Documente Academic

Documente Profesional

Documente Cultură

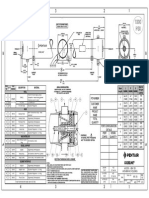

Specification For Fire Monitor

Încărcat de

romdhan880 evaluări0% au considerat acest document util (0 voturi)

113 vizualizări4 paginiThe document provides specifications for a water monitor, including:

1. It specifies materials like copper alloy, steel, and brass for parts of the monitor body, barrel, joints, and gearing.

2. It outlines design requirements like horizontal and vertical rotation ranges, discharge rate of 1750 lpm at 7 kg/cm2 pressure.

3. It details testing requirements including hydraulic testing of assemblies to 21 kg/cm2 pressure for 5 minutes without leakage.

Descriere originală:

Fire Fighting works with Construction of Pump House, Fire Detection System, Fire Hydrants etc. at ICD/Dadri including AMC

Titlu original

Specification for Fire Monitor

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document provides specifications for a water monitor, including:

1. It specifies materials like copper alloy, steel, and brass for parts of the monitor body, barrel, joints, and gearing.

2. It outlines design requirements like horizontal and vertical rotation ranges, discharge rate of 1750 lpm at 7 kg/cm2 pressure.

3. It details testing requirements including hydraulic testing of assemblies to 21 kg/cm2 pressure for 5 minutes without leakage.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

113 vizualizări4 paginiSpecification For Fire Monitor

Încărcat de

romdhan88The document provides specifications for a water monitor, including:

1. It specifies materials like copper alloy, steel, and brass for parts of the monitor body, barrel, joints, and gearing.

2. It outlines design requirements like horizontal and vertical rotation ranges, discharge rate of 1750 lpm at 7 kg/cm2 pressure.

3. It details testing requirements including hydraulic testing of assemblies to 21 kg/cm2 pressure for 5 minutes without leakage.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

SignatureofTenderer SignatureofAcceptingAuthority

SPECIFICATION FOR WATER MONITOR

CORRIGENDUM 2

FOR

TENDER NO: CON/EP/DER/FF/700/T-I/2012

Fire Fighting works with Construction of Pump House,

Fire Detection System, Fire Hydrants etc. at ICD/Dadri

including AMC

Container Corporation of India Ltd.

C-3, Mathura Road, Opposite Apollo Hospital,

New Delhi 110076

SignatureofTenderer SignatureofAcceptingAuthority

1. SCOPE

This specification covers the general requirements regarding the material, design and

construction, performance and test for stand post type water monitor.

2. MATERIAL

2.1. Monitor body, swivel joints, worm wheel, base flange and change over valve

assembly shall be made of copper alloy confirming to IS:8442 Cl. 3.3.1. Body shall

be of C.S. pipe heavy grade to IS: 1239 and base flange shall be of M.S.to IS 226

or IS 6392.

2.2. Water barrel shall be M.S. seamless pipe to IS:1239 heavy grade.

2.3. Water nozzle shall be made from copper alloy as specified in IS: 8442 Cl. 3.3.1.

2.4. Pickup tube shall be made from rubber hose with chrome plated brass strainer.

2.5. Worm gear for traverse mechanism shall be made from phosphorus bronze or

copper alloy as per Cl. 3.3.1 of IS: 8442.

2.6. Nuts and bolts for base flange and change over valve shall confirm toIS:1367

Cl.10.9 and 12 respectively while gasket shall be of CAF 40 to IS:2712.

2.7. Drain valve shall confirm to IS: 778 class 2. Locks on swivels shall be made of

brass to IS:291.

3. DESIGN AND CONSTRUCTION

3.1. Monitor shall be capable of discharging 1750 lpm at a pressure of 7 Kg/cm2.

3.2. It shall have traversing mechanism to give 360` in either direction in horizontal

plane and 125` in vertical plane (80`, -45`) through geared unit with worm wheel

operated by separate hand wheel for horizontal and vertical rotation. Swival joints

shall be provided both for horizontal and vertical rotation. The arrangement shall be

such that monitor shall be self lockingtype and operated by a single person.

3.3. The valve shall be lever operated type.

3.4. The monitor shall be mounted on a 100mm (4) N.B. flat face slip on type flange

confirming to ANSI B 16.5 150lbs rating. Bolts and nuts for base flange shall have

dimension confirming to ANSI B 16.5 Gasket shall be full face 3mmthick with drilling

dimension same as for flange.

3.5. 3.5 Near the base flange a drain connection shall be provided with a 15mm (1/2)

NB drain valve at the end of pipe. The drain pipe shall be long enough to drain

water away from the base flange.

SignatureofTenderer SignatureofAcceptingAuthority

3.6. 3.6 The threaded end of the water nozzle shall be hexagonal to facilitate screwing

of the nozzle on the water barrel with nozzle spanner. Threads shall confirm to

IS:2643 (Pt.-1) with class A tolerance.

3.7. 3.8 The inner surface of the nozzle shall be finished smooth and polished for the

converging length of the nozzle.

4. HYDRAULIC PERFORMANCE

4.1. Monitor shall be capable of discharging 1750lpm at a pressure of 7 Kg/cm2.

4.2. The horizontal ranges for water jet shall be 60m and 45m respectively while the

vertical throw shall be 30m and 20 to 25m respectively.

5. WORKMANSHIP AND FINISH

5.1. All the parts shall have good workmanship and finish. All burrs and sharp edges

shall be removed and nozzle shall have smooth finish.

6. ANTICORROSIVE TREATMENT AND PAINTING

6.1. All steel components subject to direct water shall be hot dipped galvanized to a

minimum thickness of 0.12mm. The thickness of coating shall be measured as per

IS:3203. External surfaces and non ferrous components may wetted with lead tin

alloy by electrical deposition process.

6.2. Monitors steel part shall be painted with fire red colour confirming to IS: 5 shade

no. 536 and the paint shall confirm to IS:2932 and copper alloy part shall be

polished.

7. TEST

7.1. Monitor shall be tested to fulfill requirements at clause 4.0.

7.2. The entire assembly shall be hydraulically tested to a pressure of 2.1 MN/M2 (21

Kgf/Cm2) for 5 minutes without any leakage.

8. MARKING

8.1. Each monitor shall be clearly and permanently marked with the following:

8.1.1. Manufacturers name or trade mark

SignatureofTenderer SignatureofAcceptingAuthority

8.1.2. Year of manufacture

8.1.3. Purchasers name

9. APPROVED MAKE

9.1. Following approved makes or alternatively as approved by CCI should be

considered

9.1.1. New Age

9.1.2. Winco

9.1.3. HD Fire

This will also form part of the tender document and all tederes have to sign

and attach this alongwith the tender document. All other terms and

conditions remain unaltered.

S-ar putea să vă placă și

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Job Procedure For Eriction of TankDocument13 paginiJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Business Plan For T-SHIRTDocument19 paginiBusiness Plan For T-SHIRTKayode Olorunsola100% (1)

- Cylinder ManufacturingDocument6 paginiCylinder ManufacturingRavi AgarwalÎncă nu există evaluări

- Section 5 Solid Core Post Type InsulatorsDocument5 paginiSection 5 Solid Core Post Type Insulatorsthumula.rameshÎncă nu există evaluări

- Fabrication ProcedureDocument16 paginiFabrication ProcedureAryo WicaksonoÎncă nu există evaluări

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 paginiSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANÎncă nu există evaluări

- Valve Procurement SpecsDocument39 paginiValve Procurement Specsjoseph.maquez24100% (2)

- Oil and Gas Instrument AbbreviationsDocument4 paginiOil and Gas Instrument AbbreviationsDjil Rezoug100% (5)

- Oil and Gas Instrument AbbreviationsDocument4 paginiOil and Gas Instrument AbbreviationsDjil Rezoug100% (5)

- XKM.206.02.005!0!124 - Operation and Maintenance InstructionDocument49 paginiXKM.206.02.005!0!124 - Operation and Maintenance InstructionHoàn BùiÎncă nu există evaluări

- Is-909 Underground Fire HydrantDocument9 paginiIs-909 Underground Fire HydrantCharls JamesÎncă nu există evaluări

- Disclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Document20 paginiDisclosure To Promote The Right To Information: IS 5290 (1993) : Specification For Landing Valves (CED 22: Fire Fighting)Tanmoy Dutta100% (1)

- Particular Specifications Plumbing and Sanitary Work: 1.0 GeneralDocument19 paginiParticular Specifications Plumbing and Sanitary Work: 1.0 GeneralCherryl Chrissie JamesÎncă nu există evaluări

- BFV STD - SpecdamperDocument39 paginiBFV STD - Specdamperkselvan_1Încă nu există evaluări

- Valves SpecificationDocument13 paginiValves Specificationkselvan_1Încă nu există evaluări

- Technical Specification For 33 KV, Single Phase, Dead Tank TypeDocument11 paginiTechnical Specification For 33 KV, Single Phase, Dead Tank Typechandrakanth0083396Încă nu există evaluări

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 paginiSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaÎncă nu există evaluări

- Specification - 2023 02 01 09 02 41Document10 paginiSpecification - 2023 02 01 09 02 41Chinnaraj SÎncă nu există evaluări

- Dgms All Circular 2002 PDFDocument61 paginiDgms All Circular 2002 PDFravimutyamÎncă nu există evaluări

- DGMS circulars on mining safety standardsDocument61 paginiDGMS circulars on mining safety standardsravimutyamÎncă nu există evaluări

- HV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601Document9 paginiHV Porcelain Bushing: IS2099 Galvanization: IS2633 Primary Terminals: IS 10601AnilÎncă nu există evaluări

- DO Fuse UnitDocument8 paginiDO Fuse UnitImran KhanÎncă nu există evaluări

- Special Notes On ValvesDocument101 paginiSpecial Notes On ValvesamithcivilÎncă nu există evaluări

- Annexture N1 427Document14 paginiAnnexture N1 427DEBASISH SARKARÎncă nu există evaluări

- CT SizingDocument10 paginiCT SizingAmit NagÎncă nu există evaluări

- Appendix III - Spec - TNK - FBR PDFDocument12 paginiAppendix III - Spec - TNK - FBR PDFJaswinder SohalÎncă nu există evaluări

- Busbar Trunking System 800A Sandwich ConstructionDocument3 paginiBusbar Trunking System 800A Sandwich Constructionsajeevi piumikaÎncă nu există evaluări

- Pneumatic Butterfly Valves Technical SpecificationDocument12 paginiPneumatic Butterfly Valves Technical SpecificationFactory FactoryÎncă nu există evaluări

- Technical Notes and Specifications Part CDocument29 paginiTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- 11kV CT & PTDocument6 pagini11kV CT & PTSanjeev RajputÎncă nu există evaluări

- Specification For Water Purifier, Potable: Indian StandardDocument6 paginiSpecification For Water Purifier, Potable: Indian StandardAbinashBeheraÎncă nu există evaluări

- Is 13349Document20 paginiIs 13349raji357100% (1)

- Current Transformers (72.5 kV to 420 kV) SpecificationsDocument4 paginiCurrent Transformers (72.5 kV to 420 kV) SpecificationsPaulo CardosoÎncă nu există evaluări

- Electricity Board DocsDocument41 paginiElectricity Board DocsM_D_MendisÎncă nu există evaluări

- Is 14845-2000Document18 paginiIs 14845-2000Sarbendu Paul100% (1)

- Dragon 50194B PDFDocument9 paginiDragon 50194B PDFGEORGEKCÎncă nu există evaluări

- 17 Gral CT Pipe InfoDocument15 pagini17 Gral CT Pipe InfogcgironÎncă nu există evaluări

- Tower AccessoriesDocument2 paginiTower AccessoriesmulualemÎncă nu există evaluări

- PPTDocument35 paginiPPTVenkat RamanaÎncă nu există evaluări

- STANDARD TECHNICAL SPECIFICATION Ball Valves PDFDocument2 paginiSTANDARD TECHNICAL SPECIFICATION Ball Valves PDFSen vanÎncă nu există evaluări

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pagini(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Section - 9 Main L.T. Switchboard: 9.1 GeneralDocument4 paginiSection - 9 Main L.T. Switchboard: 9.1 GeneralHusnain AssociatesÎncă nu există evaluări

- Medium Voltage Composite InsulatorsDocument14 paginiMedium Voltage Composite Insulatorsdeepthik27Încă nu există evaluări

- Is 6595 2 1993Document10 paginiIs 6595 2 1993mishraenggÎncă nu există evaluări

- Materials Specification Table of ContentsDocument40 paginiMaterials Specification Table of ContentsLuong Do Dat0% (1)

- RMC Technical Material Specification SummaryDocument27 paginiRMC Technical Material Specification Summarysat palÎncă nu există evaluări

- Receiving Inspection of Pressure VesselsDocument5 paginiReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுÎncă nu există evaluări

- Technical Specification of Stainless Steel Centrifugal BlowersDocument10 paginiTechnical Specification of Stainless Steel Centrifugal BlowersJohn CelisÎncă nu există evaluări

- Carbon steel fittings and bends specificationsDocument9 paginiCarbon steel fittings and bends specificationsALIÎncă nu există evaluări

- 1212.03 15kV Submersible Transformer SpecificationDocument8 pagini1212.03 15kV Submersible Transformer SpecificationurramarianiÎncă nu există evaluări

- PS-G00-091 (Executia-Controlul-Executiei-Sudurilor-Aluminotermice)Document8 paginiPS-G00-091 (Executia-Controlul-Executiei-Sudurilor-Aluminotermice)AlinaIordacheÎncă nu există evaluări

- Is - 14845Document17 paginiIs - 14845mechftpÎncă nu există evaluări

- 8931 PDFDocument27 pagini8931 PDFPawan Kumar100% (1)

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 paginiCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- PEE 1560-ACMV SpecDocument97 paginiPEE 1560-ACMV SpecjimiÎncă nu există evaluări

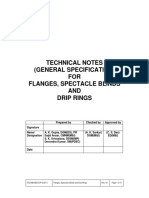

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 paginiTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Technical SpecificationsDocument6 paginiTechnical Specificationspradeep reddyÎncă nu există evaluări

- Memoria de Calculo. 1407970 - r1Document19 paginiMemoria de Calculo. 1407970 - r1Alex Javier Garzon OrduñaÎncă nu există evaluări

- Current Transformer Technical SpecificationDocument8 paginiCurrent Transformer Technical SpecificationbinodeÎncă nu există evaluări

- DB Tech Specs - BDDocument5 paginiDB Tech Specs - BDDarshit VyasÎncă nu există evaluări

- Basic Flow Assurance Engineering BrochureDocument1 paginăBasic Flow Assurance Engineering Brochureromdhan88Încă nu există evaluări

- Advance Flow Assurance Engineering BrochureDocument1 paginăAdvance Flow Assurance Engineering Brochureromdhan88Încă nu există evaluări

- Effectively Control Column PressureDocument12 paginiEffectively Control Column Pressureromdhan88Încă nu există evaluări

- Eaton Pipeline Strainer Pressure Drop CalculationsDocument1 paginăEaton Pipeline Strainer Pressure Drop Calculationsreborn_willyÎncă nu există evaluări

- IEC 60034 Pt.11 Ch.2 (Thermal Protection)Document2 paginiIEC 60034 Pt.11 Ch.2 (Thermal Protection)romdhan88Încă nu există evaluări

- NPSH Calculations For Reciprocating PumpDocument1 paginăNPSH Calculations For Reciprocating PumpMadan YadavÎncă nu există evaluări

- Agma 6000 Spec Vibration For GearDocument16 paginiAgma 6000 Spec Vibration For Gearromdhan88100% (1)

- IEC 60034 Pt.11 Ch.3 (Thermal Protection)Document2 paginiIEC 60034 Pt.11 Ch.3 (Thermal Protection)romdhan88Încă nu există evaluări

- SSPC SP 1Document2 paginiSSPC SP 1romdhan88Încă nu există evaluări

- Kern Method Heat ExchangerDocument30 paginiKern Method Heat ExchangerCS100% (3)

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 paginiChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiÎncă nu există evaluări

- Designing Compact Heat ExchangersDocument6 paginiDesigning Compact Heat ExchangersAndrés Ramón Linares100% (1)

- Water properties Excel add-inDocument9 paginiWater properties Excel add-inKathryn CottonÎncă nu există evaluări

- NPSH Calculations For Reciprocating PumpDocument1 paginăNPSH Calculations For Reciprocating PumpMadan YadavÎncă nu există evaluări

- ME303 2.4.1 Original Content Note 1 FINAL2 Pressure Drop Calculation For Orifice and MenteriDocument1 paginăME303 2.4.1 Original Content Note 1 FINAL2 Pressure Drop Calculation For Orifice and Menteriromdhan88Încă nu există evaluări

- Terminal Specification, Access Procedures, and SchedullingDocument29 paginiTerminal Specification, Access Procedures, and Schedullingromdhan88Încă nu există evaluări

- Fire Relief Dynamic StudyDocument2 paginiFire Relief Dynamic Studylutfi awnÎncă nu există evaluări

- Storage Tank Normal Venting Capacity Calculations PDFDocument1 paginăStorage Tank Normal Venting Capacity Calculations PDFNathan MoralesÎncă nu există evaluări

- Dissolved Oxygen Curve ComputationDocument4 paginiDissolved Oxygen Curve Computationromdhan88Încă nu există evaluări

- Loading, Unloading, StackingDocument37 paginiLoading, Unloading, Stackingromdhan88Încă nu există evaluări

- Emergency ShowerDocument8 paginiEmergency Showerromdhan88Încă nu există evaluări

- Heat and Material Balance of Gas Stripping Deaerator ColumnDocument1 paginăHeat and Material Balance of Gas Stripping Deaerator Columnromdhan88Încă nu există evaluări

- Guidelines For Odor SamplingDocument13 paginiGuidelines For Odor Samplingromdhan88Încă nu există evaluări

- Emergency ShowerDocument8 paginiEmergency Showerromdhan88Încă nu există evaluări

- FlareDocument10 paginiFlareromdhan88Încă nu există evaluări

- 06 CompressorsDocument16 pagini06 CompressorsmunatsiÎncă nu există evaluări

- Xodus20article20impact20significance20 20a20risk20based20approachDocument4 paginiXodus20article20impact20significance20 20a20risk20based20approachromdhan88Încă nu există evaluări

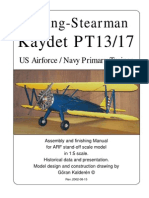

- Boeing-Stearman Kaydet PT13 - 17Document12 paginiBoeing-Stearman Kaydet PT13 - 17Mihaela Apostol100% (2)

- Business Class Trucks Maintenance Manual PDFDocument148 paginiBusiness Class Trucks Maintenance Manual PDFtransteven93100% (1)

- Dot Hill Assured San 24xx4-Fig-Guide-3q15-FinalDocument44 paginiDot Hill Assured San 24xx4-Fig-Guide-3q15-FinalRichard WoodÎncă nu există evaluări

- "Antonia Polygon - Standard" Documentation: (Render by Glitterati3D)Document22 pagini"Antonia Polygon - Standard" Documentation: (Render by Glitterati3D)Robin StaceyÎncă nu există evaluări

- Process Synchronization: Critical Section ProblemDocument8 paginiProcess Synchronization: Critical Section ProblemLinda BrownÎncă nu există evaluări

- CCS - View Topic - SOLVED - Problem With INT - RDA Not Beeing FDocument5 paginiCCS - View Topic - SOLVED - Problem With INT - RDA Not Beeing Fapi-3755810100% (3)

- Simulink Support Package For ArduinoDocument4 paginiSimulink Support Package For ArduinofredÎncă nu există evaluări

- Rainbow Six - Rogue Spear - Urban Operations - UK Manual - PCDocument18 paginiRainbow Six - Rogue Spear - Urban Operations - UK Manual - PCAnonymous utXYfMAXÎncă nu există evaluări

- EIL Shedule of Rates ENQ - REV0Document20 paginiEIL Shedule of Rates ENQ - REV0kotiÎncă nu există evaluări

- Ece Upcp ResumeDocument1 paginăEce Upcp Resumeapi-532246334Încă nu există evaluări

- Transmission Software Service Tool ConnectionDocument3 paginiTransmission Software Service Tool ConnectionpitbullÎncă nu există evaluări

- HG240641Document1 paginăHG240641sdk00Încă nu există evaluări

- Circuit diagram iPad chargerDocument1 paginăCircuit diagram iPad chargeraplus guideÎncă nu există evaluări

- EX1Document4 paginiEX1mohamedmusarafÎncă nu există evaluări

- Data ExchangeDocument44 paginiData Exchangepalaniappan_pandianÎncă nu există evaluări

- Service Description: Smartnet ServicesDocument5 paginiService Description: Smartnet Serviceszona5guateÎncă nu există evaluări

- DNS Interview Questions and AnswersDocument4 paginiDNS Interview Questions and AnswersRavi SankasrÎncă nu există evaluări

- Pg063 Dist Mem GenDocument60 paginiPg063 Dist Mem GendanicasÎncă nu există evaluări

- DatasheetDocument8 paginiDatasheetgijiskariaÎncă nu există evaluări

- Solax Mini ManualDocument20 paginiSolax Mini ManualFlorin Mihut100% (1)

- Tecumseh Engine Parts Manual OHSK120 223601ADocument7 paginiTecumseh Engine Parts Manual OHSK120 223601AT-BuzzardÎncă nu există evaluări

- Remote Accident Report System For Highways Using RFDocument17 paginiRemote Accident Report System For Highways Using RFPradeep CheekatlaÎncă nu există evaluări

- STM32 Full ManualDocument66 paginiSTM32 Full ManualxiliantonioÎncă nu există evaluări

- How To Configure Microplex Print Server For Automatic RCF CommandsDocument4 paginiHow To Configure Microplex Print Server For Automatic RCF CommandsJoseph AlbertÎncă nu există evaluări

- Chapter 1Document42 paginiChapter 1Raju RajÎncă nu există evaluări

- Administrator's Guide To VMware Virtual SANDocument63 paginiAdministrator's Guide To VMware Virtual SANHoang KhuyenÎncă nu există evaluări

- Count lines, words and characters in C filesDocument9 paginiCount lines, words and characters in C filesYash Yadav100% (1)

- IV BTech I Semester CAD/CAM Exam QuestionsDocument4 paginiIV BTech I Semester CAD/CAM Exam QuestionsMD KHALEELÎncă nu există evaluări