Documente Academic

Documente Profesional

Documente Cultură

B31.3 Process Piping Course - 06 Flexibility Analysis For Intro

Încărcat de

Jose BijoyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

B31.3 Process Piping Course - 06 Flexibility Analysis For Intro

Încărcat de

Jose BijoyDrepturi de autor:

Formate disponibile

ASME B31.3 Process Piping Course 6.

Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 1

ASME B31.3 Process Piping

Charles Becht IV, PhD, PE

Don Frikken, PE

Instructors

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 2

1. Establish applicable system standard(s)

2. Establish design conditions

3. Make overall piping material decisions

Pressure Class

Reliability

Materials of construction

4. Fine tune piping material decisions

Materials

Determine wall thicknesses

Valves

5. Establish preliminary piping system layout & support

configuration

6. Perform flexibility analysis

7. Finalize layout and bill of materials

8. Fabricate and install

9. Examine and test

Piping Development Process

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 3

6. Flexibility Analysis

What are we trying to achieve?

Flexibility Analysis Example

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 4

The Material in This Section is

Addressed by B31.3 in:

Chapter II - Design

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 5

What are we trying to achieve?

1. Provide adequate support;

2. Provide sufficient flexibility; and

3. Prevent the piping from exerting

excessive reactions

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 6

What are we trying to achieve?

1. Provide adequate support to resist loads

such as pressure, weight, earthquake

and wind

J anuary 17 1994 Northridge Earthquake

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 7

What are we trying to achieve?

2. Provide sufficient flexibility to safely

accommodate changes in length resulting

from temperature variations

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 8

What are we trying to achieve?

3. Provide sufficient support and flexibility to

prevent the piping from exerting

excessive reactions on equipment and

restraints

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 9

What are we trying to achieve?

And we do that in order to

make the piping look well supported to the

facility engineers and operators

prevent collapse of the piping

prevent leaks due to fatigue cracks

prevent joint leakage caused by excessive

forces , and

prevent failure or malfunction of attached

equipment caused by excessive reactions

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 10

Flexibility Analysis Example

A two step analysis is shown.

1. Weight and Pressure Loads verify

proper support and check reactions

2. Thermal Expansion Load verify

adequate flexibility and check

reactions

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 11

Proposed System

NPS 4

Carbon Steel

Ambient to 600F (315C)

SG contents = 1.0

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 12

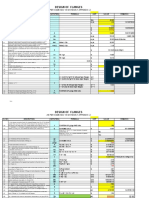

Sustained Load Analysis

Check Deflections

Deflected 0.4 (10 mm)

Marginal:

> 0.3 (8 mm)

Normal

Maximum

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 13

30% 5%

Check Reactions

60% =

1020#

(4500 N)

5%

Reactions

Poorly

Distributed

Sustained Load Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 14

Check Stresses

Max. is 66% of allowable

Stresses

OK

Sustained Load Analysis

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 15

30 to 20% 5 to 10%

Revised System (Added Support)

Max. Displacement

0.4 to 0.1 (10 to 2 mm)

Max. Stress

66%to 34% of allowable

Displacement Load Analysis

60 to 35% 5 to 5%

Displacements

Stresses &

Reactions

All OK

0 to 30%

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 16

Check Deflections

0.4 (10 mm)

0.9 (23 mm)

Deflections

OK

Displacement Load Analysis

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 17

Check Reactions

0% 10% 45% =

1240# (5520 N)

40% 5%

Reactions

High, Poorly

Distributed

Displacement Load Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 18

Check Stresses

Max. is 79% of allowable

Stresses

OK

Displacement Load Analysis

ASME B31.3 Process Piping Course 6. Flexibility Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 19

0 to 0% 10 to 0% 45 to 5%

40 to 0% 5 to 5%

Revised System (Added Spring

Support)

Max. Displacement

0.9 to 1.5 (23 to 38 mm)

Max. Stress

79%to 48% of allowable

Displacements

Stresses &

Reactions

All OK

100% =

1240# (5520 N)

Displacement Load Analysis

BECHT ENGINEERING COMPANY, INC. Flexibility Analysis - 20

Is the process of calculating the strains, and

resultant stresses and forces in a piping

system to determine if the system

Flexibility Analysis

has adequate support

has sufficient flexibility to safely

accommodate changes in length

resulting from temperature variations

exerts sufficiently low reaction forces at

restraints and equipment

S-ar putea să vă placă și

- B31.3 Process Piping Course - 08 FlexibilityDocument23 paginiB31.3 Process Piping Course - 08 Flexibilitydalianbouri100% (1)

- ASME B31.3 Process Piping Reactions CourseDocument0 paginiASME B31.3 Process Piping Reactions CourseCarlos Del ToroÎncă nu există evaluări

- B31.3 Process Piping Course - 17 High Pressure PipingDocument12 paginiB31.3 Process Piping Course - 17 High Pressure PipingpfpmatosÎncă nu există evaluări

- B31.3 Process Piping Course - 04 Pressure Design of MetalsDocument22 paginiB31.3 Process Piping Course - 04 Pressure Design of MetalsEryl YeongÎncă nu există evaluări

- B31.3 Process Piping Course - 07 Layout and SupportDocument15 paginiB31.3 Process Piping Course - 07 Layout and SupportgerrydimayugaÎncă nu există evaluări

- Unlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsDocument5 paginiUnlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsProkopÎncă nu există evaluări

- ASME B31.3 Process Piping InspectionDocument20 paginiASME B31.3 Process Piping InspectionPedro DiazÎncă nu există evaluări

- ASME B31.3 Piping Inspection GuideDocument19 paginiASME B31.3 Piping Inspection GuideferooxidanÎncă nu există evaluări

- B31.3 Process Piping Course - 11 Designing With Expansion Joints PDFDocument15 paginiB31.3 Process Piping Course - 11 Designing With Expansion Joints PDFSulist N WahyudieÎncă nu există evaluări

- B31.3 Process Piping Course - 01 IntroductionDocument19 paginiB31.3 Process Piping Course - 01 IntroductionBala Kumar100% (2)

- ASME B31.3 Nonmetallic Piping Design and FabricationDocument0 paginiASME B31.3 Nonmetallic Piping Design and FabricationAxel MoorÎncă nu există evaluări

- B31.3 Process Piping Course - 12 Fabrication and InstallationDocument21 paginiB31.3 Process Piping Course - 12 Fabrication and InstallationLuong AnhÎncă nu există evaluări

- ASME B31.3 Process Piping Fabrication InstallationDocument21 paginiASME B31.3 Process Piping Fabrication InstallationMuhammed SulfeekÎncă nu există evaluări

- ASME B31.3 Category M Fluid Service Design RequirementsDocument8 paginiASME B31.3 Category M Fluid Service Design RequirementsRomner CordovaÎncă nu există evaluări

- B31.3 Process Piping Course - 03 Materials PDFDocument19 paginiB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungÎncă nu există evaluări

- B31.3 Process Piping Course - 03 Materials-LibreDocument45 paginiB31.3 Process Piping Course - 03 Materials-LibrejacquesmayolÎncă nu există evaluări

- Whats Different in B31.1 PDFDocument30 paginiWhats Different in B31.1 PDFhirenkumar patel100% (2)

- Piping MaterialDocument125 paginiPiping MaterialSargunam SankaravadivelÎncă nu există evaluări

- Ipebs 31 CourseDocument9 paginiIpebs 31 Coursevenky2hemaÎncă nu există evaluări

- 4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesDocument23 pagini4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesMahmoud samahaÎncă nu există evaluări

- 1 PipelineDocument69 pagini1 PipelineEhab MohammedÎncă nu există evaluări

- Piping TechniquesDocument8 paginiPiping TechniquespiglitÎncă nu există evaluări

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988De la EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockÎncă nu există evaluări

- PipeDocument47 paginiPipemohanÎncă nu există evaluări

- Inspection of Heat ExchangerDocument83 paginiInspection of Heat ExchangerRaghavanÎncă nu există evaluări

- Piping CodesDocument47 paginiPiping CodesSankar MukaÎncă nu există evaluări

- History b16 34Document5 paginiHistory b16 34qazi12100% (1)

- Flange Leakage Check: Equivalent Pressure / Kellogg MethodDocument3 paginiFlange Leakage Check: Equivalent Pressure / Kellogg Methodtom hÎncă nu există evaluări

- PetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Document5 paginiPetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Engr Khurram Jaan RamayÎncă nu există evaluări

- Asmepcc 2repairleaks Article 4Document23 paginiAsmepcc 2repairleaks Article 4amalhaj2013Încă nu există evaluări

- Piping BasicsDocument10 paginiPiping Basicstulasirao.nammiÎncă nu există evaluări

- Implementing Expansion Loops to Absorb Thermal StressDocument13 paginiImplementing Expansion Loops to Absorb Thermal StressAan DamaiÎncă nu există evaluări

- GRE Piping Fire WaterDocument10 paginiGRE Piping Fire WaterMubeenÎncă nu există evaluări

- Shell Corrosion Under InsulationDocument16 paginiShell Corrosion Under InsulationDavide CongiuÎncă nu există evaluări

- ASME Piping Stress Analysis RequirementsDocument8 paginiASME Piping Stress Analysis RequirementsjjirwinÎncă nu există evaluări

- Technical Bid Evaluation of Vendor Spring Hanger Offers With PDFDocument3 paginiTechnical Bid Evaluation of Vendor Spring Hanger Offers With PDFAmjadali ChoudhariÎncă nu există evaluări

- Piping CodesDocument32 paginiPiping Codesengrabrar100% (3)

- How Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedDocument2 paginiHow Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedTay Hua SetÎncă nu există evaluări

- Why Insulate Pipes: 3 Key Benefits of InsulationDocument13 paginiWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenÎncă nu există evaluări

- 436 Piping Course DescriptionDocument2 pagini436 Piping Course DescriptionAnonymous q9eCZHMuS100% (1)

- Pressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesDocument37 paginiPressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesPham LanphuongÎncă nu există evaluări

- In Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFDocument33 paginiIn Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFKrishna Vacha100% (2)

- Brittle Fracture of Carbon Steel Piping During Hydrostatic TestingDocument4 paginiBrittle Fracture of Carbon Steel Piping During Hydrostatic TestingSH1961Încă nu există evaluări

- Piping QC Guide (For Saudi Aramco Project)Document11 paginiPiping QC Guide (For Saudi Aramco Project)HengÎncă nu există evaluări

- 35 Common Piping Interview Questions AnsweredDocument8 pagini35 Common Piping Interview Questions AnsweredEzhil ArasanÎncă nu există evaluări

- Hydrotesting Not Required Under New API-653 Procedure - Oil & Gas JournalDocument9 paginiHydrotesting Not Required Under New API-653 Procedure - Oil & Gas JournalamokhtaÎncă nu există evaluări

- Piping Questionnaire - Piping Study-NDocument14 paginiPiping Questionnaire - Piping Study-NBhanu Prakash100% (1)

- Pipe Stress Amp SupportDocument24 paginiPipe Stress Amp SupportShilpa GanganÎncă nu există evaluări

- API 510-Kuwait PetroleumDocument392 paginiAPI 510-Kuwait PetroleumVijay Kumar100% (1)

- Hydrostatic TestingDocument18 paginiHydrostatic TestingRicardoÎncă nu există evaluări

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pagini650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhÎncă nu există evaluări

- B31.3 Process Piping Course - 06 - FlexibilityAnalysisDocument25 paginiB31.3 Process Piping Course - 06 - FlexibilityAnalysislyesÎncă nu există evaluări

- B31.3 Process Piping Course - 06 Flexibility Analysis For IntroDocument10 paginiB31.3 Process Piping Course - 06 Flexibility Analysis For IntroRyan Goh Chuang HongÎncă nu există evaluări

- Unlock-B31.3 Process Piping Course - 01 IntroductionDocument19 paginiUnlock-B31.3 Process Piping Course - 01 IntroductionProkopÎncă nu există evaluări

- Piping Design Concepts: July 9 2016 BY CAE TeamDocument14 paginiPiping Design Concepts: July 9 2016 BY CAE TeamJaydeep RamaniÎncă nu există evaluări

- What Is A Piping System?Document20 paginiWhat Is A Piping System?SARA VijayÎncă nu există evaluări

- Asme b31.3 Training SeminarDocument382 paginiAsme b31.3 Training Seminarglazetm96% (45)

- Piping StressDocument30 paginiPiping Stresscharan100% (2)

- Marine Breakaway Couplings Information PaperDocument20 paginiMarine Breakaway Couplings Information Paperjamolina9093100% (5)

- AOGV Presentation Nov 2018Document25 paginiAOGV Presentation Nov 2018Jose BijoyÎncă nu există evaluări

- Pressure Equivalent CalculationDocument1 paginăPressure Equivalent CalculationJose BijoyÎncă nu există evaluări

- FSA Gasket Handbook - June 2017Document138 paginiFSA Gasket Handbook - June 2017Dijin MaroliÎncă nu există evaluări

- Design of Flanges - 12 600# CalculationsDocument5 paginiDesign of Flanges - 12 600# CalculationsJose BijoyÎncă nu există evaluări

- Marine Breakaway Couplings Information PaperDocument20 paginiMarine Breakaway Couplings Information Paperjamolina9093100% (5)

- BP Ground Flare Control System PR OG1 0409ADocument1 paginăBP Ground Flare Control System PR OG1 0409AJose BijoyÎncă nu există evaluări

- Bro Spiral WoundDocument52 paginiBro Spiral WoundBruno SantosÎncă nu există evaluări

- Bolting Equipment of Flange JointsDocument22 paginiBolting Equipment of Flange JointsJose BijoyÎncă nu există evaluări

- Piping Vibration Risk Assessment GuideDocument2 paginiPiping Vibration Risk Assessment GuideJose BijoyÎncă nu există evaluări

- Statement - Public Hearing - Process Safety Performance IndicatorsDocument28 paginiStatement - Public Hearing - Process Safety Performance IndicatorsJose BijoyÎncă nu există evaluări

- Process Safety Leading and Lagging Metrics - CCPS - 2011Document44 paginiProcess Safety Leading and Lagging Metrics - CCPS - 2011Haribo1962Încă nu există evaluări

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFDocument4 paginiA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyÎncă nu există evaluări

- Introduction to Compressor Vibration ProblemsDocument20 paginiIntroduction to Compressor Vibration ProblemsJose Bijoy100% (1)

- Applyingtheenergyinstituteandprcipaper GMC 140625101214 Phpapp01Document29 paginiApplyingtheenergyinstituteandprcipaper GMC 140625101214 Phpapp01Jose BijoyÎncă nu există evaluări

- Small Bore Tubing Sample Pages PDFDocument8 paginiSmall Bore Tubing Sample Pages PDFJose BijoyÎncă nu există evaluări

- Training Courses - BETA Machinery AnalysisDocument8 paginiTraining Courses - BETA Machinery AnalysisJose BijoyÎncă nu există evaluări

- Flow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureDocument6 paginiFlow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureJose BijoyÎncă nu există evaluări

- Small Bore Tubing Sample PagesDocument8 paginiSmall Bore Tubing Sample PagesJose BijoyÎncă nu există evaluări

- Small Bore Fittings - Your Hidden Risk - SVT Articles - SVT Engineering ConsultantsDocument4 paginiSmall Bore Fittings - Your Hidden Risk - SVT Articles - SVT Engineering ConsultantsJose BijoyÎncă nu există evaluări

- Specifications - BETA Machinery AnalysisDocument2 paginiSpecifications - BETA Machinery AnalysisJose BijoyÎncă nu există evaluări

- Small-Bore Connections (SBC) Assessment - BETA Machinery AnalysisDocument7 paginiSmall-Bore Connections (SBC) Assessment - BETA Machinery AnalysisJose BijoyÎncă nu există evaluări

- A4 SPEC Pumping Systems 201507 PDFDocument5 paginiA4 SPEC Pumping Systems 201507 PDFJose BijoyÎncă nu există evaluări

- A4 SPEC Pumping Systems 201507 PDFDocument5 paginiA4 SPEC Pumping Systems 201507 PDFJose BijoyÎncă nu există evaluări

- Small-Bore Connections (SBC) Assessment - BETA Machinery AnalysisDocument7 paginiSmall-Bore Connections (SBC) Assessment - BETA Machinery AnalysisJose BijoyÎncă nu există evaluări

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFDocument4 paginiA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyÎncă nu există evaluări

- Small Bore Tubing Sample PagesDocument8 paginiSmall Bore Tubing Sample PagesJose BijoyÎncă nu există evaluări

- Vibration Induced Failure Avoidance and Management Around Vendor PackagesDocument24 paginiVibration Induced Failure Avoidance and Management Around Vendor PackagesJose Bijoy100% (1)

- Piping Vibration Risk Assessment GuideDocument2 paginiPiping Vibration Risk Assessment GuideJose BijoyÎncă nu există evaluări

- Training Courses - BETA Machinery AnalysisDocument8 paginiTraining Courses - BETA Machinery AnalysisJose BijoyÎncă nu există evaluări

- Aci 318R 08Document1 paginăAci 318R 08Sayed Diab AlsayedÎncă nu există evaluări

- T100 Thrusters PropellerDocument15 paginiT100 Thrusters PropellerNikhilkrishna NairÎncă nu există evaluări

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDocument36 paginiTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeÎncă nu există evaluări

- Sony Dsc-w630 Ver1.1 Level2Document25 paginiSony Dsc-w630 Ver1.1 Level2Alberto MorenoÎncă nu există evaluări

- Lyophilic and Lyophobic SolsDocument7 paginiLyophilic and Lyophobic Solssatvik guptaÎncă nu există evaluări

- Solid Waste Management System-1Document7 paginiSolid Waste Management System-1husnasyahidahÎncă nu există evaluări

- AcknowledgementDocument4 paginiAcknowledgementEndalkachew AddisÎncă nu există evaluări

- Bridgestone Databook 2010 - 0911Document52 paginiBridgestone Databook 2010 - 0911jesus_pacco100% (1)

- L&T M30Document2 paginiL&T M30Kannan GnanaprakasamÎncă nu există evaluări

- Internship Report CRDocument22 paginiInternship Report CRRockyXYZÎncă nu există evaluări

- Latching Assignment PLC Ladder LogicDocument4 paginiLatching Assignment PLC Ladder LogicsalonyÎncă nu există evaluări

- Pile Soil InteractionDocument250 paginiPile Soil Interactionnallay1705100% (3)

- Astm D 6184Document3 paginiAstm D 6184김인식Încă nu există evaluări

- Unimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfDocument2 paginiUnimog Techdata u4000 Euro5 1209 en PDF Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdf Unimog_techdata_u4000_euro5_1209_en_pdf.pdfIvana Ilic67% (3)

- EdDocument1 paginăEdpandirajaÎncă nu există evaluări

- Class 10 Social Science2Document15 paginiClass 10 Social Science2Sumit BainÎncă nu există evaluări

- ATA24 Bombardier q400 Electrical PowerDocument85 paginiATA24 Bombardier q400 Electrical PowerAbiyot AderieÎncă nu există evaluări

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 paginiPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharÎncă nu există evaluări

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDocument9 paginiAMMIE 2023 Conference on Advanced Materials and ManufacturingrjÎncă nu există evaluări

- High Efficiency Compressed Air Filtration & Water SeparationDocument8 paginiHigh Efficiency Compressed Air Filtration & Water SeparationMelvic BinosÎncă nu există evaluări

- Shell and Tube Heat Exchanger: Wall ThicknessDocument10 paginiShell and Tube Heat Exchanger: Wall ThicknessZeke KazamiÎncă nu există evaluări

- APEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2Document2 paginiAPEF - Electrochemistry - Multiple Choice Questions - Page 1 of 2alyaa sheirÎncă nu există evaluări

- YK60A Digital Inverter Battery Charger ManualDocument35 paginiYK60A Digital Inverter Battery Charger ManualS M NaveedÎncă nu există evaluări

- Gujarat Milk ProductionDocument25 paginiGujarat Milk ProductionvizindiaÎncă nu există evaluări

- Dies and Inserts Catalog 2018Document36 paginiDies and Inserts Catalog 2018Ahmed MohamedÎncă nu există evaluări

- Volvo EC160Document25 paginiVolvo EC160superbludnik100% (3)

- Flow Diagram SymbolsDocument5 paginiFlow Diagram SymbolshussainÎncă nu există evaluări

- NPSH - Net Positive Suction HeadDocument5 paginiNPSH - Net Positive Suction HeadSutrisno KlsÎncă nu există evaluări

- 154 Loesche Mills For Cement Raw Material E 2016Document28 pagini154 Loesche Mills For Cement Raw Material E 2016faheemqcÎncă nu există evaluări

- Simrit Cassette SealsDocument6 paginiSimrit Cassette SealsfahazumeeÎncă nu există evaluări