Documente Academic

Documente Profesional

Documente Cultură

42 DST Packer Test Tool

Încărcat de

Kim MissonTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

42 DST Packer Test Tool

Încărcat de

Kim MissonDrepturi de autor:

Formate disponibile

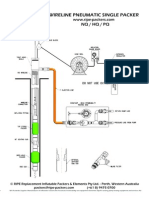

VOLU E (Litres) I D (m m )

NO D RI LL ROD SPE

OD (m m )

M r 0:

%m oo

WEI GHT (4)

23.55 69.9 60.3 87.05 I NO

I NFLATI ON / WI RELI NE

SEALI NG TI GHT HEAD

bility Packer Test Procedure

Pull thI nneYTe assem bly from the core barrel,

leaving the drill string in place.

Elevate the drill stria9 off the drill hole bottom and

I expose th perm eaffliity zone.

Secure/ st bilise the drill)ktringinplace.

Install the sealingtight head.

Lower the packer through the sealingtight head

anddrilPtring, positioninginto the core barrel.

Install steel washers and rubber shies inthe tight

1.

2.

RI G WI RELI NE

C O N D U C T O R

\, ___----1110 CORED HOLE

c - - -

4 k ,

ROD STE $

0 D R ILL ROD S

. I nject wa

Le

, packer into

O . ermeability

oject engin

1 1

O nce

testingis

1 ,

1 2. Make suee pack

fromthe drill ho

1 3. U ndo comp

seals andstee

1 4. R einstall the co

1 5. R emove the seal

inner tube assembl

eadandtightenthe compressioncap.

7. C o ect the nylon inflation tube to the g s/air supply

8. Slowinflate the permeabilitypacker in i rements

of until e desiredpressure is met.

r through the tight headasse

he test zone.

est is run inunder instructionb

SI

r.

omplete deflate the packer.

r is fullydeflatedbefore movin

e.

n tight head and remove rubbe

shers.

pressioncap and remove the packs

ngtight head and thenlower the

intoposition.

r.

B 16. C onnect the dr" Irods, loweringthe drill stringt

the hole botto and restart drilling.

1 7. O HSprocedues must be followed.

1 8. Inflation an use of packers andpacker equip

h rators ownrisk.

BI T SEATI NG S

0 WI RE ORI NG D I AMOND BI T SPE

IAMO N D C O R ED

EN HO LE

Bi I D

47.044m m

CORED HOLE SI ZE

75.7 m m

GEO -Packers T M

D ST PAC KER T EST T O O L

G E O - P A C K E R 0 4 2 m m

N O D ST SIN GLE PAC KER T EST IN G T O O L

N O 42LP1 6SE0.5

Max Working pressure vs hole diam eter

Boreholes diam eter (m m ) 45 50 55 60 65 70 75 80 85 90 95

Percentage inflationdiam eter 7.1 19 31 42.9 54.8 66.7 78.6 90.5 102.4 114.3 126.2

I nflationpressure (bar) 145 125 105 85 80 75 70 45 40 35 30

Nonconfined Free air I nflation

D iam eter (m m ) 45 50 55 60 65 70 75 80 85 90 95

I nflationpressure (bar) 2 2.5 3 3.5 4 4.5 5 7 10 13 23

R eplacement Inflatable Packers and Elements PtyLtd

29 Wheeler St Belmont 61 04, Perth Western Australia

T el: (+6 1 (08) 9475 0700 Fax: +61 (08) 9475 0770 packers@ripe-packers.comwww.ripe-packers.com

WA AustraliaSupplier Manufacturer of inflatable Packers for D ST Well Packer TestingPerm eabilitysingle/ double packer testingequipm ent andServices AU.

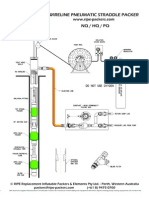

GEO-Packers T M

DST PACKER T EST T OOL

G E O - P A C K E R 0 4 2 m m

NQ DST DOUBLE PACKER T EST ING T OOL N1 0 4 2 LP1 6 SE0 . 5

NFLATION / WIRELINE

SEALING T IGHT HEAD Perm bility Packer Test Procedure

RIG WIRELINE

1.

E M PACKER

1 0 .

v 4 N.

1.10 .

1 3.

1 4 .

1 5 .

inn

1 6 .

7.

Pull th inneYT e assembly from the core barrel,

leav ing the drill string in place.

Elev ate the drill stria9 off the drill hole bottomand

I expose th permeaffliity zone.

Secure/ st bilise the drill)ktring in place.

Install the sealing tight head.

Lower the packer through the sealing tight head

and drilPtring, positioning into the core barrel.

Install steel washers and rubber shies in the tight

ead and tighten the compression cap.

Co ect the nylon inflation tube to the g s/air supply.

Slow inflate the permeability packer in i rements

of until e desired pressure is met.

Inject wa r through the tight head asse

packer into he test zone.

est is run in under instruction b

er.

omplete deflate the packer.

r is fully deflated before mov in

e.

n tight head and remov e rubbe

shers.

pression cap and remov e the packer.

ng tight head and then lower the

into position.

I rods, lowering the drill string t

and restart drilling.

es must be followed.

use of packers and packer equip

ermeability

oject engin

Once testing is

M ake suds pack

fromthe drill ho

Undo comp

seals and stee

Reinstall the co

Remov e the seal

er tube assembl

Connect the dr'

the hole botto

OHS procedu

flation an

SI

h rators own risk.

WIREL GORING DIAM OND BIT SPEC

CORED HOLT SIZE

75.7 mm

NO DRILL ROD S PE C I F I C A TI O N S

Bit set O D

75.3 'in

Bit set I D

4 7. 6 mm

N O

I D ( mm)

60.3

WEIGHT ( 4)

23.55

E (Litres)

M ax Working pressure vs hole diameter

Boreholes diameter ( mm) 45 50 55 60 65 70 75 80 85 90 95

Percentage inflation diameter 7.1 19 31 42.9 54.8 66.7 78.6 90.5 102.4 114.3 126.2

I nflation pressure ( bar) 145 125 105 85 80 75 70 45 40 35 30

N on confined F ree air I nflation

Diameter ( mm) 45 50 55 60 65 70 75 80 85 90 95

I nflation pressure ( bar) 2 2.5 3 3.5 4 4.5 5 7 10 13 23

Replacement Inflatable Packers and Elements Pty Ltd

2 9 Wheeler St Belmont 6 1 0 4 , Perth Western Australia

T el: (+6 1 (0 8) 94 75 0 70 0 Fax: +6 1 (0 8) 94 75 0 770 packers@ripe-packers. com www. ripe-packers. com

WA A ustralia S upplier M anufacturer of I nflatable Packers for DS T Well Packer Testing Permeability single/ double packer testing equipment and S ervices AU.

S-ar putea să vă placă și

- 73 DST Packer Test ToolDocument2 pagini73 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 56 DST Packer Test ToolDocument2 pagini56 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 2.1 DST Packer Test ToolDocument2 pagini2.1 DST Packer Test ToolKim MissonÎncă nu există evaluări

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- 43 DST Packer Test ToolDocument2 pagini43 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 42mm NQ DST Permeability Testing Inflatable PackersDocument2 pagini42mm NQ DST Permeability Testing Inflatable PackersRipe PackersÎncă nu există evaluări

- 2.2 DST Packer Test ToolDocument2 pagini2.2 DST Packer Test ToolKim MissonÎncă nu există evaluări

- Balance Disk Replacement PDFDocument8 paginiBalance Disk Replacement PDFOscar Araya RojasÎncă nu există evaluări

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 paginiInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYÎncă nu există evaluări

- Peco Filter CaseDocument11 paginiPeco Filter CaseLuis MaureraÎncă nu există evaluări

- Mercer 9100 ManualDocument11 paginiMercer 9100 Manualanara.aidÎncă nu există evaluări

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 paginiCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Model 21150 Differential Sticking TesterDocument31 paginiModel 21150 Differential Sticking Testerwaleed El-azabÎncă nu există evaluări

- Williamsons PluGDocument3 paginiWilliamsons PluGSARATH KRISHNAKUMARÎncă nu există evaluări

- MSA Cylinder ValveDocument13 paginiMSA Cylinder ValveTammanurRaviÎncă nu există evaluări

- Low Torc ValveDocument4 paginiLow Torc Valvejinyuan74100% (2)

- Agco Type81sek PDFDocument15 paginiAgco Type81sek PDFMargaret DaughertyÎncă nu există evaluări

- Peco Filter CaseDocument11 paginiPeco Filter CaseLuis MaureraÎncă nu există evaluări

- Angle Type Blowdown ValveDocument7 paginiAngle Type Blowdown ValverikumohanÎncă nu există evaluări

- Features/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001Document3 paginiFeatures/Description: 054-0240-001 CSU-1 Tubing Tester, 2-3/8" 054-0240-001scignoniÎncă nu există evaluări

- BFL Chanju - 13846 SPV o & M Manual PDFDocument64 paginiBFL Chanju - 13846 SPV o & M Manual PDFजितेन्द्र कुमार शर्माÎncă nu există evaluări

- 5r55e Valve Body SonnaxDocument8 pagini5r55e Valve Body SonnaxjoshetoÎncă nu există evaluări

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 paginiTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranÎncă nu există evaluări

- wp1148 IVDocument1 paginăwp1148 IVaugustinhodjÎncă nu există evaluări

- Air CylinderDocument4 paginiAir Cylindersimbua720% (1)

- Preventive Maintenance Program For Spherical Blowout PreventerDocument19 paginiPreventive Maintenance Program For Spherical Blowout Preventernjava1978100% (1)

- 755Document19 pagini755JOHNÎncă nu există evaluări

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 paginiTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuÎncă nu există evaluări

- p077 02 PDFDocument8 paginip077 02 PDFJuan ZamoraÎncă nu există evaluări

- Method Statement of Gasket, Flange, Fittings and Valves Tightening SequenceDocument6 paginiMethod Statement of Gasket, Flange, Fittings and Valves Tightening SequenceRuel CabonceÎncă nu există evaluări

- DC2686 PDFDocument6 paginiDC2686 PDFPT DJAS SUCCES SUPPORTÎncă nu există evaluări

- Slot Dipping Device by LecoreDocument4 paginiSlot Dipping Device by Lecoretarun1976Încă nu există evaluări

- Balanced Pressure Thermostatic Steam Trap: BPT21YDocument2 paginiBalanced Pressure Thermostatic Steam Trap: BPT21YJozsef MagyariÎncă nu există evaluări

- Syahrul Muhrisol FDocument6 paginiSyahrul Muhrisol FkomengudinÎncă nu există evaluări

- WPI C or CHD Tubing Spider Manual Rev1Document14 paginiWPI C or CHD Tubing Spider Manual Rev1Dean Rein100% (1)

- Series 808Y Installation InstructionsDocument4 paginiSeries 808Y Installation InstructionsFEBCOÎncă nu există evaluări

- Tank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDocument4 paginiTank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDanielle JohnsonÎncă nu există evaluări

- Type 2600 Relief Valve Capacities GuideDocument2 paginiType 2600 Relief Valve Capacities GuidetakenoveraccountÎncă nu există evaluări

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 paginiValves S&S B Series 8-Inch Globe: Instruction ManualpedroÎncă nu există evaluări

- ESG Service Information: GeneralDocument4 paginiESG Service Information: GeneralHectorFalconLlenderrozosÎncă nu există evaluări

- Catálogo Anderson Greenwood 400sDocument32 paginiCatálogo Anderson Greenwood 400sDaniela BeltranÎncă nu există evaluări

- OSYSU valve monitoring switchesDocument3 paginiOSYSU valve monitoring switchesAnwar SyedÎncă nu există evaluări

- Pipeline Prover SpheresDocument2 paginiPipeline Prover SpheresandraÎncă nu există evaluări

- Assignment 5Document7 paginiAssignment 5Sharizada KanapiyevaÎncă nu există evaluări

- Maintain Series 800 Pressure Relief ValvesDocument24 paginiMaintain Series 800 Pressure Relief ValvesJohnny VargasÎncă nu există evaluări

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 paginiMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقÎncă nu există evaluări

- Cam-Tite Ball Valve Operating Instructions: WarningDocument3 paginiCam-Tite Ball Valve Operating Instructions: WarningSubbarayan SaravanakumarÎncă nu există evaluări

- 4r44e 5r55e Zip BookletDocument8 pagini4r44e 5r55e Zip BookletDaniel BernardÎncă nu există evaluări

- RD Circulating ValveDocument6 paginiRD Circulating ValvearslanadeelÎncă nu există evaluări

- H-6745_00_MEF_00_081_DCDocument33 paginiH-6745_00_MEF_00_081_DCfuad aliÎncă nu există evaluări

- Oil and Gas Well Completion TaskDocument4 paginiOil and Gas Well Completion Taskapi-370721250% (2)

- 3-Well Complation PDFDocument4 pagini3-Well Complation PDFDodi DodoÎncă nu există evaluări

- PVC-PP-PVDF Swing Check Valve SpecificationsDocument4 paginiPVC-PP-PVDF Swing Check Valve SpecificationsthangÎncă nu există evaluări

- Flange Dimensions and Pressure Ratings ChartDocument24 paginiFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDocument11 paginiI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezÎncă nu există evaluări

- E 911 - 98 R04 - RTKXMQDocument4 paginiE 911 - 98 R04 - RTKXMQabualamalÎncă nu există evaluări

- Install piston governorDocument2 paginiInstall piston governorJose ChuctayaÎncă nu există evaluări

- Wireline Hydraulic Straddle PackerDocument1 paginăWireline Hydraulic Straddle PackerKim MissonÎncă nu există evaluări

- Grab Packer ImperialDocument1 paginăGrab Packer ImperialKim MissonÎncă nu există evaluări

- Wireline Pneumatic Straddle PackerDocument1 paginăWireline Pneumatic Straddle PackerKim MissonÎncă nu există evaluări

- Wireline Pneumatic Single PackerDocument1 paginăWireline Pneumatic Single PackerKim MissonÎncă nu există evaluări

- 83 Standard Wireline Packer System ReplacementsDocument1 pagină83 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- Kpackers MetricDocument1 paginăKpackers MetricKim MissonÎncă nu există evaluări

- Replacements and RebuildsDocument1 paginăReplacements and RebuildsKim MissonÎncă nu există evaluări

- Wireline Hydraulic Single PackerDocument1 paginăWireline Hydraulic Single PackerKim MissonÎncă nu există evaluări

- Ripe K Packers and Telescopic SealsDocument1 paginăRipe K Packers and Telescopic SealsKim MissonÎncă nu există evaluări

- RIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsDocument1 paginăRIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsKim MissonÎncă nu există evaluări

- Mini Hydrualic Frac PackersDocument1 paginăMini Hydrualic Frac PackersKim MissonÎncă nu există evaluări

- Permeability TestingDocument1 paginăPermeability TestingKim MissonÎncă nu există evaluări

- K PackersDocument1 paginăK PackersKim MissonÎncă nu există evaluări

- Hydraulic Fracturing Inflatable PackersDocument1 paginăHydraulic Fracturing Inflatable PackersKim MissonÎncă nu există evaluări

- Grab Packer MetricDocument1 paginăGrab Packer MetricKim MissonÎncă nu există evaluări

- 54 DST Packer Test ToolDocument2 pagini54 DST Packer Test ToolKim MissonÎncă nu există evaluări

- 72 DST Packer Test ToolDocument2 pagini72 DST Packer Test ToolKim MissonÎncă nu există evaluări

- Drill Able Bridge PlugsDocument1 paginăDrill Able Bridge PlugsKim MissonÎncă nu există evaluări

- 60 Standard Wireline Packer System ReplacementsDocument1 pagină60 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- 42 Standard Wireline Packer System ReplacementsDocument1 pagină42 Standard Wireline Packer System ReplacementsKim MissonÎncă nu există evaluări

- 30 Bridge Plug Metric Sliding EndDocument1 pagină30 Bridge Plug Metric Sliding EndKim MissonÎncă nu există evaluări

- 30 Bridge Plug Metric Fixed EndDocument1 pagină30 Bridge Plug Metric Fixed EndKim MissonÎncă nu există evaluări

- 30 Bridge Plug Imperial Sliding EndDocument1 pagină30 Bridge Plug Imperial Sliding EndKim MissonÎncă nu există evaluări

- 30 Bridge Plug Imperial Fixed EndDocument1 pagină30 Bridge Plug Imperial Fixed EndKim MissonÎncă nu există evaluări

- 26 Bridge Plug Imperial Sliding EndDocument1 pagină26 Bridge Plug Imperial Sliding EndKim MissonÎncă nu există evaluări

- 26 Bridge Plug Metric Sliding EndDocument1 pagină26 Bridge Plug Metric Sliding EndKim MissonÎncă nu există evaluări

- California Clothing Vs QuinonesDocument4 paginiCalifornia Clothing Vs QuinonesLily MondaragonÎncă nu există evaluări

- Important Tips On The Law On SalesDocument34 paginiImportant Tips On The Law On SalesJanetGraceDalisayFabreroÎncă nu există evaluări

- Ch5 Multivariate MethodsDocument26 paginiCh5 Multivariate MethodsRikiÎncă nu există evaluări

- Demand Letter Jan 16Document8 paginiDemand Letter Jan 16jhean0215Încă nu există evaluări

- 4.3-Euler's Equation PDFDocument6 pagini4.3-Euler's Equation PDFRonald Cario SeguinÎncă nu există evaluări

- 1201 CCP Literature ReviewDocument5 pagini1201 CCP Literature Reviewapi-548148057Încă nu există evaluări

- Mod 1 1 Concepts of Everyday LeadershipDocument26 paginiMod 1 1 Concepts of Everyday LeadershipSaifuzzaman AntorÎncă nu există evaluări

- Living Water by David FeddesDocument44 paginiLiving Water by David FeddesBenjaminFigueroaÎncă nu există evaluări

- Case Epidural HematomaDocument16 paginiCase Epidural HematomaBahRunÎncă nu există evaluări

- Chisholm - Referring To Things That No Longer ExistDocument13 paginiChisholm - Referring To Things That No Longer ExistMichele Paolini PaolettiÎncă nu există evaluări

- Pope Francis' Call to Protect Human Dignity and the EnvironmentDocument5 paginiPope Francis' Call to Protect Human Dignity and the EnvironmentJulie Ann BorneoÎncă nu există evaluări

- November 2008Document14 paginiNovember 2008Aldrin ThomasÎncă nu există evaluări

- Field Study 2 Ep. 5 AnswerDocument10 paginiField Study 2 Ep. 5 AnswerShane Via CainticÎncă nu există evaluări

- RM Group 9 - Research PaperDocument25 paginiRM Group 9 - Research Paperakash advisorsÎncă nu există evaluări

- Chauvin Arnoux 8220Document43 paginiChauvin Arnoux 8220Danilo MuñozÎncă nu există evaluări

- Two Sides of Effective Oral CommunicationDocument17 paginiTwo Sides of Effective Oral CommunicationSharath KumarÎncă nu există evaluări

- Description Text About Cathedral Church Jakarta Brian Evan X MIPA 2Document2 paginiDescription Text About Cathedral Church Jakarta Brian Evan X MIPA 2Brian KristantoÎncă nu există evaluări

- Analysis and Design of Circular Beams-2017Document49 paginiAnalysis and Design of Circular Beams-2017Ragheb Ibrahim0% (1)

- Novena in Honor of St. Elizabeth Ann SetonDocument3 paginiNovena in Honor of St. Elizabeth Ann SetonLadiesofCharityUSAÎncă nu există evaluări

- Antenna & Wave Propagation - Course OutlineDocument2 paginiAntenna & Wave Propagation - Course OutlineSabuj AhmedÎncă nu există evaluări

- Holy Trinity University: Puerto Princesa City Basic Education DepartmentDocument2 paginiHoly Trinity University: Puerto Princesa City Basic Education DepartmentBrian Reyes GangcaÎncă nu există evaluări

- Reactions of Hydrocarbons and HaloalkanesDocument6 paginiReactions of Hydrocarbons and HaloalkanesGwynethAdrienneLeighVillapandoÎncă nu există evaluări

- CHAP 1: STATS & SCIENTIFIC METHODDocument9 paginiCHAP 1: STATS & SCIENTIFIC METHODJesheryll ReasÎncă nu există evaluări

- ChaseDream Business School Guide LBS - ZH-CN - enDocument27 paginiChaseDream Business School Guide LBS - ZH-CN - enRafael LimaÎncă nu există evaluări

- Rehotrical AnalysisDocument3 paginiRehotrical AnalysisShahid MumtazÎncă nu există evaluări

- Professional Teaching ResumeDocument2 paginiProfessional Teaching Resumeapi-535361896Încă nu există evaluări

- Corporal Lesson PDFDocument6 paginiCorporal Lesson PDFCarmeli VillavicencioÎncă nu există evaluări

- Christoffel Symbols: PHYS 471: Introduction To Relativity and CosmologyDocument9 paginiChristoffel Symbols: PHYS 471: Introduction To Relativity and Cosmologyarileo3100% (1)

- KARG - (Ravenloft) Quoth The Raven #10Document179 paginiKARG - (Ravenloft) Quoth The Raven #10David CullifordÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)