Documente Academic

Documente Profesional

Documente Cultură

2 1 32

Încărcat de

Sergey MovchanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2 1 32

Încărcat de

Sergey MovchanDrepturi de autor:

Formate disponibile

SECTION 2 STRUCTURE AND FUNCTION

Group 1 Pump Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

Group 2 Main Control Valve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-21

Group 3 Swing Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-51

Group 4 Travel Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-60

Group 5 RCV Lever - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-67

Group 6 RCV Pedal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-74

2-1

1. STRUCTURE

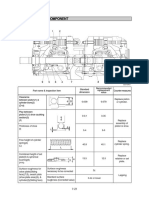

The pump device consists of main pump, regulator and gear pump.

SECTION 2 STRUCTURE AND FUNCTION

GROUP 1 PUMP DEVICE

Pi1 Pm1

Dr

Pi1

Pm1

Psv

Psv

Pm2

Pi2

Pm2 Pi2

a4

a4

A3

B3

Dr

B3

B1

a3

a1

a1

A1

A2

A3 B3 B1

Dr

Pi1

Pm1

Psv

a2

a4

a3

Qmin adjusting screw

Regulator Regulator

Gear pump Rear pump Front pump

Port block

Qmax adjusting screw

Qmin adjusting screw

a2

Port

A1,2

B1

Dr

Pi1,i2

Pm1,m2

Psv

a1,2,4

a3

A3

B3

Port name

Delivery port

Suction port

Drain port

Pilot port

Qmax cut port

Servo assist port

Gauge port

Gauge port

Gear pump delivery port

Gear pump suction port

Port size

SAE6000psi 3/4"

SAE2500psi 2 1/2"

PF 3/4 - 20

PF 1/4 - 15

PF 1/4 - 15

PF 1/4 - 15

PF 1/4 - 15

PF 1/4-14

PF 1/2 - 19

PF 3/4 - 20

Pm2

Pi2

2-2

MAIN PUMP(1/2)

The main pump consists of two piston pumps(front & rear) and valve block.

1)

04 Gear pump

111 Drive shaft(F)

113 Drive shaft(R)

114 Spline coupling

123 Roller bearing

124 Needle bearing

127 Bearing spacer

141 Cylinder block

151 Piston

152 Shoe

153 Set plate

156 Bushing

157 Cylinder spring

211 Shoe plate

212 Swash plate

214 Bushing

251 Support

789, 732 532 214 548 531 724

702

792 901 808 954 717 151 152 534 211 113

04

401 271 141 314 885 466

725

114 312 124 313 468

728

157 156 153 490

212

251

123

710

127

824

111

774

261

406

886

953

717

806

535

261 Seal cover(F)

271 Pump casing

312 Valve block

313 Valve plate(R)

314 Valve plate(L)

401 Hexagon socket bolt

406 Hexagon socket bolt

466 VP Plug

468 VP Plug

490 Plug

531 Tilting pin

532 Servo piston

534 Stopper(L)

535 Stopper(S)

548 Pin

702 O-ring

710 O-ring

717 O-ring

724 O-ring

725 O-ring

728 O-ring

732 O-ring

774 Oil seal

789 Back up ring

792 Back up ring

806 Hexagon head nut

808 Hexagon head nut

824 Snap ring

885 Pin

886 Spring pin

901 Eye bolt

953 Set screw

954 Set screw

22007C2MP02

2-3

MAIN PUMP(2/2)

079 Proportional reducing valve

541 Seat

543 Stopper 1

544 Stopper 2

545 Steel ball

544

543

545

541

079

VIEW A

2-3

2-4

REGULATOR(1/2) 2)

A

A

A

B

B

B

SECTION B-B

VIEW C

P2

Pf

Pm

Pi

KR3G-9C32

755

858

614

615

613

611

438

801

924

647

648

723

642

801

656

438

735

722

897

612

875 874 412

641 730 643 708 644 645 646 728

413 438

496 724 725 436

Port

A

B

Pi

Pm

Port name

Delivery port

Suction port

Pilot port

Qmax cut port

port size

3/4"

2 1/2"

PF 1/4-15

PF 1/4-15

2-4

2-4

2-5

REGULATOR(2/2)

412 Hexagon socket screw

413 Hexagon socket screw

436 Hexagon socket screw

438 Hexagon socket screw

496 Plug

601 Casing

611 Feed back lever

612 Lever(1)

613 Lever(2)

614 Fulcrum plug

615 Adjust plug

621 Compensator piston

622 Piston case

623 Compensator rod

624 Spring seat(C)

625 Outer spring

626 Inner spring

627 Adjust stem(C)

628 Adjust screw(C)

629 Cover(C)

630 Lock nut

631 Sleeve, pf

641 Pilot cover

642 Pilot cover(QMC)

643 Pilot piston

644 Spring seat(Q)

645 Adjust stem(Q)

646 Pilot spring

647 Stopper

648 Piston(QMC)

651 Sleeve

652 Spool

653 Spring seat

654 Return spring

655 Set spring

656 Block cover

708 O-ring

722 O-ring

723 O-ring

724 O-ring

725 O-ring

728 O-ring

730 O-ring

732 O-ring

733 O-ring

734 O-ring

735 O-ring

755 O-ring

756 O-ring

763 O-ring

801 Nut

814 Snap ring

836 Snap ring

858 Snap ring

874 Pin

875 Pin

887 Pin

897 Pin

898 Pin

924 Set screw

925 Adjust screw(QI)

734 653 654 836 651 652 601 624 629 630 628

655

641

814

898

631

732

733

622

C

801

925

627

732

621 623 625 626 887 763 756

SECTION A-A

2-5

2-6

GEAR PUMP 3)

307 Poppet

308 Seat

309 Spring seat

310 Spring

311 Screw

312 Nut

351 Gear case

353 Drive gear

354 Driven gear

355 Filter

361 Front case

433 Flange socket

434 Flange socket

435 Flange socket

466 Plug

700 Ring

710 O-ring

725 O-ring

732 O-ring

850 Snap ring

700 354 351 433

434

311

312

850

355

a3

A3

B3

710 435 361 353 732 309 307 310 308 434 466, 725

2-6

2-7

Rotary group

The rotary group consists of drive shaft

(F)(111), cylinder block(141), piston

shoes(151,152), set plate(153), spherical

bush(156), spacer(158) and cylinder

spring(157). The drive shaft is supported

by bearing(123,124) at its both ends.

The shoe is caulked to the piston to from

a spherical coupling. It has a pocket to

relieve thrust force generated by loading

pressure and the take hydraulic balance

so that it slides lightly over the shoe

plate(211). The sub group composed by

a piston and a shoe is pressed against the

shoe plate by the action of the cylinder

spring via a retainer and a spherical bush.

Similarly, the cylinder block is pressed

against valve plate(313) by the action of

the cylinder spring.

Swash plate group

The swash plate group consists of swash

plate(212), shoe plate(211), swash plate

support(251), tilting bush(214), tilting

pin(531) and servo piston(532).

The swash plate is a cylindrical part

formed on the opposite side of the sliding

surface of the shoe and is supported by

the swash support.

If the servo piston moves to the right and

left as hydraulic force controlled by the

regulator is admitted to hydraulic chamber

located on both sides of the servo piston,

the swash plate slides over the swash

plate support via the spherical part of the

tilting pin to change the tilting angle()

2. FUNCTION

MAIN PUMP

The pumps may classified roughly into the rotary group performing a rotary motion and working as

the major part of the whole pump function: the swash plate group that varies the delivery rates: and

the valve cover group that changes over oil suction and discharge.

1)

(1)

(2)

157

211

211

123

111

212

251

532

151

152

531

548

214

124

313

141

158

156

153

2-7(1)

2-7

2-8

Valve block group

The valve block group consists of valve

block(312), valve plate(313) and valve

plate pin(885).

The valve plate having two melon-shaped

ports is fixed to the valve block and feeds

and collects oil to and from the cylinder

block.

The oil changed over by the valve plate is

connected to an external pipeline by way

of the valve block.

Now, if the drive shaft is driven by a prime

mover(electric motor, engine, etc), it

rotates the cylinder block via a spline

linkage at the same time. If the swash

plate is tilted as in Fig(previous page) the

pistons arranged in the cylinder block

make a reciprocating motion with respect

to the cylinder block, while they revolve

with the cylinder block.

If you pay attention to a single piston, it

performs a motion away from the valve

plate(oil sucking process) within 180

degrees, and makes a motion towards the

valve plate(or oil discharging process) in

the rest of 180 degrees. When the swash

plate has a tilting angle of zero, the piston

makes no stroke and discharges no oil.

(3)

313

885

312

2-8

2-9

Negative flow control

By changing the pilot pressure Pi, the

pump tilting angle(delivery flow) is

regulated arbitrarily, as shown in the

figure.

This regulator is of the negative flow

control in which the delivery flow Q

decreases as the pilot pressure Pi rises.

With this mechanism, when the pilot

pressure corresponding to the flow

required for the work is commanded, the

pump discharges the required flow only,

and so it does not consume the power

uselessly.

REGULATOR

Regulator consists of the negative flow control, total horse power control and power shift control

function.

2)

(1)

Pilot pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

2-10

Flow reducing function _

As the pilot pressure Pi rises, the pilot piston(643) moves to the right to a position where the force

of the pilot spring(646) balances with the hydraulic force.

The groove(A) in the pilot piston is fitted with the pin(875) that is fixed to lever 2(613). Therefore,

when the pilot piston moves, lever 2 rotates around the fulcrum of point B [fixed by the fulcrum

plug(614) and pin(875)]. Since the large hole section(C) of lever 2 contains a protruding pin(897)

fixed to the feedback lever(611), the pin(897) moves to the right as lever 2 rotates. Since the

opposing-flat section(D) of the feedback lever is fitted with the pin(548) fixed by the tilting pin(531)

that swings the swash plate, the feedback lever rotates around the fulcrum of point D, as the

pin(897) moves.

Since the feedback lever is connected with the spool(652) via the pin(874), the spool moves to

the right.

The movement of the spool causes the delivery pressure P1 to connect to port CL through the

spool and to be admitted to the large diameter section of the servo piston. The delivery pressure

P1 that is constantly admitted to the small diameter section of the servo piston moves the servo

piston to the right due to the area difference, resulting in decrease of the tilting angle.

When the servo piston moves to the right, point D also moves to the right. The spool is fitted

with the return spring(654) and is tensioned to the left at all times, and so the pin(897) is pressed

against the large hole section(C) of lever 2.

Therefore, as point D moves, the feedback lever rotates around the fulcrum of point C, and the

spool is shifted to the left. This causes the opening between the sleeve(651) and spool(652) to

close slowly, and the servo piston comes to a complete stop when it closes completely.

643 654 651 652 613 646

B(E)

874

897

875

C

A

611

CL P1

531

548

D

Small diameter

chamber

Servo piston

Large diameter

chamber

2-10

2-11

Flow increasing function _

As the pilot pressure Pi decreases, the pilot piston(643) moves to the left by the action of the pilot

spring(646) and causes lever 2(613) to rotate around the fulcrum of point B. Since the pin(897)

is pressed against the large hole section(C) of lever 2 by the action of the return spring(654) via

the spool(652), pin(874), and feedback lever(611), the feedback lever rotates around the fulcrum

of point D as lever 2 rotates, and shifts the spool to the left. Port CL opens a way to the tank port

as the spool moves. This deprives the large diameter section of the servo piston of pressure,

and shifts the servo piston to the left by the discharge pressure P1 in the small diameter section,

resulting in an increase in the flow rate.

As the servo piston moves, point D also moves to the left, the feedback lever rotates around the

fulcrum of point C, and the spool moves to the right till the opening between the spool and sleeve

is closed.

643 654 651 652 613 646

B(E)

874

897

875

C

611

CL P1

531

548

D

Small diameter

chamber

Servo piston

Large diameter

chamber

2-11

2-12

The flow control characteristic can be

adjusted with the adjusting screw.

Adjust it by loosening the hexagon

nut(801) and by tightening(or loosening)

the hexagonal socket head screw(924).

Tightening the screw shifts the control

chart to the right as shown in the figure.

Adjusting values are shown in table.

Adjustment of flow control characteristic

Pilot pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

Adjustment of flow control

characteristic

Speed

Tightening Flow control Flow change

amount of starting amount

adjusting pressure

screw(924) change

amount

(min

-1

) (Turn) (kgf/cm

2

) (/min)

1950 +1/4 +1.5 +12.6

801

924

_

2-13

Total horsepower control

The regulator decreases the pump tilting

angle(delivery flow) automatically to limit

the input torque within a certain value with

a rise in the delivery pressure P1 of the

self pump and the delivery pressure P2 of

the companion pump.

(The input horsepower is constant when

the speed is constant.)

Since the regulator is of the simultaneous

total horsepower type that operates by the

sum of load pressures of the two pumps

in the tandem double-pump system, the

prime mover is automatically prevented

from being overloaded, irrespective of the

load condition of the two pumps, when

horsepower control is under way.

Since this regulator is of the simultaneous

total horsepower type, it controls the tilting

angles(displacement volumes) of the two

pumps to the same value as represented

by the following equation :

Tin = P1q/2+ P2q/2

= (P1+P2)q/2

The horsepower control function is the

same as the flow control function and is

summarized in the following.(For detailed

behaviors of respective parts, refer to the

section of flow control).

(2)

Delivery pressure, (P1+P2)

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

2-14

Overload preventive function _

When the self pump delivery pressure P1 or the companion pump delivery pressure P2 rises, it

acts on the stepped part of the compensating piston(621). It presses the compensating rod(623)

to the right till the force of the outer spring(625) and inner spring(626) balances with the hydraulic

force. The movement of the compensating rod is transmitted to lever 1(612) via pin(875).

Lever 1 rotates around the pin(875) (E) fixed to the casing(601).

Since the large hole section(F) of lever 1 contains a protruding pin(897) fixed to the feedback

lever(611), the feedback lever rotates around the fulcrum of point D as lever 1 rotates, and then

the spool(652) is shifted to the right. As the spool moves, the delivery pressure P1 is admitted to

the large diameter section of the servo piston via port CL, causes the servo piston move to the

right, reduces the pump delivery, flow rate, and prevents the prime mover from being overloaded.

The movement of the servo piston is transmitted to the feedback lever via point D. Then the

feedback lever rotates around the fulcrum of point F and the spool is shifted to the left. The

spool moves till the opening between the spool(652) and sleeve(651) is closed.

621 651 652 623 612 601 625 626

B(E)

897

875

F

611

CL P1

P2 P1

D

Small diameter

chamber

Servo piston

Large diameter

chamber

2-14

2-15

Flow reset function _

As the self pump delivery pressure P1 or the companion pump delivery pressure P2 decreases,

the compensating rod(623) is pushed back by the action of the springs(625 & 626) to rotate lever

1(612) around point E. Rotating of lever 1 causes the feedback lever(611) to rotate around the

fulcrum of point D and then the spool(652) to move to the left. As a result, port CL opens a way

to the tank port.

This causes the servo piston to move to the left and the pump's delivery rate to increase.

The movement of the servo piston is transmitted to the spool by the action of the feedback

mechanism to move it till the opening between the spool and sleeve is closed.

621 651 652 623 612 601 625 626

B(E)

897

875

F

CL P1

P2 P1

D

Small diameter

chamber Servo piston

Large diameter

chamber

2-15

2-16

Adjustment of outer spring

Adjust it by loosening the hexagon

nut(630) and by tightening(or loosening)

the adjusting screw C(628). Tightening

the screw shifts the control chart to the

right and increases the input

horsepower as shown in the figure.

Since turning the adjusting screw C by

N turns changes the setting of the inner

spring(626), return the adjusting screw

QI(925) by NA turns at first.(A=2.2)

Adjusting values are shown in table

Low tilting angle(Low flow) command preferential function

As mentioned above, flow control and horsepower control tilting angle commands are

transmitted to the feedback lever and spool via the large-hole sections(C & F) of levers 1 and 2.

However, since sections C and F have the pins(+4) protruding from the large hole(+8), only the

lever lessening the tilting angle contacts the pin(897) ; the hole(+8) in the lever of a larger tilting

angle command is freed without contacting the pin(897). Such a mechanical selection method

permits preference of the lower tilting angle command of the flow control and horsepower control.

Adjustment of input horsepower

Since the regulator is of total cumulative horsepower type, adjust the adjusting screws of both the

front and rear pumps, when changing the horsepower set values. The pressure change values

by adjustment are based on two pumps pressurized at the same time, and the values will be

doubled when only one pump is loaded.

_

_

a.

Delivery pressure, (P1+P2)

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

625 626 630 628

801

925

2-16

Adjustment of flow control

characteristic

Speed

Tightening Flow control Flow change

amount of starting amount

adjusting pressure

screw(924) change

amount

(min

-1

) (Turn) (kgf/cm

2

) (/min)

1950 +1/4 +15.9 +4.3

2-17

Adjustment of inner spring

Adjust it by loosening the hexagon nut

(801) and by tightening(or loosening)

the adjusting screw QI(925).

Tightening the screw increases the flow

and then the input horsepower as

shown in the figure.

Adjusting valves are shown in table

b.

Delivery pressure, (P1+P2)

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

626

801

925

2-17

Adjustment of flow control

characteristic

Speed

Tightening Compensa Input torque

amount of ting control change

adjusting starting amount

screw(QI) pressure

(925) change

amount

(min

-1

) (Turn) (kgf/cm

2

) (kgfm)

1950 +1/4 +9.7 +4.2

2-18

Power shift control

The set horsepower valve is shifted by

varying the command current level of the

proportional pressure reducing valve

attached to the pump.

Only one proportional pressure reducing

valve is provided.

However, the secondary pressure Pf

(power shift pressure) is admitted to the

horsepower control section of each pump

regulator through the pump's internal path

to shift it to the same set horsepower level.

This function permits arbitrary setting of the pump output power, thereby providing the optimum

power level according to the operating condition.

The power shift pressure Pf controls the set horsepower of the pump to a desired level, as shown

in the figure.

As the power shift pressure Pf rises, the compensating rod(623) moves to the right via the

pin(898) and compensating piston(621).

This decreases the pump tilting angle and then the set horsepower in the same way as explained

in the overload preventive function of the horsepower control. On the contrary, the set

horsepower rises as the power shift pressure Pf falls.

(3)

Delivery pressure, (P1+P2)

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

P

f

=

M

A

X

.

P

f

=

M

I

N

.

621 651 652 623 612 625 626

B(E)

897

875

898

611

F

CL P1

P2

Pf

P1

D

Small diameter

chamber Servo piston

Large diameter

chamber

2-18

2-19

Adjust it by loosening the hexagon

nut(808) and by tightening(or loosening)

the set screw(954).

The maximum flow only is adjusted

without changing other control

characteristics.

Adjustment of minimum flow

Adjust it by loosening the hexagon

nut(808) and by tightening(or loosening)

the hexagonal socket head set screw

(953). Similarly to the adjustment of the

maximum flow, other characteristics are

not changed.

However, remember that, if tightened too

much, the required horsepower during

the maximum delivery pressure(or during

relieving) may increase.

Adjustment of maximum and minimum flows (4)

Delivery pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

808

954

806

953

Adjustment of max flow

Speed

(min

-1

)

1950

Tightening

amount of

adjusting screw

(954)

(Turn)

+1/4

Flow change

amount

(/min)

-5.6

Delivery pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

2-19(1)

2-19(2)

Adjustment of min flow

Speed

(min

-1

)

1950

Tightening

amount of

adjusting screw

(953)

(Turn)

+1/4

Flow change

amount

(/min)

+4.5

2-20

Qmax cut control

The regulator regulates the

maximum delivery flow by

inputting the pilot pressure

Pm. Since this is a 2-position

control method, the maximum

delivery flow may be

switched in two steps by

turning on/off the pilot

pressure Pm. (The maximum

control flow cannot be

controlled in intermediate

level.)

Functional explanation

As shown in the figure, the pilot pressure

Pm switches the maximum flow in two

steps.

When the pilot pressure Pm is given, it is

admitted to the lefthand side of the piston

QMC(648). The piston QMC moves the

stopper(647) and pilot piston(643) to the

right, overcoming the force of the pilot

spring(646), thereby reducing the

delivery flow of the pump.

Since the adjusting screw QMC(642) is

provided with a flange, the piston QMC

stops upon contact with the flange, and

the position of the pilot piston at this time

determines the maximum flow of the

pump.

Adjustment of Qmax cut flow

Adjust it by loosening the hexagon

nut(801) and by tightening(or loosening)

the adjusting screw QMC(642).

Tightening the screw decreases the

Qmax cut flow as shown in the figure.

_

_

Pilot pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

Pilot pressure, Pi

D

e

l

i

v

e

r

y

f

l

o

w

,

Q

647

648

723

642

801

438

801

924

641 730 643 708 644 645 646 728

Pm

(5)

2-4

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Group 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitDocument210 paginiGroup 4 Disassembly and Assembly: 1. Electro-Hydraulic Control UnitSergey MovchanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Section 7 Disassembly and AssemblyDocument4 paginiSection 7 Disassembly and AssemblySergey MovchanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Group 2 Major ComponentDocument11 paginiGroup 2 Major ComponentSergey MovchanÎncă nu există evaluări

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Group 2 Major ComponentDocument11 paginiGroup 2 Major ComponentSergey MovchanÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Group 2 Tightening TorqueDocument3 paginiGroup 2 Tightening TorqueSergey MovchanÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 paginiGroup 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Group 2 Major Component: 1. Main PumpDocument11 paginiGroup 2 Major Component: 1. Main PumpSergey MovchanÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Group 5 Travel Speed Control SystemDocument1 paginăGroup 5 Travel Speed Control SystemSergey MovchanÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- G Group 3 Tests and Adjustments: 1. Parking Brake PerformanceDocument2 paginiG Group 3 Tests and Adjustments: 1. Parking Brake PerformanceSergey MovchanÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Group 2 Operational Checks and TroubleshootingDocument11 paginiGroup 2 Operational Checks and TroubleshootingSergey MovchanÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Group 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorDocument14 paginiGroup 4 Main Control Valve Group 4 Main Control Valve: 1. Removal and Install of MotorSergey MovchanÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Group 3 Pump Device: 1. Removal and InstallDocument22 paginiGroup 3 Pump Device: 1. Removal and InstallSergey MovchanÎncă nu există evaluări

- Cat Forklift Nr3500 36v Schematic Operation Maintenance ManualDocument27 paginiCat Forklift Nr3500 36v Schematic Operation Maintenance Manualmichellemacias080283gfz100% (53)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Electro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Document22 paginiElectro-Hydraulic Actuators For Valves SKB32.. SKB82.. SKB62.. SKB60Anand MunkhbatÎncă nu există evaluări

- 2000 Nissan Frontier KA24DE LCDocument16 pagini2000 Nissan Frontier KA24DE LCDavid CervantesÎncă nu există evaluări

- NM Methane Advisory Panel Draft Technical ReportDocument301 paginiNM Methane Advisory Panel Draft Technical ReportNM Transparency InitiativeÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- PSS 1.1-300 - Operating Manual - Vol. 2 - 2019Document41 paginiPSS 1.1-300 - Operating Manual - Vol. 2 - 2019Centrifugal SeparatorÎncă nu există evaluări

- Chapter 11 Types of PumpsDocument45 paginiChapter 11 Types of Pumpssuraj7266Încă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Hydraulic EnergyDocument10 paginiHydraulic EnergySameer KhanÎncă nu există evaluări

- Hydro ConeDocument11 paginiHydro ConeJubert Angelo Ramos ParedesÎncă nu există evaluări

- Electric Heater Plastic: Item No. 141600 (-02) - 141605 (-02)Document2 paginiElectric Heater Plastic: Item No. 141600 (-02) - 141605 (-02)Ala AlasdiÎncă nu există evaluări

- Front Shovel enDocument15 paginiFront Shovel enAlejandro RodriguezÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Price List 50-2017 - EN Low Res ItaliaDocument84 paginiPrice List 50-2017 - EN Low Res ItaliaivoniciuÎncă nu există evaluări

- Hole Cleaning DynamicsDocument38 paginiHole Cleaning DynamicsSAKÎncă nu există evaluări

- General Online QuestDocument80 paginiGeneral Online QuestPankaj PooniaÎncă nu există evaluări

- National Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838Document51 paginiNational Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838sorangel_123100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- SPE 68747 Clean Up and Well Testing Operations in High-Rate Gas-Condensate Field Result in Improved Sand Management SystemDocument14 paginiSPE 68747 Clean Up and Well Testing Operations in High-Rate Gas-Condensate Field Result in Improved Sand Management SystemTheNourEldenÎncă nu există evaluări

- Vol IE Tender DrawingsDocument53 paginiVol IE Tender DrawingsAnnisa Nabilah Mohd HashimÎncă nu există evaluări

- For Liquefied Gases: Cryogenic Transfer PumpsDocument13 paginiFor Liquefied Gases: Cryogenic Transfer PumpsSud Haldar100% (1)

- Baviera Steam System 11Document17 paginiBaviera Steam System 11Mustafa Mert SAMLIÎncă nu există evaluări

- Industrial Visit Report NoboDocument17 paginiIndustrial Visit Report Noboaemon05Încă nu există evaluări

- Group 3 Disassembly and AssemblyDocument99 paginiGroup 3 Disassembly and AssemblyBaciu NicolaeÎncă nu există evaluări

- Batch Pasteurizer For MilkDocument8 paginiBatch Pasteurizer For MilkMustafa AmroÎncă nu există evaluări

- Nene II. V.H. Aust. Operational InstructionsDocument10 paginiNene II. V.H. Aust. Operational InstructionsLeft VentricleÎncă nu există evaluări

- 3 - Hydraulic System DesignDocument33 pagini3 - Hydraulic System DesignAbere GetachewÎncă nu există evaluări

- Mechanical Seal AramcoDocument18 paginiMechanical Seal AramcoMohamed AbdelsalamÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- TOO Catalog File 2022 - 30.10.22Document6 paginiTOO Catalog File 2022 - 30.10.22Hen BenjaminÎncă nu există evaluări

- Specification of CAT 330D CaterpillarDocument24 paginiSpecification of CAT 330D CaterpillarBassel AmmarÎncă nu există evaluări

- 2 EuxtnziktmzuvnaDocument7 pagini2 Euxtnziktmzuvnaسام سپه پورÎncă nu există evaluări

- Pump Element Type MPE and PE For Radial Piston Pumps Pump Element Type MPE and PE For Radial Piston PumpsDocument14 paginiPump Element Type MPE and PE For Radial Piston Pumps Pump Element Type MPE and PE For Radial Piston PumpsHasan DEPECİKÎncă nu există evaluări

- 21 - MANUAL ORIGINAL DE USUARIO - Operación y Servicio BásicoDocument74 pagini21 - MANUAL ORIGINAL DE USUARIO - Operación y Servicio BásicoNorbey Marin MorenoÎncă nu există evaluări

- MAXIMATOR High Pressure Pumps 09 2015Document40 paginiMAXIMATOR High Pressure Pumps 09 2015Anonymous 8rb48tZSÎncă nu există evaluări