Documente Academic

Documente Profesional

Documente Cultură

Aws Classificati v991N

Încărcat de

Max RosasDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aws Classificati v991N

Încărcat de

Max RosasDrepturi de autor:

Formate disponibile

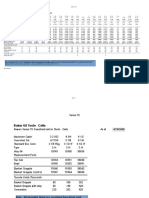

AWS

Classifications

Causes

and Cures

of Common Welding Troubles

Low Alloy

Covered Electrodes

Mild Steel Covered Electrodes,

SMAW Process

E8018-B2

E7018-1 H4R

Electrode

Electrode

Tensile in ksi

Tensile in ksi

Position

Position

Type of coating and current

Type of coating and current

Meets lower temperature impact requirements

Chemical composition of weld metal deposit

Hydrogen: H4 = Less than 4 ml/100 g. H8 = Less than 8 ml/100 g

Meets requirements of absorbed moisture test

Chemical Composition of Weld Metal Deposit

AWS

Suffix

Mn

Si

Ni

Cr

Mo

Position

E7018

A1

0.12

0.90*

.80

.40-.65

.03

.03

E8018

B2L

.05

.90

0.80

1.00 -1.50 .40-.65

.03

.03

1 Flat, Horizontal, Vertical, Overhead

E8018

B2

.05-.12

.90

0.80

1.00-1.50 .40-.65

.03

.03

2 Flat and Horizontal only

E9018

B3L

.05

.90

0.80*

2.00-2.50 .90-1.20

.03

.03

E9018

B3

.05-.12

.90

0.80*

2.00-2.50 .90-1.20

.03

.03

E8018

B6

.05-.10

1.0

.90

.40

4.0-6.0

.03

.03

E8018

B8

.05-.10

1.0

.90

.40

8.0-10.5 .85-1.20

.03

.03

E9015

B9

.08-.13

1.20

.30

8.0

8.0-10.5 .85-1.20 .15-.30

.01

.01 .25 .04 .02-.10 .02-.07

E8018

C1

.12

1.25

0.80*

2.00-2.75

.03

.03

E8018

C2

.12

1.25

0.80*

3.00-3.75

.03

.03

E8018

C3

.12

.40 -1.25

.80

.80-1.10

.15

.35

.05

.03

.03

E10018

D2

.15

1.65-2.00

0.80*

.90

.25-.45

.03

.03

EXXXX

G**

1.00 Min .80 Min

.50 Min

.20 Min

.20 Min

.10 Min

.03

.03

E9018

.10

.60-1.25

.80

1.40-1.80

.15

.35

.05

.030 .030

E10018M

.10

.60 -1.25

.80

1.40-1.80

.15

.35

.05

.030 .030

E11018M

.10

1.30-1.80

.60

1.25-2.50

.40

.25-.50

.05

.030 .030

E12018

.10

1.30 -2.25

.60

1.75-2.50

.30-1.50

.30-.55

.05

.030 .030

E7010

P1

.20

1.20

.60

1.00

.30

.50

.10

.030 .030

E8010

P1

.20

1.20

.60

1.00

.30

.50

.10

.030 .030

Types of Coating & Current

AWS

6010

6011

6022

6013

7014

7018

DIGIT

0

1

2

3

4

8

TYPE OF COATING

cellulose sodium

cellulose potassium

titania sodium

titania potassium

iron powder titania

iron powder low hydrogen

WELDING CURRENT

DCEP

AC or DCEP

AC or DCEN

AC or DCEP or DCEN

AC or DCEP or DCEN

AC or DCEP

DCEP Direct Current Electrode Positive

DCEN Direct Current Electrode Negative

AC Alternating Current

*

**

Nb

.2

Amount depends on electrode classification. Single values indicate maximum.

All G Classifications have the same chemical minimum requirements.

Mild Steel Solid Electrodes,

GMAW, GTAW and PAW

Low Alloy Solid Electrodes,

GMAW, GTAW and PAW

ER70S-3

Electrode or rod

.45-.65

Cr Al

ER80S-D2

Electrode or rod

Tensile in ksi

Tensile in ksi

Solid

Solid

Chemical composition & shielding gas

Chemical composition

Chemical Composition of Solid Wires Using CO2 Shielding Gas

AWS

classification

Shielding

gas

Tensile

Strength

ksi (MPa)

Yield

Strength

ksi (MPa)

% Elongation

min. in 2"

(50 mm)

Impact strength

Min.

ft-lbs at F (J at C)

Mn

Si

Ni

Cr

Mo

Cu

Other

ER70S-2

C02

70 (500)

60 (420)

22

20 at -20 (27 at -29)

.07

.90-1.40

.40-.70

.025

.035

.50

Ti, Zr, Al

ER70S-3

C02

70 (500)

60 (420)

22

20 at 0 (27 at -18)

.06-.15

.90-1.40

.45-.70

.025

.035

.50

ER70S-4

C02

70 (500)

60 (420)

22

.07-.15

1.00-1.50

.65-.85

.025

.035

.50

ER70S-5

C02

70 (500)

60 (420)

22

.07-.19

.90-1.40

.30-.60

.025

.035

.50

Al

ER70S-6

C02

70 (500)

60 (420)

22

20 at -20 (27 at -29)

.07-.15

1.40-1.85

.80-1.15

.025

.035

.50

ER70S-7

C02

70 (500)

60 (420)

22

20 at -20 (27 at -29)

.07-.15

1.50-2.00

.50-.80

.025

.035

.50

ER80S-D2

C02

80 (550)

68 (470)

17

20 at -20 (27 at -29)

.07-.12

1.60-2.10

.50-.80

.025

.025

.15

.40-.60

.50

CHEMICAL COMPOSITION

S-ar putea să vă placă și

- To Stamp Not StampDocument4 paginiTo Stamp Not Stampkinjalpatel12345Încă nu există evaluări

- ASTM A36 DatasheetDocument4 paginiASTM A36 DatasheetRene D. ArrietaÎncă nu există evaluări

- Esab Buddy TIG400iDocument2 paginiEsab Buddy TIG400iJeganeswaranÎncă nu există evaluări

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 paginăTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16Încă nu există evaluări

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 paginiCSM-QR-02-2, Medical Gas BPS TablesaadmaadmÎncă nu există evaluări

- GTAW Welding of CP Titanium and Ti6Al4VDocument1 paginăGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarÎncă nu există evaluări

- Calculating Weld Wire ConsumptionDocument1 paginăCalculating Weld Wire ConsumptionDavid D'AgostinoÎncă nu există evaluări

- Hidden Defects in FittingsDocument3 paginiHidden Defects in FittingsFerlie IndrapatiÎncă nu există evaluări

- QW 442 A Number PDFDocument1 paginăQW 442 A Number PDFMadidj_2014Încă nu există evaluări

- Q235 Steel Equivalent StandardDocument1 paginăQ235 Steel Equivalent StandardigorÎncă nu există evaluări

- Filler Metal Selection GuideDocument3 paginiFiller Metal Selection GuideJorge Sobrevilla100% (2)

- ASTM A131 Steel, Grade DDocument1 paginăASTM A131 Steel, Grade DjulianmorantesÎncă nu există evaluări

- Fr20-016.007-1-Bridas de 10-SlipDocument1 paginăFr20-016.007-1-Bridas de 10-SlipEduardo Dudlei Jimenez CarbajalÎncă nu există evaluări

- Comp SA36, IS 2062, SA516 GR 60Document2 paginiComp SA36, IS 2062, SA516 GR 60RajendraÎncă nu există evaluări

- Api 5l Test PressrureDocument2 paginiApi 5l Test PressrureSıddık SarıcalarÎncă nu există evaluări

- A514 Grade S Brochure 06-25-08Document2 paginiA514 Grade S Brochure 06-25-08anjangandak2932Încă nu există evaluări

- Tungsten ElectrodesDocument2 paginiTungsten ElectrodesSyed Furqan Rehmani0% (2)

- STAINLESS Filler Selector Guide PDFDocument1 paginăSTAINLESS Filler Selector Guide PDFArul Edwin VijayÎncă nu există evaluări

- Weld Visual Inspection For Store Girder 1Document1 paginăWeld Visual Inspection For Store Girder 1Ashwani DograÎncă nu există evaluări

- PQR For 32 MM PlateDocument1 paginăPQR For 32 MM PlateMuhammed MubeenÎncă nu există evaluări

- Nip Material ComparsionDocument1 paginăNip Material ComparsionRob WillestoneÎncă nu există evaluări

- BohlerThyssen PDFDocument386 paginiBohlerThyssen PDFElMacheteDelHuesoÎncă nu există evaluări

- AWS C5.10 - Sheilding Gas PDFDocument6 paginiAWS C5.10 - Sheilding Gas PDFBoby ThomasÎncă nu există evaluări

- Astm, Sae and Iso Bolting MaterialDocument7 paginiAstm, Sae and Iso Bolting MaterialSds Mani SÎncă nu există evaluări

- GMAWDocument12 paginiGMAWsushant47Încă nu există evaluări

- Ferrous Metals: General Grade Cast IronsDocument8 paginiFerrous Metals: General Grade Cast IronskkamalakannaÎncă nu există evaluări

- A Review of Postweld Heat Treatment Code Exemption - Part 1 (March 2006) - TWIDocument26 paginiA Review of Postweld Heat Treatment Code Exemption - Part 1 (March 2006) - TWItuanÎncă nu există evaluări

- Evaluation of Welding Properties of Construction Materials Using The SEP 1390 TestsDocument7 paginiEvaluation of Welding Properties of Construction Materials Using The SEP 1390 TestsRoman BugajÎncă nu există evaluări

- Welding Recommendation TS890Document2 paginiWelding Recommendation TS890max_powerÎncă nu există evaluări

- PreheatDocument2 paginiPreheatScott TrainorÎncă nu există evaluări

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 paginiA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrÎncă nu există evaluări

- 202 1sp 0 Saw Cs CsDocument8 pagini202 1sp 0 Saw Cs CskrishimaÎncă nu există evaluări

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 paginiJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeÎncă nu există evaluări

- PQRDocument2 paginiPQRafqzfieÎncă nu există evaluări

- Asme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023Document42 paginiAsme BPVC - Ssc.iv - Ii.v.ix - Xiii-2023mmendozagÎncă nu există evaluări

- Specification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsDocument19 paginiSpecification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsT arekiÎncă nu există evaluări

- 60 MM SA 516 GR 70 MTCDocument21 pagini60 MM SA 516 GR 70 MTCgeoanburajaÎncă nu există evaluări

- Comaparação A572 G50-A992Document4 paginiComaparação A572 G50-A992Tiago CastelaniÎncă nu există evaluări

- ASTM Specs FittingsDocument10 paginiASTM Specs FittingskhaireddinÎncă nu există evaluări

- SB410 (JIS) - Worldwide Equivalent Grades 11Document1 paginăSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Go Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionDocument2 paginiGo Back To Wilson Supply Gas - Welding Supplies Page: AWS Class Polarity DescriptionmohamedabubackerÎncă nu există evaluări

- ASME Weld Number Tables (P, F, A)Document19 paginiASME Weld Number Tables (P, F, A)Osman GoneÎncă nu există evaluări

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 paginiSample Wps Carbon Steel GTAW SMAW PDFirwanÎncă nu există evaluări

- Poster Welding P VoxXa PDFDocument1 paginăPoster Welding P VoxXa PDFAd Man GeTigÎncă nu există evaluări

- Astm A514 GR SDocument9 paginiAstm A514 GR SMario GaytanÎncă nu există evaluări

- API Welding ProcedureDocument2 paginiAPI Welding ProcedureSamarakoon BandaÎncă nu există evaluări

- En Aw-6082 (Aisi1mgmn)Document1 paginăEn Aw-6082 (Aisi1mgmn)Vanessa Gomes100% (1)

- Calculate Weld Metal VolumeDocument7 paginiCalculate Weld Metal VolumeChris De La Torre0% (1)

- Wps FormatDocument2 paginiWps FormatMeghan GhoneÎncă nu există evaluări

- The Complete Guide to Telephone Interview Questions and AnswersDe la EverandThe Complete Guide to Telephone Interview Questions and AnswersÎncă nu există evaluări

- AWS Classification System SAWDocument5 paginiAWS Classification System SAWperungguÎncă nu există evaluări

- AWS ClassificationDocument4 paginiAWS ClassificationBarita JonBos SilalahiÎncă nu există evaluări

- Consumable by AWS D5.1Document8 paginiConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- Weld Filler Metal SelectionDocument7 paginiWeld Filler Metal SelectionRajesh AutorajeshÎncă nu există evaluări

- CERTILAS EN Edition2023 313Document1 paginăCERTILAS EN Edition2023 313Alireza KhodabandehÎncă nu există evaluări

- MMA Electrode ClassificationDocument5 paginiMMA Electrode ClassificationRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Steel Clasification and WeldabilityDocument32 paginiSteel Clasification and Weldabilitycentaury2013Încă nu există evaluări

- MulcoaDocument2 paginiMulcoaRolando Cordova100% (1)

- Asme GT2005-68799 PDFDocument9 paginiAsme GT2005-68799 PDFJeeEianYannÎncă nu există evaluări

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 paginiiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhÎncă nu există evaluări

- Prism Cryogenic Oxygen Generators: Reliable On-Site SupplyDocument4 paginiPrism Cryogenic Oxygen Generators: Reliable On-Site SupplyEdwin RosasÎncă nu există evaluări

- Accounting EssayDocument5 paginiAccounting Essaylorie anne valleÎncă nu există evaluări

- DKM AC CatalogueDocument65 paginiDKM AC Cataloguejlruiz06Încă nu există evaluări

- Biomass Technology OverviewDocument28 paginiBiomass Technology Overviewbdeol267% (3)

- List of Spinning MachineDocument8 paginiList of Spinning MachinegunaÎncă nu există evaluări

- EnvisionTEC Lost Wax Casting GuideDocument7 paginiEnvisionTEC Lost Wax Casting GuidedbpeÎncă nu există evaluări

- Galva FroidDocument2 paginiGalva FroidVenkata RaoÎncă nu există evaluări

- Boiler AnnexDocument66 paginiBoiler Annexrenjithv_4Încă nu există evaluări

- Technical DocumentsDocument3 paginiTechnical DocumentsRaluca MutuÎncă nu există evaluări

- 380kV DiagonalConnection Brochure 50hertzDocument15 pagini380kV DiagonalConnection Brochure 50hertzburvanovÎncă nu există evaluări

- Paint Booth HVAC Control SystemDocument6 paginiPaint Booth HVAC Control SystemPraveenkumar KashyabÎncă nu există evaluări

- Shell Lubricants Tco Manufacturing PaperDocument13 paginiShell Lubricants Tco Manufacturing PaperNokiabhre WijayaÎncă nu există evaluări

- All OvershotsDocument25 paginiAll OvershotsnjileoÎncă nu există evaluări

- BAGHOUSEDocument210 paginiBAGHOUSEAllan Roelen Bacaron100% (5)

- Reverse Osmosis SystemsDocument1 paginăReverse Osmosis SystemsNaresh KhubaniÎncă nu există evaluări

- Flushing ProcedureDocument1 paginăFlushing Proceduremahi1437Încă nu există evaluări

- 50 MCQ Engineering Mechanics PDFDocument8 pagini50 MCQ Engineering Mechanics PDFAntonette LimÎncă nu există evaluări

- Batchflux 5015 C: Electromagnetic Flowmeter For Volumetric Filling and BatchingDocument8 paginiBatchflux 5015 C: Electromagnetic Flowmeter For Volumetric Filling and BatchingavikbhaiÎncă nu există evaluări

- Riser Mounted Air Compressor: Electrical DevicesDocument12 paginiRiser Mounted Air Compressor: Electrical DevicesChen MingliangÎncă nu există evaluări

- Advanced Tool Design Question PaperDocument1 paginăAdvanced Tool Design Question PaperMr. N. GnaneswaranÎncă nu există evaluări

- EKT Mech 2014 2Document9 paginiEKT Mech 2014 2Ravinder ReddyÎncă nu există evaluări

- Viking New Products 2013Document7 paginiViking New Products 2013Zefanya Hesa Satio LukitoÎncă nu există evaluări

- Touran FuseboxDocument16 paginiTouran FuseboxRiki Nurzaman100% (3)

- Instructions For Use Tau Clave 3000 Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)Document14 paginiInstructions For Use Tau Clave 3000 Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)soufianeÎncă nu există evaluări

- Perform Brazing-Silver Soldering PDFDocument33 paginiPerform Brazing-Silver Soldering PDFtereve100% (1)

- NKK SWITCHES ATseries PDFDocument33 paginiNKK SWITCHES ATseries PDFcosÎncă nu există evaluări

- Type of Earthing SystemDocument6 paginiType of Earthing SystemMokr AchourÎncă nu există evaluări