Documente Academic

Documente Profesional

Documente Cultură

Differential Reactor

Încărcat de

Cik Tiem NgagimanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Differential Reactor

Încărcat de

Cik Tiem NgagimanDrepturi de autor:

Formate disponibile

[ASSIGNMENT OF CHEMICAL REACTION ENGINEERING] December 21, 2013

DIFFERENTIAL REACTOR:

Differential reactors are running in a very low conversion mode. They are good

reactor for kinetic measurement. When the conversion is infinitesimally small, our

conversion represents directly the reaction rate. Typical differential reactors are fixed bed

reactor with very low fixed bed height. For getting rid of the problem of very small

concentration differences we can take the differential loop reactor with high recirculation

factors. Here we get an 'enhancement' by multiple passing of the 'differential bed' and as a

further advantage that we can use the material balance of a CSTR for the differential loop

reactor with high recirculation. For the differential reactors, it can be single pass reactor,

recycle reactor or stirred gas reactor. All of these reactors are involved about the kinetic

measurement characteristics.

Differential reactors are primarily used for studies of heterogeneous catalysis. While

for homogeneous reaction, it is very difficult to confine as sharply as necessary to a very

small flow reactor.

A differential reactor operated with once-through flow has the advantages of

functioning, like a CSTR at one well-defined conversion level. Moreover, other than in

CSTR, this level is directly set by the chosen composition of the entering fluid. The principal

problem is how to measure the minimal composition difference between the entering and

existing fluid with the required accuracy.

Differential reactors with once-through flow thus are especially suited for

determination of initial reaction rate; with an entering fluid as yet free of products, but

much less so far measurements at moderate to high conversion.

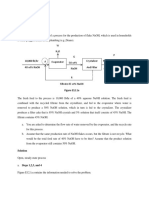

THE FIGURE OF DIFFERENTIAL

REACTOR:

[ASSIGNMENT OF CHEMICAL REACTION ENGINEERING] December 21, 2013

Since the conversion that across the reactor is minimal thus, no corrections for the

possible fluid-density variation with conversion need to be applied. Because of the difficulty

of measuring minimal conversions accurately, differential reactors are often operated with

recycle instead of once-through. A large constant amount of the fluid is rapidly circulated

through the reactor and its composition is monitored continuously or at frequent time

intervals.

Although conversion with each pass through the reactor is minimal, it is cumulative

and so progresses steadily with time. Thus, like a batch reactor, a differential recycle

reactor operated over a prolonged time span scans a wide conversion range.

In performance, a differential recycle reactor resembles a batch reactor in that

conversion progresses with time. The difference is that in a batch reactor, the reaction

occurs in all of the fluid whereas in a differential recycle reactor it does so only in a small

fraction because at any time most of the fluid is in the recycle loop rather than the reactor

itself.

APPLICATION OF DIFFERENTIAL REACTOR:

1. Waste water management that used reactor in order to pre-treat the waste water to

produce biogas and bio fertilizer.

2. Waste water reduction and recycling in food processing operations because the

water always used and vital for the food cleaning, sanitizing and etc.

3. Pharmaceutical production

4. Pulp and paper industry.

ADVANTAGES OF DIFFERENTIAL REACTOR:

1. Excellent for measurement of initial rates.

2. Sampling from reactor effluent.

3. Easy temperature control

4. Minimum attrition of solid catalyst.

[ASSIGNMENT OF CHEMICAL REACTION ENGINEERING] December 21, 2013

DISADVANTAGES OF DIFFERENTIAL REACTOR:

1. Accurate measurement of minimal product concentration required.

2. Exact, constant flow rate required.

3. Not well suited homogeneous reaction

4. Uniform flow pattern difficult to achieve.

ADVANTAGES FOR DIFFERENTIAL RECYCLE REACTOR:

1. Sampling from reactor effluent.

2. Easy temperature control

3. Minimum attrition of solid catalyst

4. Can scan wide conversion ranges in single experiment

DISADVANTAGES OF DIFFERENTIAL RECYCLE REACTOR:

1. Exact, constant flow rate required

2. Not well suited for homogeneous reactions.

3. Uniform flow patterns difficult to achieve.

4. Long running times required.

S-ar putea să vă placă și

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringDe la EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringÎncă nu există evaluări

- CRE Theory QuestionsDocument2 paginiCRE Theory QuestionsJunaid ParkerÎncă nu există evaluări

- Chương 1 - Bài TậpDocument25 paginiChương 1 - Bài TậpTÍN Phạm Nguyễn TrọngÎncă nu există evaluări

- 2019 CPC Problem SheetDocument1 pagină2019 CPC Problem SheetjacksonÎncă nu există evaluări

- 4-Nonelementary Reaction KineticsDocument23 pagini4-Nonelementary Reaction KineticsFajri AmrullahÎncă nu există evaluări

- CAP13Document21 paginiCAP13LIma NetoÎncă nu există evaluări

- Lecture 9Document4 paginiLecture 9Asif AliÎncă nu există evaluări

- Enzimas Fogler Resolução PDFDocument30 paginiEnzimas Fogler Resolução PDFOdilon LeiteÎncă nu există evaluări

- Two Film Theory Applied at Steady-State: N K (P - P) K (C - C) K (P - P) K (C - C)Document25 paginiTwo Film Theory Applied at Steady-State: N K (P - P) K (C - C) K (P - P) K (C - C)ermias100% (1)

- Mid Sem 2012Document5 paginiMid Sem 2012JimÎncă nu există evaluări

- Cap 222222Document27 paginiCap 222222Paty ChiluisaÎncă nu există evaluări

- Lec 14 Mass TransferDocument36 paginiLec 14 Mass TransferWaseem abbas100% (1)

- Castellan Physical Chemistry (PDFDrive - Com) - Halaman-51-83Document33 paginiCastellan Physical Chemistry (PDFDrive - Com) - Halaman-51-83rabiatulÎncă nu există evaluări

- Ch516 Chemical & Catalytic Reaction Engineering Assignment 5Document3 paginiCh516 Chemical & Catalytic Reaction Engineering Assignment 5Janaki Devi Parrat0% (1)

- Synthesis Gas Flue Gas: BurnerDocument2 paginiSynthesis Gas Flue Gas: BurnerAbu Bakar Ameer KhanÎncă nu există evaluări

- Chemical Reactors: FoglerDocument34 paginiChemical Reactors: FoglerMike PoulinÎncă nu există evaluări

- Geankoplis 12.10-5: Nama: Qasimatul Wasilah Kelas: 3d D4 Tki Nim: 1841420068Document8 paginiGeankoplis 12.10-5: Nama: Qasimatul Wasilah Kelas: 3d D4 Tki Nim: 1841420068CiciÎncă nu există evaluări

- CHE S402 Chapter9 Deactivation Part2Document9 paginiCHE S402 Chapter9 Deactivation Part2Sonu SinghÎncă nu există evaluări

- (Solved) 8.4-3. Effect of Evaporator Pressure On Capacity and Product..Document3 pagini(Solved) 8.4-3. Effect of Evaporator Pressure On Capacity and Product..CycuÎncă nu există evaluări

- Exercise CH 1 (New)Document22 paginiExercise CH 1 (New)Wengki MuhammadÎncă nu există evaluări

- Separation Process QuestionDocument3 paginiSeparation Process QuestionuniversalgÎncă nu există evaluări

- Thermodynamics TutorialDocument2 paginiThermodynamics TutorialMuhamad Hazim Zaaba0% (1)

- LAB5Document1 paginăLAB5Tarmizi Al-AminÎncă nu există evaluări

- Tute ProblemsDocument5 paginiTute Problemsralston204Încă nu există evaluări

- Kinetics and Mechanism of Urea FormaldehydeDocument5 paginiKinetics and Mechanism of Urea FormaldehydeDessy A. SariÎncă nu există evaluări

- CH - Chemical Reaction Engineering PDFDocument23 paginiCH - Chemical Reaction Engineering PDFGlexer Dazo CorralesÎncă nu există evaluări

- Tugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Document8 paginiTugas 1 Termo 2 - Rabu - Putra Maulana - 5213415062Putra MaulanaÎncă nu există evaluări

- Chapter 4 م. احسان حبيبDocument22 paginiChapter 4 م. احسان حبيبعبد اللهÎncă nu există evaluări

- The BET IsothermDocument7 paginiThe BET IsothermBasemÎncă nu există evaluări

- Ideal Reactors Part 2 Solved ProblemsDocument15 paginiIdeal Reactors Part 2 Solved ProblemsWaldi SagalaÎncă nu există evaluări

- Semibatch UniDocument22 paginiSemibatch UniMelgi159100% (1)

- SelectionDocument11 paginiSelectionRahmat Agustriono100% (1)

- Chemical Reactor Design++ PDFDocument72 paginiChemical Reactor Design++ PDFKiran Patil0% (1)

- Enrtl-Rk Rate Based Dga ModelDocument30 paginiEnrtl-Rk Rate Based Dga ModelsamandondonÎncă nu există evaluări

- TesDocument6 paginiTesDanika PutriÎncă nu există evaluări

- By: Carlo Manuel A. BanquerigoDocument10 paginiBy: Carlo Manuel A. BanquerigoChristy Joy RetanalÎncă nu există evaluări

- Question: 7.29. Liquid Water Is Fed To A Boiler at 24°C and 10 Bar and IDocument1 paginăQuestion: 7.29. Liquid Water Is Fed To A Boiler at 24°C and 10 Bar and IHaikal JamilÎncă nu există evaluări

- Vapour in Air DiffusionDocument12 paginiVapour in Air Diffusionshivangsharma105629Încă nu există evaluări

- XDocument2 paginiXXxxÎncă nu există evaluări

- Tugas2 ParalelB 4Document14 paginiTugas2 ParalelB 4Thobroni AkbarÎncă nu există evaluări

- RingMethod Zuidema WatersDocument2 paginiRingMethod Zuidema WatersJack Yoseph Martinez OrtegaÎncă nu există evaluări

- HimmelblauDocument17 paginiHimmelblauadilla nitaaÎncă nu există evaluări

- Mass Transfer CoefficientDocument5 paginiMass Transfer CoefficientPinjala AnoopÎncă nu există evaluări

- Example 6.3 Kelompok VDocument13 paginiExample 6.3 Kelompok VMiranda Amiroh SulaimanÎncă nu există evaluări

- WO2017121980A1Document24 paginiWO2017121980A1Hardimas dwi cahyoÎncă nu există evaluări

- Something Related To Catalysts.Document2 paginiSomething Related To Catalysts.Deepro BhattacharyaÎncă nu există evaluări

- Patel TejaDocument3 paginiPatel TejaFisicoquimica ULSÎncă nu există evaluări

- Lab 5 Full ReportDocument9 paginiLab 5 Full Reporttirahanafi100% (1)

- Non-Ideal Reactors: Deviations From Ideal Reactor BehaviorDocument8 paginiNon-Ideal Reactors: Deviations From Ideal Reactor BehaviorrawadÎncă nu există evaluări

- Perrys Handbook ViscosityDocument3 paginiPerrys Handbook ViscosityAlexis Cieza Bailon0% (2)

- Heisler Graphics PDFDocument3 paginiHeisler Graphics PDFPedro Augusto Soares100% (1)

- Perry Hal 132-133 Densitas AirDocument2 paginiPerry Hal 132-133 Densitas AiraaÎncă nu există evaluări

- CLO-2 Packed and Fluidized BedsDocument44 paginiCLO-2 Packed and Fluidized BedskhalifaÎncă nu există evaluări

- Semester-6 3360503 CRE MCQ KRD PDFDocument9 paginiSemester-6 3360503 CRE MCQ KRD PDFDhruv RanaÎncă nu există evaluări

- Properties of Petroleum ProductsDocument30 paginiProperties of Petroleum ProductsBharath KumarÎncă nu există evaluări

- Vapor-Phase Chemical Equilibrium For The Hydrogenation of Benzene To Cyclohexane From Reaction-Ensemble GazDocument13 paginiVapor-Phase Chemical Equilibrium For The Hydrogenation of Benzene To Cyclohexane From Reaction-Ensemble GazebrarÎncă nu există evaluări

- Tripoli University Faculty of Engineering Chemical Engineering DepartmentDocument9 paginiTripoli University Faculty of Engineering Chemical Engineering DepartmentSrewaBenshebilÎncă nu există evaluări

- Tutorial Chapter 2 PDFDocument2 paginiTutorial Chapter 2 PDFKaul PatrickÎncă nu există evaluări

- Continuous Stirred Tank ReactorDocument11 paginiContinuous Stirred Tank ReactorFikrie Muhd100% (1)

- Reactors1 29Document2 paginiReactors1 29Mourad kharbachÎncă nu există evaluări

- Stirrer Batch ReactorDocument4 paginiStirrer Batch ReactorCik Tiem NgagimanÎncă nu există evaluări

- Simulation Using PFR (Aspen Plus)Document10 paginiSimulation Using PFR (Aspen Plus)Cik Tiem NgagimanÎncă nu există evaluări

- Packed Bed ReactorDocument6 paginiPacked Bed ReactorCik Tiem Ngagiman89% (9)

- CSTR 40 LDocument28 paginiCSTR 40 LCik Tiem Ngagiman50% (2)

- L9-Tubular Flow ReactorDocument20 paginiL9-Tubular Flow ReactorCik Tiem Ngagiman82% (11)

- Fluid Lab 2 - Bernoulli ExpDocument19 paginiFluid Lab 2 - Bernoulli ExpCik Tiem Ngagiman89% (65)

- Social Networking Problems Among Uitm Shah Alam StudentsDocument21 paginiSocial Networking Problems Among Uitm Shah Alam StudentsCik Tiem Ngagiman100% (1)

- Perfect Gas ExpansionDocument35 paginiPerfect Gas ExpansionCik Tiem Ngagiman63% (8)

- Flow of Water by Notch and WeirsDocument15 paginiFlow of Water by Notch and WeirsCik Tiem Ngagiman93% (29)

- Determination of Concentration of ChromiumDocument26 paginiDetermination of Concentration of ChromiumCik Tiem Ngagiman70% (10)

- Soap and DetergentDocument24 paginiSoap and DetergentCik Tiem Ngagiman80% (10)

- Defeating An Old Adversary Cement Kiln BallsDocument5 paginiDefeating An Old Adversary Cement Kiln BallsManish KumarÎncă nu există evaluări

- 7Document101 pagini7Navindra JaggernauthÎncă nu există evaluări

- Vicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Document10 paginiVicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Vieyah Angela VicenteÎncă nu există evaluări

- Syed Hamid Kazmi - CVDocument2 paginiSyed Hamid Kazmi - CVHamid KazmiÎncă nu există evaluări

- PW Unit 8 PDFDocument4 paginiPW Unit 8 PDFDragana Antic50% (2)

- Certification and LettersDocument6 paginiCertification and LettersReimar FerrarenÎncă nu există evaluări

- Outage Analysis of Wireless CommunicationDocument28 paginiOutage Analysis of Wireless CommunicationTarunav SahaÎncă nu există evaluări

- Data Mining - Exercise 2Document30 paginiData Mining - Exercise 2Kiều Trần Nguyễn DiễmÎncă nu există evaluări

- Introduction To AirtelDocument6 paginiIntroduction To AirtelPriya Gupta100% (1)

- Simavi - Project Officer PROPOPIDocument4 paginiSimavi - Project Officer PROPOPIAgus NugrahaÎncă nu există evaluări

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Document9 paginiBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanÎncă nu există evaluări

- Donation Drive List of Donations and BlocksDocument3 paginiDonation Drive List of Donations and BlocksElijah PunzalanÎncă nu există evaluări

- Income Tax Calculator 2023Document50 paginiIncome Tax Calculator 2023TARUN PRASADÎncă nu există evaluări

- Icom IC F5021 F6021 ManualDocument24 paginiIcom IC F5021 F6021 ManualAyam ZebossÎncă nu există evaluări

- Understanding Consumer and Business Buyer BehaviorDocument47 paginiUnderstanding Consumer and Business Buyer BehaviorJia LeÎncă nu există evaluări

- Frigidaire Parts and Accessories CatalogDocument56 paginiFrigidaire Parts and Accessories CatalogPedro RuizÎncă nu există evaluări

- Switch CondenserDocument14 paginiSwitch CondenserKader GüngörÎncă nu există evaluări

- Modulation and Frequency Synthesis X Digital Wireless RadioDocument233 paginiModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Încă nu există evaluări

- Danube Coin LaundryDocument29 paginiDanube Coin LaundrymjgosslerÎncă nu există evaluări

- Ethercombing Independent Security EvaluatorsDocument12 paginiEthercombing Independent Security EvaluatorsangelÎncă nu există evaluări

- Agreement Deed BangladeshDocument8 paginiAgreement Deed BangladeshVabna EnterpriseÎncă nu există evaluări

- Allplan 2006 Engineering Tutorial PDFDocument374 paginiAllplan 2006 Engineering Tutorial PDFEvelin EsthefaniaÎncă nu există evaluări

- Admissibility of Whatsapp Messages in Court For Family MattersDocument3 paginiAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliÎncă nu există evaluări

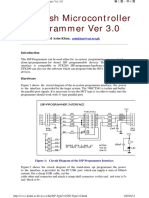

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocument4 paginiISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićÎncă nu există evaluări

- Starkville Dispatch Eedition 12-9-18Document28 paginiStarkville Dispatch Eedition 12-9-18The DispatchÎncă nu există evaluări

- CY8 C95 X 0 ADocument32 paginiCY8 C95 X 0 AAnonymous 60esBJZIj100% (1)

- Rs 422Document1 paginăRs 422rezakaihaniÎncă nu există evaluări

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDocument64 paginiMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrÎncă nu există evaluări

- Different Software Life Cycle Models: Mini Project OnDocument11 paginiDifferent Software Life Cycle Models: Mini Project OnSagar MurtyÎncă nu există evaluări

- Home Guaranty Corp. v. Manlapaz - PunzalanDocument3 paginiHome Guaranty Corp. v. Manlapaz - PunzalanPrincess Aliyah Punzalan100% (1)

- Hero Found: The Greatest POW Escape of the Vietnam WarDe la EverandHero Found: The Greatest POW Escape of the Vietnam WarEvaluare: 4 din 5 stele4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonDe la EverandSully: The Untold Story Behind the Miracle on the HudsonEvaluare: 4 din 5 stele4/5 (103)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDe la EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureEvaluare: 5 din 5 stele5/5 (125)

- The Fabric of Civilization: How Textiles Made the WorldDe la EverandThe Fabric of Civilization: How Textiles Made the WorldEvaluare: 4.5 din 5 stele4.5/5 (58)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachDe la EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachEvaluare: 3.5 din 5 stele3.5/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldDe la EverandThe Future of Geography: How the Competition in Space Will Change Our WorldEvaluare: 4 din 5 stele4/5 (6)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDe la EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyÎncă nu există evaluări

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDe la EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceEvaluare: 5 din 5 stele5/5 (5)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe la EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellEvaluare: 4.5 din 5 stele4.5/5 (82)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe la EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaÎncă nu există evaluări

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDe la EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreEvaluare: 4.5 din 5 stele4.5/5 (33)

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeDe la EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeEvaluare: 4.5 din 5 stele4.5/5 (99)

- Mini Farming: Self-Sufficiency on 1/4 AcreDe la EverandMini Farming: Self-Sufficiency on 1/4 AcreEvaluare: 4 din 5 stele4/5 (76)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- System Error: Where Big Tech Went Wrong and How We Can RebootDe la EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootÎncă nu există evaluări

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDe la EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationEvaluare: 4.5 din 5 stele4.5/5 (46)

- Highest Duty: My Search for What Really MattersDe la EverandHighest Duty: My Search for What Really MattersÎncă nu există evaluări

- Pale Blue Dot: A Vision of the Human Future in SpaceDe la EverandPale Blue Dot: A Vision of the Human Future in SpaceEvaluare: 4.5 din 5 stele4.5/5 (588)

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- Reality+: Virtual Worlds and the Problems of PhilosophyDe la EverandReality+: Virtual Worlds and the Problems of PhilosophyEvaluare: 4 din 5 stele4/5 (24)

- The Knowledge: How to Rebuild Our World from ScratchDe la EverandThe Knowledge: How to Rebuild Our World from ScratchEvaluare: 3.5 din 5 stele3.5/5 (133)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Process Plant Equipment: Operation, Control, and ReliabilityDe la EverandProcess Plant Equipment: Operation, Control, and ReliabilityEvaluare: 5 din 5 stele5/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (122)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)