Documente Academic

Documente Profesional

Documente Cultură

Springs Course Notes

Încărcat de

ChusnadiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Springs Course Notes

Încărcat de

ChusnadiDrepturi de autor:

Formate disponibile

1

Chapter 13: Springs

with several figures from:

MACHINE DESIGN - An Integrated Approach, 2ed by Robert L. Norton,

Prentice-Hall 2000

Outline

Spring Functions & Types

Helical Springs

Compression

Extension

Torsional

The Function(s) of Springs

Most fundamentally: to STORE ENERGY

Many springs can also: push

pull

twist

Some Review

F

y

k

linear springs: k=F/y

nonlinear springs:

dy

dF

k =

Parallel

k

total

=k

1

+k

2

+k

3

Series

3 2 1

1 1 1 1

k k k k

total

+ + =

Types of Springs

Helical:

Compression

Extension

Torsion

More Springs

Washer Springs:

Beams:

Power springs:

2

Helical Compression

Springs

d diameter of wire

D mean coil diameter

L

f

free length

p pitch

N

t

Total coils

may also need:

D

o

and D

i

Length Terminology

Free Length

Assembled

Length

Max Working

Load

Bottomed

Out

minimum of 10-15%

clash allowance

L

f

L

a

L

m

L

s

End Conditions

Plain

Square

Plain Ground

Square Ground

N

a

=

Active Coils

F

F

F

F

Stresses in Helical

Springs

Spring Index C=D/d

C

C

K where

d

FD

K

s s

2

1 2

,

8

3

max

+

= =

F

F

T

T

Typically:

12 4 C

Curvature Stress

under static loading, local yielding eliminates stress

concentration, so use K

s

under dynamic loading, failure happens below S

y

:

use K

s

for mean, K

w

for alternating

Inner part of spring is a stress concentration

(see Chapter 4)

K

w

includes both the direct shear factor and

the stress concentration factor

C C

C

K where

d

FD

K

w w

615 . 0

4 4

1 4

,

8

3

max

+

= =

Spring Deflection

G d

N FD

y

a

4

3

8

3

Spring Rate

G d

N FD

y

a

4

3

8

a

N D

G d

k

3

4

8

k=F/y

Helical Springs

Compression

Nomenclature

Stress

Deflection and Spring Constant

Static Design

Fatigue Design

Extension

Torsion

Static Spring Design

Inherently iterative

Some values must be set to calculate

stresses, deflections, etc.

Truly Design

there is not one correct answer

must synthesize (a little bit) in addition to

analyze

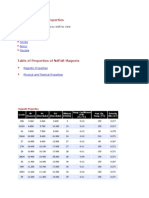

Material Properties

S

ut

ultimate tensile strength

Figure 13-3

Table 13-4 with S

ut

=Ad

b

S

ys

torsional yield strength

Table 13-6 a function of S

ut

and set

Spring/Material

Treatments

Setting

overstress material in same direction as applied

load

increase static load capacity 45-65%

increase energy storage by 100%

use K

s

, not K

w

(stress concentration relieved)

Load Reversal with Springs

Shot Peening

What type of failure would this be most effective

against?

What are You Designing?

Given

F, y

k, y

Find

k

F

Such that:

Safety factor is > 1

Spring will not buckle

Spring will fit in hole, over pin, within vertical space

d, C, D

*

, L

f

*

, N

a

*

, clash

allowance ()

**

, material

**

design variables

+

* - often can calculate from given

** - often given/defined

4

Static Spring Flow Chart

STRESSES

N

s

=S

ys

/

for shut spring if possible

if not, for max working load

if GIVEN F,y, then find k; If GIVEN k, y, then find F

D, K

s

, K

w

material strengths

DEFLECTION

L

f

, y

shut

, F

shut

Three things to know:

effect of d

shortcut to finding d

how to check buckling

ITERATE?

d, C

material

N

a

,

CHECK

buckling, N

shut

, D

i

, D

o

N

shut

=S

ys

/

shut

Static Design: Wire

Diameter

Three things to know:

effect of d

shortcut to finding d

how to check buckling

3

max

8

d

FD

K

s

=

G d

N FD

y

a

4

3

8

*maintain units (in. or mm) for A, b

use Table 13-2 to select standard d near

calculated d

( ) ( ) ( ) | |

) 2 ( 1

1 5 . 0 8

b

m

initial work s

A K

F F C N

d

+

)

`

+ +

=

Based on N

s

=S

sy

/ and above equation for :

K

m

=S

ys

/S

ut

Buckling

Three things to know:

effect of d

shortcut to finding d

how to check buckling

In general;

f

working init

f

L

y y

y

D

L

R S

+

=

= . .

f

D

L

R S = . . < 4 for safe design

Helical Springs

Compression

Nomenclature

Stress

Deflection and Spring Constant

Static Design

Fatigue Design

Torsion

Material Properties

S

us

ultimate shear strength

S

us

0.67 S

ut

S

fw

torsional fatigue strength

Table 13-7 -- function of S

ut

, # of cycles

repeated, room temp, 50% reliability, no corrosion

S

ew

torsional endurance limit

for steel, d < 10mm

see page 816 (=45 ksi (310 MPa) if unpeened,

=67.5 ksi (465 MPa) if peened)

repeated, room temp., 50% reliability, no corrosion

Modified Goodman for

Springs

S

fw

, S

ew

are for torsional strengths, so von

Mises not used

0.5 S

fw

0.5 S

fw

m

R

e

p

e

a

t

e

d

S

fs

C

B

S

us

A

( )

fw us

us fw

fs

S S

S S

S

5 . 0

5 . 0

=

5

Fatigue Safety Factor

0.5 S

fw

0.5 S

fw

m

S

fs

S

us

l

o

a

d

l

i

n

e

S

a

i

m

m

load

m

good

a

a

fs

S

N

a,load

=

a,good

at intersection

( )

( )

a us i m fs

i us fs

fs

S S

S S

N

+

=

on page 628

F

i

=F

min

F

a

=(F

max

-F

min

)/2

F

m

=(F

max

+F

min

)/2

What are you Designing?

Given

F

max

,F

min

, y

k, y

Find

k

F

Such that:

Fatigue Safety Factor is > 1

Shut Static Safety Factor is > 1

Spring will not buckle

Spring is well below natural frequency

Spring will fit in hole, over pin, within vertical space

d, C, D

*

, L

f

*

, N

a

*

, clash

allowance ()

**

, material

**

design variables

+

* - often can calculate from Given

** - often given/defined

Fatigue Spring Design

Strategy

d, C

if GIVEN F,y, then find k; If GIVEN k, y, then find F

N

shut

=S

ys

/

shut

CHECK

buckling, frequency,

N

shut

, D

i

, D

o

D, K

s

, K

w

material strengths

DEFLECTION

L

f

, y

shut

, F

shut

Two things to know:

shortcut to finding d

how to check frequency

ITERATE?

material

N

a

,

STRESSES

( )

( )

a us i m fs

i us fs

fs

S S

S S

N

+

=

Fatigue Design:Wire

Diameter

as before, you can iterate to find d, or you can use an equation

derived from relationships that we already know:

) 2 ( 1

min

1 34 . 1

1

67 . 0

8

b

a w

fw

b

s

fs

fs

m s

fs

F K

S

Ad

F K

N

N

F K

A

CN

d

+

(

(

|

|

.

|

\

|

+

use Table 13-2 to select standard d near

calculated d

Two things to know:

shortcut to finding d

how to check frequency

*maintain units (in. or mm) for A, b

Natural Frequency: Surge

Two things to know:

shortcut to finding d

how to check frequency

Surge == longitudinal resonance

for fixed/fixed end conditions:

a

n

W

kg

f

2

1

= (Hz)

see pages 814-815 for more

ideally, f

n

will be at least 13x more than f

forcing

it should definitely be multiple times bigger

Review of Design Strategy

Find Loading

Select C, d

Find stresses

Determine material properties

Find safety factor

Solve for d, pick standard d

Find stresses

Determine material properties

Check safety factor

Find Loading

Select C, safety factor

ITERATIVE USING d EQUATION

6

Strategy Review

Continued

Find spring constant, N

a

, N

t

Find F

SHUT

(must find lengths and ys to do this)

Find static shut shear stress and safety factor

Check Buckling

Check Surge

Check D

i

, D

o

if pin to fit over, hole to fit in

Consider the Following:

Helical Springs

Compression

Nomenclature

Stress

Deflection and Spring Constant

Static Design

Fatigue Design

Torsion

Torsion Springs

Deflection & Spring Rate

rev

M

k

=

E d

MDN

a

roundwire rev

4

,

2 . 10 =

DN wire of length L

a w

= = EI

ML

w

rev

,

2

1

=

64

4

d

I

=

where,

E d

MDN

a

roundwire rev

4

,

8 . 10 = (if we account for

Friction)

Stresses

(1) Static -Compressive is Max (K

bi

> K

bo

) Inside of Coil

3

max max

32

max

d

M

K

I

c M

K

i i

b b i

= =

) 1 ( 4

1 4

2

=

C C

C C

K

i

b

(2) Fatigue (since fatigue is a tensile stress phenomenon) Outside of Coil

) 1 ( 4

1 4

2

+

+

=

C C

C C

K

o

b

3

max

32

max

d

M

K

o

b o

=

3

min

32

min

d

M

K

o

b o

=

Materials

see Tables 13-13 and 13-14, page 850

follow book on S

ewb

=S

ew

/0.577 for now

7

Strategy

M K

fit over pin (if there is one)

dont exceed stresses

Select C, d

Helical Springs

Compression

Nomenclature

Stress

Deflection and Spring Constant

Static Design

Fatigue Design

Torsion

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- "Raphy" PinaDocument34 pagini"Raphy" PinaMetro Puerto RicoÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Slave Ship JesusDocument8 paginiSlave Ship Jesusj1ford2002Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- McKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaDocument9 paginiMcKissick - 431 Super Champion Snatch Block W Shackle Specs Lengkap Dengan PerhitungannyaChusnadiÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Malala YousafzaiDocument13 paginiMalala YousafzaiAde SihombingÎncă nu există evaluări

- Behavior Theory ABC Model by Thomas KrausDocument28 paginiBehavior Theory ABC Model by Thomas KrausChusnadiÎncă nu există evaluări

- Design of Pressure VesselDocument137 paginiDesign of Pressure VesselAnand Bhandarkar75% (4)

- People Vs ParanaDocument2 paginiPeople Vs ParanaAnonymous fL9dwyfekÎncă nu există evaluări

- Din 15061 Translate EngDocument1 paginăDin 15061 Translate EngMaey Akim50% (2)

- Buku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase RendahDocument240 paginiBuku PUIL Keselamatan Dan Pemasangan Instalasi Listrik Voltase Rendahlamenty55100% (1)

- Safety Engineering IIDocument2 paginiSafety Engineering IIChusnadiÎncă nu există evaluări

- Fatality Assessment and Control EvaluationDocument2 paginiFatality Assessment and Control EvaluationChusnadiÎncă nu există evaluări

- Safety Health and Environmental EbookDocument1 paginăSafety Health and Environmental EbookChusnadiÎncă nu există evaluări

- Marine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5Document1 paginăMarine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5ChusnadiÎncă nu există evaluări

- Welding Standard For Formula StudentDocument1 paginăWelding Standard For Formula StudentChusnadiÎncă nu există evaluări

- Oq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceDocument3 paginiOq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceChusnadiÎncă nu există evaluări

- MSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionDocument2 paginiMSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionChusnadiÎncă nu există evaluări

- Magnet Materials PropertiesDocument6 paginiMagnet Materials PropertiesChusnadiÎncă nu există evaluări

- Popov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952Document1 paginăPopov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952ChusnadiÎncă nu există evaluări

- Construction Criteria Base WBDG Whole Building Design GuideDocument3 paginiConstruction Criteria Base WBDG Whole Building Design GuideChusnadi100% (1)

- Handbook of HYTOPS15000rev10-09Document182 paginiHandbook of HYTOPS15000rev10-09ChusnadiÎncă nu există evaluări

- Index of Materials Science and Engineering HandbookDocument1 paginăIndex of Materials Science and Engineering HandbookChusnadiÎncă nu există evaluări

- Sample Blogger Agreement-14Document3 paginiSample Blogger Agreement-14api-18133493Încă nu există evaluări

- 2018 NFHS Soccer Exam Part 1Document17 pagini2018 NFHS Soccer Exam Part 1MOEDÎncă nu există evaluări

- Isa 620Document15 paginiIsa 620baabasaamÎncă nu există evaluări

- Rainforest Foundation - 2016.04 - Conservation and IPs in The Congo Basin PDFDocument144 paginiRainforest Foundation - 2016.04 - Conservation and IPs in The Congo Basin PDFLaraÎncă nu există evaluări

- Separation of PowersDocument23 paginiSeparation of PowersLubna Iftikhar 4506-FSL/LLB/F15Încă nu există evaluări

- Uy Tong V CADocument3 paginiUy Tong V CAcmv mendozaÎncă nu există evaluări

- Accounting For Insurance Contracts Deferred Tax and Earnings Per ShareDocument2 paginiAccounting For Insurance Contracts Deferred Tax and Earnings Per ShareJanine CamachoÎncă nu există evaluări

- Industries-Heritage Hotel Manila Supervisors Chapter (Nuwhrain-HHMSC) G.R. No. 178296, January 12, 2011Document2 paginiIndustries-Heritage Hotel Manila Supervisors Chapter (Nuwhrain-HHMSC) G.R. No. 178296, January 12, 2011Pilyang SweetÎncă nu există evaluări

- Retro 80s Kidcore Arcade Company Profile Infographics by SlidesgoDocument35 paginiRetro 80s Kidcore Arcade Company Profile Infographics by SlidesgoANAIS GUADALUPE SOLIZ MUNGUIAÎncă nu există evaluări

- VDC: The Weekly Statistical ReportDocument8 paginiVDC: The Weekly Statistical ReportimpunitywatchÎncă nu există evaluări

- Acko Insurance Copy - PDF - Insurance Policy - InsuranceDocument5 paginiAcko Insurance Copy - PDF - Insurance Policy - InsuranceMalaya Ranjan SahuÎncă nu există evaluări

- Notes 1. All Dimensions Are in Millimetres. 2. No Dimension Shall Be Scaled Off, Only Written Dimension To Be FollowedDocument4 paginiNotes 1. All Dimensions Are in Millimetres. 2. No Dimension Shall Be Scaled Off, Only Written Dimension To Be FollowednidhisasidharanÎncă nu există evaluări

- Midterm Org. ManagementDocument5 paginiMidterm Org. Managementnm zuhdiÎncă nu există evaluări

- Andreí Gómez. A Genocidal Geopolitical Conjucture. Contextualising The Destruction of The Union Patriotica in ColombiaDocument261 paginiAndreí Gómez. A Genocidal Geopolitical Conjucture. Contextualising The Destruction of The Union Patriotica in ColombiaAndres Caicedo RamirezÎncă nu există evaluări

- Kalabagh DamDocument40 paginiKalabagh DamwaleedÎncă nu există evaluări

- Stevens V University of Birmingham (2016) 4 All ER 258Document25 paginiStevens V University of Birmingham (2016) 4 All ER 258JYhkÎncă nu există evaluări

- CBF 10 Motion For Provisional Dismissal For Failure To Present WitnessDocument3 paginiCBF 10 Motion For Provisional Dismissal For Failure To Present WitnessAndro DayaoÎncă nu există evaluări

- Sop EnglishDocument42 paginiSop Englishapi-236690310Încă nu există evaluări

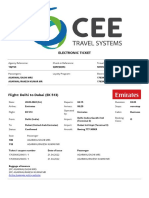

- Electronic Ticket For 1gjtsx Departure Date 20-05-2022Document3 paginiElectronic Ticket For 1gjtsx Departure Date 20-05-2022Vikas BalyanÎncă nu există evaluări

- Brisnet Preakness Stakes 2021 Contender PPs OptimizedDocument5 paginiBrisnet Preakness Stakes 2021 Contender PPs OptimizedAsbury Park PressÎncă nu există evaluări

- 9 ST Lukes Medical Center v. TorresDocument17 pagini9 ST Lukes Medical Center v. TorresKris OrenseÎncă nu există evaluări

- Second Semester of Three Year LL.B. Examination, January 2011 CONTRACT - II (Course - I)Document59 paginiSecond Semester of Three Year LL.B. Examination, January 2011 CONTRACT - II (Course - I)18651 SYEDA AFSHANÎncă nu există evaluări

- DOX440 Gun Setup Chart Rev 062019Document4 paginiDOX440 Gun Setup Chart Rev 062019trọng nguyễn vănÎncă nu există evaluări

- Gmail - Bus Ticket - Sagar To Bhopal On Wed, 18 Dec 2019 and Rate Your ExperienceDocument3 paginiGmail - Bus Ticket - Sagar To Bhopal On Wed, 18 Dec 2019 and Rate Your ExperienceShivamSrivastavaÎncă nu există evaluări

- Complaint Affidavit Pag Ibig FundDocument3 paginiComplaint Affidavit Pag Ibig FundHaider De LeonÎncă nu există evaluări

- Rohmayati Pertemuan 8Document5 paginiRohmayati Pertemuan 8Mamah ZhakiecaÎncă nu există evaluări