Documente Academic

Documente Profesional

Documente Cultură

CW 01 With Answers

Încărcat de

Mohammad Aamir PerwaizDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CW 01 With Answers

Încărcat de

Mohammad Aamir PerwaizDrepturi de autor:

Formate disponibile

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

1. Two examples of Hygroscopic salts would be:

(a) Iron Phosphates and Iron Chromates

(b) Iron Chlorates and Iron Oxides

(c) Iron Sulphates and Iron Chlorides

(d) Iron Sulphides and Iron Silicates

2. What is an electrolyte

(a) It is a mixture of salts and water

(b) ! substance which will conduct electricity and cause rusting

(c) Oxidising li"uid which will attac# steel

(d) ! substance which will conduct a current and be bro#en down by it

3. Corrosion is defined as:

(a) $usting of the Cathode by electrophysical means

(b) Oxidation of a metal in contact with water

(c) %egradation of a material by chemical or electrochemical means

(d) &rea#down of the metal by hydrogen

4. Hydrogen is e'ol'ed at:

(a) The !node at all times

(b) The Cathode at all times

(c) The Cathode as a by(product of the corrosion reaction

(d) The !node as corrosion ta#es place

5. The )degradation of material by chemical or electrochemical means* is:

(a) Pic#ling followed by passi'ation

(b) !cid cleaning

(c) Corrosion

(d) !n +lectrolyte

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

6. The &,as specification for site application of paint systems is

(a) &,C-PS-P!./

(b) &,C-PS-CW0

(c) &,C-PS-P!1

(d) &S 2/23

7. !nother name for the ,al'anic 4ist5 is:

(a) The Corrosion 4ist

(b) +lectro 6egati'e 4ist

(c) +lectrical Corrosi'e Properties Series

(d) +lectromoti'e 7orces Series

8. In the corrosion circuit5 electrons tra'el from:

(a) !node to cathode

(b) Cathode to !node

(c) +lectrolyte to both cathode 8 anode

(d) 6one of the abo'e

9. If 9inc and !luminium were in close contact5 in the presence of electrolyte:

(a) !luminium would corrode

(b) They would corrode e"ually

(c) 9inc would corrode

(d) 6one of the abo'e

10. When the electrolyte is water5 what occurs at the cathode during a corrosion

reaction

(a) $usting of the surface would begin

(b) Oxygen is gi'en off

(c) +lectrons are entering the material

(d) Hydrogen is e'ol'ed

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

11. :+:;s are also #nown as:

(a) :oisture +nriched :aterials

(b) :etal +ating :icrobes

(c) :aximum +'ol'ed :oistures

(d) :aterial +lectron :obility

12. When chec#ing surface profile using <(Course replica tape:

(a) 0/ micron must be added to the final reading

(b) The a'erage number of readings must be ta#en

(c) 0/ microns must be deducted from the reading

(d) ! minimum of ten readings must be ta#en

13. Which of the following is not a sub atomic particle

(a) Proton

(b) 6eutron

(c) :icron

(d) +lectron

14. Three factors which can affect the rate of corrosion are:

(a) Temperature5 Time5 and Coating system

(b) &i(metallic contact5 Hygroscopic Salts5 and &acteria

(c) Coating system5 Pipe diameter5 and =ltra >iolet light

(d) &lasting ,rades5 $ust ,rades5 and Surface Profile

15. How many !brasi'e &last Cleaning photographs are in &S 2/23 part !

(a) ?

(b) .?

(c) 1

(d) .@

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

16. The thic#ness of :illscale is approximately:

(a) A0 m to .// m

(b) .// to .0/ m

(c) Bero

(d) %ependant upon the material thic#ness

17. The three compressed oxides which form :illscale are:

(a) Iron oxide5 $ust5 and Iron sulphate

(b) Wustite5 Haematite5 and :agnetite

(c) Iron Sulphate5 Iron Chloride5 and Iron Phosphate

(d) $SC5 $SC5 and $S!

18. When preparing stainless steel5 what abrasi'e should be used

(a) Copper Slag

(b) Steel Shot

(c) !luminium Oxide

(d) !ngular Chilled Iron

19. ! &anana gauge wor#s on which principle

(a) :agnetic resistance

(b) Conducti'e resistance

(c) Tension reluctance

(d) >iscosity relati'ity

20. $ust ,rade ! can be described as

(a) Tightly adhering :illscale5 with e'ident hea'y pitting

(b) Clean white metal

(c) Tightly adhering :illscale5 with no apparent corrosion

(d) :illscale which has begun to fla#e5 or can be scraped away

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

21. Which &lasting ,rade best describes )Thorough &last cleaning*

(a) Sa A

(b) Sa AD

(c) Sa E

(d) Sa .

22. The two factors to consider when inspecting a surface preparation:

(a) %egree of cleanliness5 and time ta#en

(b) Surface Profile5 and material condition

(c) Surface Profile and degree of cleanliness

(d) %egree of cleanliness5 and surface contamination

23. !brasi'e used on site for &ritish ,as proFects must be:

(a) :ixed with sand5 to reduce cost

(b) Stored correctly prior to use

(c) +xpendable

(d) =sed up to a maximum of three times onlyG

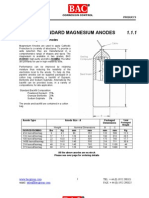

24. Which two materials are commonly used as sacrificial anodes

(a) Copper and Tungsten

(b) !luminium and ,raphite

(c) 9inc and !luminium

(d) 4ead and Tin

25. 6ame a sub atomic particle

(a) !tom

(b) :icron

(c) +lectron

(d) :oron

BGas Painting Inspection

Grade 2&3 CW 01

TWI Training and Examination Services

CW 01 Answers

1. C

2. D

3. C

4. C

5. C

6. A

7. D

8. B

9. C

10. D

11. B

12. C

13. C

14. B

15. B

16. A

17. B

18. C

19. A

20. C

21. A

22. C

23. C

24. C

25. C

S-ar putea să vă placă și

- Office 365 For End Users PDFDocument287 paginiOffice 365 For End Users PDFMohammad Aamir Perwaiz100% (1)

- Model Papers PDFDocument33 paginiModel Papers PDFSeemab Malik85% (20)

- BGAS-CSWIP Grade 2 (2017) - Slides and Screen Tests PDFDocument89 paginiBGAS-CSWIP Grade 2 (2017) - Slides and Screen Tests PDFshahid khan86% (7)

- Bgas PaintingDocument85 paginiBgas PaintingDandaman92% (12)

- BGAS QustionDocument47 paginiBGAS QustionAbu Anas M.SalaheldinÎncă nu există evaluări

- Valve PresentationDocument52 paginiValve Presentationtarut_islandÎncă nu există evaluări

- Scanner LinkDocument2 paginiScanner LinkMohammad Aamir PerwaizÎncă nu există evaluări

- Scanner LinkDocument2 paginiScanner LinkMohammad Aamir PerwaizÎncă nu există evaluări

- 21 CandlesticksDocument65 pagini21 CandlesticksDxtr V Drn100% (1)

- Sabp Z 002e PDFDocument38 paginiSabp Z 002e PDFimmuÎncă nu există evaluări

- Sabp Z 002e PDFDocument38 paginiSabp Z 002e PDFimmuÎncă nu există evaluări

- Painting Study NotesDocument243 paginiPainting Study NotesAryan Kaul100% (6)

- Painting Defects - Cswip BgasDocument63 paginiPainting Defects - Cswip BgasLuan Nguyen86% (7)

- CSWIP 3.1 QuestionsDocument43 paginiCSWIP 3.1 QuestionsMichael Albuquerque100% (1)

- BGAS 2 Questions-1 PDFDocument33 paginiBGAS 2 Questions-1 PDFShyam Sundar Gayen100% (1)

- BGAS Level 2,3 Q A Monday To FridayDocument32 paginiBGAS Level 2,3 Q A Monday To FridayAbdul Khaliq93% (58)

- Bgas Question With AwnserDocument106 paginiBgas Question With Awnserthongmuadong100% (3)

- Bgas Practical PicturesDocument79 paginiBgas Practical PicturesFaiz Ahmad80% (5)

- Q & A BgasDocument33 paginiQ & A BgasAbdulRahman Mohamed Hanifa86% (7)

- HAL - Pravara Aviation Inst Itute: WeldingDocument3 paginiHAL - Pravara Aviation Inst Itute: WeldingIgnite TutorialÎncă nu există evaluări

- Bgas Question and Answer DocumentDocument34 paginiBgas Question and Answer DocumentRaje A is100% (1)

- Model Examination Grade 2 Ver 2Document5 paginiModel Examination Grade 2 Ver 2Muhammad Nasir100% (1)

- Painting Inspection Grade, 2Document7 paginiPainting Inspection Grade, 2valararumugams100% (1)

- Orgchem Lab - Activity 2Document7 paginiOrgchem Lab - Activity 2MikahAngelaCenizaAliban100% (1)

- BGas Painting Inspection Grade 2 Multiple ChoiceDocument12 paginiBGas Painting Inspection Grade 2 Multiple Choicetcagokl93% (43)

- GP 00-01-ETP Introduction Document PDFDocument20 paginiGP 00-01-ETP Introduction Document PDFMohammad Aamir PerwaizÎncă nu există evaluări

- BGAS Theory PaperDocument22 paginiBGAS Theory PaperAdilMunir100% (3)

- NAVEDTRA 14251A STEELWORKER ADVANCED Reduced PDFDocument233 paginiNAVEDTRA 14251A STEELWORKER ADVANCED Reduced PDFDuc Anh MaterialÎncă nu există evaluări

- Model Examination Grade 2 Ver 2Document6 paginiModel Examination Grade 2 Ver 2moonstar_dmeÎncă nu există evaluări

- SP1246 Part-5 PDFDocument23 paginiSP1246 Part-5 PDFMohammad Aamir Perwaiz100% (1)

- Bgas Book (Colour)Document42 paginiBgas Book (Colour)imtiaz100% (1)

- CHEM SPM Chapter 4 Periodic Table StudentDocument23 paginiCHEM SPM Chapter 4 Periodic Table Studentangie0812Încă nu există evaluări

- Q & A 3 BgasDocument8 paginiQ & A 3 BgasAbdulRahman Mohamed Hanifa100% (2)

- BGAS Qustins-1Document40 paginiBGAS Qustins-1Shyam Sundar GayenÎncă nu există evaluări

- Paints Coating Failure Defects GOOD PDFDocument46 paginiPaints Coating Failure Defects GOOD PDFVasileios Iliopoulos100% (1)

- Paints Coating Failure Defects GOOD PDFDocument46 paginiPaints Coating Failure Defects GOOD PDFVasileios Iliopoulos100% (1)

- OUFT Fibonacci Ratio FinalDocument35 paginiOUFT Fibonacci Ratio FinalMohammad Aamir Perwaiz100% (1)

- OUFT Fibonacci Ratio FinalDocument35 paginiOUFT Fibonacci Ratio FinalMohammad Aamir Perwaiz100% (1)

- Q A BgasDocument33 paginiQ A BgasAnonymous rpcAOp100% (2)

- Bgas Question and AnswerDocument25 paginiBgas Question and AnswerMohammad Aamir Perwaiz94% (16)

- BGas Painting Multiple Choice 2Document17 paginiBGas Painting Multiple Choice 2Abdul Gafoor86% (14)

- BGAS Question Answer PrintableDocument2 paginiBGAS Question Answer PrintableSiddiqui Abdul Khaliq100% (1)

- Painting Inspection Grade 2 P 1: ApixamsDocument12 paginiPainting Inspection Grade 2 P 1: Apixamsmahmoud aliÎncă nu există evaluări

- BGAS Question AnswerDocument14 paginiBGAS Question Answerراجہ شہزاد انور100% (1)

- BGAS Ques With PA10 - AnswerDocument12 paginiBGAS Ques With PA10 - Answer94408644590% (1)

- Revision Questions - BGASDocument47 paginiRevision Questions - BGASVarun Gill80% (15)

- BGas MaterialDocument65 paginiBGas Materialslxanto100% (4)

- New Trial Paper BGasDocument2 paginiNew Trial Paper BGasmoonstar_dme100% (1)

- Question BGASDocument17 paginiQuestion BGASAbdulRahman Mohamed Hanifa86% (7)

- GP 00-01-ETP Introduction DocumentDocument20 paginiGP 00-01-ETP Introduction DocumentMohammad Aamir Perwaiz100% (1)

- Codes Standards RegulationsDocument6 paginiCodes Standards RegulationsKoshala Balasuriya100% (3)

- Bgas gr-2 W AnswerDocument33 paginiBgas gr-2 W AnswerShaji Thomas100% (4)

- ISO Standards On NDT of WeldingDocument2 paginiISO Standards On NDT of WeldingDavid Alejandro Vega Alfonso100% (1)

- B GAS Painting Multiple Choice 2Document9 paginiB GAS Painting Multiple Choice 2Muhammad NasirÎncă nu există evaluări

- Identifying and Correcting Paint DefectsDocument37 paginiIdentifying and Correcting Paint Defectsismael barreraÎncă nu există evaluări

- Identifying and Correcting Paint DefectsDocument37 paginiIdentifying and Correcting Paint Defectsismael barreraÎncă nu există evaluări

- Paint Notes BgasDocument4 paginiPaint Notes BgasEhsan Khan100% (1)

- BgasDocument3 paginiBgasHari Babu100% (4)

- BgasDocument3 paginiBgasSenthil Kumar100% (2)

- GENERAL TEST From Actual BGAS ExamsDocument8 paginiGENERAL TEST From Actual BGAS Examsmahmoud ali100% (1)

- BGAS Short NotesDocument2 paginiBGAS Short NotesSameh Amin80% (5)

- Atc88 Day 1 Hs Master April 2008Document52 paginiAtc88 Day 1 Hs Master April 2008petershankerÎncă nu există evaluări

- BGAS Exame QuestionsDocument16 paginiBGAS Exame Questionsaamirsaddiq100% (4)

- B-GAS Question Papers1Document24 paginiB-GAS Question Papers1Sampath Kumar100% (2)

- Painting Inspector: Passbooks Study GuideDe la EverandPainting Inspector: Passbooks Study GuideÎncă nu există evaluări

- CW 01 With AnswersDocument2 paginiCW 01 With Answersmathaikutty100% (1)

- PDF YesterdayDocument352 paginiPDF Yesterdaysudhasingh162900Încă nu există evaluări

- BGAS Qustion Bank Part 1Document128 paginiBGAS Qustion Bank Part 1Ahmed AlzaghÎncă nu există evaluări

- 2001 Objectives (Eng Materials) 101-200Document10 pagini2001 Objectives (Eng Materials) 101-200Chilvin ChipmunkÎncă nu există evaluări

- 2001 ESAS - Engineering Materials Part 2Document10 pagini2001 ESAS - Engineering Materials Part 2Chilvin ChipmunkÎncă nu există evaluări

- Chemistry 2007Document3 paginiChemistry 2007SaadHassanÎncă nu există evaluări

- Du Chemistry Entrace Questions For PG 2016 PaperDocument9 paginiDu Chemistry Entrace Questions For PG 2016 PaperKERALA SEARCHSÎncă nu există evaluări

- Painting Study NotesDocument243 paginiPainting Study Noteslarsito tukinoÎncă nu există evaluări

- Paper IIDocument142 paginiPaper IIPritamjit RoutÎncă nu există evaluări

- CUET (UG) ChemistryDocument8 paginiCUET (UG) Chemistrysajidsiddki138Încă nu există evaluări

- 10th MCQ-QP AnswersDocument5 pagini10th MCQ-QP AnswersNARENDRAN S0% (1)

- 8th-Std-Science MCQ /ADocument7 pagini8th-Std-Science MCQ /AMiss LauraÎncă nu există evaluări

- MCQs-MTEDocument8 paginiMCQs-MTEsivaÎncă nu există evaluări

- 100 TOP MOST Electrical Engineering MaterialsDocument17 pagini100 TOP MOST Electrical Engineering MaterialsPrateek DevÎncă nu există evaluări

- Civil Engineering Objecticfsve Type QuestionsDocument22 paginiCivil Engineering Objecticfsve Type QuestionsKarthik PalaniswamyÎncă nu există evaluări

- Brightstars International SchoolDocument8 paginiBrightstars International SchooldeeokusÎncă nu există evaluări

- Trading InfoDocument7 paginiTrading InfoMohammad Aamir PerwaizÎncă nu există evaluări

- 1 Doji 1Document20 pagini1 Doji 1Mohammad Aamir PerwaizÎncă nu există evaluări

- ZFP 05 Suggested NDE DocumentsDocument4 paginiZFP 05 Suggested NDE DocumentsMohammad Aamir PerwaizÎncă nu există evaluări

- Surface Imperfection RequirementsDocument5 paginiSurface Imperfection RequirementsMohammad Aamir PerwaizÎncă nu există evaluări

- Glossary PDFDocument18 paginiGlossary PDFKukuh WakujiÎncă nu există evaluări

- Welding Consumables Approved Suppliers List PDFDocument2 paginiWelding Consumables Approved Suppliers List PDFMohammad Aamir PerwaizÎncă nu există evaluări

- 21 Samss 0xxaDocument4 pagini21 Samss 0xxaBIPIN BALANÎncă nu există evaluări

- Banana Gauge ExplainedDocument1 paginăBanana Gauge ExplainedSameh Amin100% (1)

- A0105 A0105m-13Document5 paginiA0105 A0105m-13Mohammad Aamir PerwaizÎncă nu există evaluări

- A Pi ScheduleDocument6 paginiA Pi ScheduleMohammad Aamir PerwaizÎncă nu există evaluări

- ITC 78 BrochureDocument8 paginiITC 78 Brochureskynyrd75Încă nu există evaluări

- Iron and Mangenese Removal - 062Document11 paginiIron and Mangenese Removal - 062Firdaus YahyaÎncă nu există evaluări

- ALUMINUM - Chemistry PresentationDocument8 paginiALUMINUM - Chemistry PresentationAkshay BankayÎncă nu există evaluări

- I. Multiple Choice Questions (Type-I) : S F P FDocument12 paginiI. Multiple Choice Questions (Type-I) : S F P FAditya SallyÎncă nu există evaluări

- Msds - AluminiumDocument5 paginiMsds - Aluminiumsarvesh_24Încă nu există evaluări

- Bab 12 - Nota A+Document7 paginiBab 12 - Nota A+Azemi AhmadÎncă nu există evaluări

- Thiourea Corrosion InhibitorDocument5 paginiThiourea Corrosion InhibitorDr. Syed Khalid HasanÎncă nu există evaluări

- Electron ConfigurationDocument3 paginiElectron ConfigurationJess TagtagÎncă nu există evaluări

- Astm B 862 - 02 Titanium Weld PipeDocument9 paginiAstm B 862 - 02 Titanium Weld Pipeisrael.serrano.rodriguezÎncă nu există evaluări

- 0620 s21 QP 33 PDFDocument16 pagini0620 s21 QP 33 PDFTshegofatso SaliÎncă nu există evaluări

- 11 Gas TestsDocument16 pagini11 Gas TestsArmaanÎncă nu există evaluări

- Physical Science: First Quarter - Module 6: StoichiometryDocument43 paginiPhysical Science: First Quarter - Module 6: StoichiometryWeapon StorageÎncă nu există evaluări

- WELD-Electrode Products Comparability ChartDocument7 paginiWELD-Electrode Products Comparability ChartpeterÎncă nu există evaluări

- Test Bansal Coordinationcompounds PDFDocument10 paginiTest Bansal Coordinationcompounds PDFAdityaÎncă nu există evaluări

- Qualitative Analysis Chemistry Physical Question BankDocument34 paginiQualitative Analysis Chemistry Physical Question BankRajeev Kaushik83% (6)

- Supplements For ADDDocument4 paginiSupplements For ADDBoreasBÎncă nu există evaluări

- Limiting Reagent ProblemsDocument2 paginiLimiting Reagent ProblemsMarijan VrhovácÎncă nu există evaluări

- Binder1 MixturesDocument12 paginiBinder1 Mixturesjomabi0% (1)

- 1.1.1 ISOLINE MG Anode StandardDocument2 pagini1.1.1 ISOLINE MG Anode StandardJaka SembungÎncă nu există evaluări

- Steel Grades Equivalence Table1 PDFDocument13 paginiSteel Grades Equivalence Table1 PDFVictor ParvanÎncă nu există evaluări

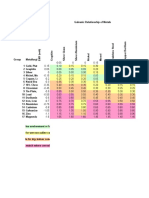

- Galvanic Relationship of MetalsDocument2 paginiGalvanic Relationship of MetalsRay FaiersÎncă nu există evaluări

- Seminar Skor A+ StudentDocument21 paginiSeminar Skor A+ StudentSora HikaruÎncă nu există evaluări

- HNO3 UllmanDocument57 paginiHNO3 UllmanNaila RahmahÎncă nu există evaluări

- 0620 w09 QP 2Document20 pagini0620 w09 QP 2Matipi ThebeeakhaleÎncă nu există evaluări

- Api and British Standard Trim DesignationsDocument1 paginăApi and British Standard Trim DesignationsPOTDARÎncă nu există evaluări

- No. Parameter Uji Satuan Kadar Max. (Dikutip Dari Standar Raw Water PG Asembagus)Document6 paginiNo. Parameter Uji Satuan Kadar Max. (Dikutip Dari Standar Raw Water PG Asembagus)Kartika RizqimaulidaÎncă nu există evaluări

- Normas Chinas PDFDocument25 paginiNormas Chinas PDFgisseltelloÎncă nu există evaluări

- Chapter 5 - Physical and Thermodynamic DataDocument19 paginiChapter 5 - Physical and Thermodynamic DataImad AghilaÎncă nu există evaluări