Documente Academic

Documente Profesional

Documente Cultură

Fault Tolerant Operation in Aero Engine Using Distributed Computation System

Încărcat de

editor_ijtelTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fault Tolerant Operation in Aero Engine Using Distributed Computation System

Încărcat de

editor_ijtelDrepturi de autor:

Formate disponibile

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 391

Fault Tolerant Operation in Aero Engine Using

Distributed Computation System

Neela A G

M Tech Scholar,

VLSI Design & Embedded Systems,

VTU Regional Centre @ UTL

Technologies, Bangalore, India

Shobha S Prabhu

Scientist F, GTRE

DRDO, CV Raman Nagar,

Bangalore, India

Channabassappa Baligar

Scientist E, LRDE,

DRDO, C V Raman Nagar,

Bangalore, India

Abstract The paper presents fault tolerant operation in an

aero engine based on real-time systems which is built for a very

small set of mission-critical applications like space crafts ,

avionics and other distributed control systems. The modern

software deals with external interfaces and has to consider

various timing implications The platform is based on the C and

developed using Keil MDK tool with the targeted deadline of 100

milliseconds at the baud rate of 500 kbps. CAN interface

executes the role of Transportation and Communication, an

interface cable used for serial communication between Digital

Electronic Control Unit (DECU) and the host to transfer data to

the pilot Online Monitoring System and that is based on

Laboratory Virtual Instrument Engineering Workbench (Lab

VIEW )7.1. Fault diagnosis typically assumes a sufficiently large

fault signature and enough time for a reliable decision to be

reached. However, for a class of safety critical faults on

commercial aircraft engines, prompt detection is paramount

within a millisecond range to allow accommodation to avert

undesired engine behavior. At the same time, false positives must

be avoided to prevent inappropriate control action.

Keywords- Aero gas turbine Engine; Digital Electronic

Control Unit (DECU); Online Monitoring display; CAN serial

communication.

I. INTRODUCTION

Defence aircraft is a high-performance avionics mission

computer which is the central computing resource. It evaluates,

coordinates, controls large amount of data like rig, ground,

altitude, temperature, fuel intake, power dissipated, pressure,

amount of air taken, speed etc .It must also respond quickly to

the changing conditions within the aircraft and in its own

operating environment. An avionics mission computer has very

strict hard Real Time requirements. Very low latency and

exceedingly predictable behaviors are crucial nod only to

mission success, but also to the safety of the pilots. Any

computer hardware or software designed for this environment,

receives intense scrutiny for its performance and reliability [1].

In embedded system its important that the behavior of the

application has to be same on development environment (host

PC) as well as deployed environment (target). Due to

unavailability of target there is a need to check for application

functionality, timing performance etc. The simulator

development environment and operating system is different

from target board where actual application is residing. In

embedded system executable application has to be deployed on

the limited available size of the flash. Execution of application

from FLASH creates unforeseen timing dependencies as

well as other behaviors, which are tolerable in FLASH [1].

Presently, CAN interface cable is used for real-time

communication between Gas turbine aero engine controller and

Pilot critical display. Due to redundancy, there is a need for

similitude component to provide alternative in case of

any component failure. In order to achieve this, CAN

serial communication is used in this application. Fault detection

typically assumes a sufficiently large fault signature and

enough time to come up with a reliable decision. However,

faults that affect aircraft safety must be detected quickly.

Otherwise, undesired consequences may arise such as engine

surge stall events, power loss, severe vibrations,

power loss, and no thrust response to commanded power.

These events in addition to inappropriate crew response may

lead to accidents [8]. Since the air traffic is projected to

increase in the long term, and at the current level of reliability,

the number of accidents would increase as well. Based on the

review of an engine events database of the past 20 years

of DEC and FADEC operated aircraft a list of root

cause faults was compiled. From this list a set of

representative cases from different categories including sensor

faults, actuator faults was chosen. More specifically,

compressor damage, turbine damage, variable stator vanes

faults, and ps3 sensor loss were selected. The results of

these failures can lead to compressor stall, loss of Power ,loss

of thrust control and flameouts. Requirements for time to

detection were established to range from roughly 100ms for

some actuator faults . This means that in the worst case, only a

few samples of sensor data are available to perform the fault

detection. With these time constraints, the full magnitude of the

fault signature will in some cases not be seen in the

measurement data. To allow for the detection of small changes

in engine components, a suite of techniques was employed to

address certain aspects of these issues in parallel.

The presented work is organized in six categories. Section

II describes with Keil MDK and LPC 4357 features . It also

gives a brief overview of Lab VIEW and serial communication.

Section III deals with Aero gas turbine engine controller and

the Pilot online monitoring system. Section IV is emphasized

on the hardware system of the application. Section V shows

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 392

low chart of the presented application. Section VI presents the

tested results of the application tested results of the application

II. KEIL MDK AND LPC4357 FEATURES

The MDK-ARM is a complete software development

environment for Cortex

-M, Cortex-R4, ARM7

and ARM9

processor-based devices. MDK-ARM is specifically designed

for microcontroller applications. microcontroller devices offer

a wide range of communication interfaces to meet any

embedded design requirement. However, implementing these

interfaces presents software developers with real challenges.

Middleware components are essential for developers to make

efficient use of the device capabilities.

MDK-Professional includes a number of royalty-free,

tightly coupled middleware components which enable

developers to more easily implement complex communication

interfaces in their applications. Middleware components

include[4]:

Graphical User Interface

USB Host and Device

TCP Networking Suite

Flash File System

CAN Driver

All middleware components are specifically designed and

optimized for ARM processor-based MCU devices. The

libraries are seamlessly integrated with the Vision

environment and offer a modular design with well documented

APIs. time features including fast multitasking, hardware

interrupts, both priority-preemptive and round-robin

scheduling[6].

Fig. 1 illustrates the Keil Architecture and Development

Platform. The basic components of Keil e include Graphical

User Interface (GUI).

Figure 1. Keil Architecture and Application Development Platform

The GUI Library is a fully featured graphics suite that

makes it possible to add graphical user interfaces to embedded

applications. It supports a large number of displays and

includes tools for rapid GUI creation [2].

Supports monochrome, grayscale and color LCDs

Drivers for many displays and display controllers included

Window Manager for handling multiple windows

Many widget-like buttons, checkboxes and icons

available

Skinning support for a custom look and feel

Optimized for speed and size

Wide range of examples for evaluation boards.

A. Flash File System

The Flash File System allows your embedded applications

to create, save, read, and modify files in a wide range of

standard storage devices. The Flash File System offers:

Standard ANSI C File I/O application interface

NOR and NAND Flash support

RAM, ROM, and SD/MMC/SDHC Memory Cards

FAT12, FAT16, and FAT32 formats

SD/MMC card file-caching

Reentrant and thread-safe operation

Simultaneous access to multiple storage devices

B. LPC4357

The LPC4357 development board is a full function

evaluation platform base NXP LPC4357 ARM Cortex-M4

processor working at 204MHZ; The LPC4357 board integrate

all core components, memory, interfaces and tested software

source code, which enable users make a reliable product

prototype base it. The board help users to make quick software

application and evaluation for NXP LPC4357 ARM Cortex-

M4/M0 processor[5]. The LPC4357 board deliver a rich set of

memory resource and periphery interfaces, include 32MB

SDRAM, 2MB NorFlash and 4MB SPI FLASH, Hi-speed

USB Host, audio input/output, 10/100Mbps Ethernet, CAN,

JTAG,4.3/7.0 TFT LCD Module, UART, MicroSD and

user GPIO pins. These peripheries interfaces and user

extension connector working with full tested source code to

build a develop platform helps users evaluate, learning and

make prototype base NXP LPC4357ARM Cortex-M4

processor at a fast period[5].

1) LPC4357 development board specifications[3]

PCB Size: 115mm x 90mm

PCB layers: 4

Power supply: 5V/2A

Debug interface: 20-pin,2.54mm JTAG connector

Working temperature-40~+85

ROHS Compliance

2) Hardware features Processor[3]

NXP LPC4357, Cortext-M4, Cortext-M0 dual-core ,

working at 204MHZ

204 MHz, 32-bit ARM Cortex-M4

204 MHz, 32-bit ARM Cortex-M0 asymmetrical

coprocessor

200 kB SRAM for code and data use

64 kB ROM containing boot code and on-chip

3) Software drivers

32/128-bit One-Time Programmable (OTP) memory

for general-purpose use.

4) External memory

32MB SDRAM

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 393

2MB NorFlash

4MB SPI FLASH

5) Audio interface

Audio 3.5mm input

Dual track audio 3.5mm output

6) TFT LCD

24 Bit color

80x272 pixel support 1024 x 768

7) Data interface

3 x UART (UART0,UART2 and UART3, UART2

need external MAX3232)

1x Hi-speed USB HOST

1x Mini USB OTG

1x Ethernet interface

2x CAN interface

1x RS485(reuse with UART1)

8) LED

1x Power indicator

6x User LED

C. LabVIEW

Lab VIEW is a development environment based on

graphical programming. It includes terminology, icons and

ideas recognizable to technicians, scientists and engineers. Lab

VIEW relies on graphical symbols rather than text-based

language to describe programming actions. It is integrated fully

for communication with hardware such as GPIB, VXI, CAN,

TCP/IP networking, ActiveX and plug-in data acquisition

boards [5].

D. Serial Communication

Asynchronous serial communication technology plays an

important role in automatic testing field for embedded system,

because of its flexibility, facility and reliability.CAN interface

is for the transferring information between the devices and

debugging of application. Serial communication requires

mainly four parameters: the baud rate of the transmission, the

number of data bits encoding a character, the sense of the

optional parity bit and the number of stop bits [2][3].

E. Control Area Network (CAN)

Development of the CAN-bus started originally in 1983

at Robert Bosch. The protocol was officially released in 1986

at the Society of Automotive Engineers (SAE) congress

in Detroit, Michigan. The first CAN controller chips, produced

by Intel and Philips, came on the market in 1987. Bosch

published the CAN 2.0 specification in 1991 [2].

CAN is a multi-master broadcast serial bus half duplex

wired standard for connecting Electronic Control Units

(ECUs). Each node is able to send and receive messages, but

not simultaneously. A message consists primarily of an

identifier, which represents the priority of the message, and up

to eight data bytes. It is transmitted serially onto the bus. This

signal pattern is encoded in non-return-to-zero and is sensed

by all nodes [3].

The devices that are connected by a CAN network are

typically sensors, actuators, and other control devices. These

devices are not connected directly to the bus, but through a host

processor and a CAN controller. If the bus is free, any node

may begin to transmit. If two or more nodes begin sending

messages at the same time, the message with the more

dominant will overwrite other nodes' less dominant id's, so that

eventually only the dominant message remains and is received

by all nodes[2][3]. This mechanism is referred to as priority

based bus arbitration. Messages with numerically smaller

values of ids have higher priority and are transmitted first.

Each node requires a:

1) Host processor

The host processor decides what received messages

mean and which messages it wants to transmit itself.

Sensors, actuators and control devices can be

connected to the host processor [8].

2) CAN controller (hardware with a synchronous clock)

Receiving: the CAN controller stores received bits

serially from the bus until an entire message is

available, which can then be fetched by the host

processor (usually after the CAN controller has

triggered an interrupt).

Sending: the host processor stores its transmit

messages to a CAN controller, which transmits the bits

serially onto the bus.

3) Transceiver

Receiving: it adapts signal levels from the bus to levels

that the CAN controller expects and has protective

circuitry that protects the CAN controller.

Transmitting: it converts the transmit-bit signal

received from the CAN controller into a signal that is

sent onto the bus.

Bit rates up to 1 Mbps are possible at network lengths

below 40 m. decreasing the bit rate allows longer network

distances. The CAN data link layer protocol is standardized in

ISO 11898-1. This standard describes mainly the data link

layer composed of the logical link control sub layer and the

media access control and some aspects of the physical layer of

the OSI reference model. All the other protocol layers are the

network designer's choice[2][3].

III. AERO GAS TURBINE ENGINE CONTROLLER AND PILOT

ONLINE MONITORING DISPLAY

Aero gas turbine engine controller performs engine control

functions as per the control laws apart from providing the

monitoring display system with details of various engine

parameters. Since engine needs to be monitored and controlled

periodically, the presence of engine controller is inevitable.

Aero gas turbine engine controller is a critical component of

the aircraft. This criticality demands a high reliability of the

engine and its control unit. The Aero gas turbine engine

controller is controlled by a full authority digital engine control

system consisting of hydro mechanical components, actuators,

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 394

sensors and digital electronic control unit (DECU). DECU is a

rugged and robust industrial computer, which acts as a black

box, and runs infinitely and gets data periodically for every 30

seconds from aero gas turbine engine.

The online monitoring system functionality is to monitor,

store and analyze engine parameters. This is done through

serial communication. As engine controller is critical,

expensive and sophisticated component, so the online

monitoring system may not be always available for testing.

Hence, a simulator is required for testing of online monitoring

system in its absence.

The various hardware interfaces of the online monitoring

system and their interaction with one another are illustrated in

"Fig II". Aero engine comprises of ADC, DAC, CAN interface,

timer, Pentium III processor, power cards etc which is used in

embedded controller display. There is a requisite for real time

communication between aero gas turbine engine controller and

pilot online monitoring display. This is accomplished by using

CAN serial communication. The application software which is

designed and developed will be real time and it takes care of

serial communication protocol.

Figure 2. Hardware Interface Diagram of the Monitoring System

IV. HARDWARE SYSTEM

Figure 3. Block Diagram of hardware system

The Fig. 3 shows block diagram of cross development

hardware system. Hardware system comprises of following.

Host PC: Host PC consists of host operating system i.e.

windows 2000. This host operating system has a target

operating system i.e. Keil MDK Pro can be configured and

scaled based on the application.

A. Ethernet LAN

Ethernet LAN acts as a media for communication between

host PC and DECU.

B. Engine controller

Engine controller is Commercial Off The Shelf component

(COTS) which controls the engine.

C. CAN

CAN acts as a serial communicator between engine

controller and pilot critical display.

D. Pilot critical display

Pilot critical display is a standalone application which gets

the information from engine controller periodically for every

30milisecond which is needed to be displayed. This is

developed by using Lab VIEW.

The hierarchy of the design carried is as follows.

Initially, the configuration of CAN serial communication

port COM-1 is done. The data taken from aero gas turbine

engine to the Digital Electronic Control Unit (DECU) is

processed for 100 milliseconds. The data residing in the DECU

is converted into packets for the communication between

DECU and pilot online monitoring system. Then the packets

are transferred to the pilot online monitoring display system

through the configured CAN serial communication port COM-

1.

V. FLOW CHART

The flow chart of the presented cross developed application

is as shown in "Fig IV". It includes four stages.

In stage1, the Microcontroller LPC 4357 senses the

various parameters of the Engine at different points of

engine run .

The data format of CAN is as shown in "Fig VI" which

includes SOF (Start Of Frame )bit, Arbitration

ID,RTR(Remote Transmit Request),IDE (Identifier

Extension),DLC(Data Length Code),Data Bytes,

CRC(Cyclic Redundancy Check) .

Every 30milisecound updated data is being packed for

transmission.

The processed data is transmitted to online monitoring

system to the display for the pilot on real time.

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 395

Figure 4. Flow Diagram of CAN Serial Communication

Fig. 5 dscribes The Fault Handling Techniques and the

operation process [7]:

1. Assume that the system is running with copy 0 as active

unit and copy 1 as standby.

2. When the copy 0 fails ,copy 1 will detect the fault by any of

the fault detection mechanisms.

3. At this point, copy 1 takes over from over from copy 0 and

becomes active. The state of copy 0 is marked suspect,

pending diagnostics.

4. The system raises an alarm ,notifying the operator that the

system is working in a non-redundant configuration.

5. Diagnostics are scheduled on copy 0 .This includes power

on diagnostics and hardware interface diagnostics .

6. If the diagnostics on copy 0 pass ,copy 0 is brought in

service as standby unit. If the diagnostics fail, copy 0 is

marked failed and the operator is notified about the field card.

7. The operator replaces the failed card and commands the

system to bring the card in service.

8. The system schedules diagnostics on the new card to

ascertain the card is healthy .

9. Once the diagnostics pass, copy 0 is marked standby.

10.The copy 0 now starts monitoring the health of copy 1

which is currently the active copy .

11.The system clears the non-redundant configuration alarm

as redundancy has been restored .

12. The operator can restore the original configuration by

switching over the two copies.

Figure 5. Fault Handling Life Cycle

Figure 6. Data Format

VI. TEST RESULTS

Due to non availability of actual system, several systems

can be tested with simulator. The proposed application is tested

for the performance in terms of serial communication interface

and exchange of expected messages using pilot online

monitoring system simulator. The test results are as shown in

Fig. 7 and Fig. 8. The test results show that the proposed

application is developed on the target board and information is

transmitted to pilot online monitoring system. The application

is successfully developed using serial communication interface

and message is transmitted between aero gas turbine engine

controller and pilot control display system.

Figure 7. Test Result using Keil MDK

INTERNATIONAL JOURNAL OF TECHNOLOGICAL EXPLORATION AND LEARNING (IJTEL)

www.ijtel.org

IJTEL, ISSN: 2319-2135, VOL.3, NO.2, APRIL 2014 396

Figure 8. Test Results using Block diagram of LAB View

Figure 9. Test Results using Front Panel of LAB View

VII. CONCLUSION

The design and development for real time communication

between aero gas turbine engine controller and pilot online

monitoring display is successful. Aero gas turbine engine

controller is enclosed by an unique polymorphic approach

which could adapt itself easily to any testing environment

videlicet rig, ground, altitude, temperature, fuel intake, power

dissipated, pressure, amount of air taken, speed etc. To ensure

deterministic performance, the application is developed using

CAN AND for communication based and fault tolerance on

the Keil MDK platform and implemented through Lab VIEW

execution system. Tested for data fault tolerance and redundant

system.

REFERENCES

[1] Prindle.j. A method for providing turnkey embedded computer

operating systems for independently developed user applications in a

military environment, digital avionics system, 18

th

IEEE conference,

vol-1, 1999, pp .A.5-2.A.5-8.

[2] Shuangyou Wang, Zhian Wang and Xuhui Wang Multichannel

temperature acquisition System based on ARM and CAN", International

conference on computer, control engineering, pp 33-34, 2010.

[3] Zhu qishen , Zhu dongmei and Su xunhon Distributed remote

temperature monitoring and acquisition system based on CAN bus,

2010 prognostic and system health management Conference, 2010.

[4] Getting started creating application with vision 4

[5] ARM Keil MDK toolkit featuring Serial Wire Viewer and ETM

Trace For the Keil MCB4357 EVAL board Version 1.0 Robert Boys

[6] "Sam Seiuort",Real Time Operating Systems

[7] Rajendra Prasad, "Fault Tolerance in Aerospace Systems", Published

and Printed by D Murugan,OM offset ,sharada industrial estate,

Sinhagad road ,Pune -51,Maharashtra.

[8] AWAECMA Project Report on PSM+ICR, http://www.faa.gov/

certification /aircrafLeng~e~sm+~cr.doc , 1998.

[9] Christine M. Belcastro, Celeste M. Belcastro,Application of failure

detection, identification, and accommodation methods for improved

aircraft safety, Proceedings of the American Control Conference, Vol.

4 , 25- 27,pp. 2623 -2624, June 2001.

S-ar putea să vă placă și

- Applications of Artificial Neural Networks in Friction Stir Welding: A ReviewDocument5 paginiApplications of Artificial Neural Networks in Friction Stir Welding: A Revieweditor_ijtelÎncă nu există evaluări

- Experimental Investigations of CI Engine by Using Different Blends of Neat Karanja Oil and Diesel at Different Injection PressuresDocument3 paginiExperimental Investigations of CI Engine by Using Different Blends of Neat Karanja Oil and Diesel at Different Injection Pressureseditor_ijtelÎncă nu există evaluări

- Design of Floating Point Arithmetic Logic Unit With Universal GateDocument5 paginiDesign of Floating Point Arithmetic Logic Unit With Universal Gateeditor_ijtelÎncă nu există evaluări

- Online Marketing in Indian Politics: Role of Social MediaDocument8 paginiOnline Marketing in Indian Politics: Role of Social Mediaeditor_ijtelÎncă nu există evaluări

- Advanced File Sharing in Peer To Peer SystemsDocument4 paginiAdvanced File Sharing in Peer To Peer Systemseditor_ijtelÎncă nu există evaluări

- Wireless Power Transfer in 3D SpaceDocument5 paginiWireless Power Transfer in 3D Spaceeditor_ijtelÎncă nu există evaluări

- Essential Requirements of PPAPDocument4 paginiEssential Requirements of PPAPeditor_ijtelÎncă nu există evaluări

- Design and Fabrication of Compact Size Fluidized Bed Gasifier For Automotive VehicleDocument4 paginiDesign and Fabrication of Compact Size Fluidized Bed Gasifier For Automotive Vehicleeditor_ijtelÎncă nu există evaluări

- Adaptive Non-Linear Bayesian Filter For ECG DenoisingDocument5 paginiAdaptive Non-Linear Bayesian Filter For ECG Denoisingeditor_ijtelÎncă nu există evaluări

- Control Strategy For Three Phase PWM Rectifier Using SVM ModulationDocument7 paginiControl Strategy For Three Phase PWM Rectifier Using SVM Modulationeditor_ijtelÎncă nu există evaluări

- Design and Implementation of Fast - Lifting Based Wavelet Transform For Image CompressionDocument5 paginiDesign and Implementation of Fast - Lifting Based Wavelet Transform For Image Compressioneditor_ijtelÎncă nu există evaluări

- A Study On Indian License Plate IdentificationDocument5 paginiA Study On Indian License Plate Identificationeditor_ijtelÎncă nu există evaluări

- Accessible Content Generation For The Learning DisabledDocument3 paginiAccessible Content Generation For The Learning Disablededitor_ijtelÎncă nu există evaluări

- Mobile Rescue Robot For Human Detection in Case of DisasterDocument4 paginiMobile Rescue Robot For Human Detection in Case of Disastereditor_ijtelÎncă nu există evaluări

- A Study On Multi Material Gate All Around SOI MOSFETDocument5 paginiA Study On Multi Material Gate All Around SOI MOSFETeditor_ijtelÎncă nu există evaluări

- Hierarchical Organization of Data Centre To Improve Quality of Services (QoS)Document5 paginiHierarchical Organization of Data Centre To Improve Quality of Services (QoS)editor_ijtelÎncă nu există evaluări

- Implementation of Different Low Power Multipliers Using VerilogDocument6 paginiImplementation of Different Low Power Multipliers Using Verilogeditor_ijtelÎncă nu există evaluări

- FPGA Based Three Phase Multilevel PWM InverterDocument4 paginiFPGA Based Three Phase Multilevel PWM Invertereditor_ijtel100% (1)

- Implementation of A Capacitor Less Low Dropout Voltage Regulator On Chip (SOC)Document7 paginiImplementation of A Capacitor Less Low Dropout Voltage Regulator On Chip (SOC)editor_ijtel100% (1)

- G.P.S. Use in EHV and HVDC Transmission Line ProtectionDocument5 paginiG.P.S. Use in EHV and HVDC Transmission Line Protectioneditor_ijtelÎncă nu există evaluări

- The Effect of Under Nutrition On Schooling, Adult Productivity and Economic Growth in South - West Madhya Pradesh, IndiaDocument7 paginiThe Effect of Under Nutrition On Schooling, Adult Productivity and Economic Growth in South - West Madhya Pradesh, Indiaeditor_ijtelÎncă nu există evaluări

- Low Cost Computerized Digital IC TesterDocument4 paginiLow Cost Computerized Digital IC Testereditor_ijtelÎncă nu există evaluări

- Gender Identification in Digital X-Ray Images of Femur BoneDocument4 paginiGender Identification in Digital X-Ray Images of Femur Boneeditor_ijtelÎncă nu există evaluări

- Preserve The Privacy of Anonymous and Confidential Database Using K-AnonymityDocument5 paginiPreserve The Privacy of Anonymous and Confidential Database Using K-Anonymityeditor_ijtelÎncă nu există evaluări

- Courseware Quality Groups Tie-In To ReinforcingDocument4 paginiCourseware Quality Groups Tie-In To Reinforcingeditor_ijtelÎncă nu există evaluări

- Spiritual and Moral Principles For Promoting Gender Sensitivity and EqualityDocument3 paginiSpiritual and Moral Principles For Promoting Gender Sensitivity and Equalityeditor_ijtelÎncă nu există evaluări

- Performance Comparison of M-PSK and M-QAM Modulations For WiMAX OFDM System Under The Rayleigh Fading ChannelDocument5 paginiPerformance Comparison of M-PSK and M-QAM Modulations For WiMAX OFDM System Under The Rayleigh Fading Channeleditor_ijtelÎncă nu există evaluări

- Max Min Sorting Algorithm A New Sorting ApproachDocument4 paginiMax Min Sorting Algorithm A New Sorting Approacheditor_ijtelÎncă nu există evaluări

- Creep Life Estimation of Low Pressure Reaction Turbine BladeDocument3 paginiCreep Life Estimation of Low Pressure Reaction Turbine Bladeeditor_ijtelÎncă nu există evaluări

- Effect of Interactive Hypermedia Program On Mathematics Achievement in Relation To Locus of ControlDocument5 paginiEffect of Interactive Hypermedia Program On Mathematics Achievement in Relation To Locus of Controleditor_ijtelÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Attachment - 1 - 2021-10-27T013155.320Document3 paginiAttachment - 1 - 2021-10-27T013155.320oliver wekesaÎncă nu există evaluări

- Java Fundamentals Section 7 Part 2: Creating An Inventory Project ProjectDocument4 paginiJava Fundamentals Section 7 Part 2: Creating An Inventory Project ProjectnaniÎncă nu există evaluări

- Conduit Installation WMSDocument7 paginiConduit Installation WMSmanohar GurramÎncă nu există evaluări

- Use LiveSuite To Install Driver and Upgrade FirmwareDocument3 paginiUse LiveSuite To Install Driver and Upgrade FirmwareVictor Siruela MatosÎncă nu există evaluări

- Python - PPT CieDocument18 paginiPython - PPT CieSurisetty ManjuÎncă nu există evaluări

- Avr 505 ManualDocument34 paginiAvr 505 ManualaxxelloneÎncă nu există evaluări

- SX-KLCS-B: Product Data SheetDocument2 paginiSX-KLCS-B: Product Data SheetTECUMCE GOMEZ PEREZÎncă nu există evaluări

- An Introduction To The CISSP & SSCP Certifications: Wilfred L. Camilleri, CISSPDocument49 paginiAn Introduction To The CISSP & SSCP Certifications: Wilfred L. Camilleri, CISSPchirag2beÎncă nu există evaluări

- GIS Siemens Catalogo 36kVDocument16 paginiGIS Siemens Catalogo 36kVCristian Rene Orozco PerezÎncă nu există evaluări

- Sap C ts452 2022 Dumps by Odom 15 08 2023 7qa VceexamstestDocument9 paginiSap C ts452 2022 Dumps by Odom 15 08 2023 7qa VceexamstestLilian Michel Youssef MalekÎncă nu există evaluări

- VSL Heavy LiftingDocument16 paginiVSL Heavy LiftingDrPadipat ChaemmangkangÎncă nu există evaluări

- Quality Assurance CV TemplateDocument2 paginiQuality Assurance CV Templatebaluchakp100% (1)

- FLEXIS Fluxus G704, G704 A2 (Ing)Document241 paginiFLEXIS Fluxus G704, G704 A2 (Ing)biotech666Încă nu există evaluări

- 20480A ENU TrainerHandbookDocument627 pagini20480A ENU TrainerHandbookMiticuta SurubÎncă nu există evaluări

- LT3 Lt3se00mDocument2 paginiLT3 Lt3se00mLucian SinpetruÎncă nu există evaluări

- Ursalink UR71 Industrial Cellular Router DatasheetDocument6 paginiUrsalink UR71 Industrial Cellular Router DatasheetUrsalink MarketingÎncă nu există evaluări

- Nokia Siemens Networks Information Browser Installation and Setup GuideDocument16 paginiNokia Siemens Networks Information Browser Installation and Setup GuideФантомас МихалычÎncă nu există evaluări

- GL Studio Aero Brochure 2023 - WebDocument4 paginiGL Studio Aero Brochure 2023 - WebAnees KhanÎncă nu există evaluări

- ITIL Interview QuestionsDocument6 paginiITIL Interview QuestionsasimÎncă nu există evaluări

- Calibration Procedure of Concrete Batching Plant ScalesDocument2 paginiCalibration Procedure of Concrete Batching Plant ScalesKevin Tang100% (2)

- Step by Step Procedure-PMAY (U) Mobile AppDocument16 paginiStep by Step Procedure-PMAY (U) Mobile AppAshokÎncă nu există evaluări

- What Is Burst in GSM and Burst Types in GSMDocument2 paginiWhat Is Burst in GSM and Burst Types in GSMAbid Ur RehmanÎncă nu există evaluări

- AutoKriti 7.0Document60 paginiAutoKriti 7.0Bhanuj VermaÎncă nu există evaluări

- Types of Simple MachinesDocument37 paginiTypes of Simple MachinesAd Man GeTigÎncă nu există evaluări

- B. Inggris XiDocument6 paginiB. Inggris XiAnita LestariÎncă nu există evaluări

- Instrument TransformerDocument8 paginiInstrument TransformerShaip DautiÎncă nu există evaluări

- MPSA13 Data SheetDocument5 paginiMPSA13 Data SheetbananameepÎncă nu există evaluări

- l2 Uplink Discard IssueDocument5 paginil2 Uplink Discard IssueSumanth JoglekarÎncă nu există evaluări

- Cloud Based VOIP Phone System Including The Mitel 6900 SeriesDocument7 paginiCloud Based VOIP Phone System Including The Mitel 6900 SeriesTele-Verse Communications, Inc.Încă nu există evaluări

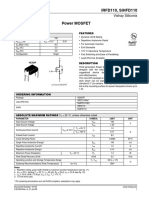

- Irfd110, Sihfd110: Vishay SiliconixDocument8 paginiIrfd110, Sihfd110: Vishay SiliconixJaviÎncă nu există evaluări