Documente Academic

Documente Profesional

Documente Cultură

CPR Techniques in Ontario - 15 Years Experience

Încărcat de

shauhramDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CPR Techniques in Ontario - 15 Years Experience

Încărcat de

shauhramDrepturi de autor:

Formate disponibile

CPR TECHNIQUES IN ONTARIO

- 15 YEARS EXPERIENCE

Thomas J. Kazmierowski, P.Eng.

Manager, Pavements and Foundations Section

Tom.Kazmierowski@mto.gov.on.ca

Susanne Chan, M.A.Sc., P.Eng.

Pavement Design Engineer

Susanne.Chan@mto.gov.on.ca

Ministry of Transportation of Ontario

Materials Engineering and Research Office

Pavements and Foundations Section

Room 232, Central Building, 1201 Wilson Avenue

Downsview, Ontario M3M 1J8 Canada

Telephone: (416) 235-3512

Fax: (416) 235-3919

Paper prepared for presentation at the

Very Long-Term Life-Cycle Analysis of Pavements

Determining the True Value of Our Investment (B)

of the 2005 Annual Conference of the

Transportation Association of Canada

Calgary, Alberta

ABSTRACT

In the summer of 1989, the Ministry of Transportation of Ontario (MTO) undertook the

rehabilitation of an exposed concrete pavement exhibiting various distress

manifestations. Highway 126 in Southwestern Ontario is a four-lane divided arterial with

22,000 AADT and 9.6% commercial traffic in year 2000. The existing pavement,

originally constructed in 1963, consisted of 230 mm mesh reinforced Portland Cement

Concrete (PCC) pavement with dowelled joints at a spacing of 21.3 m.

The rehabilitation of the highway in the northbound lanes (NBL), which had experienced

moderate deterioration, consisted of using the latest concrete pavement rehabilitation

(CPR) techniques, material specifications and construction methods. The rehabilitation

techniques included full depth repair, partial depth repair, diamond grinding and joint

sealant replacement. The southbound lanes (SBL) received a 180 mm thick plain

jointed unbonded PCC overlay to address the severe 'D' cracking and spalling at all the

joints and cracks.

This paper will discuss the fifteen-year evaluation of this rehabilitated pavement in terms

of roughness measurements using the Automatic Roughness Analyzer (ARAN),

frictional resistance measured with the ASTM brake-force trailer, and Pavement

Condition Ratings. Also included will be a discussion on subsequent localized concrete

pavement repair work completed on the highway during the fifteen years.

Monitoring the performance of the pavement over the last fifteen years has indicated

that locations for partial depth repairs must be chosen judiciously to ensure that they are

not greater than one-third of the slab depth. Where existing pavement joints have

seized and full depth repairs are constructed at mid-slab, further deterioration of

secondary minor transverse cracks can occur. Consideration should be given to

carrying out full depth repairs at these locations during initial construction. Although

diamond grinding significantly improved the ride of the rehabilitated pavement, the initial

improvement in skid resistance has dissipated so that after fifteen years, the average

SN

80

is 7 units lower than the burlap dragged/tined surface.

Overall, the rehabilitated concrete pavement, both NBL and SBL, is performing well,

with acceptable levels of ride quality, frictional resistance and distress propagation.

1.0 INTRODUCTION

Until 1989 the traditional method of rehabilitating concrete pavements in Ontario was to

remove the distressed concrete full depth or partial depth and replace it with asphaltic

concrete. Although these repairs performed well in the short-term, in the long-term the

hot mix patches would begin to distort and crack resulting in a rough ride. During the

mid to late 1980's, significant advances in concrete pavement rehabilitation (CPR)

techniques in North America were achieved allowing the restoration of rigid pavements

1

with concrete. This maintained the integrity of the PCC slabs and the long-term benefits

of concrete. A site was selected in the late 1980's to demonstrate various restoration

techniques, including methods that had not previously been utilized in Ontario.

At the time of construction, this project utilized the most comprehensive CPR

techniques undertaken in Canada. The demonstration site is located on Highway 126,

a 5 km urban arterial facility in London, Ontario. The highway has since been assumed

by the City of London and is now known as Highbury Avenue. Rehabilitation techniques

included partial and full depth repairs and diamond grinding on the northbound lanes

and an unbonded concrete overlay on the southbound lanes. Construction was

completed late in the summer of 1989.

2.0 BACKGROUND

2.1 General

Highbury Avenue is located approximately 200 kilometres west of Toronto. It is a four-

lane divided arterial, with an AADT of 22,000, and 9.6% commercial vehicles in year

2000. According to the year 2000 traffic study data, the southbound commercial vehicle

traffic is 11.3%, which is significantly higher than the northbound traffic of 7.9%.

The original pavement was constructed in 1963 with 225 mm of mesh reinforced PCC

(JRCP) on 300 mm of granular base and subbase materials. The pavement was

constructed with a 21.3 m joint spacing with dowel bars at the transverse joints. The

joints were sealed with preformed neoprene seals.

The pavement serviceability in 1989 varied dramatically between the northbound and

southbound lanes. The general pavement condition of the northbound lanes was

considered better than average considering the 26-year service life. The distresses on

these lanes consisted of approximately three transverse cracks per slab, with one being

a severe working crack and two slight cracks, occasional spalling at joints and cracks,

and a moderately polished surface. Typically the transverse contraction joints had

seized, leading to the severe mid-slab working cracks. Minimal faulting (stepping) was

exhibited at the joints. The joint seals were approximately 85% intact, although there

was significant bond failure between concrete and sealant throughout.

The pavement on the southbound lanes was in much poorer condition, with full and

partial width transverse cracks in each slab, severe D-cracking, spalling of all joints

throughout, and moderate pavement edge break-up.

The variance in the 26-year pavement performance was attributed to the different

aggregate types used in the concrete on the opposing lanes. The quarried aggregate

used on the southbound lanes exhibited absorptive characteristics and was highly

susceptible to D-cracking under freeze/thaw conditions. A pit run gravel source was

2

used for the coarse aggregate on the northbound lanes, which did not exhibit this D-

cracking performance characteristic.

Three rehabilitation strategies were considered:

crack and seat with an asphalt overlay;

repair of the PCC pavement with hot mix and a multiple lift asphalt overlay; and

full depth repairs and spall repairs with concrete plus diamond grinding on the

northbound lanes; and placement of an unbonded concrete overlay on the

southbound lanes.

The estimated initial construction costs for the three options varied from $1.5 to

$1.8 million, however, the total life cycle costs over 30 years were similar. The option of

concrete repairs with PCC, diamond grinding and an unbonded concrete overlay was

selected, as it best addressed the actual performance deficiencies exhibited by the

pavement and provided the longest anticipated service life.

2.2 Design

The PCC rehabilitation techniques utilized on the northbound lanes incorporated the

latest designs and construction procedures. The design of the full depth repairs

included a minimum repair width of 2.0 m with epoxy coated dowel bars epoxied into

drilled holes spaced at 300 mm on both transverse faces. Also, the existing concrete

had to be removed in such a manner as not to disturb the underlying granular base.

See Figure 1 below for the full depth repair operation.

Figure 1. Typical Full Depth Repair in NBL

3

The partial depth repair requirements included sawcutting the perimeter to a depth of

50 mm, removal of loose concrete, and sandblasting of the final exposed surfaces. A

cement paste was applied immediately prior to concrete placement. The designs used

are fully detailed in [1].

The design of the unbonded concrete overlay on the southbound lanes included the

placement of a 20 mm asphaltic sand hot mix bondbreaker over the existing pavement

surface. Then overlain by a 180 mm thick unreinforced plain jointed concrete

pavement. Slipforming of the concrete overlay used revised specifications based on

experience gained on an earlier MTO demonstration project on Highway 3N, which

placed and monitored four types of experimental concrete pavements [2, 3]. Skewed

randomized joints were utilized with no effort made to avoid matching the underlying

joints. See Figure 2 below for the slipform paving of the unbonded concrete overlay.

Figure 2. Slipforming Unbonded Concrete Overlay in SBL

2.3 Construction

There were some initial difficulties with the removal of the existing concrete for the full

depth repairs without disturbing the granular base. Once this was resolved, the

construction of the concrete repairs, diamond grinding, and the unbonded overlay went

smoothly. Details of the construction procedure and material testing have been

published in the earlier report [1].

2.4 Maintenance

Routine maintenance is required to prolong the pavement structure. Maintenance

activities included resealing of cracks and joints, as well as some full depth and partial

4

depth concrete repairs performed in the NBL in years 1995 and 2000. SBL activities

included resealing of cracks and joints plus minor full depth and partial depth concrete

repairs in 1997.

The remedial work carried out on both NBL and SBL after the last major rehabilitation in

1989 were summarized in Table 1 below:

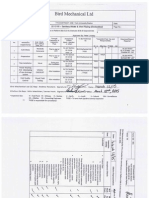

Table 1. Remedial Works Carried Out after Major Rehabilitation

Year Location Types & Quantities of Repair

1994 Northbound lanes Full depth repair - 800 m

2

Partial depth repair - 35 m

2

1995 Northbound lanes Resealing of joints and cracks - 375 m

1997 Southbound lanes Full depth repair 535 m

2

Partial depth repair 10 m

2

Resealing of joints and cracks 110 m

2000 Northbound lanes Full depth repair 1300 m

2

Partial depth repair 20 m

2

Resealing of joints and cracks 810 m

3.0 PAVEMENT PERFORMANCE

3.1 Pavement Distress Survey

The visible distresses in the pavement surface were surveyed using the ministry's Rigid

Pavement Evaluation Procedure [4] to provide an overall indication of pavement

performance.

3.1.1 Northbound Lanes At 3 years of service

In 1992, after three years, seven of the 266 full depth repairs were exhibiting a very

slight longitudinal cracking in the right wheelpath of the driving lane. In a few locations,

these cracks began to propagate into the adjacent slabs. No signs of movement or

faulting of the repairs were observed.

At that time, approximately half of the 75 partial depth repairs were exhibiting distress.

The majority of the failures were in the driving lane and in the outside third of the slab.

In 1992 a limited investigation of a few partial depth repairs was undertaken. The

investigation revealed that the partial depth repairs had extended to the level of the

dowel bars, with associated joint movements resulting in rapid deterioration (cracking

and spalling) occurring at the repairs. This reaffirms the generally accepted practice of

5

not undertaking partial depth repairs for depths greater than one third the slab depth or

where shallow dowel bars/reinforcing meshes are encountered [5]. Cores were taken

through some slabs where the partial depth repairs did not exhibit any cracking. In

these uncracked repairs, the replacement did not exceed a third of the slab depth and

bond between the old and new concrete was excellent. In the deteriorated repairs,

bond between the old and new concrete was also very good, indicating the weakness or

spalling in the slab extended below the repair level. These findings confirm the

importance of critical assessment of where partial depth repairs should be used.

3.1.2 Northbound Lanes At 5 years of service

In 1994 a detailed distress survey was also carried out indicating that further full depth

repairs were required. A total of 96 areas requiring full depth repairs (including 13 of the

original repairs) and 16 new partial depth repairs were identified. Pavement monitoring

has revealed that where existing pavement joints are seized (non-working), and full

depth repairs are constructed at mid-slab working cracks, future deterioration of

secondary minor transverse cracks, requiring full depth repairs, may occur.

Consideration should be given to carrying out full depth repairs at the time of initial

rehabilitation or scheduling them at a future date. The majority of the full depth repair

locations required the minimum one lane width by 2.0 m long repair. The partial depth

repairs were all one-half a square meter in size. An additional 46 cracks identified that

need to be removed and replaced did not exist or were not wide enough to require full

depth repairs a the time of original construction.

In the summer of 1994, the City of London completed 96 full depth and 16 partial depth

repairs along with limited joint and crack resealing. The repairs were completed in the

same manner as the original repairs as detailed in [1], except that the surface of the

repairs was not diamond ground but tined longitudinally by hand, while the concrete was

plastic.

3.1.3 Northbound Lanes At 10 years of service

In 1999, the survey of the northbound lanes indicated that a few of the new repairs have

cracked in the wheelpath of the driving lane, as happened with the original repairs.

These cracks are slight in severity. There was also some slight spalling of the repairs

and original concrete at the joints and cracks.

3.1.4 Northbound Lanes At 15 years of service

A recent survey of the northbound lanes in Fall 2004 indicates the pavement is in fair to

good condition, with a Pavement Condition Rating (PCR) of 63 in the driving lane, and

70 in the passing lane. MTOs Pavement Condition Rating (PCR) is a composite

pavement serviceability index ranging from 0 to 100; with the higher rating indicating a

better pavement condition. Routing and sealing of cracks and joints, plus additional full

depth and partial depth concrete repairs was carried out in early 2000. Most of the

6

joints and cracks are performing well. There were a few moderate faulted joints and

intermittent moderate joint and crack spalls. In addition, extensive severe pavement

edge drop off was identified. See Figure 3 below showing the typical northbound lanes

performance in 2004 adjacent to full depth repair.

Full depth repair

Figure 3. Typical NBL Pavement Condition

3.1.5 Southbound Lanes At 10 years of service

There were minimal distresses identified in southbound lanes for the first 9 years, until

1999 the only distress observed in the southbound lanes is slight longitudinal cracking

in 11 of the driving lane slabs. This can probably be attributed to inadequate

longitudinal joint construction (i.e., delayed saw cutting) as the cracks were visible soon

after construction. No transverse or reflection cracking has been observed, which

correlates with other agencies' experience [6].

3.1.6 Southbound Lanes At 15 years of service

7

A recent survey of the southbound lanes in Fall 2004 indicates the pavement is in good

condition with Pavement Condition Rating (PCR) of 70 in the driving lane, and 78 in the

passing lane. In 1997, southbound lanes maintenance activities included routing and

sealing of cracks and joints, as well as a few full depth and partial depth concrete

repairs. There were a few moderate joint and crack spalls, localized slight faulting at

the joints, and intermittent very severe pavement edge drop off. The longitudinal cracks

identified in 1999 are now of moderate severity. In addition, a few severe reflection

diagonal cracking and occasional moderate transverse cracking were identified. See

Figure 4 below for the typical southbound lanes condition showing localized slight

faulting at the joint.

Figure 4. Typical Condition of Unbonded Concrete Overlay, SBL

3.2 Roughness Measurements

Roughness was measured just after construction, prior to opening to traffic, using the

California Profilograph. The Portable Universal Roughness Device (PURD) was initially

used for ongoing roughness monitoring on a yearly basis. In 2001, the Automatic Road

Analyzer (ARAN) replaced the PURD to collect International Roughness Index (IRI)

based measurements.

The profilograph measurements were taken on the new concrete overlay with readings

taken in both wheelpaths of the driving and passing lanes. For details on the function

and operation of a profilograph, refer to [7]. The average profilograph reading (profile

index) for the length of the project in the driving lanes was 175 mm/km and 169 mm/km

in the passing lanes. These readings were taken prior to diamond grinding the 21

locations where the roadway did not meet the surface tolerance specifications of 3 mm

in 3 m. For this demonstration project, the initial ride measured with the profilograph

indicated that it met the smoothness requirements expected of a new exposed concrete

pavement.

8

Roughness measurements using the PURD were taken until 2000. The PURD is a

trailer-mounted, accelerometer-based mechanical measuring device operated at

constant highway speed that uses the root mean square vertical acceleration of the

trailer axle to measure roughness. PURD measurements are converted into a ride

comfort index (RCI) using a transfer function for application in Ontario's Pavement

Management System. RCI is based on a scale from 0-10, with 10 considered a smooth

and pleasant ride.

Since 2001, the ARAN is used to collect roughness data. The ARAN consists of a van,

equipped with various testing and data logging systems traveling at highway speed.

Rutting is measured (in mm) by a series of ultrasonic sensors that are mounted to an

aluminum smart bar at the front of the van. Roughness is measured in the wheelpaths

and converted into an International Roughness Index (IRI) value. IRI is a roughness

measure with scale of mm/m (or m/km). The IRI scale starts from 0 mm/m which

represents absolute smoothness. The lower the IRI value, the smoother the pavement.

Testing for roughness was undertaken prior to rehabilitation, after rehabilitation just prior

to opening to traffic, and on an annual basis since. For ease of comparison and

consistency, all roughness measurements collected using ARAN are converted from IRI

to RCI.

3.2.1. Northbound Lanes

The roughness improved significantly after the concrete pavement surface was diamond

ground in 1989, with an improvement in RCI from initially 5.6 to 9.4 and 6.7 to 9.4 in the

driving and passing lanes respectively. The ride quality levels (smooth, comfortable,

uncomfortable) indicated on the graph are converted based on the established RCI.

The ride data for the diamond ground surface indicates that the initial roughness value

deteriorated to an approximate value of 7.7 after two years and has remained fairly

constant over the next three years. These RCI values are in the comfortable range of

the ride categories.

The maintenance history indicated the northbound lanes were rehabilitated in 1995 and

2000 with resealing of cracks and joints, as well as some full depth and partial depth

concrete repair. Due to an incorrectly correlated transfer function used to convert

PURD measurement to RCI coupled with several additional cycles of remedial work,

roughness results from 1996 to 2000 are out of trend, see Figure 5.

9

0

1

2

3

4

5

6

7

8

9

10

1989 1990 1991 1992 1993 1994 1995 1996 1997 1999 2000 2001 2002 2003 2004

Year

R

C

I

Driving Lane

Passing Lane

Resealing of cracks

& joints and f ull &

partial depth repair

Smooth

Comfortable

Uncomfortable

Very Rough

Dangerous

Figure 5. Summary of Roughness (RCI) in NBL

The ARAN surveys from 2001 to 2004 indicates the roughness remained constant over

these years, with an average RCI of 7.0 and 7.6 for the driving and passing lane

respectively. Overall, the northbound lanes rehabilitated using full CPR techniques are

still performing within the comfortable range, after 15 years of service.

3.2.2 Southbound Lanes

The unbonded overlay on the southbound lanes resulted in an improvement in

roughness in RCI from 5.6 to 7.9 and 6.5 to 8.0 in the driving and passing lanes

respectively; see Figure 6. The newly tined surface texture on the unbonded overlay

was very aggressive and may have contributed to some of the initial roughness. The

roughness in both the passing and driving lanes in the southbound direction have had

fairly constant RCI values from 1990 to 1995, with an average RCI of 7.6 and 7.8 in the

driving and passing lane respectively.

The RCI roughness values between 1996 to 2000 appear elevated as a result of an

erroneous transfer function used in converting PURD measurements into RCI values.

The conversion was based on limited correlation data.

The survey from 2001 to 2004 indicates the roughness remained fairly constant over

these years, with an average RCI of 6.7 and 7.2 for the driving and passing lane

respectively. Overall, the southbound lanes are in the comfortable category, indicating

that after 15 years service, the unbonded concrete overlay treatment is performing well

within anticipated life cycle parameters.

10

0

1

2

3

4

5

6

7

8

9

10

1989 1990 1991 1992 1993 1994 1995 1996 1997 1999 2000 2001 2002 2003 2004

Year

R

C

I

Driving Lane

Passing Lane

Resealing of cracks

& joints and full &

partial depth repair

Resealing of cracks

& joints and full &

partial depth repair

Smooth

Comfortable

Uncomfortable

Very Rough

Dangerous

Figure 6. Summary of Roughness (RCI) in SBL

3.3 Skid Testing

The skid resistance of the pavement was measured with a brake-force trailer

conforming to ASTM Standard E274. The measured friction force is described as a skid

number (SN) at a specific speed; for example, SN

80

is the skid number at 80 km/h. A

skid number is the average coefficient of friction across the test interval with a practical

range from 10 to 60 (the higher the better).

3.3.1 Northbound Lanes

On the diamond ground surface, the skid numbers improved just after construction in

1989, from an average of 25 and 35 to 48 and 49 for the driving and passing lanes

respectively. Skid numbers of this magnitude indicate a good friction factor and are

similar to numbers obtained on premium hot mix surface courses in Ontario [8]. Over

the last fifteen years, the skid resistance appears to be consistent in the range of 24 to

33 (average of 27) for driving lane, range of 30 to 39 (average of 35) for the passing

lane, see Figure 7.

These values are approximately 7 units lower than the results of the burlap dragged and

tined texture on the southbound lanes. The fractured ridges in the diamond ground

surface have worn away fairly quickly under high traffic and heavy winter maintenance

activities. The micro-texture created with diamond grinding may not be as durable as

11

that created by the burlap drag/tined texture resulting in an earlier reduction in

measured frictional properties.

0

5

10

15

20

25

30

35

40

45

50

1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2003 2004

Year

S

N

(

8

0

k

m

/

h

r

)

Driving Lane

Passing Lane

Figure 7. Summary of Average SN

80

in NBL

3.3.2 Southbound Lanes

The skid numbers in the southbound lanes increased to an average SN

80

of 55 for both

lanes after the overlay in 1989, from an SN

80

of 18 and 29 in the driving and passing

lanes respectively. The skid resistance has stayed fairly constant since construction

with the driving lanes ranging from 31 to 39 (average of 34) and the passing lanes

ranging from 37 to 45 (average of 41). See Figure 8 for a summary of the skid

resistance in the southbound lanes.

As anticipated, in the first year the initial sharp projections of the burlap drag/tined

surface have been worn, polished and sheared off by traffic and snow removal

operations.

12

0

5

10

15

20

25

30

35

40

45

50

1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2003 2004

Year

S

N

(

8

0

k

m

/

h

r

)

Driving Lane

Passing Lane

Figure 8. Summary of Average SN

80

in Southbound Lanes

3.4 Sound Level Measurements

Sound level measurements were undertaken prior to and following rehabilitation to

provide data for future projects. The procedure used to measure pavement noise on

this project was to measure noise from individual vehicle pass-bys at a 15 m distance

from the travelled lane. The results indicated that the diamond ground surface was

approximately 1 dBA quieter than the old worn concrete surface and the MTO sample.

The diamond ground surface was only 1 dBA louder than an open graded asphalt

friction course, which is used for its low noise characteristics and good skid resistance.

The MTO sample was obtained from [9] was derived by testing several hundred

vehicles on a variety of pavement surfaces, predominantly asphaltic concrete, across

the province.

The burlap dragged and transversely tined concrete surface was approximately 1 dBA

noisier than the old worn concrete and MTO sample. For further details on the sound

emission measurements see [1].

4.0 CONCLUSIONS

1. Diamond grinding has significantly improved and restored the ride quality of an old

unfaulted concrete pavement over the fifteen-year monitoring period. Initially,

diamond grinding of the northbound lanes was also very effective in restoring

13

pavement skid resistance. However, after a few years the beneficial effect of

diamond grinding on skid resistance has dissipated. After 15 years of service,

average measured SN

80

values of the diamond ground surface were approximately

7 units lower than that of the burlap drag/tined surface.

2. Visual observations of partial depth repairs in the northbound lanes, in conjunction

with core analysis, confirms the importance of both construction quality and judicious

selection of repair locations on the effectiveness and durability of partial depth

concrete repairs. The partial depth repairs that extended to the level of dowel bars

resulted in rapid deterioration (cracking and spalling) of the repairs.

3. Pavement monitoring of the northbound lanes has revealed that where existing

pavement joints are seized (non-working), and full depth repairs are constructed at

mid-slab working cracks, ongoing deterioration of secondary minor transverse

cracks, requiring subsequent full depth repairs, may occur. Consideration should be

given to carrying out additional full depth repairs at the time of initial rehabilitation or

scheduling them at a future date.

4. The 15-year performance of the unbonded 180 mm thick overlay on the southbound

lanes has been good with acceptable ride quality and skid resistance, and with

occasional reflection cracking and slight faulting at the joints.

5. As anticipated, due to less truck traffic, the overall performance of the passing lane

for both northbound and southbound is better than the driving lane.

6. The PCR for the southbound lanes is higher than for the northbound lanes; however,

the corresponding RCI values show the opposite trend. The northbound lanes are

experiencing greater distress features which have not, as of yet, been reflected in

the ride quality. See Table 2 below for a summary of the pavement performance.

7. To add to the body of knowledge on concrete pavement rehabilitation (CPR)

techniques and to obtain data on life cycle costing of CPR strategies, the monitoring

of pavement performance and pavement maintenance on this project will continue.

The serviceability of this concrete pavement, after 15 years since major rehabilitation,

has been good with acceptable levels of ride, frictional resistance, and distress

propagation. The knowledge gained on this project has been successfully used on

numerous rigid pavement rehabilitation contracts in Ontario.

14

Table 2. Summary of Pavement Performance after 15 Years

PERFORMANCE

AT YEAR 15

NORTHBOUND SOUTHBOUND

Distress

Intermittent, moderate

joint and crack spalls

Few, moderate faulting

along the joints

Extensive, edge of

pavement drop off (25

mm)

Few, moderate joint and

crack spalls

Intermittent, slight faulting

along the joints

Occasional, moderate

transverse cracking

Frequent pavement edge

drop off (25 to 50 mm)

PCR* 67 74

RCI* 7.3 6.8

SN

80

* 28 35

Ride Quality Comfortable Comfortable

* These values are the average of driving and passing lanes readings.

5.0 REFERENCES

1. Kazmierowski, T.J., and Sturm, H.J. Concrete Pavement Rehabilitation and

Overlay: Ontario's Experience, Presented TRB 70th Annual Meeting, 1991, and

published in Transportation Research Record 1307.

2. Kazmierowski, T.J., Wrong, G.A., and Phang, W.A. Design Construction,

Performance of Four Experimental Concrete Pavement Sections in Ontario.

Ministry of Transportation Report, December 1985.

3. Kazmierowski, T.J., and Bradbury, A. Ten Years Experience with Experimental

Concrete Pavement Sections in Ontario. Proceedings 5th International

Conference on Concrete Pavement Design and Rehabilitation, Purdue University,

1993.

4. Chong, G.J., Wrong, G.A., Prakash, A. Manual for Condition Rating of Rigid

Pavements. Ministry of Transportation of Ontario Report SP-026, 1995.

5. Hall, K.T., Darter, M.I., Snyder, M.B., and Charpenter, S.H. "Nation Wide

Performance of Concrete Pavement Rehabilitation. Proceedings 4th International

Conference on Concrete Pavement Design and Rehabilitation, Purdue University,

1989.

15

6. Hall, K.T., Darter, M.I., and Elliott, R.P. Revision of AASHTO Pavement Overlay

Design Procedures. Presented TRB 71st Annual Meeting, 1992.

7. Chojnacki, B. Development of Special Provisions for the Acceptance of Lean

Concrete Base and Concrete Pavement. Ministry of Transportation of Ontario

Report M-76.

8. Ryell, J., Corkill, J.T., and Musgrove, G.R. Skid Resistance of Bituminous

Pavement Test Sections-Highway 401, Toronto Bypass. Ministry of

Transportation of Ontario Report IR67, 1978.

9. Jung, F.W., Blaney, C.T., and Kazakov, A.L. Noise Emission Levels for Vehicles in

Ontario. Ministry of Transportation of Ontario Report.

16

S-ar putea să vă placă și

- CPR Techniques in Ontario - 15 Years ExperienceDocument17 paginiCPR Techniques in Ontario - 15 Years ExperienceRavinder kumarÎncă nu există evaluări

- The Rehabilitation of The Oldest Transit Tunnel in The United StatesDocument8 paginiThe Rehabilitation of The Oldest Transit Tunnel in The United StatesHarold TaylorÎncă nu există evaluări

- White ToppingDocument7 paginiWhite ToppingMuhamMed UvaiZe0% (1)

- Innovative Deployment of Reinforced Concrete Bridge DecksDocument5 paginiInnovative Deployment of Reinforced Concrete Bridge DecksIqbal AhmadÎncă nu există evaluări

- Short Paneled Concrete Pavement - A Better Alternative Solution For Sustainability On ADocument47 paginiShort Paneled Concrete Pavement - A Better Alternative Solution For Sustainability On ArajibchattarajÎncă nu există evaluări

- Ultra Thin WhitetoppingDocument21 paginiUltra Thin WhitetoppingDHRUV KDMC ProjectsÎncă nu există evaluări

- Long-Life Concrete Pavements in Florida - Armaghani, JDocument13 paginiLong-Life Concrete Pavements in Florida - Armaghani, JRob DamhuisÎncă nu există evaluări

- Ultra-Thin WhitetoppingDocument21 paginiUltra-Thin WhitetoppingLohith Kumar HPÎncă nu există evaluări

- Shotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationDocument6 paginiShotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationHarold TaylorÎncă nu există evaluări

- Construction of Short Paneled Concrete Pavement On ADocument28 paginiConstruction of Short Paneled Concrete Pavement On ARajib ChattarajÎncă nu există evaluări

- Parsons Brinckerhoff ConsructionDocument43 paginiParsons Brinckerhoff ConsructionNorhalim IdrrisÎncă nu există evaluări

- Lessons Learned - Cost Schedule Scope Categories - Methodology To Rehabilitining WallsDocument4 paginiLessons Learned - Cost Schedule Scope Categories - Methodology To Rehabilitining Wallsvinoth kannaÎncă nu există evaluări

- Structural Design Procedure of Pavements On Lime Stabilised Subgrades - State of Queensland (2012)Document9 paginiStructural Design Procedure of Pavements On Lime Stabilised Subgrades - State of Queensland (2012)Raphael Da Silva CarinhanhaÎncă nu există evaluări

- 1ST ReviewDocument16 pagini1ST ReviewretechÎncă nu există evaluări

- Execution Method For Spillway Hydraulic Surfaces of HKO Main DamDocument20 paginiExecution Method For Spillway Hydraulic Surfaces of HKO Main DamJoseph NguyenÎncă nu există evaluări

- Uttar Pradesh Public Works Department Varanasi: Presentation On Summer TrainingDocument40 paginiUttar Pradesh Public Works Department Varanasi: Presentation On Summer TrainingEng mohammadÎncă nu există evaluări

- Geology - Case StudyDocument20 paginiGeology - Case StudyChrysel MarieÎncă nu există evaluări

- Reinforced Concrete PavementDocument13 paginiReinforced Concrete Pavementvish5610100% (1)

- GeoQuebec2015 - Sam Bhat J.Thomas PaperDocument6 paginiGeoQuebec2015 - Sam Bhat J.Thomas PaperJimmy ThomasÎncă nu există evaluări

- Paver Block SpecificationDocument8 paginiPaver Block SpecificationsintuÎncă nu există evaluări

- Medeiros 1999 (Análisis de La Instrumentación)Document9 paginiMedeiros 1999 (Análisis de La Instrumentación)Benjamin GonzalezÎncă nu există evaluări

- Life Extension of Bridges, 2010Document6 paginiLife Extension of Bridges, 2010LvisionÎncă nu există evaluări

- Title: Modern Trends in Concrete: Kelambakkam, ChennaiDocument11 paginiTitle: Modern Trends in Concrete: Kelambakkam, ChennaishanithisanitationÎncă nu există evaluări

- White Topping: An Excellent Solution For Pavement RehabilitationDocument23 paginiWhite Topping: An Excellent Solution For Pavement RehabilitationLohith Kumar HPÎncă nu există evaluări

- Ultra-Thin WhitetoppingDocument21 paginiUltra-Thin WhitetoppingLohith Kumar HPÎncă nu există evaluări

- White Topping As A Rehabilitation Method: A Case Study of Budhel-Ghogha RoadDocument4 paginiWhite Topping As A Rehabilitation Method: A Case Study of Budhel-Ghogha RoadashayshaÎncă nu există evaluări

- FP01Document9 paginiFP01Harold TaylorÎncă nu există evaluări

- Drainage DesignDocument46 paginiDrainage DesignpridyzÎncă nu există evaluări

- Unit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Document29 paginiUnit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Zara Nabilah76% (33)

- Road Surface: AsphaltDocument44 paginiRoad Surface: AsphaltAlbyÎncă nu există evaluări

- Latest Development in Horizontal Grouting For Cross Passages in Thomson East Coast Line C1 C2 Ilovepdf CompressedDocument20 paginiLatest Development in Horizontal Grouting For Cross Passages in Thomson East Coast Line C1 C2 Ilovepdf CompressedGrace MarieÎncă nu există evaluări

- What Is A Cement Concrete RoadDocument17 paginiWhat Is A Cement Concrete Roadknolly.matthiasÎncă nu există evaluări

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringDe la EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringEvaluare: 4 din 5 stele4/5 (5)

- Pavement Design and ConstructionDocument82 paginiPavement Design and Constructiondist2235Încă nu există evaluări

- Guided By: Prepared By: Prof. Jain Sir Saurabh P. VDocument42 paginiGuided By: Prepared By: Prof. Jain Sir Saurabh P. VNagesh ChitariÎncă nu există evaluări

- 015 Wathne Green Highways - USA Concrete Paveing PerspectiveDocument13 pagini015 Wathne Green Highways - USA Concrete Paveing PerspectiveRob DamhuisÎncă nu există evaluări

- Sevilla - Technical and Economic Feasibility of Road Widening in Concrete in The NetherlandsDocument10 paginiSevilla - Technical and Economic Feasibility of Road Widening in Concrete in The Netherlandsمنير أحمدÎncă nu există evaluări

- Precast Prestressed Concrete Short Span BridgesDocument41 paginiPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Dke78 Ch19Document30 paginiDke78 Ch19Hồ ThắngÎncă nu există evaluări

- White ToppingDocument11 paginiWhite ToppingGossetto75% (4)

- Dut Workshop - Horizontal Cracking Paper Abeeldens Etal FinalDocument13 paginiDut Workshop - Horizontal Cracking Paper Abeeldens Etal Finalapi-22997377Încă nu există evaluări

- Construction Details and Guide Specifications For Interlocking Concrete PavementDocument16 paginiConstruction Details and Guide Specifications For Interlocking Concrete PavementKervin SysingÎncă nu există evaluări

- Latex ModificatedDocument24 paginiLatex ModificatedjonathasiohanathanÎncă nu există evaluări

- ReportDocument16 paginiReportRyane SsekajjigoÎncă nu există evaluări

- White Topping: An Excellent Solution For Pavement RehabilitationDocument23 paginiWhite Topping: An Excellent Solution For Pavement RehabilitationLohith Kumar HPÎncă nu există evaluări

- 22m High Wall at Durga Temple With PECDocument5 pagini22m High Wall at Durga Temple With PECGerald TanÎncă nu există evaluări

- TRAININGDocument24 paginiTRAININGDheeraj dhiman100% (1)

- Challenging Features in Design and Execution of A Low Overburden Underpass - A Case History From Malaysia: PLUS North-South HighwayDocument10 paginiChallenging Features in Design and Execution of A Low Overburden Underpass - A Case History From Malaysia: PLUS North-South HighwayYap Wen KhongÎncă nu există evaluări

- Ramboda Pass TunnelDocument11 paginiRamboda Pass Tunnelnandasoma100% (1)

- Design and Construction of Cement-Bound Macadam PavementsDocument11 paginiDesign and Construction of Cement-Bound Macadam PavementsviralisursÎncă nu există evaluări

- Pavement RepairDocument15 paginiPavement RepairtoddlbyrnesÎncă nu există evaluări

- Concrete Repair: Case StudiesDocument2 paginiConcrete Repair: Case StudiesVijay KumarÎncă nu există evaluări

- Diseño Articulados Icpi AmericanoDocument21 paginiDiseño Articulados Icpi AmericanoHugo Arenas LozanoÎncă nu există evaluări

- Problems Encountered in Diaphragm Wall ExcavationDocument5 paginiProblems Encountered in Diaphragm Wall ExcavationrasanavaneethanÎncă nu există evaluări

- 2-1-3 Design of Temporary Embedded Retaining Walls For Gardens by The Bay StationDocument12 pagini2-1-3 Design of Temporary Embedded Retaining Walls For Gardens by The Bay StationSeng SiongÎncă nu există evaluări

- 1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassDocument11 pagini1201-Cheng Kim Hua Pipe Roof As Alternative in Building - UnderpassCheng KimHuaÎncă nu există evaluări

- Road Surface: From Wikipedia, The Free EncyclopediaDocument34 paginiRoad Surface: From Wikipedia, The Free EncyclopediaAlbyÎncă nu există evaluări

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionDe la EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionÎncă nu există evaluări

- Transactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155De la EverandTransactions of the American Society of Civil Engineers, Vol. LXVIII, Sept. 1910 The New York Tunnel Extension of the Pennsylvania Railroad. The North River Tunnels. Paper No. 1155Încă nu există evaluări

- Hafz Ba TsvyrDocument420 paginiHafz Ba TsvyrshauhramÎncă nu există evaluări

- Ebook6708 (WWW Takbook Com)Document19 paginiEbook6708 (WWW Takbook Com)shauhramÎncă nu există evaluări

- Salman Farsi PDFDocument0 paginiSalman Farsi PDFshauhramÎncă nu există evaluări

- Pad Sander ManualDocument22 paginiPad Sander ManualshauhramÎncă nu există evaluări

- فرهنگ لغات حقوقیDocument33 paginiفرهنگ لغات حقوقیshauhramÎncă nu există evaluări

- JBR Sal PNJM RyazyDocument102 paginiJBR Sal PNJM RyazyshauhramÎncă nu există evaluări

- GahRouzaneh10 ChoupanZadehDocument21 paginiGahRouzaneh10 ChoupanZadehshauhramÎncă nu există evaluări

- انقلاب مشروطه، از آغاز تا انجامDocument44 paginiانقلاب مشروطه، از آغاز تا انجامshauhramÎncă nu există evaluări

- 01 57 19 - Environmental ControlsDocument84 pagini01 57 19 - Environmental ControlsshauhramÎncă nu există evaluări

- 01 59 00 - SafetyDocument31 pagini01 59 00 - SafetyshauhramÎncă nu există evaluări

- ITP & QA QC of STM, SAN & Vent Piping (Embedded) by Bird MechanicalDocument9 paginiITP & QA QC of STM, SAN & Vent Piping (Embedded) by Bird MechanicalshauhramÎncă nu există evaluări

- 01 41 00 - Regulatory RequirementsDocument4 pagini01 41 00 - Regulatory RequirementsshauhramÎncă nu există evaluări

- 01 55 26 - TrafficDocument5 pagini01 55 26 - TrafficshauhramÎncă nu există evaluări

- 01 50 00 - Construction Facilities and Temporary ControlsDocument23 pagini01 50 00 - Construction Facilities and Temporary ControlsshauhramÎncă nu există evaluări

- Why Concrete CracksDocument7 paginiWhy Concrete CracksMohamed Abd ElmonemÎncă nu există evaluări

- 01 40 00 - Quality RequirementsDocument27 pagini01 40 00 - Quality RequirementsshauhramÎncă nu există evaluări

- 01 42 13 - Abbreviations and SymbolsDocument4 pagini01 42 13 - Abbreviations and SymbolsshauhramÎncă nu există evaluări

- Tarykh KashanDocument702 paginiTarykh KashanshauhramÎncă nu există evaluări

- Jasso Sandar TehranDocument209 paginiJasso Sandar TehranshauhramÎncă nu există evaluări

- 01 33 23 - Shop DrawingsDocument2 pagini01 33 23 - Shop DrawingsshauhramÎncă nu există evaluări

- Pelekane MakhfiDocument178 paginiPelekane MakhfishauhramÎncă nu există evaluări

- Yek Adam Cheghadr Zamin MikhahadDocument34 paginiYek Adam Cheghadr Zamin MikhahadshauhramÎncă nu există evaluări

- Book of Arda VirafDocument40 paginiBook of Arda VirafshauhramÎncă nu există evaluări

- Concrete BasicsDocument56 paginiConcrete Basicsengcecbepc100% (6)

- Jang 2 1Document51 paginiJang 2 1shauhramÎncă nu există evaluări

- Jang 2 2Document51 paginiJang 2 2shauhramÎncă nu există evaluări

- Comparative AnalysisDocument15 paginiComparative AnalysisshauhramÎncă nu există evaluări

- Repair Terminology 2010Document75 paginiRepair Terminology 2010shauhramÎncă nu există evaluări

- Jang 2 3Document73 paginiJang 2 3shauhramÎncă nu există evaluări

- Lesson Plan in Science IV Water CycleDocument7 paginiLesson Plan in Science IV Water CycleninsantocildesÎncă nu există evaluări

- SCIENCE 8 2ND QUARTER EXAM XXXXXXDocument4 paginiSCIENCE 8 2ND QUARTER EXAM XXXXXXMervin Bauya100% (1)

- Basic Floating Dock CheckDocument30 paginiBasic Floating Dock CheckKelly RutkowskiÎncă nu există evaluări

- Rapidly Varied Flow: Prepared By: Charles Bong Hin JooDocument30 paginiRapidly Varied Flow: Prepared By: Charles Bong Hin JooCharles BongÎncă nu există evaluări

- Wind Resource AssessmentDocument23 paginiWind Resource AssessmentHmaedÎncă nu există evaluări

- VTBS Bangkok / Suvarnabhumi Intl: AirportDocument53 paginiVTBS Bangkok / Suvarnabhumi Intl: AirportThar LattÎncă nu există evaluări

- LAS SHS DRRR MELC 6 Q2 Week-3Document9 paginiLAS SHS DRRR MELC 6 Q2 Week-3Atalanta LeeÎncă nu există evaluări

- Hazard Letter ClassificationDocument2 paginiHazard Letter ClassificationKimchiiÎncă nu există evaluări

- Mumbai FloodsDocument12 paginiMumbai FloodsvirajbmsÎncă nu există evaluări

- Dinosaurs Are A Diverse Group Of: (Note 1)Document4 paginiDinosaurs Are A Diverse Group Of: (Note 1)SpardaÎncă nu există evaluări

- Design Memo of Storage Yard-PanipatDocument22 paginiDesign Memo of Storage Yard-PanipatAnonymous CQ4rbzLVEÎncă nu există evaluări

- Science Laboratory Apparatus and Equipment InventoryDocument1 paginăScience Laboratory Apparatus and Equipment InventoryShaina Joy N. InereÎncă nu există evaluări

- WMO No.8 - 2008 - Updated 2010Document716 paginiWMO No.8 - 2008 - Updated 2010Elune LunaÎncă nu există evaluări

- nATIONAL dISASTER Resilience MonthDocument5 pagininATIONAL dISASTER Resilience MonthMaricarDimasÎncă nu există evaluări

- Department of Education Division of Rizal: Abuyod National High SchoolDocument10 paginiDepartment of Education Division of Rizal: Abuyod National High SchoolCherry Mae Monieva BelgaÎncă nu există evaluări

- Ncert Solutions Science Class 8Document4 paginiNcert Solutions Science Class 8Raj AnandÎncă nu există evaluări

- Tower Footing Resistance and Lightning TDocument9 paginiTower Footing Resistance and Lightning TiaessackjeeÎncă nu există evaluări

- Chapter-10: Atmospheric Circulation and Weather SystemDocument10 paginiChapter-10: Atmospheric Circulation and Weather SystemAjay JangraÎncă nu există evaluări

- Odp 090R17KV PDFDocument1 paginăOdp 090R17KV PDFAlberto LinaresÎncă nu există evaluări

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti - 42747Document2 paginiNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti - 42747SMPYPIDARUSSALAM1Încă nu există evaluări

- June 2011 QP - Paper 1 Edexcel Geography IGCSEDocument44 paginiJune 2011 QP - Paper 1 Edexcel Geography IGCSEtechang1Încă nu există evaluări

- David E Anderson, Andrew S Goudie, Adrian G Parker - Global Environments Through The Quaternary - Exploring Evironmental Change-Oxford University Press (2013) PDFDocument423 paginiDavid E Anderson, Andrew S Goudie, Adrian G Parker - Global Environments Through The Quaternary - Exploring Evironmental Change-Oxford University Press (2013) PDFYulitza ParadaÎncă nu există evaluări

- US - Geography PowerpointDocument74 paginiUS - Geography PowerpointOyunzaya NatsagdorjÎncă nu există evaluări

- Globe - Latitudes and LongitudesDocument2 paginiGlobe - Latitudes and LongitudesNeeraja RanjithÎncă nu există evaluări

- DLL DEMO Cruz TyphoonDocument3 paginiDLL DEMO Cruz TyphoonCynthia Cruz100% (2)

- Computation Fink TrussDocument62 paginiComputation Fink TrussJorge Christian BeldiaÎncă nu există evaluări

- An Illustrated Guide To Science-Weather and ClimateDocument209 paginiAn Illustrated Guide To Science-Weather and Climateritaycesar50% (4)

- Khan Usman Ali - Poster Presentation PDFDocument1 paginăKhan Usman Ali - Poster Presentation PDFUsman Ali KhanÎncă nu există evaluări

- Dwnload Full Structural Steel Design A Practice Oriented Approach 2nd Edition Aghayere Solutions Manual PDFDocument36 paginiDwnload Full Structural Steel Design A Practice Oriented Approach 2nd Edition Aghayere Solutions Manual PDFpauljohnsonirkczwoeym100% (9)

- Add A Heading 1Document3 paginiAdd A Heading 1api-524260600Încă nu există evaluări