Documente Academic

Documente Profesional

Documente Cultură

E Web - Catalog.sj - Cs007

Încărcat de

dedikartiwa_dk0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări5 paginiPTFE or FKM seals are available for higher temperatures and chemical products. A submerged type can also be manufactured upon request. The rotating torque varies with the storage condition and storage period of a swivel joint and the type of fluid used.

Descriere originală:

Titlu original

e Web.catalog.sj.Cs007

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentPTFE or FKM seals are available for higher temperatures and chemical products. A submerged type can also be manufactured upon request. The rotating torque varies with the storage condition and storage period of a swivel joint and the type of fluid used.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări5 paginiE Web - Catalog.sj - Cs007

Încărcat de

dedikartiwa_dkPTFE or FKM seals are available for higher temperatures and chemical products. A submerged type can also be manufactured upon request. The rotating torque varies with the storage condition and storage period of a swivel joint and the type of fluid used.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

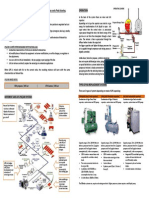

CONSTRUCTION

SERVICE CONDITIONS etc.

As to C series, PTFE or FKM seals are available for higher temperatures and chemical products.

* The standard flange is JIS 10K. JIS 20K and JIS 5K flange can also be manufactured upon request

Products of ANSI Class 150/Class 300 can also be manufactured if specified.

* A submerged type can also be manufactured upon request.

Materials of Special Packing

* Max. temperatures are given as a guide for use with hot water,

steam, and hot oil. Please consult us for use with a special fluid.

* The grease must be changed for use with a fluid at 100 or more

or with a special fluid.

* Kalrez is a registered trademark of DuPont.

Material Model

Max.

Temperature

Other materials CSZ -

Kalrez CSX -

Steam-resistant fluoro-rubber CSH 160

Silicon rubber CSN -

EPDM CSE -

FKM + PTFE coating CSQ 160

Perflour CSM -

FKM CSV 160

PTFE seal CSP 180

Connection Flange

Material Weld Stainless Steel

Seal NBR O-ring

Max. Pressure 2.1MPa

Max. Temperature 100 degrees C

Pearl Swivel Joints

CS Series

-A SHAFT-B FLANGE-A BODY-B PIPE-C FLANGESTEEL BALLSEAL(O-RING)

DUST SEAL BALL PLUG SET SCREW GREASE NIPPLEPLUG(IMAGE: CS-1)

1/5

DIMENSIONS of CS series

WEIGHT CHART(Unit = 1kg/1 piece)

FLANGEJIS10K

DYNAMIC TORQUE GRAPH

Dynamic Torque Graph

* The rotating torque varies with the storage

condition and storage period of a swivel joint

and the type of fluid used.

* This data represents typical values obtained

by measurements according to internal test

standards and does not represent guaranteed

values.

* The starting torque is larger than the dynamic

torque. When wringing (adhesion phenomenon)

occurs, the starting torque is particularly large.

It is not an abnormality.

105 114 122 200 59 68 76

39.5 43 45

150 39 42.5 46 65 68.5 72

125 25 27 30

17.0 17.9 18.7

100 15.6 16.9 18.2 24.5 25.7 26.9

80 11.3 12.1 13.0

10.6 11.0 11.3

65 10.4 11.0 11.3 15.3 15.6 16.1

50 7.2 7.6 8.0

NO.4 NO.5 NO.6

40 5.3 5.5 5.7 7.2 7.4 7.6

580

SIZE(A) NO.1 NO.2 NO.3

580 278 280 450 200 8 320 450

380

450 225 225 365 450

380

150 6 280 365

185 190 315 125 5 250 315

255

100 4 220 265 310 152 160 265 310

255 125 135 230 80 3 205 230

190

65 21/2 190 205 220 113 115 205 220

160 160

50 2 170 180 190 94 95 180

G

(A) (B)

40 11/2 160 160 160 76 80

SIZE

A B C D E F

2/5

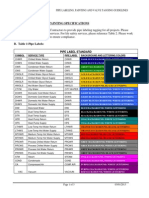

Table of CS series

CSV-6 ask

SJ-CS-6 50A10K CS50061001

SJ-CS-6 65A10K CS65061001

SJ-CS-6 80A10K CS80061001

SJ-CS-6 100A10K CS82061001

NO.6 CS-6

SJ-CS-6 40A10K CS40061001

CSV-5 ask

SJ-CS-5 50A10K CS50051001

SJ-CS-5 65A10K CS65051001

SJ-CS-5 80A10K CS80051001

SJ-CS-5 100A10K CS82051001

NO.5 CS-5

SJ-CS-5 40A10K CS40051001

CSV-4 ask

SJ-CS-4 50A10K CS50041001

SJ-CS-4 65A10K CS65041001

SJ-CS-4 80A10K CS80041001

SJ-CS-4 100A10K CS82041001

NO.4 CS-4

SJ-CS-4 40A10K CS40041001

SJ-CS-3 200A10K CS85031001 SJ-CSV-3 200A10K CS85031002

SJ-CS-3 125A10K CS83031001 SJ-CSV-3 125A10K CS83031002

SJ-CSV-3 80A10K CS80031002

CSV-3

SJ-CSV-3 40A10K CS40031002

SJ-CSV-3 100A10K CS82031002

SJ-CSV-3 150A10K CS84031002

SJ-CSV-3 50A10K CS50031002

SJ-CS-3 65A10K CS65031001 SJ-CSV-3 65A10K CS65031002

SJ-CS-3 50A10K CS50031001

NO.3 CS-3

SJ-CS-3 40A10K CS40031001

SJ-CS-3 100A10K CS82031001

SJ-CS-3 150A10K CS84031001

SJ-CS-3 80A10K CS80031001

SJ-CS-2 200A10K CS85021001 SJ-CSV-2 200A10K CS85021002

SJ-CS-2 125A10K CS83021001 SJ-CSV-2 125A10K CS83021002

SJ-CSV-2 80A10K CS80021002

CSV-2

SJ-CSV-2 40A10K CS40021002

SJ-CSV-2 100A10K CS82021002

SJ-CSV-2 150A10K CS84021002

SJ-CSV-2 50A10K CS50021002

SJ-CS-2 65A10K CS65021001 SJ-CSV-2 65A10K CS65021002

SJ-CS-2 50A10K CS50021001

NO.2 CS-2

SJ-CS-2 40A10K CS40021001

SJ-CS-2 100A10K CS82021001

SJ-CS-2 150A10K CS84021001

SJ-CS-2 80A10K CS80021001

SJ-CS-1 200A10K CS85011001 SJ-CSV-1 200A10K CS85011002

SJ-CS-1 150A10K CS84011001 SJ-CSV-1 150A10K CS84011002

SJ-CS-1 125A10K CS83011001 SJ-CSV-1 125A10K CS83011002

SJ-CS-1 100A10K CS82011001 SJ-CSV-1 100A10K CS82011002

SJ-CS-1 80A10K CS80011001 SJ-CSV-1 80A10K CS80011002

SJ-CS-1 65A10K CS65011001 SJ-CSV-1 65A10K CS65011002

SJ-CS-1 50A10K CS50011001 SJ-CSV-1 50A10K CS50011002

Name Our Code

Flange

Connection

NO.1 CS-1

SJ-CS-1 40A10K CS40011001

CSV-1

SJ-CSV-1 40A10K CS40011002

NBR O-ring FKM O-ring

Style Name Our Code Style

3/5

Table of CS series

CSQ-5

SJ-CSQ-3 100A10K CS82031005

ask NO.4 CSP-4

ask

NO.6 CSP-6 ask CSQ-6 ask

NO.5 CSP-5 ask

ask CSQ-4

SJ-CSQ-3 80A10K CS80031005 CSQ-3

SJ-CSQ-3 40A10K CS40031005

SJ-CSQ-3 50A10K CS50031005

SJ-CSP-3 65A10K SJ-CSQ-3 65A10K CS65031005

SJ-CSP-3 50A10K CS50031003

NO.3 CSP-3

SJ-CSP-3 40A10K CS40031003

SJ-CSP-3 100A10K CS82031003

SJ-CSP-3 80A10K CS80031003

CS65031003

SJ-CSP-2 100A10K CS82021003 SJ-CSQ-2 100A10K CS82021005

SJ-CSP-2 80A10K CS80021003 SJ-CSQ-2 80A10K CS80021005

SJ-CSP-2 65A10K CS65021003 SJ-CSQ-2 65A10K CS65021005

SJ-CSP-2 50A10K CS50021003 SJ-CSQ-2 50A10K CS50021005

CS40021003

CSQ-2

SJ-CSQ-2 40A10K CS40021005

CS80011003 SJ-CSQ-1 80A10K CS80011005

SJ-CSP-1 100A10K CS82011003 SJ-CSQ-1 100A10K CS82011005

CS40011003

CSQ-1

SJ-CSQ-1 40A10K CS40011005

CS50011003 SJ-CSQ-1 50A10K CS50011005

CS65011003 SJ-CSQ-1 65A10K CS65011005

Flange

Connection

NO.1 CSP-1

SJ-CSP-1 40A10K

SJ-CSP-1 50A10K

SJ-CSP-1 65A10K

SJ-CSP-1 80A10K

NO.2 CSP-2

SJ-CSP-2 40A10K

PTFE Seal FKM + PTFE coating O-ring

Style Name Our Code Style Name Our Code

4/5

Ordering Information

The following data is required:

1. Type of joint

2. Product (fluid) to be handled

3. Working & Maximum temperature and pressure

4. Style & Size of joint

5. Frequency of movement

6. Working environment: Ex) Use in a clean room, etc.

* Any other specialrequirements

Installation Suggestions

1. Standard packing material NBR (Buna-N) cannot be used, for the fluid such as phosphoric ester-type operating oil,

chlorinated hydrocarbon-type operating oil, organic solvent or acid,

2. The ball bearing section of the joint is finished precisely and has no backlash,

restricting the movement of pipeline in the direction of joint swivel.

Therefore, please make careful examination of the pipeline movement before selecting the style.

3. The life of joint depends largely on the size of moment load. Please avoid giving large moment load onto the joint when designing.

4. Swivel joints are not suited for successive rotation unlike rotary joint.

However, they have sufficient properties to be used in extremely low speed.

5. While lubrication at packing replacement is normally sufficient for use under room temperature,

lubrication of once a week may be necessary if they are used under high temperature.

6. When a joint is used correctly, the limit of packing use is when leak is discovered. Replace the packing with a new one in this case.

Frequently Asked Questions

Q. Can I use the swivel joint for running steam?

A. Yes. Please select the type PK. If there is a problem with the dimensions and rotating torque, you can use the swivel joint

with low-pressure steam up to about 160 by changing the packing material and grease of A and C.

Q. Is there no problem with using the swivel joint under high rotation speed?

A. The swivel joint can be used even under high rotation speed, though its service life will be shortened.

Q. Can I use the swivel joint by connecting it to the end of a hose?

A. The swivel joint has a bearing structure and is sealed with an O-ring. Therefore, its rotating torque is larger than that of

a rotary joint. There is no advantage in using the swivel joint unless the hose has adequate strength.

Q. The swivel joint fails to operate properly.

A. It is time to replace the swivel joint.

Q. Fluid leaks when the swivel joint is in a certain position during operation.

A. There is probably a problem regarding installation.

Tokyo Office (Export Dept.)

2-64-11,Akabane,Kita-ku,Tokyo,

115-0045 Japan

Phone.:+81-3-3598-1400

Fax.:+81-3-3598-2700

E-mail sgk-tk@sgk-p.co.jp

Osaka Office

2-9-7,Toyosaki,Kita-ku,Osaka,

531-0072 Japan

Phone.:+81-6-6371-8341

Fax.:+81-6-6371-6283

E-mail sgk-os@sgk-p.co.jp

Nagoya Office

1-107,Takaharidai,Meito-ku,Nagoya,

465-0054 Japan

Phone.:+81-52-701-4068

Fax.:+81-52-704-4051

E-mail sgk-ng@sgk-p.co.jp

Head Office

7-24 Nishi-Kobari,Ina-Machi,Saitama,

362-0811 Japan

Phone.:+81-48-728-8321

Fax.:+81-48-728-8360

E-mail sgk-spa@sgk-p.co.jp (Engineering Dept.)

The contents of this catalog subject to change without notice. E-mail sgk-tpa@sgk-p.co.jp (Administrative Division)

SHOWA GIKEN INDUSTRIAL CO., LTD.

URL http://www.sgk-p.co.jp/

5/5

S-ar putea să vă placă și

- Standards For Material Handling, Storage, and DisposalDocument13 paginiStandards For Material Handling, Storage, and Disposaljeb13Încă nu există evaluări

- Control Rods of Rubber Flexible JointDocument2 paginiControl Rods of Rubber Flexible Jointdedikartiwa_dkÎncă nu există evaluări

- Collar TypeDocument1 paginăCollar Typededikartiwa_dkÎncă nu există evaluări

- 21 TSRT PR 21 Mechanical PrecommissionngDocument8 pagini21 TSRT PR 21 Mechanical Precommissionngdedikartiwa_dkÎncă nu există evaluări

- Measuring Petroleum StandardsDocument101 paginiMeasuring Petroleum StandardsJonathan Narh-DometeyÎncă nu există evaluări

- Movement JointsDocument4 paginiMovement JointsArnold TunduliÎncă nu există evaluări

- Pipe Flow Friction Factor CalculationsDocument14 paginiPipe Flow Friction Factor Calculationsdedikartiwa_dkÎncă nu există evaluări

- ViskositasDocument1 paginăViskositasnawrim_sugaÎncă nu există evaluări

- Removal of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos AfterDocument3 paginiRemoval of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos Afterdedikartiwa_dkÎncă nu există evaluări

- MP&MH 2012 (Apr-Nov)Document1 paginăMP&MH 2012 (Apr-Nov)dedikartiwa_dkÎncă nu există evaluări

- TIASA - Thermal Insulation HandbookDocument58 paginiTIASA - Thermal Insulation HandbookSirGawain99Încă nu există evaluări

- Request For Field InspectionDocument1 paginăRequest For Field Inspectiondedikartiwa_dkÎncă nu există evaluări

- Road Vehicle Safety TalkDocument12 paginiRoad Vehicle Safety Talkdedikartiwa_dkÎncă nu există evaluări

- LPG Air Mixing 2 A3Document1 paginăLPG Air Mixing 2 A3ambientinstal instalÎncă nu există evaluări

- Kaeser ASD SeriesDocument5 paginiKaeser ASD SeriesSachith VidanapathiranaÎncă nu există evaluări

- Piping Identification and Valve Tagging PDFDocument5 paginiPiping Identification and Valve Tagging PDFdedikartiwa_dkÎncă nu există evaluări

- Underground LPG SDocument1 paginăUnderground LPG Sdedikartiwa_dkÎncă nu există evaluări

- Quality Measurement Tool & Tester ListDocument1 paginăQuality Measurement Tool & Tester Listdedikartiwa_dkÎncă nu există evaluări

- SDS - Aluflex - Marine - Protective - English (Uk) - United KiDocument5 paginiSDS - Aluflex - Marine - Protective - English (Uk) - United KiAndres Fitria FarrelÎncă nu există evaluări

- Velocity Profile Circular PipeDocument4 paginiVelocity Profile Circular Pipededikartiwa_dkÎncă nu există evaluări

- Calibration Checklist for Monitoring DevicesDocument1 paginăCalibration Checklist for Monitoring Devicesdedikartiwa_dkÎncă nu există evaluări

- Pressure Drop Excel VB FormatDocument4 paginiPressure Drop Excel VB Formatsiva242245Încă nu există evaluări

- Rp150 Juta Penawaran Harga Tank RO 230x340Document2 paginiRp150 Juta Penawaran Harga Tank RO 230x340dedikartiwa_dkÎncă nu există evaluări

- SDS - Alkydprimer - Marine - Protective - English (Uk) - UniteDocument6 paginiSDS - Alkydprimer - Marine - Protective - English (Uk) - UniteAndres Fitria FarrelÎncă nu există evaluări

- Equipment Commissioning ChecklistDocument20 paginiEquipment Commissioning ChecklistDheeraj Yadav100% (2)

- Piping Identification and Valve Tagging StandardDocument6 paginiPiping Identification and Valve Tagging Standardmanox007Încă nu există evaluări

- SDS - Barrier - Comp. B - Marine - Protective - Indonesian (IdDocument7 paginiSDS - Barrier - Comp. B - Marine - Protective - Indonesian (Iddedikartiwa_dkÎncă nu există evaluări

- Pipe Sizes Chart Nominal Outside DiametersDocument1 paginăPipe Sizes Chart Nominal Outside Diametersdedikartiwa_dkÎncă nu există evaluări

- RIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013Document3 paginiRIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013dedikartiwa_dkÎncă nu există evaluări

- Piping Identification and Valve Tagging PDFDocument5 paginiPiping Identification and Valve Tagging PDFdedikartiwa_dkÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Angel FishDocument1 paginăAngel FishWilla CrowellÎncă nu există evaluări

- Adult Education and Lifelong Learning Peter JarvisDocument63 paginiAdult Education and Lifelong Learning Peter JarvisKatherine Uran RamirezÎncă nu există evaluări

- Trainee Accountant Job DescriptionDocument5 paginiTrainee Accountant Job DescriptionNelly PilcoÎncă nu există evaluări

- Catalogo Bombas PedrolloDocument80 paginiCatalogo Bombas PedrolloChesster EscobarÎncă nu există evaluări

- Plastic BanDocument3 paginiPlastic BanSangeetha IlangoÎncă nu există evaluări

- E-Leadership Literature ReviewDocument36 paginiE-Leadership Literature ReviewYasser BahaaÎncă nu există evaluări

- tmp1AE2 TMPDocument8 paginitmp1AE2 TMPFrontiersÎncă nu există evaluări

- Martek Navgard BnwasDocument4 paginiMartek Navgard BnwasСергей БородинÎncă nu există evaluări

- PESU BTech Jan2017 6thsemCourseInfoDocument51 paginiPESU BTech Jan2017 6thsemCourseInforakshithrajÎncă nu există evaluări

- Chobani: The Falling First Mover: Jianan LiaoDocument5 paginiChobani: The Falling First Mover: Jianan Liaowofop34547Încă nu există evaluări

- Martina: Available Colors For This VersionDocument2 paginiMartina: Available Colors For This VersionUmeshÎncă nu există evaluări

- Rate of Change: Example 1 Determine All The Points Where The Following Function Is Not ChangingDocument5 paginiRate of Change: Example 1 Determine All The Points Where The Following Function Is Not ChangingKishamarie C. TabadaÎncă nu există evaluări

- Powerful Technical Computing with MathematicaDocument3 paginiPowerful Technical Computing with MathematicazoksiÎncă nu există evaluări

- Adoption ApplicationDocument3 paginiAdoption ApplicationwriterhildÎncă nu există evaluări

- Samsung Investor Presentation CE 2022 v1Document22 paginiSamsung Investor Presentation CE 2022 v1Sagar chÎncă nu există evaluări

- Mémoire ENSMDocument97 paginiMémoire ENSMAntoine Laurent100% (1)

- Keyence cv700 - Man2Document232 paginiKeyence cv700 - Man2kamaleon85Încă nu există evaluări

- Ammonium Nitrophosphate Production ProcessDocument133 paginiAmmonium Nitrophosphate Production ProcessHit Busa100% (1)

- TM 5-5031 HOLLINGSWORTH GENERATORS CE-51-DC AND DC - WK2 MODELS, 1953Document16 paginiTM 5-5031 HOLLINGSWORTH GENERATORS CE-51-DC AND DC - WK2 MODELS, 1953Advocate100% (1)

- Module 3 FP Client AssessmentDocument54 paginiModule 3 FP Client AssessmentJhunna TalanganÎncă nu există evaluări

- Ball Bearings 1Document17 paginiBall Bearings 1ManicharanÎncă nu există evaluări

- Service ManualDocument14 paginiService ManualOlegÎncă nu există evaluări

- Manual For Master Researchpproposal - ThesisDocument54 paginiManual For Master Researchpproposal - ThesisTewfic Seid100% (3)

- Gen-6000-0mh0/0mhe Gen-6000-0mk0 Gen-6000-0ms0/0mse Gen-7500-0mh0/0mhe Gen-8000-0mk0/0mke Gen-8000-0ms0/0mseDocument26 paginiGen-6000-0mh0/0mhe Gen-6000-0mk0 Gen-6000-0ms0/0mse Gen-7500-0mh0/0mhe Gen-8000-0mk0/0mke Gen-8000-0ms0/0mseAhmed Khodja KarimÎncă nu există evaluări

- Lahore School of Economics Operations Management Final Group Project Outline (Weightage 15%) Bba - Iv Instructor: Dr. Saba Fazal FirdousiDocument3 paginiLahore School of Economics Operations Management Final Group Project Outline (Weightage 15%) Bba - Iv Instructor: Dr. Saba Fazal FirdousiAshir HassanÎncă nu există evaluări

- The 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoDocument18 paginiThe 4Ms of Operations: Prepared By: Karla Jane F. BangaysisoKarla BangFerÎncă nu există evaluări

- Syllabus: Android Training Course: 1. JAVA ConceptsDocument6 paginiSyllabus: Android Training Course: 1. JAVA ConceptsVenkata Rao GudeÎncă nu există evaluări

- Salting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorDocument10 paginiSalting-Out Crystallisation Using NH Ina Laboratory-Scale Gas Lift ReactorChester LowreyÎncă nu există evaluări

- Lecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Document42 paginiLecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Francisco AraujoÎncă nu există evaluări

- DIRECTORS1Document28 paginiDIRECTORS1Ekta ChaudharyÎncă nu există evaluări