry: Presentation Onharishgnr0% (1)

- Planas V Comelec - FinalDocument2 paginiPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)