Documente Academic

Documente Profesional

Documente Cultură

The Influence of Holding Device Anchor Parameters On The Holding Force Magnitude, of An Integrated Linear Electromagnetic Motor

Încărcat de

theijesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Influence of Holding Device Anchor Parameters On The Holding Force Magnitude, of An Integrated Linear Electromagnetic Motor

Încărcat de

theijesDrepturi de autor:

Formate disponibile

The International Journal Of Engineering And Science (IJES)

|| Volume || 3 ||Issue|| 4 || Pages || 01-06 || 2014 ||

ISSN (e): 2319 1813 ISSN (p): 2319 1805

www.theijes.com The IJES Page 1

The Influence of Holding Device Anchor Parameters On The

Holding Force Magnitude, Of An Integrated Linear

Electromagnetic Motor

Ginady G. Ugarov* Vladimir IV. Moshkin** Amer Kh. Massad***

*(Professor of Power supply of industrial enterprises department, Saratov State Technical University, Russia)

** (Associate Professor, Head of Energy and technological of materials department at Kurgan State University,

Russia)

*** (Assistant professor, Head of Electrical & Mechanical Engineering Department, An-Najah National

University, Palestine)

-------------------------------------------------------ABSTRACT---------------------------------------------------

This paper investigates the influence of the design parameters of the upper ferromagnetic shunt, namely the

value of the holding area

H

S ,that creates a holding force

H

F , equal to that in breakaway stage in magnitude of

this holding force at the breakaway stage. The design of an integrated circuit and the equivalent magnetic circuit

of the integrated LEMM on breakaway stage was built, mathematical models of system were laid out. The most

acceptable range of these ranges of magnitude of holding area is

4 . 0 ... 2 . 0 >

-

H

S

, and this happens

when

4 . 0 ... 2 . 0 = u

-

ush

.The resulting holding force will vary in range of

) 15 . 0 ... 05 . 0 (

to ) 55 . 0 ... 2 . 0 ( .

I NDEX TERMS: Holding force, holding area, holding device, break away stage, upper shunt, lower shunt,

anchor

---------------------------------------------------------------------------------------------------------------------------------------

Date of Submission: 10 March 2014 Date of Publication: 15 April 2014

---------------------------------------------------------------------------------------------------------------------------------------

I. INTRODUCTION

One way of increasing specific power and energy performance of pulsed electromagnetic linear motors

(LEMM) reciprocation that implement multiple pulse technology is forced accumulation of magnetic energy in

the working clearances pulse LEMM on the breakaway anchors (armature) stage due to the delay (retention) of

its movement. In this case, the appearance and increase of the current in the windings of the motor anchor stay

for a while in a stationary state, in spite of the increasing tractive force of working clearances due to static

loading motor, the anchor is held by electromagnetic device. Anchor starts to move with increased initial

tractive force. The holding force

H

F regulation achieved by motor design, is quite simple and has a wide range

of

H

F

available by changing current in the coil of the holding electromagnet device supplied from a separate

source [1, 2].

The desire to simplify the design of pulse LEMM while increasing its specific power and energy

performance, have led to the idea of integrated design of the motor, through better holding device of anchor

based on the same magnetic core and the same magnetic motive force mmf [3, 4, 5].

II. PROBLEM STATEMENT

In such motor design, anchor on breakaway stage is held by its own magnetic field ferromagnetic guide

housing 2 Fig.1, which is called an upper magnetic shunt relative to the upper running clearance

u

o . Lower

magnetic shunt is a ferromagnetic anchor guide 3. Thus, the LEMM in this design has two working clearances

shunted by motor parts design - the upper and lower magnetic shunts. During operation in this LEMM with

holding device (holding device integrated in design), both shunts saturate an eventually affect motor

performance . Experimental studies of such integrated LEMM showed that the regulation of holding force is

difficult because it depends on several design parameters of the motor.

This paper investigates the influence of the design parameters of the upper ferromagnetic shunt, namely

the value of the holding area

H

S , that creates a holding force, equal to that in breakaway stage in magnitude of

this holding force at the breakaway stage. In this LEMM design, holding force

H

F occurs between mating

The Influence of Holding Device Anchor Parameters On The

www.theijes.com The IJES Page 2

surfaces, which is formed by the upper part of the flat anchor 1 and the top of the inside of the ferromagnetic

shunt (2) when they are in contact or almost in contact the gap

0

o .

III. MATHEMATICAL MODELS OF SYSTEM

In such a motor design, when we connect the coil to the power supply for the first time and until the initial

magnetic field has not yet unfolded, both the magnetic shunts are also not saturated and have small magnetic

reluctance

ush

R

Lsh

R , hence

2 1 ush ush ush

R R R + = .

From the equivalent of the magnetic circuit LEMM and with neglecting the leakage flux Fig.2 which is

corresponding to the design scheme in Fig. 1, the magnetic flux

yo

u yoke 5 appears as two components:

L Lsh u ush yo o o

u + u = u + u = u

(1)

these two components pass in the anchor LEMM almost entirely through the upper shunt (

ush

R and

o up

R ),

bypassing the upper working clearances

u

o , which in this case have much bigger reluctance

u

R

o

compared to

the reluctance of the upper branch of the

ub

R shunt Fig.2 and the technological gap :

o up ush ub

R R R + =

(2)

H

up

up

S

R

0

o

o

= ;

upsh

S

R

0

A

=

A

(3)

Where

o up

R , the reluctance of the air gap

up

o , creates the holding force and forms mating surfaces of the upper

shunt and the top of the anchor 1 .

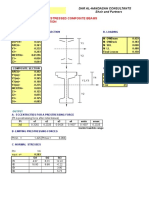

Figure 1 The Design of An Integrated Circuit LEMM.

o up

R at a given moment is much smaller than shunt

ush

R

;

due to minimal value of air gap

up

o , which is

selected in the initial state of a return spring 4 and smaller than the reluctance technological gap

A

R .

Therefore, the expressions (1) and (2) can be written as:

ush yo

u ~ u ;

ush ub

R R =

Then by the electromagnetic holding force which occurs between the upper shunt and the upper shunt of

part anchor, the anchor is attracted to the stationary shunt, and despite the increase of the current in the coil

anchor it is held in this position. The magnitude of holding force

H

F in this case depends on the magnitude of

the magnetic flux of the upper shunt

ush

u and its contact area with the flat part of the anchor - (Holding

The Influence of Holding Device Anchor Parameters On The

www.theijes.com The IJES Page 3

area)

H

S (in Fig.1 shows a heavy line). The magnitude

ush

u with a certain saturation induction

0

B material of

the guide housing (upper shunt) is determined by its cross-sectional area

ush

S . Accordingly, the value of

holding force under these conditions will be a function of two design parameters - area

H

S and area

ush

S .

Figure 2 The Equivalent Magnetic Circuit of The Integrated LEMM on Breakaway Stage

With increasing mmf winding wi on breakaway anchors stage, the magnetic flux of the upper shunt

ush

u

also increases. Thus, the holding force increases and saturates this ferromagnetic shunt, and

reluctance

ush

R begins to increase. As a result, shunt flux slowdown and a simultaneous redistribution of

ush

u and

u o

u occurs according to equation (1). That is, all the bulk of the flux in the yoke

yo

u in particular

the flux component

u o

u extends through upper working clearance (the dotted line in Fig.1) which is

represented by

u

R

o

element in the equivalent magnetic circuit (Fig.2), that creates additional tractive force

down, acting on a combined anchor 1 motor. Similar processes occur in the lower shunt with the difference that

it is saturated before the upper shunt, and the reluctance of the parasitic air gap

pag

R Fig.2 remains unchanged

when the motor is operated and accordingly the tractive force in the parasitic air gap is not created.

Anchor LEMM is pulled out from the holding area of upper shunt and begins to move when the sum of

traction forces of the upper

u

F

o

and lower

l

F

o

running clearances (excluding leakage flux) exceeds the holding

force of the upper shunt

H

F :

l u H

F F F

o o

+ < (4)

To assess the effect of parameters design of the upper shunt at breakaway moment of anchor, and to express

each of the components (4) we use Maxwell formula for one working air clearance . Then (4) takes the form:

l

l

u

u

H

ush

S S S

o

o

o

o

0

2

0

2

0

2

2 2 2

u

+

u

<

u

, (5)

where

u

S

o

,

l

S

o

are the areas of the upper and lower working clearances of LEMM respectively.

Substitute flux

ush yo u

u u = u

o

in equation (5). Assuming

a yo l u

S S S S = = =

o o

and fluxes

yo u

u = u

o

result in the following equation :

yo

yo

yo

ush yo

H

ush

S S S

2 2

2

) ( u

+

u u

<

u

(6)

Approximately fluxes

yo l

u = u

o

are equal when lower shunt is saturated. Overstating tractive force in the

lower working clearance is justified by the fact that, the leakage fluxes, which are neglected in the analysis,

participate in the creation of tractive force of the motor in the breakaway stage. Taking

ush

u , relative to

yo

u and

ush

S ,

H

S relative to the

yo

S the following equation results:

The Influence of Holding Device Anchor Parameters On The

www.theijes.com The IJES Page 4

yo

ush

ush

u

u

= u

-

,

yo

ush

ush

S

S

S =

-

,

yo

H

H

S

S

S =

-

Solving this equation with respect to

-

u

ush

we get:

(7)

An expression similar to equation (7) is obtained in [6].

From equation (7), it is clear that the dependence of holding force

H

F upper shunt on the value of the

holding area

H

S through various values of the saturated flux of the upper shunt

ush

u

.

To express the holding force

H

F in relative terms

bas

H

H

F

F

F =

-

it is appropriate to use a tractive force of

LEMM with two working clearances based on Maxwell formula.

The tractive force in Maxwells equation is equal twice the value of traction force of one of the working air

gaps, in the upper shunt or lower.

The upper shunt is used in following equation

yo

u

u bas

S

F F

0

2

2

o

o

u

= =

Then the holding force is expressed as:

2

2

2

0

0

2

) ( 2 2

ush yo H

yo ush

u H

yo ush

bas

H

H

S

S

S

S

F

F

F

u u

u

=

u

u

= =

-

o

After the rearranging above equation we get :

2

2

) 1 ( 2

- -

-

u

u

=

ush H

yo ush

H

S

S

F (8)

In formula (8), parameter

yo

ush

ush

u

u

= u

-

can be considered as saturation flux which occurs in the upper shunt .

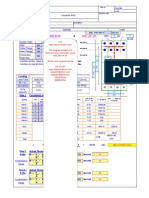

As shown in Fig.3 and with reference to equation (8) , ) (

- -

=

H H

S f F when const

ush

= u

-

, which clarify

the influence of the values of holding area of the upper shunt on holding force, when upper shunt is saturated.

The analysis shows that with increasing the magnitude of

-

H

S , the holding force

-

H

F decrease and thus

becomes more stable. This is due to the decrease of the magnetic induction in the air clearance. The magnetic

induction in the air clearance influence the force

H

F more than

H

S .

It is evident from each curve in Fig. 3 which correspond to a small change of magnitude of shunt saturation

flux , 2 . 0 ... 1 . 0 = u

-

ush

, that with small portion of shunt

-

ush

S , there are two different changeable sizes for

-

H

F , such that when you change

-

H

S there will be two areas one represents significant change and the other

represents negligible one in the curve

-

H

F .

From Fig.3 , it is indicated that the first portion of changes in

-

H

F cannot be used for the purpose of

regulating the energy stroke LEMM, but it is possible to use 2 . 0 > u

-

ush

for this purpose.

1

1

1

2

1

+

< u

-

-

-

H

H

ush

S

S

The Influence of Holding Device Anchor Parameters On The

www.theijes.com The IJES Page 5

Figure 3 The Influence of Magnitude of Holding Area

H

S and Magnetic Flux Shunt

ush

u on Holding Force

Anchor

H

F

During the process of regulating the energy of the LEMM working stroke the holding force should be less

than tractive force, therefore, the area of the graph in Fig.3, corresponds to 1 >

-

H

F , should not be used.

Since the magnetic flux lines

ush

u on breakaway anchor stage LEMM, include portions of a ferromagnetic

guide housing 1 and holding area 2 with cross-sections

ush

S and

H

S , then, taking the induction

values

H

B B =

0

of these sections we obtain the same flux

ush

u for the same values of cross-

sections

ush H

S S = .

As indicated by the next equation, the values expressed in relative terms will be equal:

- - -

= = u

ush H ush

S S (9)

Solving equation (8) for

-

H

F , to determine the maximum holding force under the condition implemented in

equation (9) the following equation results:

2 .

) 1 (

5 . 0

-

-

-

=

H

H

M H

S

S

F (10)

Equation (10) gives the range for design parameters values for holding device of the motor. The maximum

value for the holding force is shown as a dotted line in Fig.3 .

To the left of the dotted line in fig.3 combination of parameters

-

H

S

,

-

u

ush

and

-

H

S

cannot be calculated,

because of the saturation of the magnetic shunt and the holding area. This saturation leads to a decrease in

H

F

,

therefore it is advised to saturate the holding area after ferromagnetic guide housing, by the means of greater

inductions and magnetic flux respectively.

This can be achieved either by overstating section ) (

ush H H

S S S > , or by higher saturation magnetic flux

density of the material area at the same section

H

S . For these reasons, the combination of parameters is possible

to the right of the dotted line. Thus holding force can be regulated by using, for example, a removable washer as

proposed in [3, 4].

The most acceptable range of the magnitude of holding area is 4 . 0 ... 2 . 0 >

-

H

S , and this happens

when 4 . 0 ... 2 . 0 = u

-

ush

. The resulting holding force will vary in the range of ) 15 . 0 ... 05 . 0 ( to ) 55 . 0 ... 2 . 0 ( ,

above values for holding area will allow regulating the energy in working stroke of pulse LEMM at high

efficiency during the static loading of the motor [7]. The relations obtained are used in the design calculations of

pulse LEMM with an integrated holding device of anchor.

The Influence of Holding Device Anchor Parameters On The

www.theijes.com The IJES Page 6

IV. CONCLUSION

Implementation of the forced accumulation of magnetic energy in an integrated LEMM on breakaway

anchor stage can be achieved only by certain range of parameters of the holding device anchor and the shunt.

The ranges of the magnitude of holding area is

4 , 0 ... 2 . 0 >

-

H

S

, and this happens when

4 , 0 ... 2 . 0 = u

-

ush

The

resulting holding force will vary in the range of

) 15 . 0 ... 05 . 0 (

to ) 55 . 0 ... 2 . 0 ( . Increasing sectional area of the

upper shunt

-

ush

S and decreasing the magnitude of holding area

-

H

S according to above ranges of parameters

will increase the magnetic induction of the yoke, starting the anchor to move with increased initial value of the

tractive force LEMM.

REFERENCES

[1] N.P. Ryashentsev .G.G. Ugarov., A.B. Lvytsin "Electromagnetic press", Nauka Publishers, sibirsk branch, Novosibirsk, 1989.-

216p.

[2] Patent RU2018652, E21C 3/16. Electric hammer. / A.F Maer, V. I Moshkin, IP Popov (Russian Federation). 4712733/03; appl.

07.03.89, publ. 30.08.1994.

[3] Patent RU2084071, HO2K 33/02. The linear electromagnetic motor / G.G Ugov VY Neumann (Russian Federation). 95110459/07;

appl. 22.06.1995, publ. 10.07.1997.

[4] V.Y. Neiman."Integrated linear electromagnetic motors for pulse technology", Electrical Engineering, 2003. November 9. pp. 25-

30.

[5] V.I. Moshkin and G.G. Ugarov."Estimation of parameters of the device forced accumulation of magnetic energy of a linear

electromagnetic motor," Innovative technology in teaching and production. Proceedings of the VI All-Russian scientific-practical

conference Kamishyn, 15-16 December 2009 Volume 2. - Volgograd Volgograd State Technical University Publishing House,

2010. - pp 75-78.

[6] I.M. Husainov and A.Kh. Massad "The accelerated accumulation of magnetic energy in the pulse electromechanical transducer",

Problems of the electric power industry. Inter-college. scientific collection - Saratov: Saratov State Technical University in 2000.

pp.36-38.

[7] Moshkin V.I. Egorov A.A and Ugarov G.G. "The study of the forced modes of magnetic energy storage in pulse linear

electromagnetic motors", Vestnik of the Saratov State Technical University. - Saratov: SSTU 2006, 1 (10), no.1. - pp. 39-44.

S-ar putea să vă placă și

- The Effect of Design Parameters of An Integrated Linear Electromagnetic Motor, at The Process of Pulling Away Anchor, From Its Breakaway StageDocument8 paginiThe Effect of Design Parameters of An Integrated Linear Electromagnetic Motor, at The Process of Pulling Away Anchor, From Its Breakaway StageIJMERÎncă nu există evaluări

- Distance RelayDocument8 paginiDistance RelayRamzan QureshiÎncă nu există evaluări

- Principles of Electromechanical Energy Conversion: Unit-IDocument15 paginiPrinciples of Electromechanical Energy Conversion: Unit-IAbdi Abera BayesaÎncă nu există evaluări

- Magnetic Bearings: Joint Advanced Student School April 2006 - St. Petersburg, RussiaDocument15 paginiMagnetic Bearings: Joint Advanced Student School April 2006 - St. Petersburg, RussiaSanket ShahÎncă nu există evaluări

- Magn Rotor From VacuumDocument5 paginiMagn Rotor From VacuumMANNAJANELAGUNAÎncă nu există evaluări

- 2 Eee Em-1Document117 pagini2 Eee Em-1PramodÎncă nu există evaluări

- Electromechanical. Energy-Conversi On PrinciplesDocument3 paginiElectromechanical. Energy-Conversi On PrinciplesYunus SevimÎncă nu există evaluări

- Lightning Electromagnetic Fields and Their Induced Voltages On Overhead Lines: The Effect of A Non-Flat Lossy GroundDocument4 paginiLightning Electromagnetic Fields and Their Induced Voltages On Overhead Lines: The Effect of A Non-Flat Lossy GroundJavad PaknahadÎncă nu există evaluări

- Magnetic Circuits - ElectromagnetDocument8 paginiMagnetic Circuits - Electromagnetilg1Încă nu există evaluări

- 2010 Stray Losses in Power Transformer Tank Walls and Construction Parts Miljavec Kralj Univ Ljubljana ICEMDocument4 pagini2010 Stray Losses in Power Transformer Tank Walls and Construction Parts Miljavec Kralj Univ Ljubljana ICEMHaris RasoolÎncă nu există evaluări

- Articol 9Document6 paginiArticol 9Constantin DorinelÎncă nu există evaluări

- Armature Reaction and CommutationDocument4 paginiArmature Reaction and CommutationAnoop MathewÎncă nu există evaluări

- U3 ISADocument26 paginiU3 ISAjeyrajiÎncă nu există evaluări

- Vibration Control of Flexible Structures Using Semi-Active Mount: Experimental InvestigationDocument16 paginiVibration Control of Flexible Structures Using Semi-Active Mount: Experimental InvestigationElvis CarneiroÎncă nu există evaluări

- Transient Eddy 06Document1 paginăTransient Eddy 06Constantin DorinelÎncă nu există evaluări

- A Study On The Contact Force Between Catenary and PantographDocument6 paginiA Study On The Contact Force Between Catenary and PantographNoir Hamann100% (1)

- Vibration AnalysisDocument12 paginiVibration AnalysistheealokÎncă nu există evaluări

- Mechanical Forces and Magnetic Field Simulation of Transformer With Finite Element MethodDocument4 paginiMechanical Forces and Magnetic Field Simulation of Transformer With Finite Element MethodSarojakanti SahooÎncă nu există evaluări

- Analysis of Flow Induced Stress Field in A Francis Turbine Runner BladeDocument8 paginiAnalysis of Flow Induced Stress Field in A Francis Turbine Runner BladeMuhammad AfifuddinÎncă nu există evaluări

- Mems ActuatorDocument10 paginiMems ActuatorRohith RajÎncă nu există evaluări

- Experiment 1Document11 paginiExperiment 1Aneef Azlan50% (2)

- DC GeneratorDocument102 paginiDC GeneratorsandeepnitrÎncă nu există evaluări

- Solenoid Actuators: Theory and Computational MethodsDe la EverandSolenoid Actuators: Theory and Computational MethodsEvaluare: 3 din 5 stele3/5 (1)

- Modelling A Linear and Limited Travel SolenoidDocument6 paginiModelling A Linear and Limited Travel SolenoidsayproÎncă nu există evaluări

- 07 TT 02 ElectromagneticDocument4 pagini07 TT 02 ElectromagneticAzad RahmanÎncă nu există evaluări

- Maglev pdf3Document5 paginiMaglev pdf3abdulsameteskiyayla632Încă nu există evaluări

- 2 - BP Machine 3Document113 pagini2 - BP Machine 3DGAFÎncă nu există evaluări

- Journal of Advanced Mechanical Design, Systems, and ManufacturingDocument8 paginiJournal of Advanced Mechanical Design, Systems, and Manufacturingpravinrock92Încă nu există evaluări

- Generic Torque-Maximizing Design Methodology of Surface Permanent - Magnet Vernier MachineDocument8 paginiGeneric Torque-Maximizing Design Methodology of Surface Permanent - Magnet Vernier MachineJohn McLovenÎncă nu există evaluări

- Railgun PhysicsDocument24 paginiRailgun PhysicsNicholas Jackson100% (1)

- Forces On Rail PDFDocument12 paginiForces On Rail PDFRbKahnÎncă nu există evaluări

- Magnetic Bearings in Kinetic Energy Storage Systems For VehicularDocument12 paginiMagnetic Bearings in Kinetic Energy Storage Systems For Vehicularmahmoud mohamedÎncă nu există evaluări

- AMB-chances and LimitDocument14 paginiAMB-chances and LimitZi QiangÎncă nu există evaluări

- Free Energy Generator Construction Guidelines For A Zero Point Energy ConverterDocument67 paginiFree Energy Generator Construction Guidelines For A Zero Point Energy ConverterDan BeesonÎncă nu există evaluări

- Elements of Electrical Design: Prepared by Hemin D. MotiwalaDocument59 paginiElements of Electrical Design: Prepared by Hemin D. MotiwalaTanvir KaziÎncă nu există evaluări

- TRANSFLUXORS and Their Application in Automation and Remote Control 1964Document59 paginiTRANSFLUXORS and Their Application in Automation and Remote Control 1964JonÎncă nu există evaluări

- 418 DallasDocument6 pagini418 DallasbaradaranhamidÎncă nu există evaluări

- Prof. Ch. SAI BABU: Online Gate Coaching ClassesDocument103 paginiProf. Ch. SAI BABU: Online Gate Coaching ClassesHarish B. M.100% (1)

- EE352 Chapter #3 Electromechanical Energy ConversionDocument12 paginiEE352 Chapter #3 Electromechanical Energy ConversionCan ARABACIÎncă nu există evaluări

- Effects Rotor Eccentricity and Parallel Windings On Induction Machine Behavior: Study Using Finite Element AnalysisDocument7 paginiEffects Rotor Eccentricity and Parallel Windings On Induction Machine Behavior: Study Using Finite Element AnalysisRawaz AzizÎncă nu există evaluări

- Calculation Radial Forced Slot Wedge-Paper - 40Document6 paginiCalculation Radial Forced Slot Wedge-Paper - 40SISWANTOÎncă nu există evaluări

- General Physics 2Document7 paginiGeneral Physics 2Nanzkie Andrei SamanÎncă nu există evaluări

- Engineering Method For Calculation of Short-CircuitDocument7 paginiEngineering Method For Calculation of Short-CircuitnicklionsÎncă nu există evaluări

- Stark Effects On Rigid Rotor Wavefunctions:: Reprint: Journal of Chemical Education (1995) 77, 1021-1024Document12 paginiStark Effects On Rigid Rotor Wavefunctions:: Reprint: Journal of Chemical Education (1995) 77, 1021-1024KiomaxÎncă nu există evaluări

- Principles of Electromechanical Energy ConversionDocument21 paginiPrinciples of Electromechanical Energy ConversionJehovah CoelhoÎncă nu există evaluări

- Analysis of Unbalanced Magnetic Pull in A Multi-Physic Model of Induction Machine With An Eccentric RotorDocument9 paginiAnalysis of Unbalanced Magnetic Pull in A Multi-Physic Model of Induction Machine With An Eccentric Rotor9096664279Încă nu există evaluări

- Chap 1 Mach (Eng)Document8 paginiChap 1 Mach (Eng)liliÎncă nu există evaluări

- Unit 5 LicDocument13 paginiUnit 5 LicRiskKumrÎncă nu există evaluări

- Regular Paper Impact of Mechanical Forces in A 25ka Current Injection TransformerDocument14 paginiRegular Paper Impact of Mechanical Forces in A 25ka Current Injection TransformerConstantin DorinelÎncă nu există evaluări

- Magnetic CircuitsDocument61 paginiMagnetic CircuitsFaqrie AziziÎncă nu există evaluări

- Anil KumarDocument15 paginiAnil KumarRanjith BhoopalÎncă nu există evaluări

- Short Circuit Current Forces PDFDocument4 paginiShort Circuit Current Forces PDFDaniel MemijeÎncă nu există evaluări

- Investigations On A Standing Wave Thermoacoustic RefrigeratorDocument8 paginiInvestigations On A Standing Wave Thermoacoustic RefrigeratorAli AHÎncă nu există evaluări

- An Engineering Approach in Modeling Lightning Effects On Megawatt-Class Onshore Wind Turbines Using EMTP and ModelsDocument5 paginiAn Engineering Approach in Modeling Lightning Effects On Megawatt-Class Onshore Wind Turbines Using EMTP and ModelsYume YumeÎncă nu există evaluări

- PDFDocument105 paginiPDFAnney RevathiÎncă nu există evaluări

- Magnetics, Electromagnetic Forces, Generated Voltage, and Energy I ConversionDocument33 paginiMagnetics, Electromagnetic Forces, Generated Voltage, and Energy I ConversionSihamaSihamÎncă nu există evaluări

- Engineering Method For Calculation of Short-CircuitDocument8 paginiEngineering Method For Calculation of Short-CircuitHakkim Sheik Thauth J100% (1)

- 3 Synchronous Generator Operation: 3.1 Cylindrical Rotor MachineDocument12 pagini3 Synchronous Generator Operation: 3.1 Cylindrical Rotor MachineDebarpan NahaÎncă nu există evaluări

- Study of a reluctance magnetic gearbox for energy storage system applicationDe la EverandStudy of a reluctance magnetic gearbox for energy storage system applicationEvaluare: 1 din 5 stele1/5 (1)

- Defluoridation of Ground Water Using Corn Cobs PowderDocument4 paginiDefluoridation of Ground Water Using Corn Cobs PowdertheijesÎncă nu există evaluări

- Development of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencyDocument9 paginiDevelopment of The Water Potential in River Estuary (Loloan) Based On Society For The Water Conservation in Saba Coastal Village, Gianyar RegencytheijesÎncă nu există evaluări

- Mixed Model Analysis For OverdispersionDocument9 paginiMixed Model Analysis For OverdispersiontheijesÎncă nu există evaluări

- Design and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatorDocument5 paginiDesign and Simulation of A Compact All-Optical Differentiator Based On Silicon Microring ResonatortheijesÎncă nu există evaluări

- Influence of Air-Fuel Mixtures and Gasoline - Cadoba Farinosa Forskk Bioethanol Fuel Mixtures On Emissions of A Spark - Ignition Engine.Document9 paginiInfluence of Air-Fuel Mixtures and Gasoline - Cadoba Farinosa Forskk Bioethanol Fuel Mixtures On Emissions of A Spark - Ignition Engine.theijesÎncă nu există evaluări

- Introduction To Engineering AnalysisDocument8 paginiIntroduction To Engineering AnalysisSuprioÎncă nu există evaluări

- 3340 Lectures 7 To 12 S1 2015Document61 pagini3340 Lectures 7 To 12 S1 2015utsav_koshtiÎncă nu există evaluări

- CV Hamad SaeedDocument3 paginiCV Hamad SaeedHamad SaeedÎncă nu există evaluări

- CE805.2 Introduction To Transportation SystemsDocument57 paginiCE805.2 Introduction To Transportation SystemsAhsan HameedÎncă nu există evaluări

- Nexans 500 KV CableDocument22 paginiNexans 500 KV CableFiras Atwan100% (1)

- Electric Lift Installations Steel Frame Buildings: PublicationDocument72 paginiElectric Lift Installations Steel Frame Buildings: PublicationTiago CastelaniÎncă nu există evaluări

- BVAA Valve User Issue 20Document92 paginiBVAA Valve User Issue 20Daniel MikicÎncă nu există evaluări

- Structural Analysis and Design of Residential BuildingDocument16 paginiStructural Analysis and Design of Residential BuildingAnuj TripathiÎncă nu există evaluări

- Substation On Different LevelsDocument5 paginiSubstation On Different Levelsnarinder kumarÎncă nu există evaluări

- Truss SteelDocument10 paginiTruss SteelIntrinsic CmcÎncă nu există evaluări

- Brief-Bio MJeongDocument1 paginăBrief-Bio MJeongMd. Abu TaherÎncă nu există evaluări

- PSU List With GATE ScoreDocument7 paginiPSU List With GATE ScoreDandally RoopaÎncă nu există evaluări

- 2022-10-11T005751.688Document1 pagină2022-10-11T005751.688Mohamed FahadÎncă nu există evaluări

- Lab Sheet 2 (14DKM19F1007)Document10 paginiLab Sheet 2 (14DKM19F1007)Amirul RoslanÎncă nu există evaluări

- Variations and Change Orders On Construction Projects: ForumDocument8 paginiVariations and Change Orders On Construction Projects: ForumAizel JoannaÎncă nu există evaluări

- SAEP 1610 (Oct 2017)Document9 paginiSAEP 1610 (Oct 2017)nadeem shaikhÎncă nu există evaluări

- TVET-HEI Bursary Application Details 2023-24Document5 paginiTVET-HEI Bursary Application Details 2023-24NcediswaÎncă nu există evaluări

- Outline CourseDocument2 paginiOutline CourseFaiz MechyÎncă nu există evaluări

- ASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasDocument19 paginiASME Sec VIII The Most Common Code Used For Designing Pressure Vessels in Oil & GasShieeplÎncă nu există evaluări

- Guideline On RSA ManagementDocument103 paginiGuideline On RSA ManagementAmirul BassÎncă nu există evaluări

- Engineering Council of South Africa: Background: The ECSA Education System DocumentsDocument14 paginiEngineering Council of South Africa: Background: The ECSA Education System Documentsprisca ncuncuÎncă nu există evaluări

- Prestressed Precast1Document5 paginiPrestressed Precast1mahmoud IbrahemÎncă nu există evaluări

- 11 Steel Connection Design As Per AISC 23052014Document2 pagini11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri67% (3)

- Urriculum Itae: Name: Rameez SalimDocument6 paginiUrriculum Itae: Name: Rameez Salimmilind_0786Încă nu există evaluări

- Design and Analysis of Composite Spur GeDocument12 paginiDesign and Analysis of Composite Spur GeMani MaranÎncă nu există evaluări

- Reddy CV 2013Document145 paginiReddy CV 2013anpyaaÎncă nu există evaluări

- Vessel Design CalculationDocument22 paginiVessel Design CalculationAh Leng LauÎncă nu există evaluări

- Temporary Work What ChangedDocument133 paginiTemporary Work What ChangedBridger WangÎncă nu există evaluări

- 06 Btech ChemicalDocument220 pagini06 Btech ChemicalVaidik SomjiyaniÎncă nu există evaluări

- Equideck Information GuideDocument4 paginiEquideck Information GuideSvan Dxi ArulÎncă nu există evaluări