Documente Academic

Documente Profesional

Documente Cultură

Ficha Tecnica Komatsu 300 - 7

Încărcat de

bariciado1Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ficha Tecnica Komatsu 300 - 7

Încărcat de

bariciado1Drepturi de autor:

Formate disponibile

PRODUCT BULLETIN

PC300LC-7

Hydraulic Excavator

INTERNAL USE ONLY

Introducing the PC300LC-7

Hydraulic Excavator

1

1

TABLE OF CONTENTS

1 DESIGN CONCEPT

..................................................................................................................................................................................................2-3

2 HIGHLIGHTS AND TECHNICAL SELLING POINTS

......................................................................................................................................4-5

3 PRODUCTIVITY FEATURES

INCREASED PRODUCTION............................................................................................................................................................................................... 6

HIGH ENGINE OUTPUT, LOW FUEL CONSUMPTION....................................................................................................................................................... 7

LARGER DIGGING FORCE................................................................................................................................................................................................ 8

PROVEN HYDRAULIC SYSTEM...................................................................................................................................................................................9-10

GREATLY INCREASED STABILTY................................................................................................................................................................................... 11

TWO BOOM SETTINGS................................................................................................................................................................................................... 11

IMPROVEMENT OF TRAVEL PERFORMANCE ...........................................................................................................................................................12-13

4 RELIABILITY & DURABLITY FEATURES

IMPROVED DURABILITY OF TRACK LINK...................................................................................................................................................................... 14

REINFORCEMENT OF WORK EQUIPMENT................................................................................................................................................................14-15

IMPROVEMENT IN RELIABILITY OF ELECTRIC PARTS.................................................................................................................................................. 15

DT CONNECTORS........................................................................................................................................................................................................... 16

O-RING FACE SEAL ........................................................................................................................................................................................................ 16

5 OPERATOR COMFORT

LARGE-SIZED CAB......................................................................................................................................................................................................... 17

SUPER SILENT CAB....................................................................................................................................................................................................... 18

CAB DAMPER................................................................................................................................................................................................................. 19

CIRCULATION OF AIR IN CAB TO KEEP CLEANLINESS ................................................................................................................................................. 20

INCREASED CAB PRESSURIZATION.............................................................................................................................................................................. 20

WASHABLE FLOOR MAT................................................................................................................................................................................................ 20

CONVENIENT CAB ACCESSORIES.................................................................................................................................................................................. 21

CONVENIENCE OPTIONS................................................................................................................................................................................................ 21

ASSISTED PULL-UP FRONT WINDOW........................................................................................................................................................................... 22

IMPROVED VISIBILITY................................................................................................................................................................................................... 22

6 EASY MAINTENANCE & INSPECTION

RADIATOR AND OIL COOLER ........................................................................................................................................................................................ 23

ENGINE OIL AND FILTER................................................................................................................................................................................................ 24

FUEL LINE...................................................................................................................................................................................................................... 24

FUEL TANK..................................................................................................................................................................................................................... 25

TRACK FRAME MUD REMOVAL..................................................................................................................................................................................... 25

ENGINE AND HYDRAULIC OIL FILTER........................................................................................................................................................................... 26

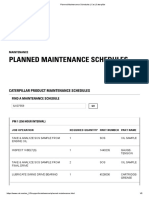

LONG REPLACEMENT INTERVAL PARTS ...................................................................................................................................................................... 27

7 SAFETY FEATURES

GLOBAL SAFETY DESIGN............................................................................................................................................................................................... 28

FULLY PRESSED CAB.................................................................................................................................................................................................... 29

OPG TOP GUARD (OPTION)........................................................................................................................................................................................... 29

8 ENVIRONMENTAL FEATURES

CLEAN ENGINE............................................................................................................................................................................................................... 30

LOW NOISE IN AND OUT OF OPERATOR'S CAB............................................................................................................................................................ 30

SELECT ECONOMY MODE.............................................................................................................................................................................................. 31

RECYCLING DESIGN FOR EFFECTIVE USE OF RESOURCES.......................................................................................................................................... 31

9 MULTI-FUNCTION COLOR MONITOR

MULTI-FUNCTION COLOR MONITOR (OPTIONAL) ........................................................................................................................................................ 32

SIMPLIFIED WORKING MODE ....................................................................................................................................................................................... 33

HYDRAULIC PUMP OIL FLOW ADJ USTMENT SYSTEM................................................................................................................................................. 33

AUTOMATIC THREE TRAVEL SPEED/LIFTING MODE..................................................................................................................................................... 34

EMMS............................................................................................................................................................................................................................. 34

EMMS, MAINTENANCE FUNCTION................................................................................................................................................................................ 35

EMMS, DATA MEMORY FUNCTION............................................................................................................................................................................... 35

10 WORK EQUIPMENT

GREASING INTERVAL EXTENDED.................................................................................................................................................................................. 36

11 ATTACHMENTS & OPTIONAL EQUIPMENT

PIPING FOR ONE ATTACHMENT...............................................................................................................................................................................37-39

12 INTERCHANGEABILITY

......................................................................................................................................................................................... 40

13 COMPETITIVE SPECIFICATIONS

..................................................................................................................................................................41-42

1

2

DESIGN CONCEPT

PC300LC-7

1. Largest production and lowest fuel consumption in its class with improved proven HydrauMind system

2. Improved fundamental performance such as arm digging force, maximum drawbar pull, stability, etc.

3. Higher reliability and durability

4. Easy maintenance and high serviceability to avoid waste and time-consuming work as much as possible

5. Low-noise and low vibration design for the highest operator comfort

6. Meets EPA, EU and Japan Tier II emission regulations

7. Set new leading edge world standards for quality, reliability and safety

8. Multi-function color monitor First in the industry (Optional)

1

3

DESIGN CONCEPT

PC300LC-7 Product Concept

Meets EPA Tier I emissions;

EPA Tier 2-ready

Push-button flow

control for attachments

- Strengthened boom and

arm

- Reliable electric parts

2

4

HIGHLIGHTS AND TECHNICAL

SELLING POINTS

High Production and Low Fuel

Consumption

Production is increased with larger output during Active

mode, while fuel efciency is further improved.

Larger Arm Crowd Force and Bucket Digging Force

Provide Increased Production.

Arm crowd force is increased 18% when the Power

Max. function is applied

Bucket digging force is increased 7% when the Power

Max. function is applied (Compared with PC300LC-6)

Maximum Drawbar Pull

is increased 17% offering

superb steering and slope climbing performance.

(Compared with PC300LC-6)

Higher Lifting Capacity

PC300LC-7s lateral stability is improved, lifting capacity

is also increased.

Excellent Reliability and Durability

High Rigidity Work Equipment

Sturdy Frame Structure

Reliable Komatsu Manufactured Major Components

Highly Reliable Electronic Devices

Easy Maintenance

Replacement Step Interval is Extended for Engine Oil,

Engine Oil Filter and Hydraulic Filter

Remote Mounted Engine Oil Filter and Fuel Drain

Valve for Easy Access

Water Separator is Standard Equipment

Easier Radiator Cleaning

Fuel Tank Capacity Increased

Easy troubleshooting with self-diagnostic monitor

2

5

Harmony with Environment

Low Emission Engine

A powerful turbocharged and air to air aftercooled

Komatsu SAA6D114E provides 180 kW

242 HP

.

This engine meets EPA Tier I emission regulations,

without sacricing power or machine productivity.

Also, this engine is EPA Tier 2-ready.

Economy Mode saves fuel consumption

Low Operation Noise

Easily Recycle Design

Large Comfortable Cab

The new PC300LC-7s cab volume is increased by 14%,

offering an exceptional roomy operating environment

Highly Pressurized cab with automatic air

conditioner

Low Noise Design

Low vibration with cab damper mounting

OPG capable with optional bolt-on top and front

guard

Photo may include optional equipment.

3

6

PRODUCTIVITY FEATURES

The PC300LC-7 produces 8% more than the PC300LC-6

by increasing the engine horsepower, digging force, and

work equipment speed.

Increase of production in Active mode

Active Mode

Production of PC300LC-7 in Active mode is 8% greater than PC300LC-6, and fuel efciency is 4% lower.

Production of PC300LC-7 in Active mode is 15% greater than 330BL and fuel efciency is 20% lower.

PC300LC-7

93

90 100 110 90 95 100 105 110 90

84

100

104 104

111

PC300LC-6

330BL

(Compared to PC300LC-6)

Production

8% increase

INCREASED PRODUCTION

3

7

PRODUCTIVITY FEATURES

The PC300LC-7 utilizes a newly developed Komatsu

SAA6D114E engine with air-cooled aftercooler.

This engine has high output, low fuel consumption and

low emission.

(1) Large output

* The output in the catalog is 184 kW {247 HP}/2,000 rpm in the

H/P mode, but only 177 kW {237 HP} is used normally. The

output is increased to 184 kW {247 HP} only when a large load

is applied in the H/P mode.

(2) Low fuel consumption

Air cooled with the air-cooled aftercooler is supplied to the

combustion chamber for higher combustion efciency.

(3) Fuel consumption is improved by reducing

hydraulic loss

The quick return circuit

is added to the arm cylinder

bottom circuit. Since a part of the return oil is sent to the

tank directly when the arm is moved IN, the hydraulic loss

is reduced about 30% to reduce the fuel consumption and

increased speed.

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Caterpillar

330CL

Engine name

KOMATSU

SAA6D114E

KOMATSU

SAA6D108E

CAT

C9

Rated

output

kW/rpm

180/1900

173/2050 182/

{HP/rpm}

{242/1900}

{232/2050} {244/}

Two return hoses

Arm cylinder Arm cylinder

Hydraulic

tank

Hydraulic

tank

Oil

cooler

Oil

cooler

Control

valve

Control

valve

Qicik return valve

Arm Hi valve Arm Lo valve Arm Hi valve Arm Lo valve

FVPM2925

HIGH ENGINE OUTPUT,

LOW FUEL CONSUMPTION

3

8

LARGER DIGGING FORCE

PRODUCTIVITY FEATURES

Larger Arm Crowd Force and Bucket Digging

Force Provide Increased Production

Arm crowd force is increased 18% and bucket digging

force is increased 7% when the Power Max function is

applied. (Compared with PC300LC-6.)

* Measured value.

Reference: Comparison of arm crowd force

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Caterpillar

330CL

Arm

digging

force

With Power

Max.

kN

{lb}

165

{37,040}

145

{32,600}

161

{36,300}

Comparison of digging force Measured with SAE rating

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Caterpillar

330CL

Bucket

digging

force

With Power

Max.

kN

{lb}

200

{44,970}

187

{42,110}

199

{44,700}

FZPM2827

Comparison of bucket digging

power

Measured with 3185 mm

(10'5") arm and SAE rating

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Bucket digging force lb

45,000

42,110

Bucket speed (digging)* sec

3.2

3.2

Bucket digging force/speed

14,063

13,159

Bucket power ratio

1.07

1.00

3

9

PRODUCTIVITY FEATURES

The high output engine combined with Komatsus

proven HydrauMind system provides high production

and easy operation

What is HydrauMind?

The HydrauMind system symbolizes the new technology

featured on the

Avance

series where the load sensing

valves and pressure compensation valves handle all

adjustments for individual work applications based on the

proportional pressure and lever stoke sensed. The load

sensing valves are the brains of the avance excavators

allowing full automatic oil ow control without the need for

computer control in all operations.

Benets of HydrauMind system

You can operate all work equipment easily and as

desired.

For example, when the ground condition changes in

digging, the required oil amount automatically ows to

the actuators.

You do not have to worry about lever stroke or the

computer program.

When moving the boom, arm and bucket at the same

time, all equipment works, just like a human hand, at

the optimum combination of speed and power without

using any electronic device.

The nest controllability you have ever experienced.

Changing or adding valves and work equipment is

easy.

1. Work equipment speed is determined only by

lever stroke

Whatever the position of the work equipment control

lever, all the oil ow from the pump goes to the

actuator.

Even if the load on the actuator changes, actuator

speed remains the same.

2. Compound operations not affected by load

When two or more actuators are operated at the

same time, the oil is divided and sent to each actuator

corresponding to the lever stroke, regardless of the

size of the load.

There is no problem of excess oil owing to the circuit

at light load, and operations can be carried out simply

in accordance with the operating feel.

Effective work using HydrauMind system

Fine control with lifting operations is easy.

(for reason 1)

The amount the work

equipment control lever is

moved is constant, so it is

easy to start movement

without being affected by the

size of the load being lifted.

Reverse scraping

operations are easy.

(for reason 1)

The arm can be moved slowly under full power, ensuring

easy operation.

No speed change

due to load

Under

heavy/light load

Lever stroke

W

o

r

k

e

q

u

i

p

m

e

n

t

s

p

e

e

d

P

o

w

e

r

Max.

Lever stroke

FVPM2867

Right-

hand

lever

Left-

hand

lever

Time

B

u

c

k

e

t

s

p

e

e

d

A

r

m

s

p

e

e

d

FVPM2868

Inching

FVPM2869

FVPM2870

PROVEN HYDRAULIC

SYSTEM

3

10

PRODUCTIVITY FEATURES

Work with additional attachments is easy

(for reason 1)

Even when attachments such as breakers or crushers

(which require a different amount of oil) are used, the

ow of oil can be adjusted simply by adjusting the

movement of the control pedal for the attachment

(= spool operating area).

It is easier to fully load the bucket. (for reason 2)

During simultaneous operation, the work equipment

moves slowly at maximum power, without being

inuenced by the other actuators, so it is easy to fully

load the bucket.

It is easy to carry out digging work along the faces

of walls. (for reason 2)

Lateral pushing is powerful allowing digging operations

to be carried out efciently.

The machine can carry out operations easily without

any undue chassis vibration. (for reason 2)

During simultaneous operations, there is no change in

the work equipment speed caused by change in load,

thus, there is minimal chassis vibration.

It is easy transport fresh concrete. (for reason 1 & 2)

Fine control of compound operations can be carried

out easily.

It is easy to scrape down. (for reason 2)

Even without operating the lever to the maximum

position, maximum digging power can be obtained,

making it possible to carry out slow control.

It is easy to operate the crusher and work equipment

simultaneously. (for reason 2)

The oil ow is divided according to the movement of the

lever, regardless of whether the load is heavy or light.

It is easy to dig soft rock or dig up boulders.

(for reason 2)

It is easy to control the boom RAISE, so the cutting

edge does not deviate from the boulders.

Crusher Breaker

FVPM2871

Slowly

FVPM2872

FVPM2873

No shaking or jerking

FVPM2874

FVPM2875

FVPM2876

FVPM2877

FVPM2878

Steady

PROVEN HYDRAULIC

SYSTEM

continued

3

11

PRODUCTIVITY FEATURES

The tail swing radius is lengthened by 150 mm (5.9") and

the counterweight is increased by 50 kg (110 lb.) to

improve the balance and stability of the machine.

1. Smooth mode

While gathering blasted rocks with the arm, lifting of

machine front portion is prevented and shock due to

machine falling is reduced. As a result, gathering

material with arm is executed smoothly. (This is

especially effective for gathering work from 1m (3'3")

under-ground to the surface.) In addition, this is

effective for scraping down facings loosened by

blasting (dealing with oating stones).

2. Power mode

Boom pushing force is increased, ditch digging and

box digging operation on hard ground are improved.

16% increase

(Compared with PC300LC-6)

Lateral stability

Model

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Item

Lateral stability (ratio)

116

100

Two boom settings switch

Boom raise

Scraping of cutting face

GREATLY INCREASED

STABILITY

TWO BOOM SETTINGS

3

12

PRODUCTIVITY FEATURES

Drawbar pull increased

Drawbar pull is increased 34.3 kN (3500 kgf/7700 lb) by

changing of nal drive reduction ratio.

PC300LC-7s maneuverability on rough ground or slope is

improved by improvement of travel performance.

Although the maximum drawbar pull is 431 kgf (950 lb.)

less than CAT 330B, the drawbar pull per operating

weight which is a reference index of the steering

performance is larger.

Travel performance is improved by utilizing travel junction valve,

increasing engine horsepower and drawbar pull.

* 3-speed auto-shift is available as a part of optional multi-

function color monitor (Deluxe spec)

Automatic gear shifting function

The automatic gear shifting function selects Hi or Lo

gears at the ideal points according to the load.

Comparison of steering performance:

PC300LC-7 can turn smoothly with the high steering

performance.

Remark: Steering index: An index to show how the

machine can be steered easily. The larger the steering

index is, the more easily the machine can be steered.

Comparison of uphill travel speed

Travel speed on 20-degree uphill slope with Hi and Lo

Model

Komatsu

PC300LC-7

Komatsu

PC300LC-6 Item

Maximum

drawbar pull

lb

59,300

51,600

Drawbar pull/

operating weight

0.81

0.71

Travel speed

km/h

(mph)

*5.5/3.2

(3.4/2.8/2.0)

5.5/4.5/3.2

(3.4/2.8/2.3)

Automatic-shift

Available

Available

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Steering index

1.38

1.18

Steering index =

Max. drawbar pull x Track gauge

x multiplier

Operating weight x Length of track on ground

unit: km/h (mph)

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Uphill travel speed

km/h

(mph)

2.8/2.7

(1.7/1.7)

2.7/2.7

(1.7/1.7)

IMPROVEMENT OF TRAVEL

PERFORMANCE

3

13

PRODUCTIVITY FEATURES

Improvement of travel performance

When machine travels straight

Oil of the same quantity ows through the travel junction

valve to both travel motors so the machine will travel

straight.

When machine is steered

The travel junction valve is closed and oil ows separately

to each travel motor, thus the machine can turn smoothly

according to the operation of the travel lever.

When machine travels uphill (Operation of work

equipment + Travel)

The travel junction valve is opened and oil of the same

quantity ows constantly from 1 pump to both travel

motors, thus the machine can travel and work

simultaneously.

The travel junction valve is installed in the control valve to improve the straight travel performance, steering

performance, and gradeability.

IMPROVEMENT OF TRAVEL

PERFORMANCE

continued

4

14

RELIABILITY & DURABILITY

FEATURES

The PC300LC-7 track link has a durable strut similar to

that of the PC300LC-6.

In addition, the square nuts are utilized to reduce drag

and allow higher working efciency.

Grease Sealed Track provides excellent undercarriage

durability

(1) Boom

The cross-section structure of the boom is enlarged to

increase the strength of the boom by 9%.

FZPM2821

Strut added

Square nut used

Comparison of arm strength

Unit: mm (in)

PC300LC-7

PC300LC-6

L1

832 (32.8")

786 (30.9")

L2

443 (17.4")

443 (17.4")

t1

19 (0.75")

19 (0.75")

t2

19 (0.75")

19 (0.75")

t3

19 (0.75")

19 (0.75")

Cross-sectional strength (ratio)

109

100

A

A

FVPM2853

L2

t

2

t

1

t3

L

1

FVPM2856A

Section A-A

IMPROVED DURABILITY OF

TRACK LINK

REINFORCEMENT OF WORK

EQUIPMENT

4

15

RELIABILITY & DURABILITY

FEATURES

(2) Arm

The cross-section structure of the arm is enlarged to

increase the strength of the boom about 35%.

(3) Link and bucket

Improvement in reliability of electrical parts

Waterproong performance on junction in wiring

harness is improved.

Heat shrink tube with seal is used to sleeve caulking

parts of junction to improve waterproong

performance.

Ground connection improved

Following measures are used to improve ground

connection performance.

Tightening of plural ground connection cables is

discontinued.

Centralized ground connection is discontinued,

and individual ground connection is utilized to

improve reliability of ground connection.

Comparison of arm strength

Unit: mm (in)

PC300LC-7

PC300LC-6

L1

819 (32.2")

709 (27.9")

L2

310 (12.2")

310 (12.2")

t1

14 (0.55")

14 (0.55")

t2

14 (0.55")

14 (0.55")

t3

25 (0.98")

25 (0.98")

Cross- sectional strength (ratio)

135

100

B

B

FVPM2854A

L2

L

1

t3

t

2

t

1

FVPM2855A

Section B-B

O-ring is used for link

and bucket connecting part to

prevent dust entry and improve

retention of sealing grease.

FZPM2806

REINFORCEMENT OF WORK

EQUIPMENT

continued

IMPROVEMENT IN

RELIABILITY OF

ELECTRIC PARTS

4

16

RELIABILITY &

DURABILITY FEATURES

The PC300LC-7 comes standard with the DT-type

electrical harness connectors that can withstand higher

terminal voltage. The connecting wires are individually

sealed with rubber for improved water and vibration

resistance.

DT connectors are adopted in the electrical harness for

improved reliability and durability in severe environmental

conditions due to heat, water and vibration.

The hydraulic hose seal method has been changed from

a conventional taper seal to the O-ring seal. This provides

improved sealing performance during vibration and shock

loads.

PC300LC-7 PC300LC-6

FZPM2908

DT CONNECTORS

O-RING FACE SEAL

5

17

OPERATOR COMFORT

The operating space inside the cab conforms to the

working space standard of ISO (PC300LC-6 does as

well).

Even a large operator should be satised with the wide

space in the cab. Since the wide door is installed, the

operator can get in and out easily.

Full at reclined seat with headrest

The large cab enables full at reclining of the seat

back with headrest for relaxing rest on a break.

Seat sliding travel is increased

Seat sliding travel is increased 120 mm (4.7") from 220

mm (8.7") to 340 mm (13.4") by use of large cab.

Foot space (distance from travel control lever to seat)

is enlarged 113 mm (4.4").

(Compared to PC300LC-6)

Cab volume

14% increase

Height

+11 mm (0.4")

(Conforms to ISO)

Width

+10 mm (0.4")

(Conforms to ISO)

Foot space

+29 mm (1.1")

Model

Item

Komatsu

Komatsu

PC300LC-7

PC300LC-6

Volume m

3

(yd

3

)

2.67 (3.49)

2.34 (3.06)

Inside dimensions

Width mm(ft.in)

930 (3'1")

920 (3'0")

Length mm(ft.in)

1650 (5'5")

1560 (5'1")

Height mm(ft.in)

1595 (5'3")

1584 (5'2")

PC300LC-7

PC300LC-6

Reclining angle

72

36

PC300LC-7

PC300LC-6

Seat sliding travel mm(in)

160 (6.3")

100 (3.9")

Console sliding travel mm(in)

180 (7.1")

120 (4.7")

LARGE-SIZE CAB

5

18

OPERATOR COMFORT

The engine sound, swinging sound, and oil over relief

sound are lowered signicantly.

Operate the PC300LC-7 and you will appreciate the low

noise design.

Noise at operators ear Countermeasure to lower noise

Comparison of noise level at the operators ears

PC300LC-6: 79 dB)

Noise working

74 dB (A)

PC300LC-6: 84.5 dB (A)

Noise swinging

81 dB (A)

PC300LC-6: 78 dB (A)

Noise at relief

73.5 dB (A)

Optimum arrangement of

sound suppressing material

Cab damper mounting

Blocking of holes on floor

Seal between cab and floor

High-rigidity pressed cab

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Noise working dB

74

79

Noise swinging dB (A)

81

84.5

Noise relief dB (A)

73.5

78

SUPER SILENT CAB

5

19

OPERATOR COMFORT

The revolutionary cab damper mounting is a rst in the

industry. This cab damper mounting prevents the operator

from vibrating even if the machine body vibrates.

Vibration is reduced signicantly by the effects of this cab

damper mounting and the reinforced deck on both sides.

dB (VL) is an index of vibration level. As it is increased,

vibration is increased and operator comfort is lowered.

Comparison of cab mount

120

130 110

100

90

80

70

60

110

100

90

80

Multi-layer cab

viscous

damper

Multi-layer cab

viscous

damper

Damper

mounting

Damper

mounting

120

115

96

80

77.5 94

Vibration of floor under

the operator's foot

[dB (VL)]

Traveling noise

at operator's ear

[dB (A)]

T

r

a

v

e

l

l

e

v

e

l

g

r

o

u

n

d

T

r

a

v

e

l

l

e

v

e

l

g

r

o

u

n

d

T

r

a

v

e

l

i

n

g

o

v

e

r

o

b

s

t

a

c

l

e

w

i

t

h

o

n

e

s

i

d

e

t

r

a

c

k

-5

-2

-5 dB (VL)

Vibration of oor under operators feet

PC300LC-6: 120 dB (VL)

FVPM2753

Floor vibration

(When either track rides over object at forward Hi gear)

Multi-layer viscous

Cab damper mount

Rubber

Silicon oil

Rubber

Silicon Oil

Spring

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Cab mount

Cab damper

mounting

Multi-layer

viscous

CAB DAMPER

5

20

OPERATOR COMFORT

Automatic air conditioner

A 27,379 BTU (6,900 kcal) (SAE) air conditioner is

utilized. The bi-level control function keeps the operators

head and feet cool and warm respectively. This improved

air ow function keeps the inside of the cab comfortable

throughout the year.

Pressurized cab

The airtight cab is utilized to prevent entry of dust even in

dusty environment. Since the airtightness of the cab is

improved, the internal pressure is increased to 6.0 mmAq

(0.2 inAq) when the air conditioner is operated (in the

fresh-air-in mode).

The internal pressure of the cab of PC300LC-7 is

increased to 9 mmAq (0.35 inAq) by employing the xed

one-piece glass for the front window. This internal

pressure prevents dust from entering the cab.

The anged oor mat is employed so that the inside of the

cab can be washed with water. Since the oor inclines

gently toward the door of the cab, water is drained easily.

Additional water can be drained off through the draining

holes at the front part of the oor under the mat.

FVPM2790

Comparison of air conditioner (Measured value)

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Type

Full-auto

Manual

Cooling capacity BTU/h (kcal/h) [SAE]

27,379 (6900)

27, 379 ( 6900)

Heating capacity BTU/h (kcal/h) [SAE]

25,792 (6500)

25, 792 ( 6500)

Pressurized value [mmAq (inAq)]*

6.0 (0.2) / 9.0 (0.35)

1.5 (0.06)

CIRCULATION OF AIR IN CAB

TO KEEP CLEANLINESS

INCREASED CAB

PRESSURIZATION

WASHABLE FLOOR MAT

5

21

OPERATOR COMFORT

The rain visor, sun visor and 12-V power supply.

Rain visor

Sun visor

(front and ceiling window)

12-V power supply

CONVENIENT CAB

ACCESSORIES

CONVENIENCE OPTIONS

5

22

OPERATOR COMFORT

The front window utilizes an assisted opening method,

facilitating front window operation.

Additionally, a front lower window glass storage space is

provided in front of rear window.

Total blind angles at eye point have been reduced from 98 to 64 degrees.

Roller unit

One-touch lock

Front lower window glass

storage space

Front visibility

Since the cab is made by pressed steel, the

pillars have proper rigidity and the front blind

angle is reduced by about 25%.

Ultra wide visibility is obtained.

Right visibility

The right pillar is eliminated to increase the

right visibility.

FVPM2812

Blind angle

Front

98 degree

64 degree

PC220LC-6 PC220LC-7

ASSISTED PULL-UP FRONT

WINDOW

IMPROVED VISIBILITY

6

23

EASY MAINTENANCE & INSPECTION

The space between the radiator and oil cooler is

increased so that the radiator can be easily cleaned with

compressed air.

The radiator and oil cooler can be removed and installed

independently and easily.

Easy cleaning with compressed air

(Remove the cover between the radiator and oil cooler.)

Independent removal and

installation of radiator

Independent removal and

installation of oil cooler

RADIATOR AND OIL COOLER

6

24

EASY MAINTENANCE & INSPECTION

The engine oil lter is remotely mounted for easy access.

In addition, the engine oil drain valve (Eco valve) is

installed with which the operator can drain the engine oil

to be replaced easily without getting their hands oily.

The water separator with integral lter is installed as

standard to remove water from fuel and prevent fuel

system trouble.

When left rear

cover is opened

Engine oil filter

Engine oil drain valve (Eco valve)

Fuel drain valve (Remote mounted)

Water separator

When right front cover is opened

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Water separator

Standard

Optional

Fuel drain valve remote mount

Available

Not available

ENGINE OIL AND FILTER

FUEL LINE

6

25

EASY MAINTENANCE & INSPECTION

The fuel tank capacity is increased from 540 to 605

liters (143 to 160 U.S. gal).

The inside (bottom) of the fuel tank is made of a ZINC

plated steel sheet to prevent rust.

The fuel ller and strainer are improved so that a

large-sized fuel gun can be used and fuel will not

spout out while fuel is supplied. Fuel can be supplied

automatically (The operator may release the fuel gun

while supplying fuel).

The shape of the track frame housing is changed so

that dirt and sand will ow outward easily and will not

be trapped.

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Fuel tank

capacity

liter

(U.S.gal)

605

(160)

540

(143)

48

(1.9")

(2.2")

1

3

0

(

5

.

1

"

)

2

2

0

(

8

.

7

"

)

56

FVPM2828

4

0

6

(

1

'

4

"

)

3

4

4

(

1

'

2

"

)

FVPM2924

FUEL TANK

TRACK FRAME MUD

REMOVAL

6

26

EASY MAINTENANCE & INSPECTION

The replacement interval of the oil and lters is extended

by employing high-performance ltration material.

Since the high-performance ltration material has ner

bers and more pores, the dirt capturing capacity of the

lter is increased.

(1) Hydraulic oil lter

The replacement interval is increased and the lter size is

reduced by using microglass (high-performance ltration

material).

(2) Engine oil lter

The lter paper is changed from the cellulose type to

strata pore type having higher dirt capturing capacity.

Conventional hydraulic

oil filter

New hydraulic oil filter

4

5

0

(

1

7

.

7

"

)

2

0

0

(

7

.

9

"

)

FZPM2775

Conventional

hydraulic oil filter

New hydraulic

oil filter

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Engine oil h

500

250

Engine oil lter h

500

250

Hydraulic oil h

5000

5000

Hydraulic oil lter h

1000

500

Fuel lter h

500

500

ENGINE AND HYDRAULIC

OIL FILTER

6

27

EASY MAINTENANCE & INSPECTION

* : Replacement interval depends on job condition.

Please ll local parts unit price and lubricant cost per liter

(US gal) and calculate parts, lubricants and labor cost.

PC300LC-7

Up to 5000 hour lubricants and lter cost calculation table

Interval

(hour)

No of

replace

ments

Parts

unit

price

Parts

cost

Rell capacity

[liter (US gal)]

Amount of

lubricants

[liter (US gal)]

Lubricants

cost/liter

Lubricants

cost

Man

hour

(hour)

Total

man

hour

(hour)

Labor

charge

A A

B A

B A

C A

C

Engine oil lter 500 10

1.0 10.0

Engine oil 500 10 39 (10.3) 390 (103)

Fuel lter 500 10 0.5 5

Air cleaner

element*

2500 2 0.125 0.25

Hydraulic

lter

1000 5 0.5 5.0

Hydraulic oil 5000 1 188 (49.7) 188 (49.7) 2.0 2.0

Hydraulic tank

breather

500 10 0.125 12.5

Swing

machinery oil

1000 5 13.4 (3.5) 67.0 (17.7) 1.02 5.1

Final drive oil 2000 2.5 17.0 (4.5) 85 (22.5) 1.0 2.5

Total 730 (193) 42.5

PC300LC-6

Up to 5000 hour lubricants and lter cost calculation table

Interval

(hour)

No of

replace

ments

Parts

unit

price

Parts

cost

Rell capacity

[liter (US gal)]

Amount of

lubricants

[liter (US gal)]

Lubricants

cost/liter

Lubricants

cost

Man

hour

(hour)

Total

man

hour

(hour)

Labor

charge

A A

B A

B A

C A

C

Engine oil lter 250 20

1.0 20.0

Engine oil 250 20 24.0 (6.3) 480 (126.8)

Fuel lter 500 10 0.5 5

Air cleaner

element*

2500 2 0.125 0.25

Hydraulic

lter

500 10 0.5 5

Hydraulic oil 5000 1 166 (54.2) 205 (54.2) 2.0 2.0

Hydraulic tank

breather

500 10 0.125 12.5

Swing

machinery

oil

1000 5 12.5 (3.3) 62.5 (16.5) 1.02 5.1

Final drive

oil

2000 2.5 18 (4.8) 36 (9.5) 1.0 2.5

Total 824.5 (218) 52.4

LONG REPLACEMENT

INTERVAL PARTS

7

28

SAFETY FEATURES

The PC300LC-7 sets the world safety standards.

Attention:

OPG top guard level 2 is the formal name to which is

changed the name of FOG (or FOGS) by ISO.

Cab has capability for

OPG top guard level 2

compliance with bolt-on

top guard

Tempered green glass

The front glass is

tempered green glass

having high strength. It

also blocks out

ultraviolet rays.

Full-cover fan guard and

thermal guard

These guards prevent the

operator from touching a

hot part or the fan during

inspection of the engine.

Large-sized steps

Large-sized steps are

installed to front and

rear so that the

operator can get on

and off easily.

Retractable-type seat belt

The convenient retractable

seat belt holds the operators

body securely.

Oil splash prevention wall

(Fire wall)

If a hydraulic leak occurs,

the bulkhead between the

pump chamber and engine

compartment prevents the

oil from spraying over the

hot parts.

Lock lever

This lever locks hydraulic

system to prevent

operation by mistake.

Since the engine neutral

start system is utilized, the

engine can start only when

the lock lever is at the

LOCK position.

Anti-skid sheet

The operator does

not slip easily

during inspection,

Large-sized handrail

The operator can get

on and off the machine

safely.

The operator can get

on and off the machine

safely.

Large side mirror

GLOBAL SAFETY DESIGN

7

29

SAFETY FEATURES

The newly designed, fully pressed, and reinforced cab is

manufactured by solid press forming process to attain an

ideal strong frame structure having high rigidity.

This cab complies to OPG top guard level 2 (FOG) with

the optional bolt-on top guard.

The optional bolt-on OPG top guard level 2 and front

full guard level 2 are available (particularly for jobsites

such as demolition, quarry, etc.)

FVPM2747

Model

Item

PC300LC-7

PC300-6LC

Bolt-on OPG top guard level 2 capable cab

Available

N/A

FVPM2748A

FULLY PRESSED CAB

OPG TOP GUARD (OPTION)

8

30

ENVIRONMENTAL FEATURES

The engine meets Tier 2 emission regulations in USA,

and Europe and Japan.

Tier 2 emission regulations

The quantity of NOx and PM (Particulate) must be the fol-

lowing values or below.

PC300LC-7s discharge amount of NOx and PM are reduced by 30% and 32% compared with than that of

PC300LC-6 respectively.

PC300-7 meets the Noise regulation of EU.

The engine sound, swinging sound, and oil relief sound

are lowered signicantly by the following

countermeasures

High cooling efciency aluminum oil cooler is used

Sound suppression cover is installed to form a seal

between the cab and engine room

Sound absorbring materials are optionally arranged.

Noise when swinging is reduced by use of large

capacity low-speed swing motor.

Regulation values

Regulated substances

Unit

EU regulation EPA regulations

Output range of engine

kW 130 225 130 225

Exhaust gas

CO g/kW-h 5.0 5.0

NOx/HC g/kW-h 6.0/1.0 6.4 (Including HC)

Particulate g/kW-h 0.2 0.2

Tier 2 emission 2003 2003

Readiness of various machines to Tier 2 regulations

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Remarks : Conformance

: Non conformance

CLEAN ENGINE

LOW NOISE IN AND OUT OF

OPERATORS CAB

Comparison of dynamic noise

* Measured value

** EU noise regulation applied value.

Model

Item

Komatsu

PC300LC-7

Komatsu

PC300LC-6

Dynamic noise dB

104.5*/106**

107.8

*

8

31

ENVIRONMENTAL FEATURES

The Economy mode is an environment-friendly mode:

Fuel consumption is reduced

Noise is lowered while machine is used at night or in a

jobsite adjacent a residential area

Discharge of CO

2

should be reduced by 20%

When Eco mode is selected

Fuel

consumption

Discharge of

CO2

Production

Ratio to Active mode

Ratio to Active mode

Ratio to PC300-6

Reduction

by 20%

Reduction

by 20%

Equivalent

Heavy duty mode

Recyclable sound absorbing material

made of PET (polyethylene

terephthalate) is utilized

The cab ceiling is made of kenaf (natural fiber)

Recyclable material symbols are put

on all resin parts

All exterior parts are made of steel

SELECT ECONOMY MODE

RECYCLING DESIGN FOR

EFFECTIVE USE OF

RESOURCES

9

32

MULTI-FUNCTION COLOR MONITOR

A newly developed Multi-Function Color Monitor has

multiple functions, such as Working mode selection,

hydraulic pump oil ow adjustment for matching to

attachment, and maintenance interval notice, etc.

Working mode

Service meter

Travel speed

Screen adjustment

switch

Windshield wiper

and washer switch

Automatic deceleration

selector switch

Travel speed selector switch

Working mode

selector switch

Maintenance switch

Selector switch

Fuel level

Hydraulic oil temperature

Engine water temperature

Initial screen

(2 sec)

Checks before

starting

(2 sec)

Display caution

when

abnormality

found

Working mode

and travel

speed display

(2 sec)

Normal screen

Display caution

and error code

when fault

occurs

When maintenance

time is exceeded

(30 sec)

Change Working Mode A B L E

Setting of

travel speed,

auto-decel,

wiper and swing

holding brake

Maintenance table

Oil flow setting

for breaker

in B mode

Oil flow setting

for attachment

when A and E mode

Selection by input operation

Automatically selected

Brightness

adjustment

OUTLINE of MULTI-FUNCTION

COLOR MONITOR

MULTI-FUNCTION COLOR

MONITOR (OPTIONAL)

9

33

MULTI-FUNCTION COLOR MONITOR

Working Mode Selection

PC300LC-7 working mode is changed from 6 to 3-modes

to concentrate hydraulic excavator fundamental

performance.

The Multi-Function Color Monitor has Lifting mode in

addition to the standard three-mode selection (

A

,

E

, and

B

modes).

Hydraulic Pump Oil Flow Adjustment System

When installing attachments (breaker, crusher, etc.) and

B, A, or E mode is selected, it is possible to adjust engine

and hydraulic pump discharge ow to match attachment

characteristics. Selection is possible throughout the LCD

(Liquid Crystal Display).

This system also allows throttling of the attachment side

discharge ow to provide smooth work equipment

movement and compound operation with work equipment

and attachment.

Working Mode Application Advantage

A

Active mode Maximum production/power

Fast cycle times

E

Economy mode Excellent fuel economy

L

Lifting mode Lifting capacity is increased by 7%

B

Breaker mode Optimum engine rpm, hydraulic ow for breaker operation

Selected

with

selector

switch

Flow rate can be selected

from menu according to

breaker.

(When B-mode is selected)

Flow rate can be set,

regardless of menu.

Flow rate can be adjusted

when crusher is used.

(When A-mode or E-mode

is selected)

SIMPLIFIED WORKING

MODE

HYDRAULIC PUMP OIL

FLOW ADJUSTMENT

SYSTEM

9

34

MULTI-FUNCTION COLOR MONITOR

Automatic Three-Travel Speed

Travel speed is automatically shifted from high to low

speed according to the pressure of the travel. This

optional system is available as part of the Multi-Function

Color Monitor.

Lifting Mode

When the Lifting mode is selected, lifting capacity is

increased by 7 % raising hydraulic pressure.

EMMS (Equipment Management Monitoring System)

Display of faults and function of checking machine

condition for faults

Display of faults

If the engine oil level, cooling water level, etc. is

abnormal, it is displayed on the LCD monitor in the

operator's cab.

Function of checking machine condition for faults

The oil pressure, engine speed, etc. can be displayed on

the LCD monitor. With this function, the downtime can be

minimized.

High Mid Low

Travel Speed

5.5 km/h

3.4 mph

4.5 km/h

2.8 mph

3.2 km/h

2.0 mph

When

abnormal

In check

mode

AUTOMATIC THREE TRAVEL

SPEED/LIFTING MODE

EMMS

9

35

MULTI-FUNCTION COLOR MONITOR

Maintenance Function

Monitor informs replacement time of oil and lters on

LCD when the replacement interval is reached.

Maintenance History Data Memory Function

Monitor stores maintenance data, such as engine oil

replacement, etc.

Trouble Data Memory Function

Monitor stores abnormalities for effective troubleshooting.

Selection with

maintenance switch

Time to replace is displayed.

Set item/time and current

time are displayed.

EMMS, MAINTENANCE

FUNCTION

EMMS, DATA MEMORY

FUNCTION

10

36

WORK EQUIPMENT

Optional Bushing for Work Equipment

BMRC bushings are used for the work equipment, SCSH

bushings for the bucket, and Tungsten Carbide injected

for bushing ends of arm top to lengthen the greasing

interval.

BMRC (Beta Matrix Reinforced Copper Alloy)

Combination of sintered copper layer impregnated with oil

and back metal (S45C).

SCSH (Steel Copper Sinter Hard Material)

Sintered iron (carburized) containing special lubricant in

its pores and hard particles diffused in it to heighten

scufng resistance and wear resistance.

Tungsten Carbide Injected

Tungsten carbide is injected over the bushing ends to

form a hard lm and increase the wear resistance of the

contact faces signicantly.

Work equipment lubrication interval

unit: hours

Tungsten Carbide

Injected

PC300LC-7

PC300-LC6

Boom foot and boom

cylinder bottom bushing

500

50

All except bucket

500

100

Hard Particles Deffused

Special Lubricants

Contained in Pores

Cu (Copper)

Backing metal (steel)

Oil Contained Powder Metallurgy

Layer Thickness 2 mm 0.08"

Changed from steel bushing

to BMRC bushing

Changed from high tensile strength

brass bushing to SCSH bushing

Changed from steel bushing

to SCSH bushing

Changed from steel bushing

to SCSH bushing

Arm top: Tungsten carbide thermal spraying

Resin made shim

Resin made shims are used for

work equipment pin connections

(except bucket connections) to

reduce noise.

Resin made shims

are used for the

encircled parts.

GREASING INTERVAL

EXTENDED

11

37

ATTACHMENTS & OPTIONAL

EQUIPMENT

1. Outline of piping for one attachment

Piping is provided to the top of arm to install one

attachment (breaker or crusher etc.) easily.

(1) Low-pressure accumlator

The low-pressure accumulator is installed as standard on

the return side to reduce the effects of deterioration of the

breaker on the machine body. The optional high-pressure

accumulator on the feed side is also available.

(3) Added lter for breaker

The additional lter is installed as standard to the breaker

circuit.

(4) Automatic changer valve

The automatic changer valve for selecting single and

double operations is installed.

(2) Stop valve

(5) In-line lter

The in-line lters are installed as standard to protect the

hydraulic equipment on the machine.

Accumlator

(low-pressure)

Added filter for breaker

In-line filter

Stop valve

Control pedal

FVPM2850

Low-pressure accumlator

Added filter for breaker

Automatic

changer valve

In-line filters

PIPING FOR ONE

ATTACHMENT

11

38

ATTACHMENTS &

OPTIONAL EQUIPMENT

2. Automatic changeover function for attachments

circuit

Automatic changeover function is added to attachment

circuit by selection of working mode.

.

3. Function of adjusting oil ow amount in attachment with multi-color monitor

With the multi-color monitor, the operator can select oil

ow amount matched to the characteristics of the

installed attachment, watching the liquid crystal display

panel in the operator's cab.

When Selecting A or E mode

Double-acting attachmnent circuit, two-pump discharge and high

pressure safety valve are selected.

(When simultaneous operation, oil ow to attachment is throttled)

When Selecting B mode

Single-action attachment circuit, one-pump discharge and low-pressure

safety valve are selected.

Breaker(B) mode

Oil ow amount other than the

left can be selected.

Oil ow amount matched to

installed breaker can be selected.

Selection of oil ow amount

PIPING FOR ONE

ATTACHMENT

continued

11

39

ATTACHMENTS & OPTIONAL

EQUIPMENT

Detail of Control

The throttle EPC valve is installed on the upstream side of

the attachment PPC valve. If the operator adjusts the oil

ow amount on the monitor, the EPC valve is throttled

(the pressure is lowered) to adjust the ow amount.

If the boom is raised and the attachment is operated

simultaneously, the oil ow amount on the attachment

side is reduced automatically. With this function, the

operator can move the work equipment smoothly (in the

"A" or "E" mode).

PIPING FOR ONE

ATTACHMENT

continued

12

40

INTERCHANGEABILITY

Interchangeability between PC300LC-7 and PC300LC-6

: Interchangeable : Not interchangeable

Device Interchange Reason for non interchangeable

U

n

i

t

Engine assy New Current

Conformance to secondary emission regulations. Model changed (SAA6D114E

SAA6D108E). Output increased

(242 HP

232 HP). Remote oil lter. Fan diameter changed 870 (34.3")

850 (33.5").

Main pump assy New Current

Model changed (HPV125 + 125

HPV160 + 160). Pump capacity changed (140 cc/rev

131 cc/rev). TVC replaced

with PC valve. LS-EPC valve mounted on pump.

Main valve assy New Current

Pump merge-divider valve assembly changed (Equipped with built-in self-pressure reducing valve). Boom lock valve

and lift check valve mounted on valves. Main relief pressure changed.

Swing motor assy New Current Large capacity motor used (229

160.7cc/rec)

Boom cylinder New Current

Min. length reduced.

BMRC bushing employed (Greasing interval: 500 H).

Arm cylinder New Current

Stroke changed.

SCSH bushing employed (Greasing interval: 500 H).

Bucket cylinder New Current Min. length reduced.

Swivel joint New Current

Port position changed.

Installation pitch changed.

Swing circle New Current

Swing machinery New Current Reduction ratio changed.

Idler New Current Made of steel plate.

Idler cushion New Current Spring force increased.

Track roller New Current Seal improved.

Carrier roller New Current Size reduced.

Shoe New Current Square nut utilized.

Final drive New Current Reduction ratio increased.

Travel motor New Current Drawbar pull increased (103.5cc/rev

110.1cc/rev)

Sprocket New Current

Cooling assy New Current Aluminum oil cooler used

Operator cab New Current New design (Same as PC200-7)

Operator seat New Current Sliding distance increased. Color and design of seat changed (Same with PC200-7).

Hydraulic tank New Current Size reduced. Return lter built in tank.

Fuel tank New Current Capacity increased (605

l

540

l

)

Boom assy New Current Piping different. For change of attachments of Model 6, piping must be changed. Cylinder boss position changed.

Arm assy New Current

Cylinder boss position changed.

SCSH bushing utilized (Greasing interval: 500 H).

Bucket assy New Current WC thermally sprayed bushing employed (Greasing interval: 250 H).

Quarry bucket assy New Current

Corner tooth and long-life tooth utilized. Tooth installation angle changed. Interchangeable, however.

WC thermally sprayed utilized.

Revolving frame New Current Structure changed.

Track frame New Current

Installation of carrier roller different.

Installation of swivel different.

Machine cab New Current New design

Controller New Current New system

Monitor New Current

New design (Multi-color monitor).

Work mode changed.

Work equipment PPC valve New Current Tolerance of output pressure to stroke different.

Travel PPC valve New Current Differential pressure signal added.

Engine control New Current Depends on engine.

Solenoid valve New Current

New 7-spool valve

DT connector utilized.

Air conditioner New Current Automatic air conditioner utilized.

Counterweight New Current Shape changed.

C

o

n

s

u

m

a

b

l

e

p

a

r

t

s

Engine oil lter New Current Replacement interval changed 250h

500h

Hyd. oil return lter New Current

Replacement interval changed 500h

1000h

Overall length reduced.

Fuel lter New Current

Air cleaner element New Current Model changed

Fan belt New Current Length changed

Hyd. hose New Current Length changed

Bucket tooth New Current

Quarry bucket tooth New Current Long-life tooth employed. Interchangeable.

Bucket adapter New Current

Quarry bucket adapter New Current Installation angles of corner tooth and tooth changed.

Side cutter New Current

13

41

COMPETITIVE SPECIFICATIONS

PC300LC-7 VS. COMPETITIVE MACHINES

** SAE Rating

*** At Power Max.

Manufacturer Model

Item

KOMATSU

PC300LC-7

KOMATSU

PC300LC-6

CATERPILLAR

330CL

HITACHI

ZX330LC

FLYWHEEL HORSEPOWER:

SAE J1349

DIN 6270

HP (kW)/rpm

PS (kW)/rpm

242 (180)/1900

245 (180)/1900

232 (172)/2050

235 (172)/2050

244 (182)/1800

247 (182)/1800

247 (184)/2000

250 (184)/2000

BUCKET CAPACITY RANGE:

SAE heaped

CECE heaped

m

3

(cu.yd)

0.84 to 1.82

(1.10 to 2.38)

0.52 to 1.80

(0.68 to 2.35)

0.48 to 1.60

(0.63 to 2.09)

0.7 to 2.7

(1.00 to 3.5)

1.15 to 1.86

(1.15 to 2.42)

OPERATING WEIGHT * kg (lb)

32830 (72,830)

31900 (70,330) 35100 (77,400) 33300 (73,500)

PERFORMANCE:

Swing speed

Max. travel speed: High

Low

Arm crowd force ** *

Bucket digging force ** *

rpm

km/h (MPH)

kg (lb)

kg (lb)

9.5

5.5(3.4)

3.2(2.0)

17400(38,360)***

23100(50,930)***

10.0

5.5(3.4)

3.7(2.3)

14300(31,530)

19100(42,110)

10.0

5.0(3.1)

2.7(1.7)

16400(36,300)

20300(44,700)

11.8

5.5(3.4)

3.8(2.4)

16800(37,000)

21100(46,500)

WORKING RANGE:

Max. digging height *

Max. dumping height *

Max. digging depth *

Max. vertical wall *

digging depth

Max. digging reach *

at ground level

mm (ft.in)

10210(33' 6")

7110(23' 4")

7380(24' 3")

6480(21' 3")

10920(35'10")

10210(33' 6")

7110(23' 4")

7380(24' 3")

6480(21' 3")

10920(35'10")

10340(33'11")

7200(23' 7")

7390(24' 3")

6490(21' 4")

10920(35'10")

10230(33' 7")

7130(23' 5")

7380(24' 3")

6480(21' 3")

11100(36' 5")

DIMENSIONS:

Overall length *

Overall width *

Overall height *

Ground clearance

Tail swing radius

Track length

Track gauge

mm (ft.in)

11140(36' 7")

3290(10'10")

3280(10' 9")

500( 1' 8")

3450(11' 4")

4955(16' 3")

2590( 8' 6")

10935(35'11")

3290(10'10")

3255(10' 8")

500( 1' 8")

3300(10'10")

4955(16' 3")

2590( 8' 6")

11140(36' 9")

3440(11' 3")

3350(11' 0")

510( 1' 8")

3500(11' 6")

5020(16' 6")

2590( 8' 6")

10970(36' 0")

3390(11' 1")

3230(10' 7")

500( 1' 8")

3310(10'10")

4940(16' 3")

2590( 8' 6")

ENGINE:

Model

No. of cylinders -

bore x stroke

Piston displacement

mm (in)

ltr.(cu.in)

Komatsu

SAA6D114E

6 - 114 x 135

(4.49 x 5.31)

8.27 (505)

Komatsu

SA6D114E-1

6 - 114 x 114

(4.49 x 4.49)

8.3 (504.5)

Caterpillar

C9

6 - 112 x 149

(4.41 x 5.87)

8.8 (537)

Isuzu

AA-6HK1X

6- 115 x 125

(4.53 x 4.92)

7.79 (475)

HYDRAULIC SYSTEM:

Hydraulic pump

Max. ow (excl. sub pump)

Relief valve setting

ltr.(USgal)/min

kg/cm

2

(psi)

Variable capacity

535(141)

380(5400)

Variable capacity

480(126.8)

355(5050)

Variable capacity

560(148)

343(4980)

Variable capacity

580(153)

320(4550)

TRACK SHOES:

Width/Ground pressure

mm (in)/

kg/cm

2

(psi)

700 (27.6)/0.54 (7.7)

800 (31.5)/0.47 (6.7)

700 (27.6)/0.53 (7.5)

600 (23.6)/0.61 (8.7)

800 (31.5)/0.47 (6.7)

850 (34.0) 800 (31.5)/0.47 (6.7)

Fuel tank rell capacity ltr.(USgal)

605 (160)

540 (143) 618 (163) 560 (148)

*) SPEC. CONDITIONS

Boom

Arm

Bucket (SAE heaped)

Track shoes: Type

Width

mm (ft.in)

mm (ft.in)

m

3

(cu.yd)

mm (in)

6470(21'3")

3185(10'5")

0.88(1.15)

Triple

800(31.5)

6470(21'3")

3185(10'5")

1.40(1.83)

Triple

700(27.6)

6500(21' 4")

3200(10' 6")

1.62(2.12)

Triple

850(34)

6400(21'0")

3200(10'6")

1.40(1.83)

Triple

800(31)

Refer No.

X21SP20010082

X21SP970013 AEHQ5463

13

42

COMPETITIVE SPECIFICATIONS

PC300LC-7 VS. COMPETITIVE MACHINES

CONTINUED

** SAE Rating

*** At Power Max.

Manufacturer Model

Item

KOBELCO

SK330LC

JOHN DEERE

330CLC

FLYWHEEL HORSEPOWER:

SAE J1349

DIN 6270

HP (kW)/rpm

PS (kW)/rpm

238 (177)/2200

241 (177)/2200

246 (183)/2000

249 (183)/2000

BUCKET CAPACITY RANGE:

SAE heaped

CECE heaped

m

3

(cu.yd)

0.67 to 1.81

(0.875 to 2.375)

0.92 to 2.09

(1.20 to 2.74)

OPERATING WEIGHT * kg (lb) 35300 (77,800) 33058 (72,800)

PERFORMANCE:

Swing speed

Max. travel speed: High

Low

Arm crowd force ** *

Bucket digging force ** *

rpm

km/h (MPH)

kg (lb)

kg (lb)

9.1

5.8(3.6)

3.4(2.1)

17917(39,500)***

22180(48,900)***

11.6

5.5(3.4)

3.6(2.2)

16963(37,396)***

21873(48,220)***

WORKING RANGE:

Max. digging height *

Max. dumping height *

Max. digging depth *

Max. vertical wall *

digging depth

Max. digging reach *

at ground level

mm (ft.in)

10490(34' 5")

7290(23'11")

7490(24' 7")

6570(21' 7")

11030(36' 2")

10190(33' 5")

7210(23' 8")

7300(23' 11")

6400(21' 0")

10840(35' 7")

DIMENSIONS:

Overall length *

Overall width *

Overall height *

Ground clearance

Tail swing radius

Track length

Track gauge

mm (ft.in)

11200(36' 9")

3400(11' 2")

3360(11' 0")

500( 1' 8")

3500(11' 6")

4980(16' 4")

2600( 8' 6")

11090(36' 5")

3390(11' 1")

3230(10' 7")

500( 1' 8")

3320(10'11")

4940(16' 2")

2590( 8' 6")

ENGINE:

Model

No. of cylinders -

bore x stroke

Piston displacement

mm (in)

ltr.(cu.in)

Mitsubishi

GD16-TLEB

6-118 x 115

(4.65 x 4.53)

7.55(461)

John Deere

6081H

8.1(494)

HYDRAULIC SYSTEM:

Hydraulic pump

Max. ow (excl. sub pump)

Relief valve setting

ltr.(USgal)/min

kg/cm

2

(psi)

Variable capacity

506(134)

350(4980)

Variable capacity

584(154)

350(4980)

TRACK SHOES:

Width/Ground pressure

mm (in)/

kg/cm

2

(psi)

800 (31.5)/0.51 (7.3) 800 (31.5)/0.47 (6.75)

Fuel tank rell capacity ltr.(USgal) 560 (148) 560 (148)

*) SPEC. CONDITIONS

Boom

Arm

Bucket (SAE heaped)

Track shoes: Type

Width

mm (ft.in)

mm (ft.in)

m

3

(cu.yd)

mm (in)

INA

3300(10'10")

1.40(1.83)

Triple

800(31)

INA

3200(10' 6")

1.76(2.30)

Triple

800(31)

Refer No. MAR 2000-355 DKAX330CLC

Materials and specifications are subject to change without notice

is a trademark of Komatsu Ltd. Japan

This information has been gathered to provide data on the performance of KOMATSU and competitive

machines under actual job conditions. Every effort was made to ensure reliable results. However,

because of the many variables peculiar to each job (including material characteristics, operator ef-

ciency, labor and other costs, haul road conditions and altitude), neither KOMATSU LTD., nor any of its

subsidiaries or distributors can or does warrant expressly or implicitly that Komatsu or competitive

equipment referred to will achieve the performance or incur the costs indicated under other, though

similar, circumstances.

The information contained herein is intended for circulation only to Komatsu employees and to those

distributor employees, whose duties require knowledge of such reports and intended solely for the

information and training of these readers. UNAUTHORIZED USE OF THIS DOCUMENT IS HEREBY

PROHIBITED AND THOSE RESPONSIBLE FOR SUCH USE SHALL BE SOLELY RESPONSIBLE

FOR ANY DAMAGES WITH THIRD PARTIES THAT MAY INCUR AS A RESULT OF SUCH USE. Any

reproduction of this release without the foregoing explanation is prohibited.

AEPB332-00 2002 Komatsu Printed in USA D7 (1.5M)CCI DataKom 7/02 (EV-1)

www.KomatsuAmerica.com

Komatsu

440 N. Fairway Dr.

Vernon Hills, IL 60061

S-ar putea să vă placă și

- Cat 307B Control JoystickDocument2 paginiCat 307B Control JoystickAtaa AssaadÎncă nu există evaluări

- Cat336D DL PDFDocument36 paginiCat336D DL PDFMohd AidilÎncă nu există evaluări

- Piston Pump (Steering) High Pressure Stall - Test and AdjustDocument6 paginiPiston Pump (Steering) High Pressure Stall - Test and AdjustDidi PrawiraÎncă nu există evaluări

- Disassemble Fuel Transfer PumpDocument4 paginiDisassemble Fuel Transfer PumpAnonymous cS9UMvhBqÎncă nu există evaluări

- Caterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)Document23 paginiCaterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)kfmuseddk0% (1)

- Boom Cylinder Remove and InstallDocument8 paginiBoom Cylinder Remove and InstallEDSON JONATHAN SALINAS AYALAÎncă nu există evaluări

- Eaton: Medium Duty Piston PumpDocument25 paginiEaton: Medium Duty Piston PumprazvanÎncă nu există evaluări

- Device Test ModeDocument14 paginiDevice Test ModeNay SoeÎncă nu există evaluări

- Inspeccion Ta2 Serial Pab Cat-320cDocument11 paginiInspeccion Ta2 Serial Pab Cat-320cRAMON CALDERONÎncă nu există evaluări

- RDSL Parts List For 320 GC 320 and 323 Ver 8 Updated June 14 2018 Updated LRC Serial NO PrefixDocument7 paginiRDSL Parts List For 320 GC 320 and 323 Ver 8 Updated June 14 2018 Updated LRC Serial NO Prefixvan100% (1)

- 329 D PDFDocument24 pagini329 D PDFCapacitaciones RutasÎncă nu există evaluări

- Cat 320d LRRDocument28 paginiCat 320d LRRt1meÎncă nu există evaluări

- 330, 330 L and 330 LN Excavators 2el00001-Up (Machine) Powered by 3306 Engine (Sebp2198 - 01) - Systems & ComponentsDocument16 pagini330, 330 L and 330 LN Excavators 2el00001-Up (Machine) Powered by 3306 Engine (Sebp2198 - 01) - Systems & ComponentsRZ Emi100% (1)

- DX Competitive Comparison - 070300Document48 paginiDX Competitive Comparison - 070300Fabricio Navarrete100% (1)

- Pump Control Output Flow AdjustDocument3 paginiPump Control Output Flow AdjustSteven Manuputty100% (2)

- Swing Bearing For Excavator PDFDocument1 paginăSwing Bearing For Excavator PDFBoodee PrayÎncă nu există evaluări

- Relief Valve (Pilot) - Test and AdjustDocument3 paginiRelief Valve (Pilot) - Test and Adjustchanlin100% (1)

- 336 CatDocument24 pagini336 CatiwantaseÎncă nu există evaluări

- Spec Excav Pc200Document3 paginiSpec Excav Pc200Soni100% (2)

- Pc200-8 Valve ClearanceDocument3 paginiPc200-8 Valve ClearanceAl FurkhanÎncă nu există evaluări

- 950g Vs Volvo - Komatsu Wa380Document14 pagini950g Vs Volvo - Komatsu Wa380Mohamed BakheetÎncă nu există evaluări

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 paginiHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesÎncă nu există evaluări

- Komatsu Excavator Pc200 6Document3 paginiKomatsu Excavator Pc200 6rameshjakarta100% (5)

- Valvula Relief Pruebas y Ajustes 325blDocument9 paginiValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresÎncă nu există evaluări

- Service Training Malaga 320/323D/324D/325D/330D HYDRAULIC EXCAVATORSDocument7 paginiService Training Malaga 320/323D/324D/325D/330D HYDRAULIC EXCAVATORSAhmed Ramadan100% (1)

- 330D and 336D Excavators Machine SystemsDocument262 pagini330D and 336D Excavators Machine SystemsWALTER EMMANUEL FLORES COSCOÎncă nu există evaluări

- Gear Pump (Pilot) - Test: Testing and AdjustingDocument8 paginiGear Pump (Pilot) - Test: Testing and AdjustingSam SungÎncă nu există evaluări

- Engine Air Intake: Service When IndicatedDocument14 paginiEngine Air Intake: Service When IndicatedLeandro Sienra100% (1)

- D65EX-15 Operational ManualDocument164 paginiD65EX-15 Operational ManualViktor Rada100% (1)

- 320, 320 L and 320 N Operation Hydraulic SystemDocument162 pagini320, 320 L and 320 N Operation Hydraulic SystemF Labio AlexÎncă nu există evaluări

- 14HDocument2 pagini14HWiliam Vega Farias100% (2)

- Manual XP-308B Eng PDFDocument30 paginiManual XP-308B Eng PDFnguyễn quốc hoànÎncă nu există evaluări

- D8R ComplianceDocument17 paginiD8R ComplianceagegnehutamiratÎncă nu există evaluări

- Battery Disconnect Switch 320 Excavator YBP00001-UPDocument3 paginiBattery Disconnect Switch 320 Excavator YBP00001-UPkiagengbrantas heavyequipmentÎncă nu există evaluări

- D65-18, D85-18 and D155AX-8 - 94335Document50 paginiD65-18, D85-18 and D155AX-8 - 94335Valter Leiriao100% (2)

- SE220 英文产品单页Document2 paginiSE220 英文产品单页Karl KarlÎncă nu există evaluări

- m0072944-07 (En-Us) - 00 - Manuals-Service-Modules - TroubleshootingDocument204 paginim0072944-07 (En-Us) - 00 - Manuals-Service-Modules - Troubleshootingmostafa ali100% (1)

- Remove & Install Travel Motor ControllerDocument3 paginiRemove & Install Travel Motor ControllerAbdellatef Bakr50% (2)