Documente Academic

Documente Profesional

Documente Cultură

Machine Design

Încărcat de

Stanly KurianDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Machine Design

Încărcat de

Stanly KurianDrepturi de autor:

Formate disponibile

I |||ilill ||l lllll lllll lllll lllll ill llll

Reg. No. :

Name 3 ......-.........o..............o""

VnI Semester

B.Tech.

(Supplementary)

-

Including Part-Time

Degree Examination, October 20ll

(2007 Admn.)

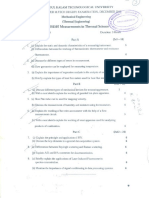

PT 2K6I2K6 ME 803 : MACHINE DESIGN

-

II

Time : 3 Hours

Max. Marks : 100

Instructinn : Machine design data hand book Vol. I and II

-

LINGAIAH

mny be provided.

I. 1) a) List any five advantages and disadvantages

of V-belts over flat belts. I

b) Derive an expression for torque transmitting capacity of a single plate clutch

according to Uniform Wear TheorY.

Z) a) With the help of schematic diagram for a bevel gaar., explain the terms

pitch cones, back cone distance, pitch angle, face angle.

b) List any four advantages and disadvantages of worm geat drive.

3) a) Explain hydrodynamic

lubrication with a neat sketch.

b) Explain the basic procedure for the selection of a rolling contact bearing.

4) a) Explain the design recommendations

for turned parts.

b) Explain the design recommendations

for screw-machine

products.

(8x5=40)

U. 1) A) Select a suitable roller chain to transmit 6 KW power from an electric

motor to an air compressor.

The speed of motor and compressor are

900 rpm and 37 5 rpm respectively. The approximate distance between the

sprockets

is 600 mm. Take a factor of safety based on breaking load as 6. I

M 19924

)

5

F

J

s

5

f

J

F

5

F

)

OR

P.T.0.

M 19924

B)

m. 1) A)

| ffitilil ilt ilIil ililt illll illll llll llll

a) A 50 KW

,

1440 rpm motor is required to drive an air compressor

througlQ the medium of V-belting. The pitch diameter of the motor

pulley and compressor

pulley are 250 mm and 800 mm respectively.

T'n" approximately centre distance between the shafts is 1.5'm.tSelect

the suitable v-belt.

10

b) A leather belt 125 mm wide and 6 mm thick, transmitting

power from a

pulley 7 50 mm diameter which runs at 500 rpm. The angle of lap

is 150" and the co-efficient of friction between the belt and the pulley

is 0.3. If the belt density is 1000 Kg/m3 and the stress in the belt is not

to exce ed 2.7 5 N/mm2, find the power that can be transmitted by the .

belt. Also find the initial tension in the belt.

5

(15x 1=15)

Two shaft at right angles are connected with a pair of bevel gears

having l4rlz" tooth form. The pinion is made of steel

(op

=

120 MN/m2)

and the geai is ro be made of cast iron (oo

=

80 MN/mz). The pinion

having 26 teeth is to transmit 10 KW power at 1200 rpm. The velocity

ratio is to be 2:5 : 1. The gears are heat treated to Brinell hardness of 200.

Design the gear for strength.

OR

B) Design a steel helical gear pair from the following data :

a) Power transmitted N

-

30 KW

b) Speed of pinion n,

=

1500 rPm

c) Pressure angle in diametral

plane G

r

=

20" full depth involute

d) Helix angle

B

=

30o

.) Velocity ratio i

-

4

0

Number of teeth on

Pinion

Zt

=

24

g) Static stress for cast steel o01

=

6oz

=

50.71 N/mm2

h) Brinell hardness number for geat material

=

350.

(15x 1= 15)

1y. l) A) A 40 mm diameter shaft is supported between two bearings A and D as

shown in fig. 1. The pulley B of weight 400 N receives power from another

equal diameter pulley mounted on 6 KW electric motor. The speed of the

motor is 600 rpm. The belt drive is horizontal and the ratio of tensions is 1.8.

-2-

15

15

r il|il|il lt ilil| ilil| llll lllt lilt ill

M 19924

The power from the shaft is transmitted through a helic aL gear C to a

pinion mounted infront of it. The teeth arc 20" stub with a helix angle

of 30'. Select a medium series ball bearing on the basis of heavily loaded

bearing. The expected life of bearing is 20,000 hours.

15

-3-

Ft

{e

I

wp

Fi e. 1 (Q. IV (1 A)

OR

B) a) A shaft running at 600 rpm is supported in a bearing of 60 mm diameter

and 60 mm long. The viscosity of oil is 0.014 Pas and the temperature

of oi l i s 110' C. The radi al cl earance i s 0.03 mm. Determi ne the

permissible load and the power lost in the bearing if there is not external

cooling is provided. The temperature of still air in the room is 20"C.

',,

b) A full

journal

bearing of length 100 mm and the

journal

diameter

of 80 mm supports a l oad of 2.5 kN at 600 rpm. What vi scosi ty

oil should be used to limit the bearing surface temperature to 60"C ?

fhe room temperature is 20"C and the clearance ratio is 0.001. Use

McKee' s equati on.

(15xL=L

V. 1) A) Explain the design recommendations for machined round holes. 1

OR

B

)

Explain the design recommendations for welded part. 15

( 15x 1=15)

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Material Testing Laboratory Manual: For Civil & Mechanical Engineering (As Per KTU Syllabus)Document95 paginiMaterial Testing Laboratory Manual: For Civil & Mechanical Engineering (As Per KTU Syllabus)Stanly KurianÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Measurements in Thermal ScienceDocument1 paginăMeasurements in Thermal ScienceStanly KurianÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- 2019 IEEE ASPP Online Title ListDocument28 pagini2019 IEEE ASPP Online Title ListStanly KurianÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Reported SpeechDocument12 paginiReported SpeechStanly KurianÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Micro Electronics TechnologyDocument2 paginiMicro Electronics TechnologyStanly KurianÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Supply Chain and Inventory ManagementDocument2 paginiSupply Chain and Inventory ManagementStanly KurianÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 2K6 CS 304 - Nov 2010Document2 pagini2K6 CS 304 - Nov 2010Stanly KurianÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Ilffiiililt Il - T Ililt Iltil - ) Il IltlDocument2 paginiIlffiiililt Il - T Ililt Iltil - ) Il IltlStanly KurianÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Marketing ManagementDocument2 paginiMarketing ManagementStanly KurianÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Radar and Navigation October 2011Document2 paginiRadar and Navigation October 2011Stanly KurianÎncă nu există evaluări

- 2K6 CS 606 (A) - May 2013Document2 pagini2K6 CS 606 (A) - May 2013Stanly KurianÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- R - Ililt Ilt LLLLL Llill L) Il Ilf, Lffi - Ill M 19926Document3 paginiR - Ililt Ilt LLLLL Llill L) Il Ilf, Lffi - Ill M 19926Stanly KurianÎncă nu există evaluări

- Stacker Lubricat TableDocument4 paginiStacker Lubricat TableSemlali ZakariaÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Group 14 Cooling: 1. Cooling System (Flow of Coolant) 2. Thermostat 3. Water PumpDocument21 paginiGroup 14 Cooling: 1. Cooling System (Flow of Coolant) 2. Thermostat 3. Water PumpclaudiosilvahÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Design MabangisDocument156 paginiDesign MabangissedexxÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- QuestionsDocument21 paginiQuestionsBiraj PoudelÎncă nu există evaluări

- Conceptual Design and Simulation of African Oil Bean Seed DehullerDocument15 paginiConceptual Design and Simulation of African Oil Bean Seed DehullerAZOJETE UNIMAIDÎncă nu există evaluări

- Obile Rusher: 228 KW 306 HP at 1950 RPMDocument8 paginiObile Rusher: 228 KW 306 HP at 1950 RPMFeby PratamaÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Stationary Air Compressors Compresseur D'air Stationnaire Compresores de Aire EstacionariosDocument8 paginiStationary Air Compressors Compresseur D'air Stationnaire Compresores de Aire EstacionariosA delca-Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hitachi VM Series Camcorder ServicingDocument3 paginiHitachi VM Series Camcorder ServicingsixstringÎncă nu există evaluări

- Centrifugal Fan ManualDocument21 paginiCentrifugal Fan ManualClaudia MaldonadoÎncă nu există evaluări

- Friction Problems PDFDocument21 paginiFriction Problems PDFMaicol Nelson Polo MauricioÎncă nu există evaluări

- Automated Portable Hammering Machine: ComponentsDocument2 paginiAutomated Portable Hammering Machine: ComponentsDheerajyadav YadavÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Planer Machine - Parts, Working, Operation, Types, Advantages (With PDF)Document1 paginăPlaner Machine - Parts, Working, Operation, Types, Advantages (With PDF)andualem saleamelakÎncă nu există evaluări

- Janome JF Series Service ManualDocument28 paginiJanome JF Series Service ManualGinny RossÎncă nu există evaluări

- 3208 Marine 75v1-Up 01z1-UpDocument52 pagini3208 Marine 75v1-Up 01z1-UpCristobal Campos100% (3)

- Increasing Bucket Elevator CapacityDocument4 paginiIncreasing Bucket Elevator Capacity4B Braime ComponentsÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- s2000 Tech Faq 030107Document65 paginis2000 Tech Faq 030107Djbower1Încă nu există evaluări

- MD 2 FinalsDocument43 paginiMD 2 FinalsRea RebenqueÎncă nu există evaluări

- Oil Grabber Model 4, Belt Oil Skimmer - Abanaki CorporationDocument4 paginiOil Grabber Model 4, Belt Oil Skimmer - Abanaki CorporationKyle ChandlerÎncă nu există evaluări

- Auto Reverse Document Feeder Df82 B714 Parts Location and ListDocument23 paginiAuto Reverse Document Feeder Df82 B714 Parts Location and ListHelpCopies SrlÎncă nu există evaluări

- Finisher SR3120 (D636) 111219Document54 paginiFinisher SR3120 (D636) 111219william lozadaÎncă nu există evaluări

- Fastrak Parts 333559 - 0510Document100 paginiFastrak Parts 333559 - 0510Mike Hunter-MallettÎncă nu există evaluări

- Booking PriceDocument12 paginiBooking Pricealaazeki90Încă nu există evaluări

- Ecostan Esm 150Document4 paginiEcostan Esm 150angdutta2Încă nu există evaluări

- Alfa Laval DecantercentrifugemanualDocument108 paginiAlfa Laval DecantercentrifugemanualPASEOS1372880% (5)

- Blower Lutos BH6 10 Manual enDocument40 paginiBlower Lutos BH6 10 Manual envictoraghiÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- List Down Some of The Benefits Obtained From Implementing A Good Material Handling SystemDocument11 paginiList Down Some of The Benefits Obtained From Implementing A Good Material Handling SystempenihaniÎncă nu există evaluări

- TD ED enDocument68 paginiTD ED enAshraf AbdelsalamÎncă nu există evaluări

- B1 (111 - 2001) Walking-Type Agricultural Tractor Methods of TestDocument21 paginiB1 (111 - 2001) Walking-Type Agricultural Tractor Methods of TestRustan Ace EstoestaÎncă nu există evaluări

- 1 6 77 KW MPI EngineDocument146 pagini1 6 77 KW MPI EngineAdrian Todea100% (1)

- CONVEYORDocument80 paginiCONVEYORMantto. MecánicoÎncă nu există evaluări