Documente Academic

Documente Profesional

Documente Cultură

Basic Info About Glaze Formulations

Încărcat de

ThongMaVanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Basic Info About Glaze Formulations

Încărcat de

ThongMaVanDrepturi de autor:

Formate disponibile

Basic Info about Glaze Formulations:

Ceramic glazes generally contain silica to form glass, in combination with a mixture of metal oxides such as sodium,

potassium and calcium which act as a flux and allow the glaze to melt at a particular temperature, alumina (usually from

added clay) to stabilize the glaze and prevent it from running off the piece, colorants such as iron oxide, copper

carbonate or cobalt carbonate, and sometimes opacifiers such as tin oxide or zirconium oxide.

FLUXES:

Barium Oxide Na

2

)

Potassium Oxide K2O

Lithium Oxide Li

2

)

Calcium Oxide CaO

Magnesium Osice MgO

Zinc Oxide ZnO

Strontium Oxide SrO

STABILIZERS

Aluminum Oxide (Alumina) Al

2

O

3

Boric Oxide B

2

O

3

Iron oxide Fe

2

O

3

GLASS FORMERS

Silicon Dioxide (Silica) SiO

2

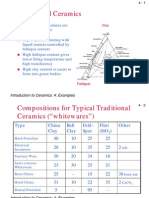

Wgt % VS Seger Unity (molar composition)

So, dont freak out herethis is just to expose you to the basics of glaze chemistry. We will be working with

glaze recipes. If you want to work on the Unity formula of a particular glaze, we can do that.

The weight % glaze formulas describe how to mix the glaze; it provides you with little information upon

which to compare 2 glazes, or predicting the stability of a glaze.

EXAMPLE (from Mastering Cone 6 Glazes, John Hesselberth & Ron Roy, 2002)

Jade Green, Cone 4 - 6

Glaze Recipe Unity Formula

Potash Feldspar 40.0 Fluxes

Barium Carbonate 20.0 K

2

O 0.127

Gerstley Borate 10.0 Na

2

O 0.080

Zinc Oxide 9.9 CaO 0.138

EPK 10.1 MgO 0.041

Silica 10.0 Li

2

O

100.0 ZnO 0.336

Add

Copper Carbonate

5.25

BaO 0.278

Stabilizers

Al

2

O

3

0.295

B

2

O

3

0.157

Glass Formers

SiO

2

2.011

Si:Al 6.5

The left side of the table shows us how to mix the glaze, but it tells us nothing of the composition. On the right

hand side of the table, the level of silica (SiO

2

) level of 2.001 violates the first rule of making stable glazes and

indicates instantly this glaze is likely to be unstable. Testing shows you need a unity formula of at least 3.0 SiO

2

and above to produce a stable glaze. Indeed, the Jade Green is found to easily leach copper and barium from

the glaze in an acidic environment.

WEIGHING THE GLAZE MATERIALS

Clean and Tare the scale

Have a good check list avoid interruptions

Wear a face mask / respirator / protective lenses / gloves

MIXING GLAZES:

Dry mix: try not to raise too much dustplease wear respirator / eye protection

Always add powder to water (approx. 90 ccs water per 100 grams of dry glaze mix, i.e., 8000 gram

recipe should take about 1.9 gallons (7.6 Qts) of water.

Dont add dry glaze too fast (dont let it accumulate into a pile on top of the water. Let it sit. Powder

should be completely wetted.

Initial mixing can be done with a spoon, stir stick.

Screen / sieve thru 80 mesh. Some recommend doing this twice, and again before each use.

Dip test with a bisqued shard. Scratch thru and visually examine the thickness of application. If glaze is

a translucent/runny glaze, should be less than 1/16 of an inch thick. Most others no more than 1/16 of

an inch

Specific Gravity: Should be about 1.45 gms/cc. An easy way to measure this is to weigh a container (1 C.

will do) = W

1

; measure and add 100 cc of your glaze. Reweigh = W

2

. Determine Gms/CC = W

2

W

1

/

100 If your Specific Density is greater than 1.45 gms/cc, add more water. If it is less, let the glaze sit

overnight, settle, and carefully remove excess water from top of glaze.

TESTING GLAZES for durability, longevity, safe usage.

Resistance to Acids insert half test tile in vinegar for 3 days. Goal is no color change/bleaching

Resistance to Alkalis (usually in dishwasher) - 5% soda ash (50 gms soda ash in 1 Liter of water), in

stainless steel pot, bring to a boil, reduce to simmer gently. Put in pan, cover, simmer gently for 6 hours.

= 250 cycles in a dishwasher . Goal is no color change

Resistance to Thermal Shock Freeze piece for 2 hrs, then carefully place in boiling water. Look for

cracking, crazing, shivering. Use black ink to bring out cracking. Compare with non-exposed sample.

Microwave Oven proof place test mug in boiling water & let it simmer for 2 hrs (absorbs as much

water as is possible). Take another mug, fill with water. Place both test mug and filled mug in

microwave and nuke on high for 10 seconds (no more). Open carefully. If your test piece is too hot to

handle, it is NOT microwave safe. It is important when conducting this test to have the mug of water

present in the test as you could otherwise damage your microwave.

GLAZE TRIAL BLENDS

Using Existing Glazes

Overlap: 2 Glaze overlaps: Dip one glaze covering most of test tile. Dry. Dip second glaze over 50% of

test tile.

Dry Blends: Using 30 gm quantities of base glaze, add known % of oxides

Wet Blend: Use 2 existing glazes (wet), try blends of 25:75, 50:50, 75:25

Using Base Glazes

Select a base glaze recipe: Matte, Semi-matte, Glossy

Dry Blends: Using 30 gm quantities of base glaze, add known % of oxides. With small quantities, you

must be VERY accurate in weighing the oxides. Recommended amount ranges:

Cobalt Oxide or Carbonate - 1%

Iron Oxide 1 10%

Copper Oxide or Carbonate 2 5%

Chrome 2 5%

Nickel - 3%

Manganese 2 6%

Vanadium Stain 4 10%

Rutile 2 10%

Ilmenite 1 5%

Line Blends / Tri-axial Blends: See Rhodes, Clay and Glazes for the Potter, 1967, Pg 136 - 138

Pg 138 provides a color description of oxide combinations.

Pgs 127 134 provides information on specific oxides.

As well as About.com Pottery Ceramic Glaze Colorants

Wikipedia Ceramic Colorants

General Resources:

Glaze Chemistry (Ceramic Arts Daily

Mid Range Glaze Recipes (Ceramic Arts Daily)

Glossary of terms (Ceramic Arts Daily)

Ceramic Colorants (Ceramic Arts Daily)

Mason Stains Color Charts

MSDS (Material Safety Data Sheets)

S-ar putea să vă placă și

- Pottery Clays and ChemicalsDocument16 paginiPottery Clays and ChemicalsDave SmithÎncă nu există evaluări

- Glaze ChemistryDocument9 paginiGlaze ChemistrydtkraeutÎncă nu există evaluări

- Ceramic Glazing for Beginners: What Every Ceramic Artist Should Know to Get Better GlazesDe la EverandCeramic Glazing for Beginners: What Every Ceramic Artist Should Know to Get Better GlazesEvaluare: 3 din 5 stele3/5 (5)

- The Potter's Craft: A Practical Guide for the Studio and WorkshopDe la EverandThe Potter's Craft: A Practical Guide for the Studio and WorkshopÎncă nu există evaluări

- STA Decorating SlipDocument2 paginiSTA Decorating SlipmohanÎncă nu există evaluări

- Ceramic Frits Guide for Transparent and Opaque GlazesDocument2 paginiCeramic Frits Guide for Transparent and Opaque Glazeslaklain100% (1)

- Crystalline Glaze Class Dan DermerDocument4 paginiCrystalline Glaze Class Dan DermerJesus MorenoÎncă nu există evaluări

- FritDocument4 paginiFritaymanfawzyÎncă nu există evaluări

- Creating A EngobeDocument105 paginiCreating A Engobeduyen nguyen chi luongÎncă nu există evaluări

- CHINESE CERAMICS TECHNOLOGYDocument60 paginiCHINESE CERAMICS TECHNOLOGYEliezer HabaÎncă nu există evaluări

- Crystalline Glaze NotesDocument5 paginiCrystalline Glaze NotesTim Carlson100% (1)

- Introduction To CeramicsDocument29 paginiIntroduction To CeramicsShrikrishna BirajdarÎncă nu există evaluări

- Slips and GlazesDocument3 paginiSlips and GlazesKelley_Eggert_800Încă nu există evaluări

- Ceramic Sculpture GordonDocument4 paginiCeramic Sculpture GordonHugo De Oliveira AssisÎncă nu există evaluări

- Pigments and Engobes For Crystalline Glazes: KnowledgeDocument2 paginiPigments and Engobes For Crystalline Glazes: KnowledgeJesus MorenoÎncă nu există evaluări

- Muy Buenos 3110Document17 paginiMuy Buenos 3110Jesus MorenoÎncă nu există evaluări

- The Sweet Life - Ceramics: Art & PerceptionDocument4 paginiThe Sweet Life - Ceramics: Art & PerceptionBlair SchulmanÎncă nu există evaluări

- Ceramics GlossaryDocument91 paginiCeramics GlossaryMohammad Youssefi100% (1)

- CeramicColor PDFDocument12 paginiCeramicColor PDFSiddharthapachisiaÎncă nu există evaluări

- Ceramic: Interior Design Assignment-IDocument35 paginiCeramic: Interior Design Assignment-IkhizarÎncă nu există evaluări

- Clay and Glaze MaterialsDocument28 paginiClay and Glaze Materialsapi-26965779100% (2)

- Glazes - For The Self-Reliant Potter: Appendix: Glaze RecipesDocument21 paginiGlazes - For The Self-Reliant Potter: Appendix: Glaze RecipesgeertjepÎncă nu există evaluări

- Roger GrahamDocument3 paginiRoger GrahamStefan Van CleemputÎncă nu există evaluări

- Advanced Ceramics SyllabusDocument4 paginiAdvanced Ceramics Syllabusapi-285550989Încă nu există evaluări

- Ceramic Vocabulary ListDocument3 paginiCeramic Vocabulary ListVioh NguyenÎncă nu există evaluări

- Cone 5 - 6 Crystalline GlazesDocument105 paginiCone 5 - 6 Crystalline GlazesVasiliy DyominÎncă nu există evaluări

- Firing Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2Document5 paginiFiring Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2stueferÎncă nu există evaluări

- Porcelain Casting Slip and Plaster Mold TechniquesDocument4 paginiPorcelain Casting Slip and Plaster Mold TechniquesLauraÎncă nu există evaluări

- Ceramic ColorDocument12 paginiCeramic ColorMeisterFidiusÎncă nu există evaluări

- The New Hamburg Pottery: New Hamburg, Ontario 1854-1916De la EverandThe New Hamburg Pottery: New Hamburg, Ontario 1854-1916Încă nu există evaluări

- Electric Kiln Firing TechDocument13 paginiElectric Kiln Firing TechStefan Van CleemputÎncă nu există evaluări

- Ceramic Pigments and GlassesDocument19 paginiCeramic Pigments and GlassesalbaqueÎncă nu există evaluări

- Low Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewDocument20 paginiLow Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewMeiliza HastutiÎncă nu există evaluări

- La Meridiana Notes Paperclay PDFDocument3 paginiLa Meridiana Notes Paperclay PDFAnonymous FF4JjPdgÎncă nu există evaluări

- Clay Culture - Blue Kashi Tiles - Ceramic Arts NetworkDocument7 paginiClay Culture - Blue Kashi Tiles - Ceramic Arts NetworkcomsianÎncă nu există evaluări

- Glazes RawMaterialsDocument16 paginiGlazes RawMaterialsVikash Agarwal100% (2)

- 08 Chapter 4Document8 pagini08 Chapter 4Ali AliÎncă nu există evaluări

- Introduction To Glaze CalculationDocument4 paginiIntroduction To Glaze CalculationThongMaVanÎncă nu există evaluări

- Greenwich House Pottery Clay and GlazeDocument18 paginiGreenwich House Pottery Clay and GlazeMohammad Youssefi100% (1)

- Firing Temperatures: & Cone EquivalentsDocument2 paginiFiring Temperatures: & Cone EquivalentsIcy45Încă nu există evaluări

- Ten Cone 10 RecipesDocument7 paginiTen Cone 10 RecipesStefan Van Cleemput100% (1)

- Preparing & Storing GlazeDocument4 paginiPreparing & Storing GlazeGianmarcoMolinaÎncă nu există evaluări

- 15 Cone 10 RecipesDocument10 pagini15 Cone 10 RecipesInga NowakÎncă nu există evaluări

- Ceramics Vocabulary GuideDocument3 paginiCeramics Vocabulary Guidehaana duggerÎncă nu există evaluări

- Self Reliant PotterDocument116 paginiSelf Reliant PotterYaroslav MatviychukÎncă nu există evaluări

- Utilizing Broken Glass in Ceramic ProductionDocument7 paginiUtilizing Broken Glass in Ceramic ProductionJane Michelle EmanÎncă nu există evaluări

- Stoneware MaturityDocument3 paginiStoneware MaturityLÎncă nu există evaluări

- 15 Raku Glazes NEWDocument9 pagini15 Raku Glazes NEWartist73Încă nu există evaluări

- Iridescent and Manganese Glaze RecipesDocument37 paginiIridescent and Manganese Glaze Recipesvolkan100% (4)

- Ceramic FritsDocument6 paginiCeramic FritsMohammad YoussefiÎncă nu există evaluări

- 407 Studio Process Sheet Ceramics 2Document5 pagini407 Studio Process Sheet Ceramics 2api-583626725Încă nu există evaluări

- How To Design, Make, and Install and Murals: Ceramic TilesDocument19 paginiHow To Design, Make, and Install and Murals: Ceramic TilesChanrathÎncă nu există evaluări

- Rutile Oct17Document2 paginiRutile Oct17api-308735650100% (3)

- Clay Packet GuideDocument4 paginiClay Packet Guideapi-290985916100% (1)

- Ceramics Monthly (Dec 91)Document90 paginiCeramics Monthly (Dec 91)Wade MacMorrighanÎncă nu există evaluări

- Discover the History and Uses of Ceramic MaterialsDocument7 paginiDiscover the History and Uses of Ceramic Materialsletter_ashish4444Încă nu există evaluări

- Studies in Glazes P 212 Pur DDocument112 paginiStudies in Glazes P 212 Pur DThongMaVanÎncă nu există evaluări

- A Study of CA-Mg Silicate Crystalline Glazes - An Analysis On Forms of CrystalsDocument5 paginiA Study of CA-Mg Silicate Crystalline Glazes - An Analysis On Forms of CrystalsThongMaVanÎncă nu există evaluări

- Kilns and Brick Making Rough DraftDocument34 paginiKilns and Brick Making Rough DraftDennis B DevilleresÎncă nu există evaluări

- Carty Nceca 2012Document23 paginiCarty Nceca 2012ThongMaVanÎncă nu există evaluări

- Glaze Chemistry Primer: Hamilton Williams, JRDocument22 paginiGlaze Chemistry Primer: Hamilton Williams, JRThongMaVan100% (1)

- Kilns and Brick Making Rough DraftDocument34 paginiKilns and Brick Making Rough DraftDennis B DevilleresÎncă nu există evaluări

- Chemically Reduced Copper Reds in Oxidation FiringsDocument8 paginiChemically Reduced Copper Reds in Oxidation FiringsAlexandre Oliveira100% (1)

- Journal of Materials Science 47 (2012) 553-582Document53 paginiJournal of Materials Science 47 (2012) 553-582ThongMaVanÎncă nu există evaluări

- Chapter 02Document31 paginiChapter 02ThongMaVanÎncă nu există evaluări

- Introduction To Glaze CalculationDocument4 paginiIntroduction To Glaze CalculationThongMaVanÎncă nu există evaluări

- 9 Studyofheatdistr08bleiDocument52 pagini9 Studyofheatdistr08bleiThongMaVanÎncă nu există evaluări

- Tuynel ThongDocument73 paginiTuynel ThongThongMaVanÎncă nu există evaluări

- Gas Kiln ManualDocument46 paginiGas Kiln ManualrivrsideÎncă nu există evaluări

- Kiln DryingDocument20 paginiKiln DryingIndera Pradana100% (1)

- An Improved Pottery Kiln Design Saves 40% FuelDocument9 paginiAn Improved Pottery Kiln Design Saves 40% FuelTefera Adugna100% (1)

- 9.electric KilnbuildingDocument55 pagini9.electric KilnbuildingThongMaVanÎncă nu există evaluări

- 9.FinalBrick.11Aprl Print VersionDocument164 pagini9.FinalBrick.11Aprl Print VersionThongMaVanÎncă nu există evaluări

- Recycle GasDocument8 paginiRecycle GasThongMaVanÎncă nu există evaluări

- Glazes and Glazes CoatingDocument343 paginiGlazes and Glazes CoatingMar Yam80% (10)

- Brick Energy Conservation Pollution ControlDocument29 paginiBrick Energy Conservation Pollution Controlindiamillers100% (1)

- Recycle GasDocument8 paginiRecycle GasThongMaVanÎncă nu există evaluări

- Cs1198811enc 001Document28 paginiCs1198811enc 001ThongMaVanÎncă nu există evaluări

- Ceramic GlazesDocument10 paginiCeramic GlazesLucia Sueli Taguchi100% (3)

- Heat Transfer-Literature ReviewDocument84 paginiHeat Transfer-Literature Reviewnewcastle74Încă nu există evaluări

- Tuynel ThongDocument73 paginiTuynel ThongThongMaVanÎncă nu există evaluări

- Gas Kiln Design & FiringDocument10 paginiGas Kiln Design & FiringStefan Van Cleemput100% (2)

- Rudolf Arnheim The Authenticies of The PhotMedia 1993Document4 paginiRudolf Arnheim The Authenticies of The PhotMedia 1993ZelloffÎncă nu există evaluări

- Single-Text AnalysisDocument4 paginiSingle-Text AnalysisbraesalÎncă nu există evaluări

- The Decorated DiagramDocument67 paginiThe Decorated DiagrammohammedÎncă nu există evaluări

- VISUAL ARTS NotesDocument3 paginiVISUAL ARTS NotesMaika Alex CalunodÎncă nu există evaluări

- Fibonacci Numbers and the Golden SectionDocument52 paginiFibonacci Numbers and the Golden SectionBharath T S100% (1)

- Elements of Visual Arts ExplainedDocument6 paginiElements of Visual Arts ExplainedMajalita DucayÎncă nu există evaluări

- Pretty CVDocument3 paginiPretty CVapi-277852952Încă nu există evaluări

- Elements of ArtsDocument13 paginiElements of ArtsYejin ChoiÎncă nu există evaluări

- THESIS TOPIC: Hyderabad Habitat Center: Name: Dhvani Patel Roll. No.: 18 Subject: ADSDocument7 paginiTHESIS TOPIC: Hyderabad Habitat Center: Name: Dhvani Patel Roll. No.: 18 Subject: ADSDhoni PatelÎncă nu există evaluări

- Emancipated Muses - Gwen John and Camille ClaudelDocument30 paginiEmancipated Muses - Gwen John and Camille Claudelapi-19512442100% (1)

- ĐỀ 1Document14 paginiĐỀ 1leng971424Încă nu există evaluări

- Thomas Hirschhorn Biography and ExhibitionsDocument31 paginiThomas Hirschhorn Biography and ExhibitionsSylvia RüttimannÎncă nu există evaluări

- Introduction to Neoclassicism and Its Influence on Literature and ArtDocument9 paginiIntroduction to Neoclassicism and Its Influence on Literature and ArtsubirÎncă nu există evaluări

- Types of Performing ArtsDocument4 paginiTypes of Performing ArtsKevin Cruz0% (1)

- Hitachi Construction Machinery MPDR Tier 4 With Adj Ver 2 48-0-0 Diagnostic Software DVDDocument22 paginiHitachi Construction Machinery MPDR Tier 4 With Adj Ver 2 48-0-0 Diagnostic Software DVDtonyagriffin051092spw100% (54)

- FinertsDocument35 paginiFinertsMoonisha RbÎncă nu există evaluări

- Wonders of The World QuizDocument3 paginiWonders of The World QuizLEELA MOLOYOS SITOUNÎncă nu există evaluări

- The History of Painting in Italy Vol. IV by Luigi Antonio LanziDocument197 paginiThe History of Painting in Italy Vol. IV by Luigi Antonio LanziSridhar BandiÎncă nu există evaluări

- Vassileva Paphlagonia BAR2432Document12 paginiVassileva Paphlagonia BAR2432Maria Pap.Andr.Ant.Încă nu există evaluări

- Art Appreciation 1Document13 paginiArt Appreciation 1graceconogana1Încă nu există evaluări

- Module-4-6 - Art AppreciationDocument8 paginiModule-4-6 - Art AppreciationAngel Von Heart PandesÎncă nu există evaluări

- 5 Best Recipes For Paper MacheDocument6 pagini5 Best Recipes For Paper Machetamaraiivana100% (5)

- Makigami: Recycle Newspaper Into Beautiful JewelryDocument77 paginiMakigami: Recycle Newspaper Into Beautiful JewelryBenjamin Coleman100% (6)

- Ganjifa: Mysore PaintingDocument18 paginiGanjifa: Mysore PaintingYakshit GoelÎncă nu există evaluări

- Tanpura 1Document10 paginiTanpura 1Jitender GoyalÎncă nu există evaluări

- Contemporary Filipino Artists To KnowDocument1 paginăContemporary Filipino Artists To KnowCharmille ArcenoÎncă nu există evaluări

- Title Block Idp UpdatedDocument1 paginăTitle Block Idp UpdatedNurul SyahirahÎncă nu există evaluări

- MAPEH 10 Q1 - Week 4 (Arts)Document4 paginiMAPEH 10 Q1 - Week 4 (Arts)Edsel BelbarÎncă nu există evaluări

- Kengo Kuma & AssociatesDocument118 paginiKengo Kuma & AssociatesXshan NnxÎncă nu există evaluări

- Development of Visual Arts in the PhilippinesDocument4 paginiDevelopment of Visual Arts in the PhilippinesRandyÎncă nu există evaluări