Documente Academic

Documente Profesional

Documente Cultură

PG 3328-3349 Chap7-TechnicalInformationSystemstis Text

Încărcat de

MKPashaPashaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PG 3328-3349 Chap7-TechnicalInformationSystemstis Text

Încărcat de

MKPashaPashaDrepturi de autor:

Formate disponibile

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

Chapter 7

Technical Information Systems (TIS)

Holderbank Management & Consulting, 2000 Page 207

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

'HOLDERBANK

Page 208 Holderbank Management & Consulting, 2000

I!MMJ;J:M?I

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

TECHNICAL INFORMATION SYSTEM (TIS)

Urs A. Herzog / Felix Fehr

HES 98/6348/E

1. Introduction

210

2. ProCess Information Management 210

2.1 Introduction to the Improvement Process 210

2.2 Importance of information for decision making 21

1

2.3 Process Information which is relevant for plant performance improvement 21

1

3. Technical Information Systems (TIS) 213

3.1 Types of Automation- and Information System in a plant, Definitions 213

3.2 Principle of a Technical Information System (TIS) 214

3.2.1 General

214

3.2.2 Tasks (requirements) of a TIS 215

3.2.3 Structure and Integration of a TIS 217

3.3 TIS Systems and Suppliers

218

4. TIS applications and experiences

219

4.1 TIS System installed and planned in "Holderbank" plants 219

4.1.1 System installed and running

219

4.1.2 System planned to be installed (Project approved) 219

4.2 Some Specific Applications and Experiences, Benefits 219

4.2.1 Alsen Breitenburg Zement

-

und Kalkwerke GmbH, Lagerdorf, Germany 219

4.2.2 Buendner Cement AG, Untervaz, Switzerland 221

4.2.3 Holnam: Holly Hill, Clarksville, Dundee, Artesia; USA 222

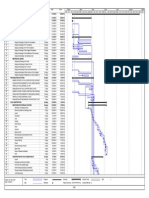

5. Typical Project Schedule AND Scope of supply 223

5.1 Project Schedules (typical)

223

5.2 Scope of supply (typical)

223

6. Results and conclusion

225

6.1 Results, Benefits

225

6.2 Conclusion

225

7. References:

227

Holderbank Management & Consulting, 2000

Page 209

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

1. INTRODUCTION

Since a few years the cement industry is under continuous pressure to optimise their

production in general. One reason is to lower production cost, another is to minimise the use

of energy and fulfil the emission limits of new environmental protection legislation. Also

cement market asks for new products and product properties, therefore production

modification and expansion must be realised in short time.

To be able to act and react to this continuous challenge, management and personnel

responsable of plant operation must have access to the relevant information about their

production, and production equipment.

Beside the three classical production resources: manpower, capital, real estate, predictions

are that information will soon be the forth.

Therefore Information Management Concepts and tools which support the user to get and

analyse this information, are getting more and more important:

This paper gives an overview of modern Process Information Management, of available

Information Systems and some experience of applications of such Information Systems.

2. PROCESS INFORMATION MANAGEMENT

2.1 Introduction to the Improvement Process

Market competence and changing regulations forces company and plant management to

optimise continuously the cement manufacturing process to increase production, improve

the equipment performance, reduce the use of energy, reduce the amount of necessary

man-hours, in summary lower the overall production cost of our product the cement.

In general, optimisation and improvement is based on the following facts: (according Jim

Harrington).

If you want to improve it, you have to control it

!

If you want to control it, you have to understand it

!

If you want understand it, you have to measure it !

The three activities: measurement, understanding (to analyse data and to come to a

conclusion) and control form together the Improvement Loop. Improvement is only

sustainable if this improvement loop is executed continuously.

Corporate programs as BCM or MAC fully relay on this improvement loop (e.g KPI

measurement, reporting, action meetings, etc.).

Nowadays (since the invention of modern computers) some of Improvement Loop tasks can

be executed automatically. The most time consuming and boring task of process data

acquisition, raw data handling and report compiling can be done with a computer system.

Plant personnel can be used for analysing information and for decision making.

-

This is a

more adequate challenge for a human being than coping numbers.

Page 210 Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (T1S)

2.2 Importance of information for decision making

The basis for management to make the daily operational and the medium term tactical

decision, is information. Information coming from the process and process related actions as

quality control, dispatch, emission monitoring and others.

If the plant or company management want to act

- proactively or reactively - they need

information. The more they fine tune the operation (e.g: BCM) and the more they optimise

the risks (e.g: MAC), the more comprehensive, reliable, accurate and direct must the

information they base there decisions on be.

A modified quotation from a Japanese Business Expert (name unknown) says it quite direct:

Information is a key success factor for business

some Managers know this

others are learning

the rest will be Victims.

2.3 Process Information which is relevant for plant performance improvement

For the daily plant operation, as well as for medium and long term plant performances

monitoring and improvement the different responsibilities in a plant need the following type

of information on hourly, day, week, month and year basis.:

What is the plant performance this day / week / month /

year?

Where is the biggest improvement potential?

How are we compared to the others (benchmarking)

Company / Plant

Management

Production

Process

Maintenance

Quality

Energy

Environment

What is the production rate, consumption, actual stock of

materials?

Does the process / equipment runs optimal?

- Why not?

What are the equipment runtimes, machine conditions,

failures rates?

- Failure reasons?

What is the quality level of our product? Why is it in / out of

specification?

What are the specific energy consumption?

- Tendencies?

What are the emissions? Are we endangered to exceed

limits?

In more general terms, the plant personnel needs a tool which provides:

Relevant Information

at the Right Time

at the Right Place

in the Right Form

to the Right People

This simple but important statement (from: Rauli Hantikainen) describes the basic

requirement of adequate Information Management.

A computer systems which can fulfil the above mentioned requirements has to be

based on a integrated Database incorporating data sets from all technical related

plant disciplines:

Holderbank Management & Consulting, 2000

Page 21

1

"Holderbank" Cement Seminar 2000

Engineering -

Technical Information Systems (TIS)

!Ml.:J:M?rcga

Figure 1 :

Such system are called: 'Technical Information System".

Page 212

Holderbank Management & Consulting, 2000

Holderbank" Cement Senear 2000

l!H3Ld.t^

Engineering

-

Technical Information Systems (TIS)

3. TECHNICAL INFORMATION SYSTEMS (TIS)

In the past, most of the management's planning and optimisation was based on different

data printouts, recorder charts and manually generated reports. But nowadays tools and

system concept are available to get immediate and accurate information on there desk top

in seconds.

3.1 Types of Automation- and Information System in a plant. Definitions

Ip this paper common industry term as CIM- and ERP- System are used. They are

indispensable for describing and defining the architectures and system concepts that are

involved in plant wide Information Management system solutions. Their definition is found

just below:

CIM = Computer-Integrated Manufacturing systems:

A series of computer-based systems, both business and technical, integrated into a single

conceptual solution. A CIM system is comprised of components and elements of both

ERP and TIS systems (see next), as well as the different automation systems like

process control, high level control, quality control (lab), etc.

ERP = Enterprise Resource Planning system:

A integrated, networked computer system providing (primarily) business functions and some

manufacturing functions. An ERP system mostly provides also the information link

between the company headquarters (HQ) and the plant. In most "Holderbank" Group

Companies the product SAP R/3 is implemented (or planned) as a ERP system.

TIS = Technical Information System:

A integrated, networked, real-time computer systems providing (primarily) manufacturing

functions. Its real-time data base technology merge all plant automation data with data

from the non-technical (or business) systems within a Plant. By capturing "live"

information about the manufacturing process as, sensor measurement, set-points, run-

times, throughput, yields, etc., a TIS can measure constraints and identify bottlenecks to

better manage and control manufacturing processes (see also decryption in chapter

3.2).

(In some industries the term MES, Manufacturing Execution System, is uses also).

The sketch below shows the structure and interactions of the different mentioned systems.

Holderbank Management & Consulting, 2000 Page 213

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

;r..:i:M?iraa

Figure 2:

Computer-Integrated Manufacturing (CIM)

Systems

-

Hierarchy

Company

Management Level

/erp\

Corporate HQ

(How is

business

running ?)

day /month

' s

Works Management

Level

hour /day

//

f

N

.

\N

/

ERP

N

minutes/ hour

7

Y

Plants

(How is plant

running ?)

Production and

Process Control Level

seconds /minutes >

/lab PCS (others) bisp\

Legend: CIM = Computer-Integrated Manufacturing (system); ERP = Enterprise Resource Planning; TIS = Technical Information System;

LAB = Laboratory Information System; PCS = Process Control System; (others) as EMS = Emission Monitoring System and

HLC = High Level Control Systems; DISP = Automatic Dispatch System

3.2 Principle of a Technical Information System (TIS)

3.2.1 General

In the CIM pyramid, a TIS is locate between the Company / Works Management Level

(ERP) and Production / Process Control Level (Plant Automation). The interaction between

those levels is as follows:

The tactical and strategic decision are made in the higher levels:

The computer systems on these levels must provide to management business data

and compiled and summarised plant information (process, production, equipment

and quality) (time range: days, month, years).

Operation of the plant is done from the lower level systems.

The computer systems on these levels must provide to plant responables immediate

accurate real-time process and process related information, (time range: seconds to

hours).

A TIS System does the automatic data acquisition and data pre-processing. It provides

tools for data evaluation, create reports, graphs and tables, for status and performance

analysis. It also serves as a data interface between Operation and Managing Level of a

plant and company.

Page 214

Holderbank Management & Consulting, 2000

i;M*.;J:MJI

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

3.2.2 Tasks (requirements) of a TIS

Data Acquisition

Data from the process and process related tasks, e.g as material handling, product

shipment and quality determination is the basis for compiling the above mentioned

information. In a up-to-date cement plant most of this data are already automatically

measured by a computer based Process Control System (PCS) and other Automation

systems (High Level Control, Lab, Dispatch, Emission, etc.). In a standard set-up of a 3000

to 5000 tones per day plant, the PCS measures and handles roughly 600 analog sensor,

600 counters and integrators and up to 15'000 alarm and event messages. Data acquisition,

data processing and visualisation is done in real time (milliseconds to seconds). Historical

data is normally presented to the operator in graphic trend charts and data historian is

stored for playback for up to a week, sometime month. The PCS capability is very limited for

tasks, as long term data storage and retrieval, history archiving, data consolidation and

report generation. Furthermore data from the lab analyser and dispatch system are normally

not interfaced to the PCS. Data acquisition scan time from data of all above mentioned

automation system is between 1 to 60 seconds.

Data Pre-Processinq, Storage and Archiving

All the automatic read in data, is filtered and pre-processed according data type (e.g.

integration of a kW signal to kWh, conversion of silo distance measurements to silo level,

combination of a cement type signal and a material flow signal to a amount of finish good

produced, calculation of specific fuel consumption out of heat content, flow of fuel, kiln feed

and clinker factor etc.).

The different type of scanned and calculated values are then stored in integrated, real-time

Database. The data storage structure is optimised for a huge amount of data to be read and

retrieved in very short time. Archiving and retrieving to and from a tape or disk unit must be

possible under on-line conditions. Raw data lifetime on harddisk is normally 6 to 12 month,

on tape between 1 to 1 years (in some special cases as emission data for the EPA, archive

data lifetime, must be guaranteed for up to 30 years).

Especially a fast and user-friendly data retrieving engine is important. Otherwise the data is

buried in a Data Graveyard with no use at all. A short estimate of the total amount of data on

such a system emphasise the importance of this statement:

Scan time = 1 minute, analog measurements = 1200 tags, amount of alarm and event

messages (132 char.) per minute = 1 data lifetime (on disk) = 1 year.

(4 Bytes per number, 1 Byte per character, 4 Bytes per message)

per minute: ==>

(1 200

*

4) + (1 32

*

1 ) + 4 = 5000 Bytes

per day: ==> 60

*

24

*

5000 = 7.2 Mbytes

per year: ==> 365

*

7.2 MB = 2.6 GB (Data Storage Capacity)

Holderbank Management & Consulting, 2000

Page 21

5

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (T1S)

Data Evaluation

To analyse this big amount of data it is indispensable to applies specific methods and tools

to transfer the raw data to useful information (remember the difficulties to analyse the pyro-

process with data on multiple, endless paper charts strips with no physical scale, date, and

remarks on it).

A state-of-the-art TIS provides most of the following Data Analysis and Reporting tools:

Plant Overview Display

Gives plant management an immediate overview over actual plant- and equipment-

operation.

Daily / week / month / year Manufacturing Report

Summary Report with information about the process, production, equipment status,

material stock, quality, shipment etc.. Medium and long-term performance

monitoring.

Operation Log Reports:

Short term production and process performance monitoring

Trend graphs

Actual

-

and historical process status and performances

Alarm List and Alarm Statistic

Shows actual and historical equipment failures and gives maintenance personnel an

overview of equipment problems.

List of running hours, production numbers and process values

Enables plant personnel to plan production and maintenance schedules; For special

situations also Ad-Hoc analysis can be done and special Reports (Emissions for

EPA, ATR for "Holderbank", etc.) can be created.

Statistical Analysis as Charts, Correlation, Pareto

For Quality control, process optimisation and maintenance support.

Manual Data Entry and Data Modification Capability

For the calculation in the pre-processing (see above) the TIS needs manual entered plant

constant. Examples of such plant constants are: clinkerfactor, raw material humidity, head

content of fuels, etc. A TIS must provide user-friendly functions to enable plant personnel to

adjust the constants in a easy way.

Furthermore, a TIS must provide functions to modify and adjust calculated and integrated

report values. In contrast to booking numbers in a transaction based ERP business system,

every physical sensor measurement has a measurement error (independent how often the

sensor has been calibrated). Integration of sensor values result in accumulation of the error.

For example in a 2 million tonnes per year cement plant, a 2% error in the produced cement

belt weigher system, results in a divergence of 40'000 tonnes of cement. TIS applications

showed that automatic generated reports must be checked for plausibility and adjusted

accordingly before they can be approved for further use (e.g. as input data for a SAP, ERP

system).

Page 216 Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

!N.H;itM?T?ga

Interfaces to Automation- and ERP System

As shown in chapter 3.1, a TIS System is located in between the ERP business system of

company / works management level and the automation system of the process / production

control level. This means a TIS reads his input data from one or multiple automation system

as Process Control System, Lab System, Emission Monitoring System etc.. Compiled

reports can be sent to the upper level ERP System for further treatment. A TIS supplier

must provide and support highly reliable interfaces to different brand of automation- and

ERP systems.

3.2.3 Structure and Integration of a TIS

The general structure of a TIS and the integration in the plant information management

concept looks as follows:

Figure 3:

Structure and Integration of a TIS

Plant Admin.

User PC

(SAP, TIS, etc.)

Plant Operation

El- 1

Link to Corporate HQ

ERP (SAP)

Server

_^3322K:

3

TIS

IS.. Server

%

m

LAB

.0

LINK

I

man

0-p

m

PCS HLC

PP..

EMS DISP

With this approach, the process related data flows in a structured flow from bottom to top.

All systems are networked, manual data entry is minimised, data transfer speed and data

quality are maximised.

Holderbank Management & Consulting, 2000 Page 217

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

!M*.:J=M?rKa

What to avoid

In some plants ("Holderbank" and Non-"Holderbank") the automation- and control systems

as well as different business computer systems were installed over several years not

applying an overall concept.

This "natural grown" computer system agglomeration are typical patchwork solutions with

individual computer islands (not using standards).

Such systems are highly complex, difficult to document and maintain and result high

operation and support costs. The flow of data is limited, because too many systems and

interfaces are necessary. Often manual data transfer is used (data printout of one computer

system, data entry typing in the other computer). Such approaches are not user friendly,

show slow data transfer, low quality of data and redundant data sets and results in user

frustration.

3.3 TIS Systems and Suppliers

The results of different Industry Market Scan (1993

-

1997), executed in co-operation with

"Holderbank" Group Companies in various countries, are summarised below. The list shows

suppliers, produc : names and country ol origin:

Supplier Product Origin

ABB CIMS Switzerland

Siemens CEMAT-MIS Germany

AspenTech CIM/21,lnfoPlus.21 USA

FLS / Fuller Plant Guide USA / Denmark

OSI PI System USA

Honeywell Uniformance USA

Page 218 Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

Engineering -

Technical Information Systems (TIS)

!M1.;J:MJnga

4. TIS APPLICATIONS AND EXPERIENCES

4.1 TIS System installed and planned in "Holderbank" plants

4.1.1 System installed and running

Company / Plant Country TIS Supplier / System Installed

AB GmbH / Lagerdorf Germany Siemens / CEMAT-MIS 1994

BCU / Untervaz Switzerland ABB/CIMS 1995

HOLNAM / Holly Hill,

Clarksville, Dundee, Artesia

USA AspenTech / CIM21 1995/96

Alpha / Dudfield, Ulco South Africa ABB/CIMS 1997/98

HOLNAM /all 15 plants

(cement and slag)

USA AspenTech / lnfoPlus21 1997/98

4.1.2 System planned to be installed (Project approved)

Company / Plant Country TIS Supplier / System planned

HCB / Siggenthal

SCL / Chekka

QCL / Gladstone

Switzerland

Lebanon

Australia

ABB/CIMS

under Evaluation

under Evaluation

1998/99

1998

1998/99

4.2 Some Specific Applications and Experiences, Benefits

4.2.1 Alsen Breitenburq Zement

-

und Kalkwerke GmbH, Lagerdorf. Germany

(Main use of TIS: Process Analysis, Quality Monitoring, MAC report data)

Cement plant with 2 kilns, with a capacity of approximately 1 .6 mio t/y cement.

The company sells more than 34 different types of products and has to keep track of all the

sales and quality of the products. Furthermore the new kiln 1 1 is designed to be feed with

numerous alternative raw materials and fuels.

TIS System implemented: Siemens CEMAT-MIS

Technical Concept

Siemens CEMAT-MIS Technical Information System installed in 1994

The system uses a Server based on a PC (Intel Pentium) running Siemens

proprietary DBMS and PC Clients running MS Excel for reporting and data analysis.

Trend display and analysing tool (extended analysis possible on integrated Excel

tool)

Use standard production, operation reports and custom defined daily production

report (realised on Excel).

Reads process and production data directly from the Process Control System (PCS

= Siemens CEMAT Coros LSB / S5). Reads approx. 2000 analog values and

process more all alarms and event messages, scan rate = 1 minute).

Quality data from the automatic, roboterised lab system (Polysius POLAB) are feed

via interface directly to the CEMAT-MIS (event driven).

Data from the Emission Monitoring system are send to the CEMAT-MIS via interface.

) Holderbank Management & Consulting, 2000 Page 21

9

"Holderbank" Cement Seminar 2000

n.i-y.i.i.<f

Engineering -

Technical Information Systems (TIS)

The CEMAT-MIS reads dispatch and sales data once per day from the company

mainframe via ASCII file transfer.

All systems are connected via an Ethernet LAN (H1 and TCP/IP protocol).

Integrates production, operation, quality, emission and consumption monitoring and

reporting.

More to 16 user PC's.

Reports on the plant files server (Novell) can be transfered via modem lines at the

terminal and grinding plant locations.

Experiences / Benefits

The CEMAT-MIS is a very reliable and adequate performing system (more than two

years of experiences).

The excellent trending and reporting features provided a tool to analyse and optimise

the process easy (for example the ball mill charges). Advantage: TIS calculate the

specific energy consumption for each type of cement individually. With this cement

type dependent energy consumption trends can be monitored which is only possible

with automatic data acquisition and pre-processing via PCS and TIS.

The CEMAT-MIS was directly used for the commissioning of the new kiln 1 1 . The

long-term data storage and trending function provided a excellent tool to speed up

commissioning. It even prevented the plant to pay the cost for a damaged EP Filter,

because with the data from the CEMAT-MIS the engineers were capable to find the

root-cause and the exact time when the damage happened. So repair cost could be

turned over to the suppliers insurance.

Tailor made reports for the MAC Initiative provide automatically, on daily basis the

necessary production- and equipment efficiency- numbers. This data were used to

calculate the KPI (Key Process Indicators) and are the basis for failure analysis. The

biggest benefit from the system is fast and automatic report generation every

morning (sustainable). Data accuracy with this system is much better than manual

data processing and saves up to 3 man-hours per day.

Complex process analysis realised with correlation charts provide new perceptions,

which help to increase production equipment efficiency.

System is very well accepted and used by plant personnel.

Further Proceeding and Projects

In 1998 a SAP R/3 ERP System will replace the now used mainframe system.

An interface for data exchange between the SAP R/3 and the Siemens CEMAT-MIS

systems is foreseen. The planed use of this interface is to transfer form the TIS

failure reasons and equipment running hours in the SAP Plant Maintenance Module

(PM). A study will check the possibility to use the SAP Production Planning Module

(PP) with production numbers from the TIS.

Page 220

Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

=============

Engineering

-

Technical Information Systems (TIS)

4.2.2 Buendner Cement AG. Untervaz. Switzerland

(Main use of TIS: Emission Reporting, Overall Manufacturing Report, Energy Reporting).

Cement plant with 2 kilns with a capacity of 1 mio t/y cement.

TIS System implemented: ABB CIMS

Technical Concept

ABB CIMS Technical Information System installed in 1994/95.

Reads process and production data directly from the Process Control System (PCS),

realised with an Allen Bradley PLC 5 and PC based HMI system (reads approx. 600

analog values and process up to 1 5'000 alarms and event messages, scan rate = 1

minute).

Integrates production-, operation, consumption and emission monitoring and

reporting.

Trend display and analysing tool (extended analysis possible on integrated EXCEL

tool).

CIMS is a Server / Client solution based on DEC Alpha server running a Oracle

DBMS and PC Clients running MS Access and Excel for reporting and data analysis.

Use standard production and operation reports and custom defined emission report

(realised on Access).

CIMS can consolidate (and compress) data to hour, shift, day, month and year

values and stores data for on-line access up to 1 year.

Experiences / Benefits

Improved and faster monitoring and reporting of emission data to EPA.

Tool to analyse operating and emission data which improved the use of HWDF

burning.

Reduced drastically the man-hours (up to 2 man-hours daily) needed for manual

data entry and manual analysis to generate emission and production reports.

A sophisticated Overall Manufacturing Report provide on daily and monthly basis a

summary of key process, production, consumption, efficiencies, stock and quality

data. Saves production management up to 0.5 man-hour daily.

Further Proceeding and Projects

Expand CIMS for enhanced production reporting and detailed electrical consumption

reporting.

An interface for data exchange between the SAP R/3 and the ABB CIMS systems is

foreseen (flow of material, equipment runhours and condition).

Adapted reports for support for MAC Initiative.

Holderbank Management & Consulting, 2000 Page 221

"Holderbank" Cement Seminar 2000

liWiimmWM

Engineering

-

Technical Information Systems (T1S)

4.2.3 Holnam: Holly Hill. Clarksville. Dundee. Artesia: USA

(Main use of TIS: Emission Reporting, Process Analysis).

Four Cement plants which burn HWDF (Hazardous Waste Derived Fuel). Legislation force

them to monitor emission (based on gas analyser and materiel input model calculation).

TIS System implemented: AspenTech CIM21 (former company: ISI)

Technical Concept

AspenTech CIM21 Technical Information System installed in 1995 and 1996

Reads process and production data directly from the Process Control System (PCS),

realised with a Modicon PLC and Gensym G2 based HMI systems (reads approx.

200

-

330 analog values per kiln, scan rate = 1 minute).

Integrates emission monitoring and reporting.

Trend display and analysing tool (extended analysis possible on EXCEL tool).

CIM21 runs on UNIX based HP workstation server. The Database is proprietary. PC

(under X-Window) can be used as user interface.

Experiences / Benefits

Provide the mandatory (according EPA) emission monitoring, reporting and data

archiving.

HWDF burning would not be possible without this TIS systems.

The system is also used for process data analysis (mainly graphic trend) because

trending features of the used PCS are not sufficient.

Further Proceeding and Projects

Upgrade the existing CIM21 system with the new lnfoPlus21 (NT based Client

/Server System).

Install in the remaining 1 1 plant a lnfoPlus21 . Use mainly as process data historian

and emission monitoring tool.

The company wide "Manufacturing Data Integration" (MDI) project will integrate

these TIS in the ERP Datawarehouse (Holnam proprietary Data Management

System based on Oracle).

Page 222 Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

Engineering

-

Technical Information Systems (TIS)

..:i:M?rr

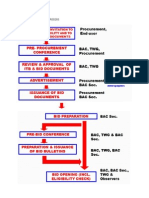

5. TYPICAL PROJECT SCHEDULE AND SCOPE OF SUPPLY

5.1 Project Schedules (typical)

The introduction of a TIS system needs some pre-project investigations resulting in a

detailed specification. With this, an evaluation (bidding process) can be executed to find the

most appropriate TIS. Normally a TIS is implemented in steps, similar to a SAP, realising the

functions with the highest priorities first. The following schedule gives some indications of

the whole procedure.

Phase Actions

0: Pre-condition

1 : Study

2: Project Planning

3: Tendering and

Evaluation, Offer

The plant must be equipped with a state-of-the-art computerbased

Process Control System (PCS).

Investigation study to determine plant requirements, elaboration of a

concept. Investigate integration in plant /company computer

infrastructure. Check of interface solutions to all automation systems

and to the ERP system.

Creation of a Specification and elaboration of a budget and an

implementation schedule.

Creation of a tender document. Execution of a system evaluation

and selection of a System / Supplier (in some case evaluation can

be skipped if a company standard exist).

Ask for offer (using specification and schedule).

Implementation and commissioning of TIS basis System. Check of

performance, adaption of functions to meet plant requirement, (if

necessary).

4: Implementation of

Step 1

5: Implementation of

Step 2

5.2 Scope of supply (typical)

The scope of supply of a TIS application may vary from plant to plant, as the requirements

are different.

Nevertheless there are basic requirements in a typical cement plant that can be satisfied

(usually in a first implementation phase). That is why the scope of supply is roughly divided

into Basic System and Options. The experience shows, that a cost estimation cannot be

given at this place, because functionality, interfaces and numbers of users differ from

project to project. But it is important to know, that project costs are higher than system

costs, because time and cost intensive tasks (study, specification, evaluation, see schedule

in 5.1) must be done prior to the system implementation.

The following sketch gives an overview of different packages of a TIS basis system (1 ...4)

with options (5. ..7).

Holderbank Management & Consulting, 2000 Page 223

"Holderbank" Cement Seminar 2000

Engineering -

Technical Information Systems (TIS)

!MI.;i=MJrOT

Figure 4:

TIS Scope of Supply (typical)

SAP Server

MMUM

Control

Network

fe^ST?

O Application

Extended

Functionality

File Server

TIS Basis System (for reference see number in sketch)

1) Server Hardware (HW) an Software (SW), TIS basis SW including DataBase

2) 4 User PC SW license for basis data evaluation

3) Interface driver SW for data acquisition from a Process Control System (PCS)

4) Application applying standard reports and evaluation methods, including system

installation and user training

TIS System Options (for reference see number in sketch)

5) Extended functionality as Maintenance Support Functions, SPC, plant specific

Manufacturing Reports, etc.

6) Interface to Lab or Dispatch (weighing) system

7) Interface to SAP System, including data exchange concept

a) Hardware is part of the plant computer infrastructure

b) not included is set-up and configuration on interfaced system

Assistance from HMC/HES

HMC offers its assistance and experience for TIS Implementation in a plant or group:

audit

elaboration of (detailed) specifications and tender documents

evaluation of offers from different suppliers

general project assistance

detailed engineering of reports (optional)

training for plant personel (optional)

performing aceptance tests

Page 224

Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

"

Engineering

-

Technical Information Systems (TIS)

6. RESULTS AND CONCLUSION

6.1 Results, Benefits

The Experience and results from different Process Information Management Projects in the

cement and other basic industries show the following benefits:

Fast and accurate information

Fast and accurate information enables the plant management to see tendencies and

to react and direct measures before limits were exceeded. Because reports were

calculated automatically, response time is hours or days, not month.

Open information exchange

All managers which use any kind of integrated Information Management System (not

necessary a TIS) confirm that such tools enables open information exchange which

improves teamwork drastically and minimises mistrust. This because every user has

access to the same information. People share information and work closer together.

In projects were an interface between the ERP System (e.g. SAP R/3) and the TIS

are planned, personnel responsible for the process and administrative personnel

form an interdisciplinary team, were both sides start to understand also the

problems and the requirements of "the other side".

Indispensable for sustainable optimisation

High sophisticated Optimising System as LINKman High Level Control need to be

fine tuned and adapted to changing process conditions. Only continuous monitoring

of the performance and process conditions with specific analysis tools, as

Correlation's, prevent from decreasing system performance.

In one plant the LINKman runtime can be maintained continuously over 95% with the

help of daily performance feedback, which allows immediate reaction to arising

problems.

Permanent monitoring of key parameters and adapted analysis methods like

Statistical Process Control (SPC) provides vital information about equipment

status and equipment failures. Maintenance Improvement procedures (like the

one in MAC) relay on such type of feedback data.

Fulfil legislation requirements

Legislation forces us to monitor, analyse and report certain critical values, (e.g

emission, use of waste fuel). In USA (BIF) and Switzerland (TA Luft) monitoring,

reporting and data archiving of emissions and waste fuel with a TIS, were accept by

the local EPA's.

Continuous Quality monitoring of shipped cement (e.g.: Germany: Cement Norm

VDZ, USA: Mill Certificate) can be realised with the help of a TIS.

Saves man-hour

In all plant using a TIS, plant management claim man-hour savings. But the even

bigger advantage is, that a TIS frees the engineers from formal work (like data entry,

manual data processing) and allows him to use more time on the data analysis.

Studies of TIS applications in different basic industries show:

* Reduced data entry time: 75%

(reports are compiled in 3 minutes, and checked in 5 minutes)

* Reduced Paperwork: up 50%

6.2 Conclusion

Considering the importance of relevant information, the actual trends in Information

Technology, the indications we have from Technology Watches of non-cement and cement

Holderbank Management & Consulting, 2000 Page 225

"Holderbank" Cement Seminar 2000

iiLava

;

fti:iKig

Engineering

-

Technical Information Systems (TIS)

industries (our competitors) and the experiences from TIS and SAP applications result in the

following conclusions:

A competitive optimised plant has to be based on computerbased, integrated

Information Management System (according CIM concept).

Process Information Management with a TIS is a central pillar of such an "Integrated Plant"

.

Individual users are empowered at the desktop. Process Data feedback and intelligent

use of this information is indispensable for a continuous improvement process and will

help the plant to be competitive.

Page 226 Holderbank Management & Consulting, 2000

"Holderbank" Cement Seminar 2000

"

Engineering

-

Technical Information Systems (TIS)

7. REFERENCES:

U. Herzog, T. Carpenter: Manufacturing Data Integration: Holnam MDI Feasibility Study,

Industrial Scan, 1996, HES Report 96/6340/E

U. Herzog: Technical Information System, "Holderbank" E-Circle NA, Mobile (AL), USA,

1996

W. Sedlmeir: Total Management Information, World Cement Feb. 1996

L. Krings: New Cement Information Management Solutions, IEEE Conference 1996, Los

Angeles, USA

R. Sauberli: Process and Quality Control Automation, Information Management;

"Holderbank" 33rd Technical Meeting 1994 Basel, Switzerland

R. Sauberli, U. Herzog, H. Rosemann: Process Control and Information Management;

VDZ Kongress 1993 Dusseldorf Germany, ZKG 46 (1993), No 1

1

Special Thank also to:

Peter Kuenne, Fritz Schneider, Ian Campbell; for discussing and providing information

about concept and experiences of the MAC Initiative.

Ivo Keller, Urs Bleisch, Michel Moser, Thorsten Fuchs; for discussing and providing

information about SAP projects concept, plans and experiences.

Holderbank Management & Consulting, 2000 Page 227

"Holderbank" Cement Seminar 2000

mMiww-fnwim

Engineering -

Technical Information Systems (TIS)

Page 228

Holderbank Management & Consulting, 2000

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Mechanical Properties For Steel FastenersDocument7 paginiMechanical Properties For Steel FastenersepriyonoÎncă nu există evaluări

- POwise Monthly Trend-812Document1 paginăPOwise Monthly Trend-812MKPashaPashaÎncă nu există evaluări

- Filtration: Fiber FilterDocument20 paginiFiltration: Fiber FilterTamer Farouk KhalifaÎncă nu există evaluări

- POwise Monthly Trend-812Document1 paginăPOwise Monthly Trend-812MKPashaPashaÎncă nu există evaluări

- POwise Monthly Trend-205206207Document1 paginăPOwise Monthly Trend-205206207MKPashaPashaÎncă nu există evaluări

- POwise Monthly Trend-102Document1 paginăPOwise Monthly Trend-102MKPashaPashaÎncă nu există evaluări

- Creating A BudgetDocument131 paginiCreating A BudgetMKPashaPashaÎncă nu există evaluări

- POwise Monthly Trend-153Document1 paginăPOwise Monthly Trend-153MKPashaPashaÎncă nu există evaluări

- POwise Monthly Trend-405406407Document1 paginăPOwise Monthly Trend-405406407MKPashaPashaÎncă nu există evaluări

- AIS-Mechanical Maintenance ModuleDocument3 paginiAIS-Mechanical Maintenance ModuleMKPashaPashaÎncă nu există evaluări

- Excel Formulas FunctionsDocument2 paginiExcel Formulas FunctionsMKPashaPashaÎncă nu există evaluări

- Pyro ProcessingDocument29 paginiPyro ProcessingMKPashaPasha100% (2)

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pagini117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaÎncă nu există evaluări

- 01 - IP SOW Template v3.0Document26 pagini01 - IP SOW Template v3.0MKPashaPashaÎncă nu există evaluări

- 07 EnvironmentDocument14 pagini07 EnvironmentMKPashaPashaÎncă nu există evaluări

- Process GuidlinesDocument20 paginiProcess GuidlinesMKPashaPasha100% (4)

- GCCL ManualDocument26 paginiGCCL ManualMKPashaPashaÎncă nu există evaluări

- Pyro ProcessingDocument29 paginiPyro ProcessingMKPashaPasha100% (2)

- 05 CombustionDocument15 pagini05 CombustionMKPashaPasha100% (1)

- 04 MillingDocument21 pagini04 MillingMKPashaPasha100% (1)

- The Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisDocument10 paginiThe Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisMKPashaPashaÎncă nu există evaluări

- 441 GC & EspDocument6 pagini441 GC & EspMKPashaPashaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Reliabilityweb Uptime 20131201Document69 paginiReliabilityweb Uptime 20131201catraioÎncă nu există evaluări

- Advertising and Sales PromotionDocument69 paginiAdvertising and Sales PromotionnhdÎncă nu există evaluări

- Resume HemaDocument2 paginiResume Hemaanil007rajuÎncă nu există evaluări

- TransoftVMSWhitePaper PDFDocument12 paginiTransoftVMSWhitePaper PDFpatra_robin9157Încă nu există evaluări

- A & N Electric June 2013 - BrinkleyDocument4 paginiA & N Electric June 2013 - BrinkleyMelissa BoldtÎncă nu există evaluări

- MSC Marketing Management Marketing Management & Strategy: Tutor: Hazel HuangDocument14 paginiMSC Marketing Management Marketing Management & Strategy: Tutor: Hazel HuangDeeban BabuÎncă nu există evaluări

- Bosch Today 2019Document50 paginiBosch Today 2019Gogul RajaÎncă nu există evaluări

- Asu 2018-08Document74 paginiAsu 2018-08Stephen BalaniÎncă nu există evaluări

- Dolly Khanna PortfolioDocument7 paginiDolly Khanna PortfoliomalhiÎncă nu există evaluări

- Porter's Five Force ModelDocument27 paginiPorter's Five Force ModelKushagra SethiÎncă nu există evaluări

- Bu3111-3280 Lecture 2003Document91 paginiBu3111-3280 Lecture 2003Sowah-Laryea FelixÎncă nu există evaluări

- Internal & External AuditsDocument7 paginiInternal & External AuditsrwillestoneÎncă nu există evaluări

- Investment BookDocument26 paginiInvestment BookBobyBrownÎncă nu există evaluări

- Credit Card DetailsDocument5 paginiCredit Card Detailsjrbossfps75% (8)

- MFIDocument48 paginiMFITim HereÎncă nu există evaluări

- Gangar EyenationDocument10 paginiGangar Eyenationpree09Încă nu există evaluări

- Geprek BensuDocument16 paginiGeprek BensuPutri AriyaniÎncă nu există evaluări

- GDR & ADRsDocument4 paginiGDR & ADRsShub SidhuÎncă nu există evaluări

- This Study Resource Was: Day 2 Negotiation (Coffee Contract)Document2 paginiThis Study Resource Was: Day 2 Negotiation (Coffee Contract)Elad BreitnerÎncă nu există evaluări

- Metrolab Industries Inc Vs Roldan-Confesor - 108855 - February 28 2996 - KapDocument28 paginiMetrolab Industries Inc Vs Roldan-Confesor - 108855 - February 28 2996 - KapJia Chu ChuaÎncă nu există evaluări

- ENoLL 10th Wave Membership BrochureDocument3 paginiENoLL 10th Wave Membership BrochureEuropean Network of Living Labs100% (1)

- RealNetworks Motion For Leave To File Second Amended ComplaintDocument10 paginiRealNetworks Motion For Leave To File Second Amended ComplaintBen SheffnerÎncă nu există evaluări

- Perenco - Oil and Gas - A Leading Independent Exploration and Production CompanyDocument3 paginiPerenco - Oil and Gas - A Leading Independent Exploration and Production CompanyCHO ACHIRI HUMPHREYÎncă nu există evaluări

- Imperia No BarcodeDocument2 paginiImperia No BarcodeSyahmiSyaNizarÎncă nu există evaluări

- Ey Fintech Exec Summary 2017Document44 paginiEy Fintech Exec Summary 2017Anonymous SNBEw8WN100% (5)

- Office Management TheoriesDocument35 paginiOffice Management TheoriesArcee Ardiente Mondragon0% (2)

- Case Study Analysis STMDocument42 paginiCase Study Analysis STMThanveer Ma100% (1)

- Block Fi - MB0051Document8 paginiBlock Fi - MB0051Gall AllÎncă nu există evaluări

- Unit 3 PlanningDocument52 paginiUnit 3 PlanningPreeti BhaskarÎncă nu există evaluări

- Bidding Process For Procurement Process and DPWHPDFDocument9 paginiBidding Process For Procurement Process and DPWHPDFGerardoÎncă nu există evaluări