Documente Academic

Documente Profesional

Documente Cultură

Analysis of Preservatives in Soft Drinks

Încărcat de

nazkudutDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Analysis of Preservatives in Soft Drinks

Încărcat de

nazkudutDrepturi de autor:

Formate disponibile

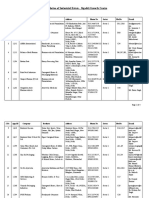

Analysis of Benzoate and Sorbate in Soft Drinks

Source: http://www.laboratorytalk.com/news/mea/mea254.html

Soft drinks have been part of our global lifestyle since the nineteenth century

and many of the soft drinks we consume today are the same as those first

enjoyed centuries ago

A preservative is a substance, such as sodium benzoate or potassium

sorbate, that enables soft drink products to have a longer shelf life by inhibiting

or arresting the growth of micro-organisms such as yeasts, moulds and

bacteria

The use of preservatives in soft drinks.

Not all soft drinks contain preservatives; their need is dependant upon

the type of product and the processing used. The presence of carbon dioxide

prevents mould growth and the high levels of acidity and carbonation help to

inhibit the growth of yeasts and lactic acid bacteria.

Conversely those beverages that contain fruit or fruit juices provide

additional nutrients that may enable organisms to grow despite the levels of

acidity and carbonation.

The soft drink products most likely to ferment are mildly acidic types

with low carbonation containing fruit juice and in these instances a

preservative is added to prevent micro-biological spoilage.

The most common preservatives used in soft drinks are sodium

benzoate and potassium sorbate and they may be used in tandem. Sodium

benzoate is the salt of benzoic acid and occurs naturally in the lingon berry,

while potassium sorbate is found in the rowan berry.

Sodium benzoate is effective against yeasts and moulds but can be

difficult to dissolve and can impart a slight flavour at high levels. Potassium

sorbate meanwhile is more effective at lower acidities than sodium benzoate

but is much more expensive and less effective against certain strains of

bacteria. In cold conditions its solubility is reduced and it can suppress the

flavour of the drink.

The use of preservatives in soft drinks throughout Europe is governed

by the EU Directive on food additives other than colours and sweeteners,

transposed to a national level for implementation by the individual member

states. In the United Kingdom, the legislation is covered under the

Miscellaneous Food Additive Regulations 95.

The ingredients in soft drinks.

The ingredients used in soft drink beverages are approved and closely

regulated by bodies such as the US Food and Drug Administration or the Food

Standards Agency in the UK.

There are an enormous number of soft drinks that are formulated to

different recipes and not all the ingredients are found in all soft drink products.

Most regular soft drinks contain around 90% of water from a pure source,

while diet variants may comprise up to 99% of water.

Drinking water can contain trace amounts of different minerals that can

affect its taste and so bottling and manufacturing plants use sophisticated

filtering and treatment equipment, to help remove residual impurities to

standardise the quality of water used to produce the beverage, to ensure the

same taste whether the drink is produced in the UK or Germany.

Carbon dioxide is an essential ingredient present in all carbonated

beverages and imparts a unique taste when dissolved in water. In the early

days of soft drink manufacturing, carbon dioxide was derived from sodium

salts giving rise to the term soda or soda water. Today, carbon dioxide gas is

absorbed into the flavoured soft drink with a carbonation machine just before

the container is sealed.

While under pressure and chilled, the soft drink can absorb up to four

times the beverage's volume of carbon dioxide. When the soft drink container

is opened, the 'pop' heard and 'fizz' observed is the rapid escape of carbon

dioxide caused by the sudden release of pressure on the product.

Many soft drink producers mix many individual flavours to create a

uniform, unique taste. Natural flavours come from spices, oils and natural

extracts while fruit flavoured beverages may contain natural fruit extracts.

Artificial flavourings are used when nature does not produce enough of certain

flavours to satisfy the global demand and some natural flavours may be limited

to geographical locations as well as seasonal fluctuations. Colourings are an

important factor in taste perception as it affects our psychological impression

of food and these may originate from both natural and synthetic sources.

Caffeine is a naturally occurring substance that is added to certain soft

drink beverages (particularly colas) as part of the flavour profile as its bitter

taste enhances other flavours.

Acidity regulators add tartness to soft drinks and help act as a

preservative and beverages may contain small amounts of either phosphoric

acid or citric acid.

Soft drinks should not normally spoil because of their acidity and

carbonation but storage conditions and time can impact the taste and flavour.

For this reason, some beverages contain small amounts of preservatives.

Most of the sodium and potassium present in soft drink products are

derived from the water used in production as well as trace amounts from other

ingredients present.

Regular soft drink beverages are sweetened with sucrose or fructose

and diet formulations with intensely sweet substances such as aspartame or

saccharin.

Manufacture of soft drinks.

The production of soft drink beverages begins by forming a sugar and

water syrup while around the same time an extract made up of fruit juice,

aromatic substances and acids is produced. The components are thoroughly

mixed into a soft drink concentrate to give a syrup mixture. The water is de-

aerated to avoid oxidation reactions that can destroy the aromatic substances.

For carbonated drinks, carbon dioxide is dissolved into the water at low

temperatures under high pressures. It is important that all the air has been

removed otherwise the beverage will froth over when the container is opened.

The syrup and carbonated water are then mixed in the correct proportions

according to their formulation prior to bottling, storage and then transportation

of the finished soft drink product to the consumer.

S-ar putea să vă placă și

- Carbonated BeveragesDocument7 paginiCarbonated BeveragesKapithas EswaranÎncă nu există evaluări

- MANUFACTURING CARBONATED BEVERAGESDocument26 paginiMANUFACTURING CARBONATED BEVERAGESBhavyata VermaÎncă nu există evaluări

- Soft Drink BasicsDocument6 paginiSoft Drink BasicsAlbert BohrÎncă nu există evaluări

- Assignment 2. BeverageDocument4 paginiAssignment 2. BeverageOctavius MuyungiÎncă nu există evaluări

- Production of Soft Drinks: From Carbonated Water to PackagingDocument5 paginiProduction of Soft Drinks: From Carbonated Water to PackagingHamsa EhsanÎncă nu există evaluări

- Pepsi Co Manufacturing ProcessDocument6 paginiPepsi Co Manufacturing ProcessJai Rathor100% (1)

- Carbonated BeveragesDocument6 paginiCarbonated BeveragesVasu ShashankÎncă nu există evaluări

- How Pepsi is Manufactured: From Water Processing to Filling and PackagingDocument3 paginiHow Pepsi is Manufactured: From Water Processing to Filling and PackagingEdith Mendoza SabantoÎncă nu există evaluări

- Presentation ON Production Of: Pepsi Soft DrinkDocument16 paginiPresentation ON Production Of: Pepsi Soft DrinkManish TiwariÎncă nu există evaluări

- Assignment of Swot AnalysisDocument38 paginiAssignment of Swot AnalysisGaurav LakhlotraÎncă nu există evaluări

- Fermentation OwolabiDocument9 paginiFermentation OwolabiGabrielle WhelanÎncă nu există evaluări

- Chemstry Project Pranjali ChhajedDocument22 paginiChemstry Project Pranjali ChhajedpranjaliÎncă nu există evaluări

- Soft Carbonated BeveragesDocument23 paginiSoft Carbonated BeveragesBikila RusiÎncă nu există evaluări

- Soda ManufacturingDocument16 paginiSoda ManufacturingswapanaÎncă nu există evaluări

- Riddhirj Banerjee Class 11 Chem ProjectDocument9 paginiRiddhirj Banerjee Class 11 Chem ProjectRiddhiraj BanerjeeÎncă nu există evaluări

- Soft Drink: How Products Are MadeDocument11 paginiSoft Drink: How Products Are MadeChetan Ganesh RautÎncă nu există evaluări

- Formulation and Production of Carbonated BeveragesDocument5 paginiFormulation and Production of Carbonated Beveragesajit_7Încă nu există evaluări

- Carbonated Soft Drinks (CSD) - NoDocument50 paginiCarbonated Soft Drinks (CSD) - NoAbdur RafeyÎncă nu există evaluări

- Food AdditivesDocument11 paginiFood AdditivesLazline BrownÎncă nu există evaluări

- Name Ingredients in Carbonated Beverages and Explain Their FunctionDocument5 paginiName Ingredients in Carbonated Beverages and Explain Their Functionkolita kamalÎncă nu există evaluări

- Juice Analysis: Comparing Properties and StandardsDocument80 paginiJuice Analysis: Comparing Properties and StandardsEmerald LlonaÎncă nu există evaluări

- Project Report On Soft Drinks ManufacturingDocument9 paginiProject Report On Soft Drinks ManufacturingEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Determination of Cold Drink ContentsDocument21 paginiDetermination of Cold Drink ContentspranjaliÎncă nu există evaluări

- Operations Management-Mini Project: Prodution Process of Soft DrinksDocument16 paginiOperations Management-Mini Project: Prodution Process of Soft Drinksgina61191Încă nu există evaluări

- Natural Food PreservativesDocument5 paginiNatural Food Preservativesdevendra kumarÎncă nu există evaluări

- 5 CQI Robusta Matching Pairs Skills Test ClassDocument16 pagini5 CQI Robusta Matching Pairs Skills Test ClassEliane LoviseÎncă nu există evaluări

- 9 Food AcidulantsDocument41 pagini9 Food AcidulantsDahniarIkaÎncă nu există evaluări

- Chemistry Investigatory ProjectDocument8 paginiChemistry Investigatory Projectkyra sanejaÎncă nu există evaluări

- Carbonation of soft drinksDocument5 paginiCarbonation of soft drinksAvik JainÎncă nu există evaluări

- BacardiDocument29 paginiBacardiMilind Gavande100% (1)

- Safety of Soft Drinks and Fruit JuicesDocument4 paginiSafety of Soft Drinks and Fruit JuicesErika ArisetianaÎncă nu există evaluări

- Difference Between Soft Drinks and Hard DrinksDocument13 paginiDifference Between Soft Drinks and Hard DrinksClint Therens BacasmasÎncă nu există evaluări

- NonalcoholicDocument46 paginiNonalcoholicReghEllorimoÎncă nu există evaluări

- Discussion Exp 2 (Pickling)Document2 paginiDiscussion Exp 2 (Pickling)Nur AsiahÎncă nu există evaluări

- Comparative Study of Different Types of Cold DrinksDocument17 paginiComparative Study of Different Types of Cold DrinksdiyaÎncă nu există evaluări

- Pharamceutical SyrupsDocument5 paginiPharamceutical SyrupsAdnan AfridiÎncă nu există evaluări

- Beverage CreationDocument7 paginiBeverage Creationdarkness480Încă nu există evaluări

- Standards for Soft Drinks & BeveragesDocument54 paginiStandards for Soft Drinks & BeveragesNeerajKPÎncă nu există evaluări

- Fruit Juice Production and Organoleptic TestDocument22 paginiFruit Juice Production and Organoleptic Testnabila shaffaÎncă nu există evaluări

- Anything PH 7 of More Than 7 Is A BaseDocument1 paginăAnything PH 7 of More Than 7 Is A Basemaconte0449lagÎncă nu există evaluări

- Fase 3 IndividualDocument4 paginiFase 3 IndividualYudy Katerine Garzon RubioÎncă nu există evaluări

- Food Processing TechniquesDocument5 paginiFood Processing TechniquesJudie Lee TandogÎncă nu există evaluări

- VinegarDocument17 paginiVinegarJannusLim100% (1)

- bài giảng Beverage Tech. No.7- soft drinkDocument40 paginibài giảng Beverage Tech. No.7- soft drinkVũ Đăng DươngÎncă nu există evaluări

- FST-Paper - II Food Beverages - IV-SemesterDocument80 paginiFST-Paper - II Food Beverages - IV-SemesterAnrey Magallanes VolanteÎncă nu există evaluări

- Common Food Preservation IngredientsDocument4 paginiCommon Food Preservation IngredientsMelissa Gisela LopezÎncă nu există evaluări

- Divita 1Document14 paginiDivita 1Riya GoelÎncă nu există evaluări

- SAI THAVIH M KRISHNA G 12 cHEM INV - PROJDocument12 paginiSAI THAVIH M KRISHNA G 12 cHEM INV - PROJsaithavish .m.krishnaÎncă nu există evaluări

- Why Soft Drinks Are UnhealthyDocument30 paginiWhy Soft Drinks Are UnhealthyTanzeel Ur Rehman MalikÎncă nu există evaluări

- A Live Project On: Process of Making The Pepsi Soft DrinksDocument10 paginiA Live Project On: Process of Making The Pepsi Soft Drinksjubin75100% (2)

- Untitled PresentationDocument12 paginiUntitled Presentationapi-269187014Încă nu există evaluări

- Content of Cold Drinks Available in The MarketDocument8 paginiContent of Cold Drinks Available in The MarketAman SharmaÎncă nu există evaluări

- Types of Fruit BeveragesDocument11 paginiTypes of Fruit BeveragesAnkit0% (1)

- Soft Drink Analysis FinalDocument18 paginiSoft Drink Analysis FinalPaul GeorgeÎncă nu există evaluări

- Composition of GrapesDocument5 paginiComposition of GrapespeepgunÎncă nu există evaluări

- Food AdditivesDocument5 paginiFood AdditiveszezethuÎncă nu există evaluări

- Pickle and Sauekraut Technology 1Document24 paginiPickle and Sauekraut Technology 1Smruthi RaoÎncă nu există evaluări

- Purchase Order SampleDocument1 paginăPurchase Order SamplenazkudutÎncă nu există evaluări

- Contoh PayrollDocument4 paginiContoh PayrollnazkudutÎncă nu există evaluări

- CombatDocument10 paginiCombatnazkudutÎncă nu există evaluări

- A Kinematic Comparison of The Judo Throw Harai-Goshi During Di9je6Document8 paginiA Kinematic Comparison of The Judo Throw Harai-Goshi During Di9je6nazkudutÎncă nu există evaluări

- Wag L3 & 4Document6 paginiWag L3 & 4nazkudutÎncă nu există evaluări

- A Kinematic Comparison of The Judo Throw Harai-Goshi During Di9je6Document8 paginiA Kinematic Comparison of The Judo Throw Harai-Goshi During Di9je6nazkudutÎncă nu există evaluări

- National Junior Artistic Gymnastics Circuit Championship ResultsDocument8 paginiNational Junior Artistic Gymnastics Circuit Championship ResultsnazkudutÎncă nu există evaluări

- SportsDocument4 paginiSportsnazkudutÎncă nu există evaluări

- Sport ScienceDocument8 paginiSport SciencenazkudutÎncă nu există evaluări

- SportsDocument7 paginiSportsnazkudutÎncă nu există evaluări

- Acceleration Training For Improving Physical Fitness and Weight Loss in Obese WomenDocument11 paginiAcceleration Training For Improving Physical Fitness and Weight Loss in Obese WomennazkudutÎncă nu există evaluări

- Typesofflexibilitytraining 1215164343955424 9Document19 paginiTypesofflexibilitytraining 1215164343955424 9nazkudutÎncă nu există evaluări

- The JournalistDocument3.102 paginiThe JournalistZasembo Ngcebo100% (1)

- Postharvest Assessment Methodology Conceptual Fra-Wageningen University and Research 582556Document46 paginiPostharvest Assessment Methodology Conceptual Fra-Wageningen University and Research 582556DAWIT AMOGNEÎncă nu există evaluări

- How Much Cost To Start Wheat Flour Mill Factory? How To Make Budget?Document13 paginiHow Much Cost To Start Wheat Flour Mill Factory? How To Make Budget?EDEN2203100% (1)

- 3rd Social InsectsDocument2 pagini3rd Social InsectsyvhonnedelimaÎncă nu există evaluări

- DA Form 4187 Instructions For Missed MealDocument2 paginiDA Form 4187 Instructions For Missed MealSingle Soldiers Rights100% (1)

- Camarines Sur High School Work ImmersionDocument7 paginiCamarines Sur High School Work ImmersionAriane Ignao LagaticÎncă nu există evaluări

- Cashew Processing Unit Small CategoryDocument21 paginiCashew Processing Unit Small Categorykishore MÎncă nu există evaluări

- Foreplay - ForbiddenDocument28 paginiForeplay - ForbiddenOmanasa Omanasa100% (5)

- NutritionDocument5 paginiNutritionSaumyaÎncă nu există evaluări

- History IVC Part 2Document8 paginiHistory IVC Part 2Rohit KumarÎncă nu există evaluări

- The Best Gift: Choco the PuppyDocument2 paginiThe Best Gift: Choco the PuppyKimberly Clarisse VegaÎncă nu există evaluări

- Topic 1 (Đư C T PH C H I)Document17 paginiTopic 1 (Đư C T PH C H I)nguyen nhatvan2001Încă nu există evaluări

- Soal Pas B.ing KLS 7 - WebsiteedukasiDocument3 paginiSoal Pas B.ing KLS 7 - WebsiteedukasiAfrianton Ribut NugrohoÎncă nu există evaluări

- Know Your FatsDocument348 paginiKnow Your Fatstamy_001100% (3)

- Order Details: Store Web Services CloudDocument2 paginiOrder Details: Store Web Services CloudJunnie Ann Flores DavidÎncă nu există evaluări

- Final Test Welcome 2Document2 paginiFinal Test Welcome 2jasminamina222Încă nu există evaluări

- Grammar Bank: QuestionsDocument1 paginăGrammar Bank: QuestionsUlrich Jhersy Mita ChurquiÎncă nu există evaluări

- Habeco: Customers Service: Supply Chain ManagementDocument13 paginiHabeco: Customers Service: Supply Chain ManagementNguyễn Hồng HạnhÎncă nu există evaluări

- Worldbuilder Questions: Patrica C. Wrede'sDocument22 paginiWorldbuilder Questions: Patrica C. Wrede'sChris AganÎncă nu există evaluări

- Homemade Mutton Masala PowderDocument6 paginiHomemade Mutton Masala PowderblackvenumÎncă nu există evaluări

- 101 Conversation Topics For KidsDocument9 pagini101 Conversation Topics For KidsBrenda AldoÎncă nu există evaluări

- Pippa and Pop Scope and SequenceDocument6 paginiPippa and Pop Scope and SequenceAnabel Mariel GelsiÎncă nu există evaluări

- Email TLUD For Rice HuskDocument4 paginiEmail TLUD For Rice HuskKewl DudzÎncă nu există evaluări

- The Hidden SoldierDocument246 paginiThe Hidden SoldierWendi PutraÎncă nu există evaluări

- Theme 7 - Food and Festivals - Vocabulary Term Translation Example/Relevant InfoDocument3 paginiTheme 7 - Food and Festivals - Vocabulary Term Translation Example/Relevant InfoKübra HilalÎncă nu există evaluări

- About PlantsDocument13 paginiAbout PlantsOmar CastilloÎncă nu există evaluări

- LAS-Cookery 8 Week 3-4Document7 paginiLAS-Cookery 8 Week 3-4jon pantzÎncă nu există evaluări

- Ayurvedic Cooking For Self Healing Imperfect Copy Vasant Lad Usha Lad.07148 - 1prefaceDocument4 paginiAyurvedic Cooking For Self Healing Imperfect Copy Vasant Lad Usha Lad.07148 - 1prefaceAppleswariÎncă nu există evaluări

- LOA SiggadiGrowthCenterKotdwar1442650109Document4 paginiLOA SiggadiGrowthCenterKotdwar1442650109UDGGAMÎncă nu există evaluări

- TLS CA Practice Sheet-93Document6 paginiTLS CA Practice Sheet-93Akanksha PriyadarshiniÎncă nu există evaluări