Documente Academic

Documente Profesional

Documente Cultură

Fresh Air

Încărcat de

afraz_xecDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fresh Air

Încărcat de

afraz_xecDrepturi de autor:

Formate disponibile

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

J ul y 1998 ASHRAE J our nal 41

New Commercial Applications

For Desiccant-Based Cooling

About the Author

Kevin McGahey is product marketing manager at Fresh Air

Solutions in Hatboro, Pa. Previously, he was director of technol-

ogy for the American Gas Cooling Center. He has an M.S. in

mechanical engineering from Ohio State University.

T

By Kevin McGahey

Associate Member ASHRAE

he expansion of desiccant technology in the market-

place has sent engineers scrambling to learn about

new applications for this technology. The require-

ment for more fresh air in buildings has dramatically

changed the way designers provide a healthy, comfortable and

productive environment for patients, customers and employ-

ees. However, when larger amounts of fresh air are brought in

to satisfy the new criteria for ventilation, a large amount of

water in the air must be removed to maintain a reasonable hu-

midity level in the conditioned space and ductwork.

Engineers have solved this problem by including a desic-

cant-based cooling unit as an integral part of the buildings HVAC

system. This supplies the large volumes of fresh air required by

building codes. As engineers evaluate these systems for the

first time, new questions arise. When should engineers consider

desiccant systems? How can engineers and customers deter-

mine if a desiccant-based system is right for their application?

Although these systems do have their applications, they are not

a panacea and cannot be considered for every application.

Market Forces

In the late 1980s a number of market forces combined to

create a demand for desiccant-based air-conditioning equip-

ment. Three distinct events provided significant opportunities

for change in an industry perceived as impervious to change.

Indoor Air Quality (IAQ). The major building codes in the

United States have adopted ANSI/ASHRAE Standard 62-1989,

Ventilation for Acceptable Indoor Air Quality into their codes

by requiring that all new buildings and major retrofits comply

with this new standard.

This means that buildings must increase ventilation air (out-

side air) on average from 5 cfm per person to 1520 cfm per

person. This trend changes the latent to sensible heat ratios

that HVAC systems must treat.

Concern over the potential for litigation has led to the de

facto adoption of Standard 62 even where it is not found in the

local building code.

Demand for Comfort. Controlling comfort involves bringing

the air temperature and relative humidity into a reasonable range

for human comfort. It is noted that humidity is at least as impor-

tant as temperature because, as is often said, Its not the heat,

its the humidity.

In the late 1980s, desiccant applications that provided a di-

rect economic benefit to supplying superior humidity control

became popular. In hotels, musty odors and clammy environ-

ments forced travelers to seek out more comfortable

accomodations. In supermarkets, cold frozen food aisles has-

tened shoppers through the freezer sectiondiscouraging im-

pulse buying. In hospital operating rooms uncomfortable sur-

geons selected alternative hospitals with better climate control

to perform their surgical procedures. The direct economic im-

pact that comfort had on these facilities resulted in the demand

for improved humidity control.

The New Economics of Air Conditioning. In the past, ap-

plications that demanded better humidity control were a chal-

lenge to engineers. Museums required humidity control all year

long to protect their collections. Hospitals required specific

temperature and humidity conditions for certain operating pro-

cedures. From the engineers perspective, if the only tool on

hand is a hammereverything looks like a nail! Similarly, engi-

neers tried to solve humidity problems using the only tool avail-

able standard cold coil technologyto over-cool and some-

times re-heat the air.

Humidity problems arose in other applications, creating a

second tier of costs that sometimes dominated the economics

of comparing equipment cost and operating cost. In supermar-

kets, humidity would frost freezer cases and frozen foods, driv-

ing up defrost and door heater costs and spoiling the

productsappearance in the cases.

In hotels, mold problems damaged floor and wall coverings

as well as furniture. The American Hotel and Motel Associa-

tion estimated this damage to be approximately $65 million

dollars annually in the United States.

1

Non-energy related eco-

nomic concerns moved to the forefront for these and other

applications.

Criteria for Evaluation

To decide whether a desiccant system makes sense for a

certain application requires an understanding of the loads (both

latent and sensible) and the functional requirements for that

particular building. However, six criteria emerge in application

after application. If one or more of the following criteria apply,

the engineer would be well advised to consider desiccant sys-

tems for that application.

2

A SHRAE J OURNAL

Bringing Fresh Air to Businesses

The following article was published in ASHRAE Journal, July 1998. Copyright 2002 American Society of Heating, Refrigerating and Air-

Conditioning Engineers, Inc. It is presented for educational purposes only. This article may not be copied and/or distributed electronically or

in paper form without permission of ASHRAE.

J ul y 1998 ASHRAE J our nal 42

D E S I C C A N T

Low Sensible Heat Ratios. A load can be broken down into

two parts: the latent (moisture) load and the sensible load. En-

gineers often refer to the ratio of the sensible load to the total

load as the sensible heat ratio. Conventional equipment (such

as a rooftop unit) works well when the sensible heat ratio is

above 80%. When the sensible heat ratio falls below 80%, con-

ventional equipment begins to lose control of humidity and the

air may begin to feel cold and clammy.

A restaurant is a good example of an application with a low

sensible heat ratio. The ASHRAE HandbookHVAC Applica-

tions states that, Often, the ideal design condition must be

rejected for an acceptable condition because of equipment cost

or performance limitations. Restaurants are frequently affected

in this way, because ratios of latent to sensible heat may result

in uneconomical equipment selection, unless a combination of

lower design dry-bulb temperature and higher relative humidity

is selected. Again, this statement only considered the con-

ventional rooftop unit.

Restaurants usually have seating areas designed to accom-

modate a large number of patrons in a relatively small area. A

high people density requires large ventilation loads per square

foot in addition to the makeup air required to replace the air

exhausted through the kitchen exhaust hoods. This situation is

worsened by the fact that restaurants draw the largest crowds

in the evenings when the sensible load carried by the ventila-

tion air is reduced. However, the ventilation air still carries a

large amount of water with it, and the people in the restaurant

continue to release moisture through perspiration and respira-

tion. All these factors combine to create a situation where the

restaurant has a very low sensible heat ratio. Consequently, the

restaurant seems cold to the patrons.

Low Humidity Requirements. Is there an economic benefit

to having low humidity? An ice rink is an excellent example of

an application that benefits financially from maintaining low

humidity. Conventional equipment does a good job of provid-

ing air at a dew point of 50F (10C). However, the ice sheet in

an ice rink is about 28F (2.2C), so water quickly condenses

out of the air onto the ice sheet, softening the ice, contributing

to fog over the ice and requiring the operator to frequently

resurface the ice. Additionally, the heat that water drops trans-

fer to the ice sheet as it condenses must be removed by the

refrigeration systems, which drives up the operating cost of the

ice-making system.

Ice rinks often shut down in the spring because of fog over

the ice created by humidity problems. Desiccant systems solve

problems like this by maintaining the rink at a dew point of 30F

to 35F (1.1C to 1.6C). The air can be kept at a warmer but

dryer condition, providing more comfort for spectators and a

higher quality ice sheet for skaters. The rink can stay open all

year long resulting in additional revenue for the owner.

Need for more fresh air. As previously discussed, Standard

62 demands 15 cfm (7 L/s) per person be brought into most

buildings to address IAQ issues. Conventional equipment works

well up to 15% outside air. However, once the percentage of

outside air goes beyond 15%, most units begin to lose control

over humidity. As owners bring their existing buildings up to

code, they are faced with this equipment limitation in providing

more fresh air to the conditioned space.

An example of a facility under this constraint would be a

school. A typical classroom in Atlanta using the old guideline

of 5 cfm (2.3 L/s) per person would have a load that is about

30% latent and 70% sensible.

4

Bringing the school up to the

new guideline of 15 cfm (7 L/s) per person of ventilation air

changes the load to one that is about 40% latent. If the new dew

Figure 1: Typical desiccant system.

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

44 ASHRAE J our nal J ul y 1998

point design conditions outlined in the 1997 ASHRAE Hand-

bookFundamentals are used, the load is now 50% latent,

making it almost impossible for conventional equipment to main-

tain a reasonable humidity condition inside the school.

One solution is to add a desiccant-based makeup air unit to

handle the majority of the fresh air requirements, while operat-

ing the existing equipment at 10% fresh air. This approach al-

lows the owner to bring a building up to code, avoid replacing

existing equipment and provide a more comfortable environ-

ment by independently controlling humidity.

Exhaust post cooling is available. Another situation that

favors desiccant technology is supply and return ducts that

are located close together allowing for heat recovery. Many

desiccant systems have a built-in heat recovery heat exchange

wheel that acts as a heat recovery device in the cooling and

heating season. In the summer, as cool air is exhausted from the

building, exchanging heat with this exhaust stream through the

heat exchange wheel cools the ventilation airstream, reducing

the sensible cooling load. Similarly, in the winter, as the warmer

exhaust air leaves the building, the exhaust air is used to heat

the ventilation air by exchanging heat in the heat exchange

wheel, reducing the buildings heating load.

Low thermal energy costs. Another advantage to desiccant

equipment is that it is thermally driven. The heat can come from

an internal boiler or from an external heat source providing heat

to a manufacturer-supplied coil in the unit. Therefore, the unit

can be driven using waste heat or an under-utilized boiler. Be-

cause natural gas costs usually are low in the summer, the des-

iccant unit saves operating costs by lowering on-peak power

consumption.

Economic benefit to dry ductwork. Fungus and bacteria

thrive when four key ingredients are present. First, bacteria or

mold spores must be present. Second, the temperature must be

suitable for their growth, which is usually the same temperature

humans enjoy. Third, a food source must be present. Mold and

bacteria can find food in just about any duct, floor or wall cov-

ering. Finally, water must be present.

Water is the only element that can be controlled effectively to

slow the growth in ductwork. Standard 62 recommends ductwork

be kept below 70% relative humidity to avoid or minimize the

mold growth in ductwork. If the air supplied by this ductwork is

supplying a hospital operating room where the air is blown to-

ward an open wound, the benefit to dry ductwork is obvious.

Equipment Applications

Finally, when an application for a desiccant-based air-condi-

tioning unit has been identified, the question shifts to how it

should be applied. Should the desiccant system replace the

conventional equipment? While a desiccant unit can act as a

stand-alone unit by providing both latent and sensible cooling,

the unit usually is used in conjunction withnot in place of

conventional equipment. This approach takes advantage of

the strengths of both types of equipment.

The two approaches to applying desiccant equipment in-

clude directly introducing the air into the space or pre-treating

the air into other equipment. Each approach has its advantages

and disadvantages.

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

J ul y 1998 ASHRAE J our nal 45

D E S I C C A N T

Please circle the appropriate number on the Reader Service

Card at the back of the publication.

Extremely Helpful ................................................... 458

Helpful ................................................................. 459

Somewhat Helpful ................................................. 460

Not Helpful ........................................................... 461

Introducing the air directly into the space is usually a good

approach for schools, hotels, supermarkets and ice rinks. This

approach usually minimizes the duct requirements, especially

when used in conjunction with fan coil units. Directly introduc-

ing the dehumidified air into the space has the advantage of

maintaining constant ventilation and humidity control while

allowing lower capacity equipment (now only handling the sen-

sible load) to react to the more diverse sensible loads.

Using this approach requires good circulation of the dehu-

midified airstream from the desiccant unit with the cool air from

the DX or fan coil units. Good air circulation is usually achieved

by positively pressurizing the classroom or hotel room, nega-

tively pressurizing the corridor or hallway with an exhaust fan

and allowing for air movement by using adequately-sized air

passages in the doorways.

The second application approach to applying desiccant-

based cooling systems is to pre-treat the air into either a pack-

aged rooftop air conditioner or into an air-handling unit. Pre-

treating the air into a rooftop unit is a good method for a restau-

rant or movie theater. This approach can be a retrofit solution to

a building with a humidity problem, while minimizing the number

of roof penetrations and using conventional equipment as an

inexpensive way to post-cool the delivered air.

Delivering the pre-treated air to an air-handling unit would

have the same benefit as before, but would be more applicable

to larger applications such as hospitals or office buildings. These

approaches help reduce the size of the conventional equipment

because it deals only with sensible load, while providing inde-

pendent control of humidity.

References

1. American Hotel and Motel Association. 1992. Mold and Mildew in

Hotels and Motels. Washington, D.C.

2. American Gas Cooling Center. 1996. Desiccant Systems Application

Guide. Arlington, Va.

3. ASHRAE Handbook HVAC Applications. 1995. Commercial

and public buildings, chapter 3.5.

4. Active humidity control systems for commercial comfort cooling.

1997. Hatboro, Pa.: Engelhard/ICC.

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

T h i s s p a c e c o n t a i n e d

a n a d v e r t i s e m e n t

S-ar putea să vă placă și

- Waste WaterDocument31 paginiWaste Waterafraz_xec100% (1)

- Adli Khalaf - Design Basis Scoping PaperDocument23 paginiAdli Khalaf - Design Basis Scoping PaperMuneer YousofÎncă nu există evaluări

- SustainabilityAssessment System - AM PDFDocument35 paginiSustainabilityAssessment System - AM PDFafraz_xecÎncă nu există evaluări

- Puron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 FinalDocument2 paginiPuron Technical Bulletin Modules 300 600 1800 PVDF Rev 11-2 Finalafraz_xecÎncă nu există evaluări

- Heat Loss and Gain CalculationDocument84 paginiHeat Loss and Gain Calculationafraz_xecÎncă nu există evaluări

- Adli Khalaf - Design Basis Scoping PaperDocument23 paginiAdli Khalaf - Design Basis Scoping PaperMuneer YousofÎncă nu există evaluări

- Water Parameters NeededDocument1 paginăWater Parameters Neededafraz_xecÎncă nu există evaluări

- GSAS Technical Guide V2.1Document90 paginiGSAS Technical Guide V2.1Laras Fadillah100% (1)

- GCC Reuse Regulations: GE Power & Water Water & Process TechnologiesDocument37 paginiGCC Reuse Regulations: GE Power & Water Water & Process TechnologiesRashid Al GaoudÎncă nu există evaluări

- GRP Water Tank SpecsDocument4 paginiGRP Water Tank Specsafraz_xecÎncă nu există evaluări

- Ashghal StandardsDocument26 paginiAshghal Standardsafraz_xecÎncă nu există evaluări

- Hydaranautics MembraneDocument3 paginiHydaranautics Membraneafraz_xecÎncă nu există evaluări

- GCC Reuse Regulations: GE Power & Water Water & Process TechnologiesDocument37 paginiGCC Reuse Regulations: GE Power & Water Water & Process TechnologiesRashid Al GaoudÎncă nu există evaluări

- Epa Water Treatment Manual Filtration 1Document80 paginiEpa Water Treatment Manual Filtration 1alkemeya100% (1)

- Auditing HealthcareDocument82 paginiAuditing Healthcareafraz_xecÎncă nu există evaluări

- GRP Water Tank SpecsDocument4 paginiGRP Water Tank Specsafraz_xecÎncă nu există evaluări

- 16 L200 LHD +GCC-E SpecDocument2 pagini16 L200 LHD +GCC-E Specafraz_xecÎncă nu există evaluări

- Mechanical-Engineering Gate2016.InfoDocument3 paginiMechanical-Engineering Gate2016.InfoHenryÎncă nu există evaluări

- HILTI Direct - FasteningDocument2 paginiHILTI Direct - Fasteningafraz_xecÎncă nu există evaluări

- Cat 6 S-FTP 4 CableDocument2 paginiCat 6 S-FTP 4 Cableafraz_xecÎncă nu există evaluări

- Mechanical-Engineering Gate2016.InfoDocument3 paginiMechanical-Engineering Gate2016.InfoHenryÎncă nu există evaluări

- List of Materials For GRP TankDocument1 paginăList of Materials For GRP Tankafraz_xecÎncă nu există evaluări

- All Polypropylene String Wound CartridgesDocument1 paginăAll Polypropylene String Wound Cartridgesafraz_xecÎncă nu există evaluări

- Tank Foundation DrawingDocument1 paginăTank Foundation Drawingafraz_xecÎncă nu există evaluări

- Flexible Conduit SpecsDocument10 paginiFlexible Conduit Specsafraz_xecÎncă nu există evaluări

- Control Cables SpecsDocument4 paginiControl Cables Specsafraz_xecÎncă nu există evaluări

- 3series MDocument0 pagini3series MMaida AgićÎncă nu există evaluări

- Koch Puron PSH 300 LDocument2 paginiKoch Puron PSH 300 Lafraz_xecÎncă nu există evaluări

- Inspection Form For New Construction: Project NameDocument1 paginăInspection Form For New Construction: Project Nameafraz_xecÎncă nu există evaluări

- Cable Tray Support SpecsDocument3 paginiCable Tray Support Specsafraz_xecÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Speed Torque Gear Ratios Motor Vehicles Internal Combustion Engine Rotational Speed TorqueDocument45 paginiSpeed Torque Gear Ratios Motor Vehicles Internal Combustion Engine Rotational Speed TorqueAkshay SinghÎncă nu există evaluări

- Notes PDFDocument252 paginiNotes PDFclose022Încă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityMaulik PatelÎncă nu există evaluări

- Civic Turbo DieselDocument202 paginiCivic Turbo DieselLuciano PereiraÎncă nu există evaluări

- Chapter 06 - Understanding Process ConditionsDocument20 paginiChapter 06 - Understanding Process ConditionsMohammed DaghurÎncă nu există evaluări

- Mfaf BK: ScopeDocument23 paginiMfaf BK: ScopesbalajimÎncă nu există evaluări

- High-Mn Steel Weldment Mechanical Properties at 4.2 KDocument9 paginiHigh-Mn Steel Weldment Mechanical Properties at 4.2 K3834saldÎncă nu există evaluări

- Bircosir - NW 150: Stability and DiversityDocument5 paginiBircosir - NW 150: Stability and Diversityjagath2005ukÎncă nu există evaluări

- Fundamentals of Fluid Mechanics Chapter 12 TurbinesDocument44 paginiFundamentals of Fluid Mechanics Chapter 12 Turbinesalisnowkiss6570Încă nu există evaluări

- Thread Standards - Tameson PDFDocument6 paginiThread Standards - Tameson PDFAmol JagtapÎncă nu există evaluări

- PN1949 Perkins Irrigation Engine Ratings GuideDocument16 paginiPN1949 Perkins Irrigation Engine Ratings GuideMd ShÎncă nu există evaluări

- Physics FormulasDocument4 paginiPhysics FormulasMica :pÎncă nu există evaluări

- Performance Based Seismic Design of Reinforced Concrete Tall BuildingsDocument175 paginiPerformance Based Seismic Design of Reinforced Concrete Tall BuildingsPatrick CanceranÎncă nu există evaluări

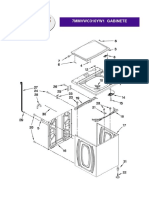

- 7MMVWC310YW11Document8 pagini7MMVWC310YW11Relavson RefaccionesÎncă nu există evaluări

- Recommendation of RILEM TC 261-CCF Test Method ToDocument20 paginiRecommendation of RILEM TC 261-CCF Test Method ToManelÎncă nu există evaluări

- CH 5 Kerja Dan EnergiDocument21 paginiCH 5 Kerja Dan EnergiDey TandirerungÎncă nu există evaluări

- Developer Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseDocument18 paginiDeveloper Instruction Guide (Video Development) : Sensitivity: LNT Construction Internal UseGokul SelvarajÎncă nu există evaluări

- Transmision Fuller 13 Vel Rtlo-14913aDocument37 paginiTransmision Fuller 13 Vel Rtlo-14913aCesar RamosÎncă nu există evaluări

- 2002 KX250 Race TuningDocument4 pagini2002 KX250 Race TuningKidKawie100% (1)

- Entropy of Mixing PDFDocument16 paginiEntropy of Mixing PDFrupaliroyÎncă nu există evaluări

- Thermodynamics-1 Semester AssignmentDocument9 paginiThermodynamics-1 Semester AssignmentShahZaib AnwarÎncă nu există evaluări

- BF08H00902 Components EngineDocument125 paginiBF08H00902 Components EngineHéctor Medina100% (1)

- Updated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012Document35 paginiUpdated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012david karasilaÎncă nu există evaluări

- Suspension A8Document5 paginiSuspension A8Bonny SidhuÎncă nu există evaluări

- 654 Guess Paper Physics 10th ClassDocument9 pagini654 Guess Paper Physics 10th ClassMuhammad MujtabaÎncă nu există evaluări

- Oxygen Cylinder 46.7 LTR (D Type - 200 CFT), Medical Oxygen Jumbo CylindersDocument2 paginiOxygen Cylinder 46.7 LTR (D Type - 200 CFT), Medical Oxygen Jumbo CylindersDebajyoti BarmanÎncă nu există evaluări

- N R P F W G: Direction of Impending MotionDocument28 paginiN R P F W G: Direction of Impending MotionAbdullah Ahsan AhmedÎncă nu există evaluări

- Hipps: High Integrity Pressure Protection SystemsDocument9 paginiHipps: High Integrity Pressure Protection SystemsAndrew XuguomingÎncă nu există evaluări

- Brayton and Rankine CycleDocument12 paginiBrayton and Rankine CycleDaryl Calderon100% (1)

- Abdul Ameen CVDocument4 paginiAbdul Ameen CVanon_151755103Încă nu există evaluări