Documente Academic

Documente Profesional

Documente Cultură

Plant and Equipment Risk Assessment Checklist1

Încărcat de

peachykrista100%(1)100% au considerat acest document util (1 vot)

480 vizualizări9 paginiPlant and Equipment Risk Assessment Checklist

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPlant and Equipment Risk Assessment Checklist

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

480 vizualizări9 paginiPlant and Equipment Risk Assessment Checklist1

Încărcat de

peachykristaPlant and Equipment Risk Assessment Checklist

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 9

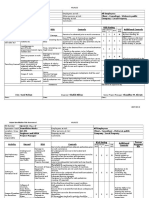

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 1 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

This form is to be completed in conjunction with the Plant Hazard Identification Form and in accordance with the

Hazard Management Policy/Procedure and Plant and Equipment Safety Management Policy/Procedure.

Overall risk rating

(existing controls)

highest score

eg L, M, VH, H

LOW

STEP 1 : ENTER INFORMATION ABOUT THE ITEM OF PLANT/EQUIPMENT, ITS LOCATION AND THE PEOPLE COMPLETING THE RISK ASSESSMENT

Campus

Waite

School/Branch

Agriculture, Food &

Wine

Building

Alverstoke Orchard - 9e

Room

1

Date assessed: 22/03/2010

Plant (Include

name and

model)

i

GMF 200mm Bench Grinder/Buff

Review date: 30/06/2015

Purpose of

Plant

Sharpening of high-speed steel cutting tools, deburring and removal of surface imperfections, polishing metal and plastic

REGISTRATION/LICENCES/

COMPETENCIES

(Refer Appendix B)

Registration required?

Yes

No

Licence/ Trade certificate required?

Yes

No

Supervisor assessment required?

(Induction required for this plant)

Yes

No

Other competency required?

Yes

No

Include in Safe Operating Procedure

LEGISLATION

OHS Legislation and/or Australian

Standard to be used for further

reference.

OHS Regulations (1995) Divisions:

1.2 OHS Responsibilities

1.3 Information, Instruction,

Training, Induction, Supervision

2.10 Noise

Part 3 Plant (including)

3.2.25 Plant with moving parts

3.2.15 Hazard Management

3.2.17 Control of risk

AS 4024 - 2006 Safety of machinery

AS 1788 Abrasive wheels

AS 60204.1 electrical equipment for

industrial machines

RISK ASSESSMENT TEAM

HSO: Terry MacKenzie

HSR: Nicola Featherstone

Operator: Benjamin Pike

Residual risk rating of HIGH to VERY HIGH must be

endorsed by the Head of School.

Date: / /

____________________ _________________

(Signature) (Name)

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 2 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

LEGEND

El = Elimination

Su = Substitution

En = Engineering

Is = Isolation

Ad = Administration

PPE = Personal Protective Equipment

CAR = Corrective Action Register

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can the following items become entangled (eg in moving parts)?

Yes (e.g. Hair, Jewellery,

Clothing, Cleaning aids

(cloth), Gloves or

Other___________________

No

NA

Rare Minor Low Draw in points (wheel spindle, and

between grinding wheel rest) may

entangle loose clothing, hair, jewellery

etc if latter not secured and they make

contact with the wheel.

Entanglement of extraneous cleaning

cloths or rags, if not previously removed

from the immediate lathe work area.

El

Su

En

Is

Ad

PPE

Fixed wheel guards in place.

Tool rest set at correct angle and

distance, relative to grinding

wheel.

Adjustable guards set to

minimise access to grinding

wheel.

Clear and ready access to

Emergency Stop button.

SOP includes essential safe

dress code (no loose clothing,

jewellery etc).

SOP requires long hair to be

constrained close to the head.

Only qualified and trained staff

allowed to operate this plant.

No No

Are Emergency Stop buttons adequate?

Yes (within easy reach and

clearly marked)

No

Other

issues______________

NA

N/A N/A N/A Emergency Stop Button and Emergency

Brake Pedal readily accessible, within

easy reach, to an operator standing in

the area reasonably deemed to be the

normal operating position.

NOTE: Normal Operating Position is

that position where an operator stands

that is within easy reach of all essential

machine controls.

El

Su

En

Is

Ad

PPE

Emergency Stop Button in place

and accessible to operator.

SOP requires Emergency Stop

Button to be tested periodically

and prior to each operation.

No No

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 3 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can anyone be crushed by:

Plant falling or unexpected

movement of the plant eg

Tipping

Falling

Rolling over

Rolling forward

The plants load

Under/between plant and a

structure eg wall

Inability to apply brake

Falling off the plant

Part of the plant

collapsing/changing shape

Other issues _____________

No

NA

N/A N/A N/A Plant DOES NOT move. El

Su

En

Is

Ad

PPE

Plant is firmly fixed in position on

a flat horizontal surface, with at

least a safe minimum (600mm +

length of work piece) all-round

clearance (see SOP for details).

N/A N/A

Can anyone be cut, stabbed or punctured, amputated by coming into contact with :

Moving plant or parts

Sharp or flying objects

Work pieces ejected

Work pieces disintegrating

Other

issues______________

No

NA

Rare Minor Low Flying (grinding dust) particles produced

through the nature of the grinding

process.

Standing in the incorrect position when

grinding.

Inadvertent contact with grinding wheel.

Work piece poorly and/or incorrectly

held in the hand, or locking pliers (self-

grip wrench).

El

Su

En

Is

Ad

PPE

Fixed wheel guards in place.

Tool rest set at correct angle and

distance, relative to grinding

wheel. Adjustable guards set to

minimise access to wheel.

SOP includes essential safe

dress code (no loose clothing or

jewellery, use of safety glasses,

face shield etc).

SOP requires long hair kept tied

up and close to the head.

USAGE Always ensure hands

are kept clear of and out of line

of grinding wheel.

Only qualified and trained staff

are allowed to operate plant

No No

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 4 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can anyone be injured from an electrical shock?

Water near equipment

Plant located near or in

contact with exposed live

electrical conductors

Leads/switch in poor

condition

Overhead and underground

wires

Other

issues______________

No

NA

N/A N/A N/A Risk of electrical shock eliminated

through the installation of an ELCB/RCD

safety device in the electrical power

distribution board

NOTE: Faulty electrical devices to be

tagged out and repaired or replaced

immediately by a qualified electrician.

El

Su

En

Is

Ad

PPE

SOP requires operator to be

aware of state of plant (i.e.

exposed wiring, switches and

surrounding area) for potential

electrical risks.

Visual inspection of plant and

allied electrical devices required

prior to machines operation.

Inline RCD device installed to

isolate current leakage. ELCB/

RCD Circuit Breaker device

installed in Electrical Power

Distribution Board. Maintained

and tested by Property Services.

N/A N/A

Can anyone be injured by an explosion?

Gas

Vapour

Dust

Liquid

Other issues _____________

No

NA

N/A N/A N/A No explosive elements or compounds

present, as part of the plant or material

being machined.

El

Su

En

Is

Ad

PPE

N/A SOP requires operator

being aware of state of plant and

surrounding area.

Visual inspection of plant and its

surrounding area mandatory

prior to operation.

N/A N/A

Can anyone be burnt due to Friction?

Contact with moving parts or

surface of the plant

Material handled by the plant

Other issues _____________

No

NA

Unlikely Minor Low Contact with rotating grinding wheel.

Overheating of work piece being ground.

NOTE: Ensure that there is an adequate

supply of cooling fluid readily at hand.

El

Su

En

Is

Ad

PPE

Fixed wheel guards in place.

Tool rest set at correct angle and

distance, relative to grinding

wheel.

Adjustable guards set to

minimise access to grinding

wheel.

At all times, keep hands clear of

rotating wheel, use locking pliers

to grip small objects.

No No

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 5 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can anyone be struck by moving objects due to:

Plant/materials being ejected

Plant/material movement

Other issues _____________

No

NA

Unlikely

Minor

Low

Flying particles ejected by the plant

during the grinding process.

Standing in the incorrect position when

grinding.

El

Su

En

Is

Ad

PPE

Tool rest set correctly.

Adjustable guards set to

minimise access to grinding

wheel

SOP (including requirement to

use self locking pliers for holding

small work pieces.)

Dress code (close fitting dustcoat

or overalls. Loose clothing or

jewellery to be secured)

PPE (Face shield/safety glasses,

steel-toed safety shoes/boots,

dust coat or overalls)

Qualified and trained staff are

only allowed to operate plant

No No

Can anyone suffocate due to:

Lack of oxygen

Atmospheric contamination

Engulfment

Other issues _____________

No

NA

N/A N/A N/A No oxygen depleting risk present.

No chemicals or other contaminants

present or required for the proper

operation of this plant.

El

Su

En

Is

Ad

PPE

N/A SOP requires operator to

be aware of state of plant and its

surrounding area.

Visual inspection of plant and its

surrounding are mandatory prior

to its operation.

N/A N/A

Can anyone be burnt due to:

High/low temperature

Naked flame

Steam

Laser beams

Other issues _____________

No

NA

N/A N/A N/A The use of Fire, Steam and/or Lasers is

NOT part of the cutting or machining

process for this machine.

El

Su

En

Is

Ad

PPE

N/A SOP requires operator to

be aware of state of plant and its

surrounding area.

Visual inspection of plant and its

surrounding are mandatory prior

to its operation.

N/A N/A

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 6 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can anyone be affected by temperature extremes?

Exposure to high temperature

Exposure to low temperature

Other issues _____________

No

NA

N/A N/A N/A The use of extreme temperature devices

is NOT part of the grinding process for

this machine.

El

Su

En

Is

Ad

PPE

N/A SOP requires operator to

be aware of state of plant and its

surrounding area.

Visual inspection of plant and its

surrounding are mandatory prior

to its operation.

N/A N/A

Can anyone slip, trip or fall due to:

The location of the plant

Uneven work surfaces

Lack of safe guards

(eg rails)

Slippery work surfaces

Other issues _____________

No

NA

Rare Minor Low No Issues present under normal working

circumstances.

El

Su

En

Is

Ad

PPE

SOP mandates a clean and tidy

work environment.

SOP requires an operator to

maintain a clean and clear work

environment.

SOP mandates a safe minimum

(600mm) all-round clearance

(see SOP for details).

SOP mandates the use of

diatomaceous earth to soak up

oil spills.

N/A N/A

Can anyone come into contact with Fluids or Gases under high pressure due to:

Failure of the plant

Nature of the plant

Other issues _____________

No

NA

N/A N/A N/A The use of High Pressure fluids of gases

is NOT part of the grinding operation for

this machine.

El

Su

En

Is

Ad

PPE

N/A SOP requires operator to

be aware of state of plant and its

surrounding area.

Visual inspection of plant and its

surrounding are mandatory prior

to its operation.

N/A N/A

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 7 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Can anyone injured due to Ergonomic issues due to:

Repetitive body movement or

posture

Insufficient space

Excessive effort (push/pull)

Working at a height

Seating design

Poor lighting

Other issues _____________

No

NA

Unlikely Minor Low Prolonged period of grinding

Adopting poor posture and/or standing

in the incorrect position when grinding.

El

Su

En

Is

Ad

PPE

SOP requires operator to be

trained in Manual Handling

technique. Supervisor to monitor

duration and frequency of the

task.

Equipment mounted at correct

operating height.

Operator is free to use muscle

stretching-relaxing exercises to

relieve stiffness caused by long

periods of standing.

No No

Can anyone be injured or suffer ill health from exposure to other hazards?

Chemicals

Radiation

Fumes

Dusts

Vibration

Noise

Toxic gases or vapours

Other issues _____________

No

NA

Rare

Rare

Negligible

Negligible

Low

Low

During grinding operation performed on

some types of material.

During grinding operation performed on

certain resonant types of material.

El

Su

En

Is

Ad

PPE

SOP and training/induction

requires operators to assess the

type material being ground and

assess any possible risk.

SOP mandates appropriate PPE

safety wear (i.e. dust mask, face

shield, hearing protection, where

required)

No No

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 8 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

Hazard Identified Likelihood Consequence Score Comments (ie when and where

hazard is present, task/activity)

Hierarchy of

Control

Current Controls Action

Required?

Y / N

Tfr to

CAR

Y / N

Does the plant generate significant environmental hazards

Energy consumption

Water consumption

Hazardous waste

Hazardous emissions

Nuisance noise

Produce ignition to the

surrounding area

Other issues _____________

No

NA

N/A N/A N/A N/A El

Su

En

Is

Ad

PPE

N/A SOP requires operator to

be aware of state of plant and its

surrounding area.

Visual inspection of plant and its

surrounding are mandatory prior

to its operation.

SOP and training and induction

require operators to assess the

type of material being ground

and assess any possible risks.

N/A N/A

STEP 3 : ACTION REQUIRED BY MANAGER/SUPERVISOR/AUTHORISED PERSON (Note : Sign off required by Head of School/Branch on Page 1)

All action items have been transferred to the Corrective Actions Register (CAR)

If no actions required and residual risk is medium to very high, the activity and the hazard(s) have been transferred to the Hazard Register and communicated to

the relevant personnel.

PLANT & EQUIPMENT RISK ASSESSMENT CHECKLIST

S:\Science\AgFood&Wine\OHS Supervisors\Ben Pike\Risk Assessments\GMF Bench Grinder.doc Version 1.0 Page 9 of 9

Produced By TJ MacKenzie 19 March 2010 Date of Last Review 25 March 2010 Date of Next Review - 30 July 2012

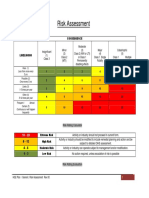

RISK ASSESSMENT TABLES

Likelihood Table

CATEGORY DESCRIPTION

Almost Certain Incident will occur at some time (0 1 month)

Likely Incident could occur at some time (1 month 1 year)

Slight Incident is possible to occur (1 year 2 years)

Unlikely Incident is possible, but unlikely to occur (2 years 5 years)

Rare Cannot imagine that this could occur (over 5 years)

Consequences Table

CATEGORY DESCRIPTION

Negligible Effects unlikely to last until the next day.

Minor Likely to affect employee the next day.

Moderate Medical Treatment injury needs formal medical treatment

Major Injury requiring extensive medical treatment and/or hospitalization

Severe Injury resulting in death or permanent incapacity

Risk Score Calculator

Likelihood

Consequences

Negligible

Minor

Moderate

Major Severe

Almost certain

Medium

High

Very High

Very High

Very High

Likely

Medium

Medium

High

Very High

Very High

Slight

Low

Medium

High

High

Very High

Unlikely

Low

Low

Medium

Medium

High

Rare

Low

Low

Low

Medium

Medium

Risk Priority Table

Descriptor

Priority Action

Very High 1 Immediate action required.

The activity should cease immediately and short term safety controls implemented.

Notify Manager and assess activity.

High 2 Implement short term safety controls immediately.

Notify Manager and assess activity

Medium 3 Short term safety controls implemented to minimise risk of injury.

Notify Manager and assess activity.

Corrective Actions within one month.

Low 4 Notify Manager and assess activity.

Corrective Actions within three months (if possible).

S-ar putea să vă placă și

- Crane Hoist Sling Safety ProgramDocument14 paginiCrane Hoist Sling Safety Programomar sadiqÎncă nu există evaluări

- Task Risk Assessment For (Compressed Air Line Tie-In)Document11 paginiTask Risk Assessment For (Compressed Air Line Tie-In)Venkadesh Periathambi100% (2)

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDocument29 paginiDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- Forklift RADocument5 paginiForklift RAFachri HidayatÎncă nu există evaluări

- Very Very Good Risk Assessment EnvironmentDocument8 paginiVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- Safe Work Method Statement: Fixed ScaffoldDocument11 paginiSafe Work Method Statement: Fixed ScaffoldJoe Waller100% (1)

- Hazard Identification & Risk Assessment GuidelineDocument81 paginiHazard Identification & Risk Assessment Guidelinebahaa mostafa100% (5)

- Under Review: First Aid in The Workplace ProcedureDocument10 paginiUnder Review: First Aid in The Workplace ProcedureLenvinÎncă nu există evaluări

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 paginiDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaÎncă nu există evaluări

- Full Risk Assessment Package PDFDocument75 paginiFull Risk Assessment Package PDFDaDemon100% (1)

- Risk AssessmentDocument25 paginiRisk AssessmentshabanÎncă nu există evaluări

- PTW PDFDocument74 paginiPTW PDFArdh0072Încă nu există evaluări

- 5 LJ Construction Health and Safety Policy 2015Document16 pagini5 LJ Construction Health and Safety Policy 2015Aditya Kumar SharmaÎncă nu există evaluări

- Tool Box SubjectsDocument70 paginiTool Box Subjectsrajeshsabitha80100% (5)

- Rescue Plan For Working at HeightDocument10 paginiRescue Plan For Working at HeightWAQAS AHMED100% (1)

- Risk Assessment HP WashingDocument5 paginiRisk Assessment HP WashingAhmad BarriehÎncă nu există evaluări

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 paginiInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiÎncă nu există evaluări

- Hazard Identification and Risk AssessmentDocument4 paginiHazard Identification and Risk AssessmentEldhose Varghese100% (1)

- First Aid Cases RecordDocument1 paginăFirst Aid Cases RecordFrancis Enriquez TanÎncă nu există evaluări

- Safe Work Method Statement WorksheetDocument3 paginiSafe Work Method Statement WorksheetSiti Salwani binti Ab RahimÎncă nu există evaluări

- JHADocument8 paginiJHARayyan ramosÎncă nu există evaluări

- Hot Work PermitDocument2 paginiHot Work PermitAndiWSutomoÎncă nu există evaluări

- Safety Manual UpdatedDocument106 paginiSafety Manual UpdatedSaddam HussianÎncă nu există evaluări

- Health Safety and Environment Manual FSDocument101 paginiHealth Safety and Environment Manual FSZulhilmi Zalizan100% (1)

- Bearing Pad InstallationDocument49 paginiBearing Pad InstallationfarooqÎncă nu există evaluări

- Plant Risk Assessment FormDocument7 paginiPlant Risk Assessment FormaKureishiÎncă nu există evaluări

- Heat Stress: by Manikandan.V HSE AdvisorDocument22 paginiHeat Stress: by Manikandan.V HSE AdvisorManikandan Vijayanarayanan100% (1)

- Toolbox Talks Lifting Safety EnglishDocument1 paginăToolbox Talks Lifting Safety EnglishkimlynroseÎncă nu există evaluări

- BargeDocument4 paginiBargeanon_222140886Încă nu există evaluări

- 8-22 Roller Shutter Door OHS TemplateDocument11 pagini8-22 Roller Shutter Door OHS Templatemsc920138Încă nu există evaluări

- Risk Assessment ProcedureDocument8 paginiRisk Assessment ProceduretemterÎncă nu există evaluări

- Risk Assessment For Material HandlingDocument15 paginiRisk Assessment For Material Handlingvural100% (5)

- Safety Presentation1Document28 paginiSafety Presentation1M Uzair ShaikhÎncă nu există evaluări

- 019 - Permit To WorkDocument23 pagini019 - Permit To WorkBob ForeverÎncă nu există evaluări

- HSE PLAN Generic RA PDFDocument5 paginiHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Pre Construction Risk AssessmentDocument4 paginiPre Construction Risk AssessmentHanny DarmoocooÎncă nu există evaluări

- HSE PolicyDocument11 paginiHSE Policysmhm_20028583100% (2)

- Safety Contractor ManagementDocument7 paginiSafety Contractor ManagementYen NguyenÎncă nu există evaluări

- SOP Excavation and PermittingDocument4 paginiSOP Excavation and PermittingTengku & Wan ResourcesÎncă nu există evaluări

- SWP-10 LockoutTagout (LOTO)Document6 paginiSWP-10 LockoutTagout (LOTO)ShafiqÎncă nu există evaluări

- Sop Angle GrinderDocument3 paginiSop Angle GrinderKyaw Kyaw Aung50% (2)

- Basic Hse TrainingDocument33 paginiBasic Hse Trainingnsankar71100% (3)

- Portable Grinder SafetyDocument20 paginiPortable Grinder SafetysabaÎncă nu există evaluări

- Zs Permit To Work System ManualDocument29 paginiZs Permit To Work System ManualHilari Eckd100% (1)

- Work at Height TrainingDocument6 paginiWork at Height TrainingRaza Muhammad SoomroÎncă nu există evaluări

- SWP Hot Work GuidelinesDocument25 paginiSWP Hot Work GuidelinesTri FebriyaniÎncă nu există evaluări

- Equipment Risk AssessmentDocument7 paginiEquipment Risk Assessmentgullipalli srinivasa raoÎncă nu există evaluări

- HSE TBT TopicDocument3 paginiHSE TBT TopicrexivyÎncă nu există evaluări

- Qatar Foundation Construction Safety Standard For Contractors Final VersionDocument119 paginiQatar Foundation Construction Safety Standard For Contractors Final VersionAnosh1978100% (3)

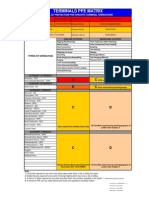

- PPE MatrixDocument1 paginăPPE MatrixcaptainphihungÎncă nu există evaluări

- Tool Box Talk 2-07 Excavation Egress - OSHADocument3 paginiTool Box Talk 2-07 Excavation Egress - OSHAloveanbu24Încă nu există evaluări

- FRM-00413 Corporate Safety - Excavation and Trenching Permit FormDocument3 paginiFRM-00413 Corporate Safety - Excavation and Trenching Permit FormAhmad Hafidz Mahendra100% (1)

- Damagix Training MatrixDocument6 paginiDamagix Training MatrixPaul UwayaÎncă nu există evaluări

- Safety Pocket Manual-11Document41 paginiSafety Pocket Manual-11Kunal JaiswalÎncă nu există evaluări

- Construction Risk Assesment For Riser Top Ring InstallationsDocument11 paginiConstruction Risk Assesment For Riser Top Ring Installationssaifulnizam86gmailcom100% (1)

- Enhancing Best Practice in Health and Safety: Peter CorfieldDocument31 paginiEnhancing Best Practice in Health and Safety: Peter CorfieldsohaibÎncă nu există evaluări

- Jsa FormDocument3 paginiJsa Formmiaicarba100% (1)

- Job Hazard Safety Analysis MachinesDocument39 paginiJob Hazard Safety Analysis Machinesdayglis100% (1)

- LEVAC Slings Instruction Manual ENGLISHDocument20 paginiLEVAC Slings Instruction Manual ENGLISHpeachykristaÎncă nu există evaluări

- Busatec Application TableDocument1 paginăBusatec Application TablepeachykristaÎncă nu există evaluări

- Straaltechniek 98CE 2000 50CE enDocument2 paginiStraaltechniek 98CE 2000 50CE enpeachykristaÎncă nu există evaluări

- Atest TipBDocument250 paginiAtest TipBpeachykristaÎncă nu există evaluări

- Etsy Business TemplateDocument28 paginiEtsy Business TemplatepeachykristaÎncă nu există evaluări

- Comunication DataDocument104 paginiComunication DatapeachykristaÎncă nu există evaluări

- UC400 S23 Cat.6: U/FTP Installation CableDocument3 paginiUC400 S23 Cat.6: U/FTP Installation CablepeachykristaÎncă nu există evaluări

- Cust SpeDocument9 paginiCust SpepeachykristaÎncă nu există evaluări

- Transformer and Electronic Controllers For HVAC: WWW - Breve.plDocument9 paginiTransformer and Electronic Controllers For HVAC: WWW - Breve.plpeachykristaÎncă nu există evaluări

- S3i Lifting Shackles Technical InformationDocument4 paginiS3i Lifting Shackles Technical InformationpeachykristaÎncă nu există evaluări

- Update ERCA Safety Warning 1 2011 WireRopeTerminationsDocument0 paginiUpdate ERCA Safety Warning 1 2011 WireRopeTerminationspeachykristaÎncă nu există evaluări

- Generic Safety Manual v2Document266 paginiGeneric Safety Manual v2Gnalagnas KarlengianÎncă nu există evaluări

- Preparation of Reagents & Aseptic TechniquesDocument21 paginiPreparation of Reagents & Aseptic TechniquesReylen OracionÎncă nu există evaluări

- Steel For PipesDocument3 paginiSteel For PipesFilip StojkovskiÎncă nu există evaluări

- Natural Gas DehydrationDocument21 paginiNatural Gas Dehydrationsudhakar100% (1)

- Wafer Biscuit PlantDocument9 paginiWafer Biscuit Planttechnocrat_vspÎncă nu există evaluări

- Inspeccion Visual de Treminales Crimpeado PDFDocument2 paginiInspeccion Visual de Treminales Crimpeado PDFCarlos ChirinosÎncă nu există evaluări

- Marchs Advanced Organic Chemistry Reactions Mechanisms and Structure 8Th Edition Michael B Smith Full ChapterDocument67 paginiMarchs Advanced Organic Chemistry Reactions Mechanisms and Structure 8Th Edition Michael B Smith Full Chapterjames.modesto652100% (6)

- Coordination ChemistryDocument43 paginiCoordination ChemistryvictorÎncă nu există evaluări

- Construction Fibre Concreate Fibre Recron 3sDocument7 paginiConstruction Fibre Concreate Fibre Recron 3sAbhishek JoshiÎncă nu există evaluări

- bw-G1030 USDocument24 paginibw-G1030 USEuojrÎncă nu există evaluări

- Lamitex CE Tube Metric DataDocument1 paginăLamitex CE Tube Metric Dataabdulloh_99Încă nu există evaluări

- Bul-Spent Mushroom Substrate (SMS)Document56 paginiBul-Spent Mushroom Substrate (SMS)Manoj Patel100% (1)

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 paginiANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezÎncă nu există evaluări

- Avian Urolithiasis EngDocument4 paginiAvian Urolithiasis Engwaseem234Încă nu există evaluări

- Tablas TermodinámicasDocument5 paginiTablas TermodinámicasSarahí CabreraÎncă nu există evaluări

- Spark Sensor FM 1-8 - EngDocument86 paginiSpark Sensor FM 1-8 - EngBarosz0% (1)

- 10 1016@j Apenergy 2019 114135 PDFDocument12 pagini10 1016@j Apenergy 2019 114135 PDFKevin Solórzano MacénÎncă nu există evaluări

- Measurements of Surface TensionDocument11 paginiMeasurements of Surface TensionHema ParasuramanÎncă nu există evaluări

- Catalogo Alu MarketDocument40 paginiCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- 2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDocument6 pagini2-7-Totally Gel-Free Fiber Optical Cables Manufactured With PBTDursunÎncă nu există evaluări

- Worksheet - Experiment 9 MilkDocument2 paginiWorksheet - Experiment 9 MilkYuraÎncă nu există evaluări

- Food Processing Module-RENDocument18 paginiFood Processing Module-RENRen RenÎncă nu există evaluări

- Chapter 13, 14 - Metals PDFDocument9 paginiChapter 13, 14 - Metals PDFAarush SharmaÎncă nu există evaluări

- Musk AmbretteDocument19 paginiMusk AmbretteSachin KausadikarÎncă nu există evaluări

- Blast FurnaceDocument28 paginiBlast Furnaceavanisharma_1991Încă nu există evaluări

- Eco Hopper GBDocument8 paginiEco Hopper GBArmand SpiderHerpÎncă nu există evaluări

- Drug and Alcohol AbuseDocument24 paginiDrug and Alcohol AbuseParitosh Kumar100% (3)

- Operation Manual - IDU - FXFQ-PVEDocument5 paginiOperation Manual - IDU - FXFQ-PVEJM ArcillaÎncă nu există evaluări

- Grundfosliterature-836 - (PG 10,24-25)Document226 paginiGrundfosliterature-836 - (PG 10,24-25)anggun100% (1)

- JewelleryDocument2 paginiJewellerynbhoanghuyÎncă nu există evaluări

- Seperator Design, K C Foong PDFDocument7 paginiSeperator Design, K C Foong PDFpomaukÎncă nu există evaluări