Documente Academic

Documente Profesional

Documente Cultură

Design of Human Powered Vehicle

Încărcat de

gijimmyyoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design of Human Powered Vehicle

Încărcat de

gijimmyyoDrepturi de autor:

Formate disponibile

Department of Mechanical Engineering

Group Design Project MEC307

Group Report for

3

rd

Year Design Project 2007 for

Motorsports Engineering Management

and Sports Engineering

The Design of a Human

Powered Vehicle for

Attempting the World

One-Hour Distance

Record

Ryan Benson,

James Froggett,

Nik Kamarudin,

Tim Lewis,

James Melia,

Kamal Zaman

18

th

May 2007

2

Summary

A team was formed under the name Glide by Icycle with the intention of breaking the Dempsey MacCready hour

record which currently stands at 53.43 miles travelled in an hour. In order to do this, we had to brainstorm ideas for

the most efficient high speed human powered vehicle which ended up being the recumbent bike. Following this

decision, we had to research current designs and the history of the vehicle in order to evaluate which changes were the

most influential, and which areas could be improved. The section that was seen to be the most influential was reducing

frontal area so this criterion was given the main priority. Sections, including aerodynamics, frame design and power

transmissions were then assigned to individual members of the group who then went on to study these areas in great

detail. After months of study we finalised the ideal components and features that we hoped to implement in our

recumbent bike. After numerous meetings, we came up with a design that was able to include all these features

without impairing the priority sections. The final design was seen to be a teardrop shape with an elongated rear. This

was to house large wheels with high pressure, smooth tyres rotating on hardened steel ball bearings with a UHMWPE

case. The power transmission was decided to be a torque converter system. The method of braking was decided to be

rim brakes. The frame was crated to be as light as possible using aluminium alloy tubes but to also house a traditional

seat to allow the rider to sit in the supine position and include an under seat steering system. The finalised design was

then modelled on Pro/Desktop and ANSYS and the calculated forces applied. These programs showed no problems or

faults with our design so all we now have to do is build and test our recumbent bike design.

3

Contents

Summary

1.0 Introduction

1.1 Aims and Objectives

1.2 Project Statement

2.0 Human Powered Vehicle Selection

3.0 Analysis of the forces on a recumbent

3.1 Effects of design changes on performance

4.0 Recumbent bike components

4.1 Tyres and Wheels

4.2 Bearings

4.2.1 Bearings in a recumbent bike

4.2.2 Bearing Conclusion

4.3 Powertrain

4.3.1 Options for the powertrain

4.3.2 Gear ratio selection

4.3.3 Powertrain Conclusion

4.4 Bicycle brakes

4.4.1 Rim brake

4.4.2 Selection of brake for recumbent bike

4.4.3 Brake balance

4.5 Breathing

4.6 Riders position

4.7 Seating

4.8 Steering

4.9 Frame Design

4.10 Aerodynamics

4.10.1 Drag

5.0 Conclusion

6.0 References

7.0 Appendix

4

Nomenclature

a/A Dimensions of contact m

2

b Wheel base m

C

RRS

Static coefficient of rolling resistance

C

RRD

Dynamic coefficient of rolling resistance

D Deceleration ms

-2

D

1

Diameter of rolling element m

D

2

Diameter of axle m

Steer angle rads

max

Maximum deflection m

Load distribution factor

E Youngs modulus Pa

E* Reduced modulus Pa

F Applied load N

F

max

Maximum applied load N

F

N

Applied normal contact load N

g Acceleration due to gravitational force ms

-2

h/Ht

CG

Height of the centre of gravity m

I Moment of inertia kgm

2

k Stiffness N/m

K Radial stiffness N/m

l Wheel radius m

m

i

Moment

m Mass kg

P Applied load N

p

o

Maximum contact pressure MPa

q Quality factor

Q Rolling element load N

Q

0

Load of a maximum loaded rolling element N

r Radius m

R Relative radius of curvature m

t Torsional deflection m

T Applied torque Nm

u

r

Clearance value mm

v/V Vehicle velocity m/s

Poissons ratio

W

df

Front dynamic weight, sum of the moment about the front tyre to the road contact point Nm

W

fs

Static Front Weight N

W

t

Total weight of recumbent bike N

Wb Wheelbase m

x Deflection m

Z Number of rolling elements per row

Angle of incline

Tilt angle rads

5

1. 0 Introduction

The traditional cycling hour record is the most famous world record in cycling. Records have been kept since 1876, in

which the first record was recorded to be 25.506 km travelled in one hour. The cycling hour record is now known as

the Dempsey-MacCready hour record. The Dempsey-MacCready hour record was created to inspire and promote

light, pollution free, human powered transportation. Originally, the $25,000 Dempsey-MacCready hour prize was

awarded to the first team that is able to travel more than 90 km in an hour. The distance, has not, thus far, been

exceeded and the prize has expired so the prize was awarded to the team that had travelled the furthest distance in one

hour. The rider of this team was Fred Markham who travelled 85.991 km in an hour which is currently the Dempsey-

MacCready hour record. This is the distance which our team, Glide by Icycles, hope to exceeded using a human

powered vehicle.

During the history of the record, the vehicles have adopted a more aerodynamic shape as the years have

progressed and the distance has increased. From this we know aerodynamics are paramount so Glide by Icycles, will

be focussing on getting the right balance between aerodynamics and power. Having a human powered vehicle with

good aerodynamic properties hampers the power the driver is able to provide due to the awkward position of the driver

and so it is essential we get this perfect if Glide by Icycles is going to break the Dempsey-MacCready hour record.

There are also many other features which will contribute to the success of the human powered vehicle such as weight,

power train, etc. However, like all world record attempts, there are also many regulations that we have to abide to,

such as the vehicle must fit into a box 1.5 m high, 1 m wide and 3.1 m long, all vehicles must have a safe means of

stopping aswell as numerous others.

1.1 Aims and Objectives

To design a human-powered vehicle to break the current Dempsey-MacCready Hour Record (85.991

km).

To improve upon the current design.

2.0 Human Powered Vehicle Selection

In order to decide which type of human powered vehicle we will used to break the Dempsey-MacCready hour record,

we performed a general brainstorm of ideas. Of the designs that were proposed, they then had to be evaluated to

determine which will be the most effective design.

We decided that amongst the factors that affect the performance of the human powered vehicle, some were of

greater importance than others. To allow for this to be taken into account whilst evaluating the designs we came up

with a way of weighting the criteria. As a group, it was decided that aerodynamics was of greatest importance to the

design, as this gives the greatest opposing force due to drag. Power is second most important, as the more power that

can be delivered, the faster the vehicle is able to travel. The lowest scoring criterion was ease of manufacture, as there

is no price limit for the design since we are producing a one-off model to break the one-hour record.

The most important of the criteria was given a power weighting of 8, meaning that the scores given to the

different designs for this criteria are multiplied by 8. The power weightings are given in order with lowest order being

multiplied by 1.

Each type of human powered vehicle that was proposed was then scored out of 5 against each of these criteria, as

shown in the performance matrix (Table 1). These scores were multiplied by the weighting factor and then totalled to

find the most effective design.

Criteria Type of human powered vehicle

6

Table 1: Performance of human powered vehicles matrix

From the evaluation using table 1, we can see that the upright bike and the recumbent bike were clearly the leading

designs. Of these, the recumbent bike scored highest, so this is the type of design that we will develop to break the

Dempsey-MacCready one hour record.

3.0 Analysis of the forces on a recumbent

In order to design our recumbent bicycle to be of optimum performance, we need to analyse the make-up of the

various opposing forces on the vehicle.

The general formula for the losses of a recumbent;

RID RRD RRS D OPP

F VC mgC v A C F 04 . 0 ) 2 (

2

1

2

+ + + = (1)

The total opposing force is made up of the aerodynamic drag, the rolling resistance and the transmission losses.

Rolling resistance is affected by a static coefficient, and a dynamic coefficient which varies with vehicle velocity. The

tyres can be assumed to have a static and dynamic rolling resistance coefficient of 0.002 and 0.05 respectively

[1]

. The

mass of the recumbent and rider has been approximated as 75kg.

A formula can be set up, as in table 2, using this equation to calculate the power requirements to overcome each

of these losses. The resulting data has been plotted on figure 1, to highlight the contribution of the different drag

forces to the total drag, and how they vary with vehicle velocity.

Velocity

(m/s)

Aerodynamic

loss

Rolling

Resistance,

F

R

Transmission

loss

Required rider

power (W)

0 0 0 0 0

10 15.104 24.715 1.59276 41.41176

20 120.832 69.43 7.61048 197.87248

30 407.808 134.145 21.67812 563.63112

40 966.656 218.86 47.42064 1232.93664

50 1888 323.575 88.463 2300.038

Table 2: Data of forces on a recumbent

Jumping

powered

Hopping

powered

Walking

powered

Zorb

ball

Upright

bike

Recumbent

bike

Aerodynamics (8) 2 2 2 1 3 5

Weight (5) 4 5 1 3 4 3

Power (7) 2 1 1 2 5 4

Tyre friction (4) 5 5 5 1 4 4

Reliability (2) 2 2 1 4 4 4

Safety (3) 1 1 3 2 3 5

Ease of manufacture

(1)

1 1 1 5 4 3

Ease of use over 1

hour period (6)

1 1 4 3 4 5

Totals with weighting 84 82 84 78 140 155

7

0

500

1000

1500

2000

2500

0 10 20 30 40 50 60

Velocity (m/s)

P

o

w

e

r

(

W

)

Total power req.

Aerodynamic

Rolling Resistance

Transmission

Figure 1 shows the losses and power required for a recumbent bicycle. As vehicle velocity increases, the losses

through rolling resistance and transmission increase fairly linearly. However, the aerodynamic losses increase

proportionally as the velocity is increased, and this loss is the main contributor to the drag force on the vehicle.

The total power required to achieve a given speed is shown, and it can be seen that the relationship between

velocity and required power is not a linear one. To achieve 50m/s, the power required is around 2300W, which drops

significantly at 30m/s to around 550W. This means that for each m/s increase in velocity we are to achieve with our

recumbent, we must take into account that the power requirements will be increasing more and more.

As figure 1 shows, the aerodynamic drag is the greatest contributor to overall drag, reducing it is of great

importance. A good recumbent design with a fairing can help to reduce this loss by minimising the frontal area. In our

design, we need to reduce this loss further, through a more aerodynamic fairing which would result in less separation

and pressure drag at the rear of the recumbent.

Figure 1 also shows that the rolling resistance loss has a fairly significant effect on performance, with around

300W of the rider power needed to overcome this at 50m/s. This is an area which must be analysed in our design in

order to reduce this loss.

Transmission loss is the other main area where energy loss occurs; this refers to energy lost largely in the chain

and gear mechanism. This will be reduced by investigating into the most efficient bearings that can be fitted, and also

a more efficient system of power delivery, using a shorter chain, in our recumbent.

3.1 Effects of design changes on performance

The current one-hour record is 53.43 miles (85.987km). If we assume that the acceleration from rest up to the

cruising speed will take approximately 30 seconds, the cruising speed for the current design can be approximated as

55mph. Our design has been based on achieving a steady speed of 60mph. This will comfortably break the hour-

record even if the losses have been slightly under-estimated in our calculations.

To see the effect that the implemented changes will have on the performance of the recumbent, a formula has

been set up so that the changes are easily visible. For the calculations, the effects will be analysed at the cruising

velocity since this is the speed the recumbent will be travelling at for the majority of the one-hour record attempt. This

cruising velocity is assumed to be 60mph, which correlates to 26.82m/s.

Figure 1: Forces on a recumbent

8

Velocity

(m/s)

Aerodynamic

Drag, F

D

Rolling Resistance,

F

RR

Rider

force,

F

RID

Transmission

loss ()

Required

rider power

(W)

Traditional

high-speed

recumbent

26.82 10.86 4.15 15.02 0.60 418.89

10% Less

frontal area

26.82 9.78 4.15 13.93 0.56 388.59

Reduce C

RRS

,

C

RRD

10%

26.82 10.86 3.74 14.60 0.58 407.31

Reduce Mass

10%

26.82 10.86 4.01 14.87 0.59 414.79

Reduce

Transmission

loss 10%

26.82 10.86 4.15 15.02 0.54 417.28

Implement all 26.82 9.78 3.61 13.38 0.48 371.87

Table 3: A table showing which features are the most critical to increasing the efficiency of the recumbent bike

Table 3 shows that reducing the frontal area of our recumbent has the greatest effect on lowering the required rider

power. At the cruising velocity, the drag force is the largest opposing force, so reducing this has the biggest effect on

performance. A more streamlined rider position will enable us to have a smaller frontal area. This will be achieved by

making the riders seat position angled closer to the horizontal, so that the fairing to encompass him will be smaller.

It can be seen that reducing the rolling resistance coefficients has a significant effect on the power requirements

of the recumbent. They can be reduced by ensuring that the wheels are as low friction as possible, through using

smoother, high pressure tyres.

The mass reduction appears to have a small effect on the power required to maintain the speed of the recumbent.

In actual fact, the effect of mass will be greater since there is an inertia force produced during acceleration which

affects the performance. Since the inertial loss has also been reduced, this will reduce the time taken for the recumbent

to accelerate up to the cruising speed. Reducing the mass of the vehicle therefore has the combined effect of reducing

the rolling resistance as well as reducing the inertial loss

The transmission efficiency for a bicycle is already very high, around 96%, so the transmission loss is very small

in comparison to the other forces involved. Bicycle gears and bearings are highly efficient, so increasing their

efficiency only has a small effect on performance.

Implementing all of these changes reduces the required power to maintain the cruising velocity by 12.6%, which

will have a significant effect on our performance, and will possibly enable us to break the record. The required power

of 371.87 W is realistic, as it has been found that a top athlete can achieve a maximum power of around 400W. It

would therefore be possible for an elite athlete to achieve the cruising velocity stated for the duration of the attempt.

4.0 Recumbent bike components

4.1 Tyres and wheels

An important feature of the recumbent bike is the wheels. They provide a

large resistive force in terms of rolling resistance, and also contribute to the

aerodynamic drag. Rolling resistance is one of the major factors contributing

to the losses of a recumbent, making up around 15% of the losses at high

speeds.

2

2

1

v A C

D

RRD RRS

VC mgC 2 +

RID

F 04 . 0

RR D

F F + ) ( q +

RID

F V

R F

RR

mg

F

Figure 2: Diagram to show the forces exerted

on the wheels

9

This force must therefore be minimised in our design if we are to break the one-hour record, so the different options

available to the team must be analysed. Figure 2 shows a simplified version of the forces on the wheels;

Rolling resistance

The rolling resistance is the mechanical friction generated between the tyre and the road as it rolls. This force opposes

that of the propelling force produced by the rider. In order to achieve optimum speeds, this rolling resistance must be

reduced as much as possible.

The fundamental equation for rolling resistance is defined as;

RRD RRS RR

VC mgC F 2 + = (2)

The equation shows that the rolling resistance is influenced by vehicle velocity, weight and coefficients of rolling

resistance. The static coefficient, C

RRS

, is based on the tyre pressure and smoothness, and the dynamic coefficient,

C

RRD

, is based on the speed. If our team is to achieve optimum speeds, the weight and the frictional coefficients

therefore need to be lowered.

This can be achieved in our design by utilising;

- Smooth high pressure tyres

- Big wheels

- Latex inner tubes

- Good quality road surface

Tyres

Theoretically, the highest tyre pressure that can be attained is desirable. This would give virtually no deformation of

the tyres as they are supporting the weight of the rider and recumbent. Tyres are cyclically loaded each time the

wheels turn through one rotation, as they bear the weight of the rider and the recumbent. Energy loss occurs as the

tyres are deformed, as transformation of mechanical into thermal energy occurs. However, this high desired tyre

pressure must be traded-off with the need for safety, so that the tyres will not suffer a blow out during the hour in

which the recumbent is being ridden. Track racing tires can typically be inflated up to c.14 bar

[2]

.

The tyre properties should also be as consistent as possible, and hence be predictable to the rider.

Tubular tyres should be used. They give a greater weight reduction compared to the

traditional clincher type. The tyres are required to be very firm, so less energy is dissipated as

heat in deforming the tyre. Smooth tread on the tyres will reduce the rolling resistance with

the road. Using a laser machining technique to produce the tyres for our recumbent could

produce an extremely smooth surface down to a molecular level.

Clincher and tubular rims

The tubular and clincher rims are shown in figures 4 and 5. It illustrates the advantage of the tubular design, which has

a very simple lightweight box-section rim, rather than the heavier U-shaped clincher rim.

Figure 3: A tubular tyre

Figure 4: Clincher rim Figure 5: Tubular rim

10

The wheelbase of our recumbent is important to its performance. Short or long wheelbase designs differ in the

position of the front wheel in relation to the cranks. Our design will use a short-wheelbase, where the pedals are out

ahead of the front wheel. The high foot position provides an aerodynamic shape, and due to the position of the pedals,

more power is transferred through the drive train.

This rider position, with the pedals located as shown, will enable us to make our design front wheel driven. This

is advantageous, since traditional designs have been rear wheel driven, leading to the need for a long, heavy chain.

This has been explored in the section on gears.

Figure 6: Short wheelbase design

A 10% reduction in the rolling resistance leads to a 10% longer braking distance on a wet road. This increase in

braking distance can be ignored in our design, however, since we are only attempting the record once, and there is a

long distance for the recumbent to slow and come to rest in.

Size of the wheel

It is clear that larger wheels will increase the performance of the recumbent, as the same effort from the cranks will

result in a longer distance covered per rotation of the wheel. Making the wheels as large as possible however would

not optimize performance, since increasing the wheel size has negative consequences of increased apparent area and

weight. A balance must therefore be struck. The higher the weight of the wheel, the harder the rider has to work to

turn the wheel. Typical racing tyres are 700mm in diameter, since this size provides an optimum balance. This is the

wheel size we will use in our design.

Rolling resistance increases in near proportion as wheel diameter is decreased for a given constant inflation pressure

[3]

Wheel mass

The mass of our wheels is important, since the rider must provide more power to ride a bike with heavier wheels. The

additional power required is proportional to the additional weight during accelerations. Heavier wheels also have an

increased rolling resistance. Weight reduction in our wheels could be achieved through;

- Straight pull, high tension spokes, enabling reduced spoke counts

- Lightweight rims sections and materials

- Lightweight spokes

- Half-discs on wheels only on the outermost exposed section

Rotational inertia

A rider must provide more power for wheels with a greater moment of inertia (MOI). The moment of inertia applies to

the wheels, since they rotate as well as tranlate as the recumbent moves. Lowering the MOI means the wheels will

accelerate more quickly and with less effort.

Mass situated a large distance from the axis of rotation of the wheel increases the rotating inertia. Since the rims are

the outermost section of the wheels, it is these that have the greatest effect on rotational inertia. The wheel rim must

therefore be of reduced weight. Tubular tyres could achieve this in our recument, as they use a very lightweight simple

box-section rim, thus helping to reduce rotational inertia.

Other features, such as the half-discs we use, and the spoke nipples must be as lightweight as possible to reduce the

MOI. Locating the spoke nipples at the hub rather than at the rims could also reduce the MOI in our design.

Moment of inertia, I, is calculated from;

2

i i

r m I E =

(3)

This gives the power required in terms of the linear velocity and acceleration as;

11

v a

r

I

P =

2 (4)

Equivalent mass

The equivalent mass is a combination of the mass and moment of inertia of the wheels. It enables a comparison

between weights of rotating and non-rotating bicycle components, such as wheels versus a frame. It also enables a

better comparison between various wheel sets that may have similar masses, but different MOI. The effect of

equivalent mass on performance is that a rider must provide more power to accelerate wheels with a greater equivalent

mass. The additional power requirement is proportional to the additional equivalent mass during accelerations

[4]

.

2

r I m m

eq

+ =

(5)

The stiffness of the wheels is an important property, as large deflections will result in energy losses and reduce the

efficiency of the bike. Stiffness can affect our wheels performance by three methodologies;

Torsional stiffness prevents any deflection in the wheels with each fluctuation in the crank torque.

T = kt * q (6)

Lateral stiffness flexing of the wheel due to side loads from events such as sprinting or cornering.

F = kl * x (7)

Radial stiffness wheels subjected to radial loads due to weight of the rider. Greater radial stiffness will result in a

harsher ride, while those with lower radial stiffness will flex more and absorb shock loads better.

[5]

K = E*A/L (8)

Materials of the wheels

Moulded carbon fibre rims

Rubber tyres

Thin Kevlar layer between the tyre casting and the outer tread provides excellent puncture resistance.

Titanium spokes

Our recumbent design is to be front wheel driven, so as our rear wheel is not driving the recumbent, reduced spoke

counts can be used, which will provide less weight. The spokes traditionally must transmit the torque applied to the

rear hub by the drivechain out to the rim. This is not the case with our rear wheel, and it will be essentially free-

wheeling. In order for the wheel to remain true and straight, the spoke tension must be equal and appropriate to give

the wheel enough strength.

3.2 Bearings

Bearings are extremely common devices used to reduce the level of friction between two surfaces. The motion

between the two surfaces is usually rotary or linear. Bearings are broadly classed by their shape or by the type of

motion they allow and in this section, Glide by Icicle will consider all the available options and materials to try and

make the recumbent bike parts rotate as freely as possible.

There are numerous places where the recumbent bike which will need a bearing type device to reduce friction

between the surfaces. These places in the front and rear hubs, the bottom bracket, the pedals and we may also need to

consider the fork tube and the freewheel

[6]

. This will depend on our steering mechanism and whether we will need to

incorporate a freewheel as this allows the pedal cranks to turn independent of the wheels. But if we are going for a

world record, will they be constant pedal power applied? If so then is there any need for a freewheel?

There are four commonly used, feasible shapes for bearings. Each shape has its own advantages and

disadvantages. The four variations of bearing are the ball bearing, the roller bearing, the tapered roller bearing and the

spherical roller bearing

[7]

.

12

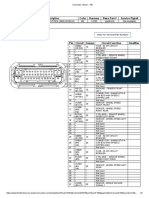

3.2.1 Bearings in a recumbent bike

The front and rear hubs are situated by the points indicated in

figure 7 as A and B along with the significant loads.

To calculate the maximum force upon the bearings

present in the front and rear hub we need to consider the

external load. The mass of the rider can be assumed to be 80

kg and the mass of the bike to be 18 kg giving a total mass of

98 kg. Therefore the applied load is;

N mg F 961 81 . 9 98 = = = (9)

Using = 0 u we get;

N mg F 1922 0 cos 961 961 cos F

max

= + = + = u (10)

The way these forces interact with the bearings can be seen in

figure 8. Since there are two tyres, and two sets of bearings per

tyre, the force on each set of bearing is 480.1N. This load is

distributed amongst the bearings within the bearing case. The

way the load is distributed depends on a number of factors.

One factor is the centrifugal force, Glide by Icycles is

expecting to make the recumbent bike travel at around 90

km/h which will create such force upon the bearings, values of which can be seen in table A13.

From table A13, it can be seen that the largest centrifugal

force we calculate is slightly above 1 N. This is tiny compared

to the overall forces so we can safely neglect the effects of

gyroscopic motion and centrifugal force from our load

distribution calculation.

Next, Glide by Icicle has to decide on the clearance value to

use. Clearance present in roller bearings allows for some

manufacturing imperfections, a small amount of deflection under

load and thermal expansion. But with greater clearance comes

increased rock and instability. By using a low clearance value,

it will allow the lubricant to make a thin film between the roller

bearing and housing. Also, less energy will be lost by vibration

and noise, removing these will allow the recumbent bike to

travel more efficiently

[7]

. However, disadvantages include

having the possibility of having a substantial amount of heat

build-up reducing fatigue life. The bearings will not be revolving

at incredible speed therefore not much heat will be generated and

the bearings only need to last an hour therefore, these

disadvantages do not pose a great problem and so the value of

0.3 mm seems ideal.

[8].

Now the factors affecting load

distribution have been considered, the maximum roller bearings

load can be calculated.

The maximum rolling element load is calculated from equation (11).

( ) c

r

ZJ

F

Q =

0

(11)

mg F

n

/2

A

B

F

n

/2

m = mass of bike + rider

F

n

= Normal contact force

= Angle of incline

A = P o s i t i o n o f f r o n t h u b

B = P o s i t i o n o f r e a r h u b

Figure 7: An analytical diagram of recumbent bike

Forks

Central

axle

Spokes

Normal

force

Force from

total mass

Bearings

Figure 8: Free body diagram of a bicycle hub

13

Using the clearance value of 0.3 mm and the maximum

deflection approximated to be 1/30

th

of the bearing diameter in

small diameter bearings. We can calculate for a 3 mm bearing;

2 . 0

3 . 0 1 . 0 2

3 . 0

1

2

1

2

1

2

1

max

= |

.

|

\

|

+

=

|

|

.

|

\

|

+ c

=

r

r

u

u

c (12)

This value of 0.2 equates to a value of 0.1590 for ( ) c

r

J which can be

seen from table A14. Inputting this value into equation (11), we can

calculate the maximum rolling element load, Q

0

. Where Z is the

number of rolling elements per row and can be approximated from

equation (13).

( )

Z

D

D D

=

+

1

2 1

t

(13)

With Q

0,

we can calculate the maximum contact pressure from formulas (A1), (A2), (A3) and (A4) found in the

appendix, which are based on spheres, point contact. These calculations are then inputted into a spreadsheet to quickly

find the optimum values. The resulting tables can be seen in the appendix. The results for the front and rear hubs as

discussed can be found in tables A1, A2 and A3.

4.2.3 Bearing Conclusion

Table A2 shows the maximum contact pressure, for an ideally sized steel bearing being of acceptable value therefore,

the higher friction but lower contact pressure type roller bearings such as the roller bearing, tapered roller bearing and

spherical roller bearing can all be neglected as these will not provide advantageous properties to a high speed

recumbent bike.

It is possible to see from tables A1, A2 and A3, the effect of changing the radius of the roller bearings and

wheel axle aswell as the material of these two components. The columns highlighted in yellow are the columns are the

columns being investigated whilst the rows highlighted in green highlights the value that is assumed to be the best

value for the task involved.

An ideal ball bearing would be as small as possible as smaller bearings deform less and therefore have smaller

energy losses. It would also be ideal to have a small as possible contact pressure. However, small contact pressures are

generally seen in large bearings so a compromise has to be made. Table A1 shows the radial value of 18 mm to be the

most appropriate value. This is when the contact pressures start to converge and it is also small enough to make an

efficient bearing. Similarly in table A2, the radius of the wheel axle of 50 mm, was decided upon by a similar method,

but with also considering the large increase in thrust loads that appears with larger axles due to a greater moment.

Table A3 provides a very narrow view of how the material affects the performance of a bearing. Table A3

shows the maximum contact force for such material and then further research has to be done of the material to see if

the material has the strength and properties to withstand such loads and provide smooth friction free motion. After

much research, Glide by Icicle came to the conclusion that hardened steel bearings with the axle layered with ultra

high molecular weight polyethylene (referred to as UHMWPE from here on in) would provide the best properties for

the bearings in the front and rear hubs. This was concluded because hardened steel with UHMWPE exhibits a very

low coefficient of friction of 0.2. Different materials are used because similar materials are prone to sticking due to

adhesion forces and bonding.

Ball

Bearings

F

D

1

Central

axle

Hub

housing

D

2

Q

0

Q

1

Q

1

Q

2

Q

2

Figure 9: A free body diagram showing the load

distribution in a wheel hub

14

UHMWPE Hardened Steel

- Extremely resistant to abrasion - Extremely hard

- Very tough - Brittle and is difficult to deform

- Extremely low coefficient of friction - High melting temperature

- Highest impact strength of any thermoplastic - High impact strength

- Self lubricating - Can be machined to high tolerances

- Highly resistant to corrosive materials - Extremely resistant to abrasion

- Low moisture absorption

- Under high contact pressure, UHMWPE possesses

a self-repairing ability

[9]

Table 4: Table showing the properties of UHMWPE and Hardened Steel

For the remaining bearings on the recumbent bike, the exact same methodology was undertaken. The results to these

can be seen in tables A1-A9 found in the appendix whilst the final sizes and materials can be seen below in table 5.

4.3 Powertrain

4.3.1 Options for the powertrain

The main options available to the team are;

Chain and sprocket chain drives a sprocket attached to the front or rear wheel. The efficiency of a chain and

sprocket system is usually over 99%.

[10]

Gear cogs Achieved by mounting a cog to the front fork, which is then driven directly by the pedals. This then

drives another gear cog, which is attached to, and drives the front wheel. Limitations are that it is restricted to being a

single-speed, fixed gear system, which may not be able to produce the desired acceleration. Another problem is that in

order to pedal forwards, an idler gear would need to be inserted, decreasing the efficiency of the transmission.

Planetary gears similar mechanism to gear cogs on bicycles, providing a more compact system. Advantages of

this design over traditional chain-driven bicycles are that there are less frictional losses without the chain; both front

and rear wheels can be made large, decreasing rolling resistance; and there is a good channelling of force, with no

torsion.

[11]

Torque converter - The use of a torque converter would give a compromise between a fixed gear system and a

multi-gear system. The application of force from the belt causes it to contract and slide into a v-shaped gulley

operating as a smaller cog. This small cog allows for a greater application of torque when accelerating. As top speed is

approached, the pulley begins to expand around a larger cog. This means the gear ratios vary continuously, so that it is

always producing the optimal gear ratio for the amount of torque applied to the crank, making the acceleration optimal

as the speed increases. There are also no jumps in the transmission caused by changing gear, as is the case with a

drailleur system.

Bearing

location

Applied

load, F R

bearing

R

axle

Clearance

(mm) Material

Hubs

480.1 0.0018 0.05

0.3 Hardened steel bearings w/ UHMWPE axle

Forks 30 0.001 0.015 0.3 Hardened steel bearings w/ UHMWPE axle

Bottom

Bracket

230.1 0.001 0.03

0.3 Hardened steel bearings w/ UHMWPE axle

Pedal

180.1 0.0015 0.015

0.3 Hardened steel bearings w/ UHMWPE axle

Flywheel N/A N/A N/A 0.3 N/A

Table 5: Final bearing sizes and materials

15

4.3.2 Gear ratio selection

The procedure to determine an optimal gear ratio is given by:

Figure 10 Procedure for determining the optimum gear ratio for a bicycle

For our design, the slope gradient can be assumed to be zero, as the competition will take place on flat ground. The

desired cruising velocity, in top gear, is determined by the currently existing record of 53.07 miles in one hour.

Allowing for the time taken to accelerate up to this top speed, a cruising velocity of approximately 60mph should be

appropriate. A driving wheel diameter of 700mm has been found to be optimal, so the rotational velocity for this size

of wheel at this velocity is:

35 . 0

8 . 26

= = =

r

v

r v e e (14)

rpm rads 5 . 731 6 . 76

1

= =

e

Davison, England, Vandy and De Leener found that for a race of an hour duration (albeit on an ordinary bike, on a

track), the optimum crank speed was 116 rpm.

[10]

Therefore, a top gear ratio of 1:6.3 (i.e. One turn of the pedal

produces 6.3 turns of the driving wheel) would be appropriate.

4.3.3 Powertrain Conclusion

Each of the power transmission systems reviewed here has a number of advantages and disadvantages, none of them

being a perfect solution. Considering this, however, I would recommend that a front wheel drive mounted torque

converter be used. Front wheel drive offers the advantage of increased efficiency over a rear wheel drive system, due

to the shorter pulley distance and associated increase in pulley tension, as well as decreasing the weight of the

transmission. Mounting the pedals and crank on the front fork has been successful in previous designs, and the

reduction in cornering ability this causes would not affect the bicycle's performance on a wide oval track. The use of a

torque converter also allows the optimal gear ratio to be used throughout the acceleration of the bicycle, and much

smoother acceleration than a drailleur system. This compares well to the single-gear system that is defined by many

of these systems, where the acceleration of the bicycle will be poor, ultimately reducing the distance travelled in an

hour. In a competition where races can be won, and records set, by a few seconds or less, this improvement in

acceleration may mean the difference between winning and losing.

4.4 Bicycle brakes

There are many types of brake have been invented to improve the stopping power and safety of a bicycle. The main

types are:

Rim brake - works by applying the force to the brake pads using the lever mounted on the handlebar and this

causes the pads to contact and apply friction to the rim of the wheel.

16

Drum brake - works by applying the force on the brake pads in the drum and the brake pads will press outward

against the inside of the drum. The drum brake has complicated components built in the hubs shell and it has lower

braking power compared to the rim brake.

Disc brake - consists of a metal disc attached to the hub of the wheel and the callipers attached to the frame of the

bicycle. The callipers actuate the brake pads to squeeze on the metal disc to apply the braking force.

4.4.1 Selection of brake for recumbent

bike

The need for braking in a recumbent bike built for

competition is less compared to the other bike

disciplines such as mountain biking. However, the

brake is still essential to provide safety. For this

project, the rim brake is recommended because it is

lightweight and provides adequate braking power.

4.4.2 Brake balance

The brake balance is a relationship between the vertical forces on the front and rear tyres of the recumbent bike with

the torques applied by the brakes at both sides. Normally for the bicycle, most of the braking power comes from the

front wheel. If the front wheel brake is too strong, the normal bicycle would have a tendency to flip over. The

recumbent bike has a long wheelbase and very low seating position so it has a very low centre of gravity. It is

impossible to flip over but the strong front brake can cause the front wheel to skid and lose the balance. On the other

hand, if the rear brake is too strong, the rear wheel will tend to deviate to the side.

The normal force of a normal bicycle with a wheelbase L and a centre of mass halfway between the wheels at the

height h, with the both wheels locked can be analysed using the following equations:

|

.

|

\

|

+ =

L

h

mg F

2

1

1

|

.

|

\

|

=

L

h

mg F

2

1

2 , where is the coefficient of friction, m is the mass and g is the

acceleration of gravity

[12]

. When the h/L is greater than , the normal force on rear tyre will have a negative value

Figure 12: Free body diagram of the forces on a bike during braking

Figure 11: Example of the mechanism of rim brake

17

and can cause the bicycle to flip over. For the recumbent bike, the height of centre of mass is usually less than half of

the wheelbase. The front wheel will skid and can cause the instability.

The optimum braking can be achieved when the brake torque distribution matches the dynamic weight distribution

[13]

.

The dynamic weight distribution can be calculated using the equation:

fs

CG t

df

W D

Wb

Ht W

W +

= [8] (15)

4.5 Breathing

A streamlined fairing on human powered vehicle provides greater impact on the performance because of less air

turbulence when moving through air. But, such a compact fairing can make breathing harder. One suggestion to

overcome this would be making ventilation into the inside of the fairing. Ventilation into the bicycle also helps cool

down the body. However, this will cause drag so any ventilation should be controlled carefully.

Another suggestion would be providing the rider with breathing apparatus, where the tubes would provide

breathing and also a water supply. Through using an oxygen tank, the breathing apparatus could be designed to

provide the rider with a higher volume of oxygen in the air breathed in. This would to help optimise the riders

performance, but should be weighed up with the negative consequences of the additional weight of the tank.

4.6 Riders Position

There are two main body position that can be considered for the design; prone and supine position. These two

positions have their own advantages and disadvantages.

Prone position is the position that involves the rider to lie flat on their chest.

The prone position does not imply any problem with regards to breathing, as long as the body is supported at the

shoulders and hips. Forehead support should also be used instead of chin support

[14]

.

Supine position is the opposite of prone, where the rider is lying on his back. This position is the more natural and

more comfortable compared to the prone position.

The average power output is greatest in the 130 and 140 range of body configuration angle (BCA)

[15]

, (see figure

14).

Figure 14: Illustration of body configuration angle

In order to decide which rider position is the best for this project, a weighted matrix analysis is performed. The

analysis is based on several criteria, which can be seen in Appendix B1:

18

The matrix is constructed with each criteria given the rank of 1-5. (1 being the worst, 5 being the best)

Criteria Supine Position Prone Position

Aerodynamics (x7) 5 5

Riders comfort (x6) 5 3

Efficiency (x5) 5 4

Steering (x4) 5 4

Stability (x3) 5 4

Feasibility to design frame (x2) 3 5

Cost (x1) 3 4

total 134 115

Table 16: Weighted matrix analysis to choose the rider position

From table 16, the supine position scored more marks compared to the prone position. Therefore, supine position will

be used to design the frame of the bike. However, having the rider to lie completely flat on his back will not allow for

maximum power output. Therefore the rider should be in supine position with 130-140body configuration angle.

4.7 Seating

Being decided on the type of riders position, we now come to the part to designing the seat. Several options can be

considered, however only two most feasible options will be presented here: -

- Hanging body

o This can be done by chaining the rider to the frame of the bicycle. This will require an extra

horizontal pole in the frame

- Traditional seating

o This is a meshed seat like most of other recumbent bicycle.

These two options are compared in a table below, where the advantages and disadvantages are discussed.

Seating Options Advantages Disadvantages

Hanging body Less weight Uncomfortable

Less power output

Traditional seat Comfortable

Higher power output

Heavier

Table 17: table showing the advantages and disadvantages of both seating options

From table 17, hanging body has the advantage of less weight compared to the traditional seat. However, this might

not be the case since a horizontal pole has to be added to the frame to do this. This addition might be even heavier than

the meshed seat, since it has to be able to support the forces without failing. To validate this, a finite element analysis

is done. The result of the test is shown in Appendix B2.

It is also stated in the disadvantages column that the hanging body option might produce less output power. This is

because the hanging body option does not have a back support for the rider, which will not be able to stabilize him

while riding.

After careful consideration and discussion, the group agreed to choose traditional style seat to be build into our

recumbent bicycle. This is based on the feasibility of the design, the comfort of the rider and also the total weight of

the bike.

19

4.8 Steering

When it comes to steering, there are two main categories in a recumbent bicycle. The categories are: -

Under Seat Steering (USS)

[16]

An under seat steering is where the steering is under the seat, as in

Figure 15.

Under seat steering is usually indirect, which means the bars link to

the headset through a system of rods and pivots. USS has a more

natural hands position that has the advantage of giving less strain

on the riders hands.

Over Seat Steering (OSS)

[17]

OSS is generally direct, where the handlebars act directly on the front

fork as in the figure above. Over seat steering has the advantage of

allowing for a lower rider position design. However, this can also be

achieved using the USS, but slightly harder. Compared to USS, over

seat steering impose more strains on hands, and for a ride of over one

hour, this factor has a huge impact.

For our design, we have decided to adapt the under seat steering

(USS). However, we did not intend to use the complicated design of

using system of rods and pivots. The steering will simply comprise of

a handlebar on each side of the front fork, which will extend to the

riders seat.

4.9 Frame design

Material selections

The frame of recumbent bike is built using the tubes welded together. There are two materials that we consider. These

materials are selected based on:

- High modulus of elasticity

- Low weight

- High yield strength

- High fatigue strength, good enough for the frame to run at full speed to finish the race

There are many materials available to choose from and we have decided to consider aluminium alloys and steel alloys

for our recumbent bike. Steels have better strength compared to aluminium alloys, but they are much heavier.

Therefore, we have to find the best material to fit our specifications. There are actually many types of aluminium

alloys or steel alloys from 1000 series to 7000 series. The specific series of the alloys were analysed and the best

option selected. The materials are:

Aluminium 2090-T83 AISI Steel 4130

Modulus of elasticity, GPa 75.8 205

Density, kg/m

3

2590.8 7861

Poisson ratio 0.34 0.29

Yield strength, MPa 520 460

Table 18: mechanical properties of the materials

Figure 16: recumbent bike with over seat steering

Figure 15: recumbent bike with under seat steering

20

Design specifications:

- Supine position with 130 body configuration angle

- Traditional seating

- Under seat steering

- Torque converter

- Front wheel drive

- Safety Factor of 2

- Maximum deflection of 3mm

- Total mass of the frame 5 kg

Geometry of the frame

Based on the design specifications above, the sketch of the frame is as followed:

Figure 17: sketch of the frame

The frame is based on the triangulated frame system with front wheel driven.

Forces

We are considering 2 main forces acting on the frame. They are riders weight and pedalling force.

Riders weight:

- The riders weight is approximated to be around 80kg maximum.

- The weight is distributed on the bar where the seat is located and acting vertically downward.

- The weight will be multiplied by a factor of 3 in order to approximate the dynamic loading on the frame

[18]

.

Pedalling force:

- The power required is approximated to be 400W with the maximum speed of 60mph on the wheel as what

has been analysed in the Section 3.1.

- The pedalling force is calculated and approximated to be around 626.4N

Modelling in finite element analysis

The frame is modelled using lines and the element used is beam3 type. Using this type of element, the structure is

assumed to be constructed from the tubes with different cross sectional areas at different parts.

The area moment of inertia is calculated using the following equation:

21

( )

4 4

4

r R I

o

=

t

, where R is the outer radius and r is the inner radius of the tube. This is the equation for hollow

cylinder.

Result of finite element analysis is shown below:

Aluminium 2090-T83 AISI Steel 4130

Maximum deflection, mm 2.436 0.900

Total mass of the frame, kg 3.25 9.87

Safety Factor 113.6 100.5

Table 19: comparison of finite element results for both materials

In the table, the results show that aluminium alloy still meets the design specification while steel has exceeded the

mass limit of the frame. So, we decided to use aluminium 2090-T83.

Aluminium 2090-T83

- Number of elements = 89

Figure 18: stresses and deflection on the frame

22

AISI Steel 4130

Figure 19: stresses and deflection on the frame

4.10 Aerodynamics

Our goal is to break the one hour distance record for a human powered vehicle and therefore aerodynamics is of the up

most importance. The design should primarily focus around a recumbent speed bike where compromises will be made

to reduce the weight and increase the streamlining. This is because the cross sectional area of a recumbent bike is far

less then that of an upright bike. Reducing the cross sectional area will directly reduce the effects of drag and therefore

greater speeds can be obtained by the same application of power.

It has also been proved that the position of the rider on a recumbent cycle can generate more power then an upright

due to the rider being able to push back into the seat.

[10]

Our bike design will include a fairing also. This is an

outer shell that will enclose the bike and the rider in

order to dramatically reduce the effect of drag. Recent

studies have found that the use of a highly streamlined

fairing can in fact reduce the drag by an average of

41.3% over a rider on an upright bike in the tuck position

[19]

.

It can also be said that a rider would not be able to

sustain a tucked position for the one hour duration

comfortably, therefore there is a massive 73.4% drag

reduction from a rider on an upright bike in an upright

position over that of a highly streamlined recumbent.

(41.3% over a tuck position and 32.1 over an upright

position)

[20]

Figure 20 - Showing approximately a 40% reduction in

cross sectional area for a recumbent bike.

23

4.10.1 Drag

As a body moves through a fluid it experiences a drag force due to the viscosity of that fluid, in our case air. There are

two components to this, viscous drag and pressure drag.

Viscous drag comes from the interaction between the fluid and the surfaces over which it is flowing causing friction.

This is because of the no slip condition where the air at the surface has a velocity component parallel to the surface of

zero. The velocity of the air flow does increase rapidly with distance away from the surface. See fig 21

In our fairing design it can be said that the flow passing over the body is laminar. This means the air behaves like a

stack of flat sheets sliding over each other from zero velocity at the wall (or fairing) to the maximum velocity some

distance away. This occurs because the adjacent air molecules between each pair of sheets collide so that the sheet

above is slowed down by the sheet below; this causes friction and thus creates viscous drag. For our recumbent bike

the viscous drag will dominate the reduction in speed as the body will be streamlined and thus

pressure drag influences of eddy currents shall be minimised.

The fairing that encloses the rider and bike will be smooth

with the fluid spending more time passing over the shell then

separating at its rear. This streamlined design will reduce the

viscous drag coefficient for the bike and thus increase its

velocity for the same application of power.

Pressure drag comes from turbulence or eddy currents that

are created within the fluid by the passing of the bike. As

our fairing design will be smooth and tear shaped there will

be no pressure drag effects over the fairing, only at its rear

where the flow separates from the surface.

This is because for one to minimise the pressure drag it is

important to keep the air flow attached to the fairing for as

long as possible. As the flow accelerates over the front of the

fairing due to the increasing cross sectional area thus

distance travelled, this produces a reduction in pressure due

to Bernoullis relationship.

So air flowing from high to low pressure produces a favourable pressure gradient and separation is unlikely unless

there is a bump or discontinuity over the fairings coating, therefore only viscous drag is present here. As discussed

earlier the main contribution to pressure drag comes from the separation of air from the fairing at the rear of the bike.

It occurs at the rear because the air slows down as it flows and thus the pressure over the rear section increases due to

Bernoullis relationship once more, causing an undesirable pressure relationship thus a separation point were the

boundary layer becomes turbulent.

A turbulent boundary layer is characterised by being considerably thicker then the laminar one. There is a mean

velocity profile and eddy currents are created causing a wake and thus pressure drag is created. See fig 22 below.

X

Max Velocity

V=0m/s at the wall

Figure 21 - showing how the parabolic flow velocity

varies with distance from the wall

24

Figure 22 - Showing the development of the boundary layer on the fairing surface

[21]

The way to avoid this is to reduce the air speed, thus increasing the pressure as gradually as possible, this will send the

energy from the air flow into the boundary layer at a high enough rate to reduce or even prevent separation occurring.

However this causes the boundary layer to thicken and again increases the viscous drag. So the idea is to reduce the

cross sectional thickness as gradually as possible in order to increase pressure as gradually also.

This can also be seen by referring to fig #4 showing the flow patterns over a smooth cylinder. It can be seen that at

higher Reynolds numbers (i.e. high velocity) the flow will separate from the rear of the sphere and thus increase

pressure drag due to the separation of the boundary layer at this point. Note how in A there is no separation because

the Reynolds number is so small.

Also when studying bodies not of a cylindrical shape it can be seen that the higher the angle of attack open to the

oncoming flow the higher the pressure drag and thus higher the drag coefficient. This is due to a higher undesirable

pressure gradient and thus sooner separation of the flow.

Figure 23 - Flow patterns for flow over a cylinder: (A) Reynolds number =

0.2; (B) 12; (C) 120; (D) 30,000; (E) 500,000.

[21]

1

1-Negative static pressure

2-Positice static pressure

3-Stagnation point

4-Velocity vector

5-Laminar boundary layer

6-Transition point

7-Turbulent boundary layer

8- Streamline

9-Seperation point

10-Seperated flow

11-Wake

25

It is therefore of the up most importance that our design focuses on having a minimal cross sectional area, angle of

attack and separation point at the rear keeping the flow attached for as long as possible, thus reducing pressure drag by

reducing the size of the fluid wake behind the bike as it moves. The best shape in order to fulfil all the desired

attributes above is the teardrop shape. It is able to exploit the benefits of a laminar boundary layer, has a smooth

continues surface and also a gradually reducing cross sectional area. Fig 24 shows the typical values for the drag

coefficient obtained from this tear shaped geometry.

Figure 24 - showing the variation of drag coefficient with fitness ratio l/d for the tear drop shape

The fineness ratio is a ratio specifically applicable to this shape and describes the maximum length divided by the

maximum diameter and is said to yield the minimum drag when the length is approx 3 times that of the diameter

[21]

,

increasing the length decreases the pressure drag caused by eddys or wake at the rear. Now our total fairing length is

2.75m so in theory a cross sectional area of 1.1m would yield the best results for this shape. However as our fairing

encloses a recumbent cycle that is much longer then it is wide therefore this shape can be modified in order to further

reduce the drag co efficient. Our group decided that 60cm in width would be the thinnest possible option as this would

be the width of the driver. If the fineness ration was adapted for this width the resulting length giving a fineness ratio

of 2.5 and thus the lowest drag coefficient possible would be 1.5m. Although this is not a feasible length as not only

are the wheels so large that the fairing wouldnt be able to encase them but the driver wouldnt fit either. Therefore a

compromise was struck. The rear of the fairing shall be made 1.5m long, reducing the effects of pressure drag thus

allowing all the energy from the air flow into the boundary layer at a high enough rate to reduce the separation. The

remaining 1.25m will be used for the front of the fairing allowing for a slender mid section at a width of 60cm. A

shaper tear drop shaped nose protruding to a point will be used, further reducing the drag coefficient by decreasing

the area normal to the on coming flow and therefore reducing the size of the stagnation point at the front of the fairing.

This way the combined fineness ratio is 2.29, resulting in a drag coefficient of 0.32.

In order to test this fairing shape accurately a scaled model should be made and placed within a wind tunnel although

this would take time. Another way is to model the fairing using CFD (computational fluid dynamics) and viewing the

pressure variations over the fairing. Ideally the fairing should be modelled in 3D flow however this could not be done.

Instead an aeronautical website

[23]

was consulted which allowed the user to input the dimensions of an aerofoil,

including the angle of attack and Reynolds number of 980700 (i.e. 90Km/h over the 60cm diameter at a pressure 1

atm, temperature of 20 degrees). It was then simply a case of inputting the fairing dimensions, making the aerofoil

symmetrical and running the java script to view the pressure variations over the fairing. It can be seen in figure 25 that

the pressure is fairly evenly distributed along the mid section. The pressure increases slowly at the tail allowing for the

flow to remain attached to the fairing and not become turbulent.

26

.

Figure 25 - Showing the pressure distribution of the fairing design.

It should however be noted that the above simulation could not provide us with an accurate indication of the drag

coefficient. This is because the program was written for aerofoils and therefore would only give a drag coefficient

when an angle of attack was induced.

There is however a problem with this adapted tear drop shape shown in figure #6. As an object is placed nearer and

nearer to the ground the air no longer flows around the object in a symmetrical way due top the ground and this

increase the drag coefficients. For our design the bike will be very close to the ground in order to reduce any friction

around the exposed tyres thus the design shall be adapted to account for this. If the tear drop shape is cambered to

further look for like an aerofoil and shaped to induce more flow around and over the fairing it will allow for a lower

coefficient of drag to be achieved. Morelli

[22]

experimented with this and came up with the following graph. It shows

how the ideal tear drop shape can be adjusted in order to account for the ground clearance. It can be noted that the

greatest result achievable is when the radius from the centre line to the upper outer shell divided by the length is 0.09.

Now for our design the distance from the centre line to the upper most outer shell is calculated as:

0.6/2=0.3m radius,

0.6/2.75=0.1091

This indicates that the camber on our fairing is similar to the greatest result found and therefore the drag coefficient

can be found via figure 26 by following the dotted cambered line and calculating the relative height of ground

clearance divided by total length. The result is given to be 0.022 with a 6cm clearance and 2.75m overall fairing

length. This corresponds to a drag coefficient of 0.17. Even lower then that calculated previously, although it should

be noted that with 6cm of wheel protruding from the bottom on the fairing this value will increase.

Pressure spike

Favourable pressure

gradient

Negative pressure gradient

decreasing at a low rate

allowing for the reduction of

turbulence

Fairing Shape

27

Figure 26 - showing the effect of camber upon ground clearance.

The final fairing design was a combination of both the dimensions given and the ground clearance acceptable. The

wheels were encased as fully as possible by the fairing, allowing for at least 20 degrees lean of the bike to allow it to

respond to side winds without crashing.

Figure 27 - showing the final fairing design for our recumbent bike.

2.75m

1.25m

0.6m

Sharpe node

reducing stagnation

point.

Enclosed wheels further

reducing drag

0.6m

0.06m

28

5.0 Conclusion

The task of producing a human powered vehicle to break the Dempsey-MacCready hour record of 85.991Km was

proposed to our team. After deliberating over the best way to propel a vehicle to achieve a distance of over 86Km in

an hour, a recumbent cycle design was selected as the best option.

The team Glide by Icycles allocated each member of the group an important component from a recumbent

bike and studied its strengths, its weaknesses and its requirements to maximise the chances of breaking the record.

Eventually the best components which fulfilled our requirements were chosen in order to produce the most efficient,

lightweight design, giving us the best chance of achieving our aims and objectives. Below is an overview of each

component set up along with the final pro desktop and finite element designs;

Firstly the bearings were studied. Bearings were required in several places on the design. Hardened steel was

chosen to provide the best properties for the ball bearings in the front and rear hubs, with an UHMWPE coated axle.

This was mainly due to the extremely low coefficient of friction of these combined materials.

Once the bearings had been selected the tyres were investigated. It was decided that tubular tyres should be

used because they give a greater weight reduction compared to the traditional clincher type. The tyres are to be

inflated to high pressure, to ensure that there is minimal deformation and energy losses in the tyres. Very smooth tread

on the tyres is also desirable to reduce rolling resistance coefficients.

The power transmission was selected to be via a front wheel drive mounted torque converter because the front

wheel drive offered the advantage of increased efficiency over a rear wheel drive system. The use of a torque

converter also allowed the optimal gear ratio to be used throughout the acceleration of the bicycle and obtain its

maximum speed. Also the brakes were selected to be rim brakes because they provide low weight and adequate

braking power.

The supine position was decided upon as the most effective and comfortable means of positioning the driver.

However the group further researched the idea and found that the rider should be in a supine position with 130-140

body configuration angle to obtain the greatest trade off between power applications, comfort and ease of use at such

speeds. The driver would also benefit from under seat steering and a traditional seat set up rather then a hanging

design.

The aerodynamic fairing was designed to enclose the whole bike and allow for greater speeds with a reduced

application of power. The final fairing design took the following shape and dimensions.

Figure 28: Final fairing design

29

Figure 29: Translucent view of final fairing design

The frame was also designed to give as low a weight, coupled with as high a strength, as possible

.

Figure 30: Design of the bicycle frame

The only thing left to do now is to build and test it

30

6.0 References

[1] Data from Cycle Design lecture notes, Richard Lukes. Reference (Broker, 2003)

[2] en.wikipedia.org/wiki/Racing_bicycle

[3] en.wikipedia.org/wiki/Bicycle_wheel

[4] www.canecreek.com/wheel_tech.html

[5] http://science.howstuffworks.com/bicycle2.htm

[6] http://en.wikipedia.org/wiki/Ball_bearing

[7] www.ahrinternational.com/bearing_radial_clearance_explained.htm

[8] www.engineparts.com/techbulletins/CL77-1-205R.pdf

[9] Large-scale friction and wear tests on a hybrid UHMWPE-pad/primer coating combination used as bearing

element in an extremely high-loaded ball-joint - Tribology International, - P. Samyn, L. Van Schepdael, J.S.

Leendertz, A. Gerber, W. Van Paepegem, P. De Baets and J. Degrieck (Vol 39, No. 8, August 2006, pp.796-811)

[10] Bicycling Science 3

rd

Edition D.G. Wilson The MIT Press (2004)

[11] Direct Drive (Chainless) Recumbent Bicycles Thomas Kretschmerb Human Power (No. 49, Winter 1999-

2000).

[12] www.sae.orgstudentspresentationsbrakes.ppt

[13] www.sae.orgstudentspresentationsbrakes.ppt

[14,15] Project Cadence: Human Powered Vehicle- Adam Christensen, Mordechai Cohen, Amoz Eckerson, John

Vesely II thesis 2003

[16,17] http://en.wikipedia.org/wiki/Recumbent_bike

[18] http://www.sheldonbrown.com/rinard/fea.htm

[19] Bicycle dynamics and control IEEE Control system magazine Astrom, Klein, Lennartssomn (Aug. 2005)

[20] http://www.mueller-hp.com/windtunnel.htm

[21] Year one notes, Introduction to aerospace engineering, University of Liverpool, Dr D Nicolaou, 93/02/1999

[22] Aerodynamics of Road Vehicles From Fluid Dynamics to Fluid Engineering Edited by Wolf-Heinrich Hucho

(4

th

Edition 1998)

[23] http://www.desktopaero.com/appliedaero/airfoils1/interactiveaf.html

Bibliography

Richard's Mountain Bike Book Charles Kelly, Nick Crane Richard's Bicycle Books Ltd. (1988)

Bicycle Dynamics and Control Anstrom, Klein, Lennartsson IEEE Control Systems Magazine (Aug. 2005)

The Speed of a Cyclist Wim Hannekam Physics Education (Issue 25, 1990)

An Ergonomic Study on the Optimal Gear Ratio for a Multi-Speed Bicycle Chang K Cho, Myung Hwan Yun,

Chang S Yoon, Myun W Lee International Journal of Industrial Ergonomics (Issue 23, 1999).

Experimental Examination of Bicycle Chain Forces MD Kidd, NE Loch, RL Reuben Experimental Mechanics

(Vol. 39 No. 4, Dec. 1999)

Backward Versus Forward Pedalling: Comparison Tests Ramondo Spinnetti Human Power (Vol. 6 No. 3, Fall

1987)

Front-Wheel-Drive Recumbent Bicycles Michael Eliasohn Human Power (Vol.9 No.2, Summer 1991)

Front Wheel Drive Bicycles Marek Utkin - Human Power (Vol.9 No.2, Summer 1991)

Cha-Cha Bike Bernd Zwikker, Bram Moens - Human Power (Vol.9 No.2, Summer 1991)

Front Wheel Drive Recumbents Tom Traylor - Human Power (Vol.9 No.2, Summer 1991)

Analysis of Rolling Element Bearings Wan Changsen pp.82-89, 1991 (in English).

Large-scale friction and wear tests on a hybrid UHMWPE-pad/primer coating combination used as bearing

element in an extremely high-loaded ball-joint - Tribology International, - P. Samyn, L. Van Schepdael, J.S.

Leendertz, A. Gerber, W. Van Paepegem, P. De Baets and J. Degrieck (Vol 39, No. 8, August 2006, pp.796-811)

Images from

Figure 3 www.ultimatepursuits.co.uk/products/list.aspx

31

Figure 4 Bicycle Design and Analysis Richard Lukes

Figure 10 - An Ergonomic Study on the Optimal Gear Ratio for a Multi-Speed Bicycle Chang K Cho, Myung Hwan Yun, Chang

S Yoon, Myun W Lee International Journal of Industrial Ergonomics (Issue 23, 1999).)

7.0 Appendix

Front and Rear Hub Bearings Tables A1-A3

R

bearing

R

axle

R E

1

E

2

E* a P

0

Z Q

0

0.0010 0.03 0.0010 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000568 3654.40 97.34 24.661

0.0015 0.03 0.0016 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000744 3138.82 65.94 36.404

0.0018 0.03 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000841 2923.73 55.47 43.273

0.0020 0.03 0.0021 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000902 2803.60 50.24 47.781

0.0025 0.03 0.0027 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001048 2558.30 40.82 58.807

0.0030 0.03 0.0033 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001185 2366.11 34.54 69.499

0.0035 0.03 0.0040 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001314 2208.67 30.05 79.872

0.0040 0.03 0.0046 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001439 2075.58 26.69 89.94

0.0045 0.03 0.0053 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001559 1960.44 24.07 99.716

0.0050 0.03 0.0060 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001675 1859.02 21.98 109.21

0.0055 0.03 0.0067 2.10E+11 2.10E+11 0.3 1.05E+11 0.00017887 1768.42 20.27 118.44

Table A1: Table showing how varying the ball bearing radius affects the resulting properties for the bearings present in the front and rear hubs

R

bearing

R

axle

R E

1

E

2

E* a p

0

Z Q

0

0.0018 0.01 0.0022 2.10E+11 2.10E+11 0.3 1.05E+11 0.0001225 3714.58 20.58 116.6

0.0018 0.02 0.0020 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000964 3244.91 38.03 63.12

0.0018 0.03 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000841 2923.73 55.47 43.27

0.0018 0.04 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000764 2697.35 72.92 32.92

0.0018 0.05 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000709 2526.98 90.36 26.57

0.0018 0.06 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000667 2392.47 107.81 22.27

0.0018 0.07 0.0018 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000633 2282.50 125.25 19.17

0.0018 0.08 0.0018 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000606 2190.22 142.70 16.82

0.0018 0.09 0.0018 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000582 2111.21 160.14 14.99

0.0018 0.10 0.0018 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000562 2042.46 177.58 13.52

Table A2: Table showing how varying the wheel axle radius affects the resulting properties for the bearings present in the front and rear hubs

Material R

bearing

R

axle

R E

1

E

2

E* a p

m

Z Q

0

Rubber 0.0018 0.05 0.0019 5.00E+07 5.00E+07 0.3 2.49E+07 0.0011434 9.71 90.36 26.57

Low Density

Polyethylene 0.0018 0.05 0.0019 2.00E+08 2.00E+08 0.3 9.96E+07 0.0007203 24.46 90.36 26.57

Nylon 0.0018 0.05 0.0019 5.00E+09 5.00E+09 0.3 2.49E+09 0.0002463 209.14 90.36 26.57

Wood (Oak) 0.0018 0.05 0.0019 1.10E+10 1.10E+10 0.3 5.48E+09 0.0001894 353.77 90.36 26.57

Aluminium

Alloy 0.0018 0.05 0.0019 6.90E+10 6.90E+10 0.3 3.43E+10 0.0001027 1203.25 90.36 26.57

Glass 0.0018 0.05 0.0019 7.20E+10 7.20E+10 0.2 3.60E+10 0.0001011 1240.53 90.36 26.57

UHMWPE 0.0018 0.05 0.0019 6.90E+08 6.90E+08 0.3 3.43E+08 0.0004767 55.85 90.36 26.57

Titanium 0.0018 0.05 0.0019 1.10E+11 1.10E+11 0.3 5.48E+10 8.791E-05 1642.04 90.36 26.57

Hardened

Steel 0.0018 0.05 0.0019 2.10E+11 2.10E+11 0.3 1.05E+11 7.087E-05 2526.98 90.36 26.57

Carbon

Fibre 0.0018 0.05 0.0019 3.00E+11 3.00E+11 0.3 1.49E+11 6.292E-05 3205.31 90.36 26.57

Tungsten

Carbide 0.0018 0.05 0.0019 6.00E+11 6.00E+11 0.3 2.99E+11 4.994E-05 5088.12 90.36 26.57

Diamond 0.0018 0.05 0.0019 1.15E+12 1.15E+12 0.3 5.72E+11 4.02E-05 7850.94 90.36 26.57

Hardened

steel

bearings w/

UHMWPE 0.0018 0.05 0.0019 2.10E+11 6.90E+08 0.3 6.26E+08 0.0003902 83.35 90.36 26.57

32

Table A3: Table showing how varying the wheel axle and ball bearing material radius affects the resulting properties for the

bearings present in the front and rear hubs

Bottom Bracket Bearings Tables A4-A6

R

bearing

R

axle

R E

1

E

2

E* a p

0

Z Q

0

0.00050 0.04 0.0005 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000254 3343.21 254.34 4.5235

0.00075 0.04 0.0008 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000333 2902.27 170.61 6.7436

0.00100 0.04 0.0010 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000404 2620.33 128.74 8.9366

0.00125 0.04 0.0013 2.10E+11 2.10E+11 0.3 1.05E+11 0.0000468 2417.19 103.62 11.103