Documente Academic

Documente Profesional

Documente Cultură

Shear Wall F

Încărcat de

10bcl0160 evaluări0% au considerat acest document util (0 voturi)

75 vizualizări13 paginishear wall

Titlu original

Shear Wall f

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentshear wall

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

75 vizualizări13 paginiShear Wall F

Încărcat de

10bcl016shear wall

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 13

76

2.3 SHEAR WALL CONSTRUCTION

2.3.1 TENDER SPECIFICATIONS

1. Formwork

Formwork shall consist of shores, bracings, sides of beams & slabs, bottoms of slabs etc.

Including, anchors, hangers, inserts etc. and shall be designed & planned for the work by

contractor.

Formwork shall be so constructed that vertical adjustments can be made to compensate

for settlement using M.S. props only.

The contractor shall indicate in his tender the minimum quantity of formwork, staging &

scaffolding materials he proposes to mobilize for the work.

Fabricated structure steel staging & steel pipe scaffolding shall be used (wood & bamboo

staging is not permitted)

(a) Design

The design of formwork & its construction & erection is the sole responsibility of

contractor.

The design shall consider all the loads (vertical & lateral) including live & vibration

loadings.

Horizontal tubes will not be permitted to carry loads. They shall be used as bracings only

& only the vertical tubes will carry the load.

(b) Tolerances for Reinforced concrete Buildings

Variation from the plumb.

o In the lines & surfaces of columns, piers, walls 5mm per 2.5m, whichever is less.

o For exposed corner columns

- In any bay or 5 m maximum: 5 mm

- In 10 m or more: 10 mm

Variation from the level or from the grids indicated on drawings.

o In 5 m: 15 mm

o In 10 m or more: 25 mm

o In buried construction: Twice the above amounts

Variation in cross sectional dimensions of columns, beams, piers & similar members.

o Minus: 5 mm

o Plus: 10 mm

Variation in thickness of slabs, walls & similar members

o Minus: 5 mm

o Plus: 10 mm

Footing for columns, walls & similar members.

o Variation of dimension in plan

- Minus: 10 mm & plus: 50 mm

o Misplacement or Eccentricity

- 2% of footing width in direction of misplacement not more than 50mm

o Reduction in Thickness

- 5% of specified thickness subject to maximum of 50 mm

77

Tolerance in other structures shall conform to those given in ACI 347 clause 2.4 of

Recommended practice for concrete formwork.

Tolerances in fixing anchor bolts shall be as follows :

o Anchor bolts without sleeves : + 1.5 mm in plan

o Anchor bolts with sleeves : + 5 mm in elevation

o Embedded parts : + 5 mm in all directions

o For bolts 32 mm dia & above : + 3 mm in all directions

o For bolts through 28 mm dia : + 5 mm in all directions

(c) Formwork Requirements

Formwork shall be conform to the shapes, lines & dimensions including cambers of

concrete as required by design.

Ample struts, walers, shores etc. of MS shall be used to hold the formwork in proper

position.

Formwork shall be strong enough to permit the use of immersion vibrators.

Faces coming into contact with concrete shall be free from adhesive grout, plaster, paint

or other defeats.

All new and used ACROW props and shuttering material shall be maintained in good

condition with respect to shape, strength, smoothness of surfaces.

Shores supporting successive storage shall be placed directly over those below or be so

designed and placed that loads will be transmitted directly to them.

Excessive construction camber to compensate for shrinkage, settlement etc. That impair

strength of members will not be permitted.

Formwork for substructure concrete may be omitted when the given excavation is firm

enough to act as formwork.

Formwork during any stage of construction showing sign of distortion to such an extent

that it does not conform to exact contours as indicated on drawing shall be repositioned

and strengthened.

Formwork to beams & slabs shall be so erected that the formwork on sides of beams and

under the soffits of slabs can be removed without disturbing beam bottoms.

Re-propping of beams shall not be done except when props have to be reinstalled to bear

construction loads anticipated in excess of design loads.

Vertical props shall be supported on wedges or other measures shall be taken whereby

props can be gently lowered vertically while striking formwork.

If formwork of columns is erected to full height, one side shall be left open & built up in

sections as concrete pouring proceeds. Windows may be left for pouring concrete from

sides to limit drop of concrete to 1m.

(d) Mould Oil

It shall be ensured that faces coming into contact with concrete are perfectly cleaned &

two coats of mould oil applied.

It shall not become flaky or removed by rain or wash.

All corners exposed in finished structure shall be formed with moldings to form chamfers

or fillets. The standard dimensions shall be 20mm x 20mm. Vertical construction joins on

faces shall be chamfered.

Wire ties passing through walls are not allowed, bolts posing through shall be used.

78

(e) Removal of formwork

In normal circumstances (when temperatures are above 20C) following striking period

shall be used

Table 2.2.1 Formwork stripping period for various elements

Elements For OPC

Walls, columns & vertical side of beams

Slabs (props left under)

Beam soffits (props left under)

Removal of props to slab

Span up to 4.5m

Span above 4.5m

Removal of props to beams

Span up to 6m

Span above 6m

24 to 48 hrs.

3 days

7 days

7 days

14 days

14 days

21 days

After removing the formwork, if it is found that timber has been embedded in concrete, it

shall be removed.

Reinforced temporary openings shall be provided to facilitate removal of formwork.

Tie rods, clamps which must be removed entirely shall be loosened not earlier than 24

hrs. nor later than 40 hrs. after concrete has been poured. Cutting ties back from faces of

walls is not permitted.

2.3.2 MATERIAL SPECIFICATIONS

1. Peri liwa shutter plates

Material- Steel fame and plywood

Source/company- PERI

Rate- Rs 8000/m

2

Specifications-

o The LIWA has been designed for a fresh concrete pressure of 50 kN/m

2

o Total thickness 100mm (85mm steel frame + 15mm ply wood)

2. Plastic shutter plates

Material- Plastic

Source/make- NOVA

Rate- Rs. 5000/m

2

Specifications-

o Can bear loads up to 60 kN/m

2

o Total thickness of 80mm (5mm plastic plate + 75mm plastic projection)

3. Shuttering Oil

Material- Mould Oil

Source/make - CERA Chemical

Rate- Rs. 78/ lit

Coverage- 35 m

2

/lit.

79

4. Tie rods

Source/make - KR SCAFF (Tamilnadu)

Rate- Rs. 83/m

5. PVC tube & PVC cone

Source/make- Delux

Rate (PVC tube)- Rs. 14/m

Rate (PVC tube)- Rs. 2.5/piece

6. Walers

Available in lengths of 1.2m, 1.98m & 2.14m

Two channels of ISMC 100 connected back to back by spacer plate of (150 x 30 x 3) mm.

7. Edge Walers

Company : PERI

2 Rolled hollow sections (RHS) (50 x 25 x 2) mm used

Weight 2.75 kg

8. Wing nut

Company KR SCAFF

Specification 100 KN pull capacity

Rate Rs. 48/piece

9. Adjustable props

Company- ACROW

Rate- Rs. 1555/Nos.

Specifications-

o Closed height: 2300 mm

o Open height (max.): 4230 mm

o 29 kN safe working load

10. Clamps

(a) Wedge clamp LIWA

Used to connect two plates when no filler material is there between two adjacent plates.

Company : PERI

(b) Wedge clamp compensation LIWA

Company : PERI

Used to connect two adjacent plates when filler of max. 5cm size is used in-between two

plates.

80

(c) DOMINO Alignment coupler

Company : PERI

It fastens, aligns and tightens in a single operation.

Used for standard panel connections or with fillers up to 120mm wide.

2.3.3 TOOLS & EQUIPMENT USED

Bar bending machine: SPARTAN SBM 42

Bar cutting machine: SPARTAN SCM 42

Transit mixer: SCHWING STETTER

Needle vibrator: WACKER NEUSON

Plumb Bob

Line - Dori

Hooked rod for binding wires (Aakdi)

Hammer

Measure tape

Concrete Boom Placer

o Model: S 36X (4 section roll and fold system, height 36m)

o Specifications :

Table 2.2.2 Boom Placer (S 36X) and Portable pump specifications

Concrete Pump

Type P1800

Max. Pumping output (m

3

/4) 96

Max. number of strokes / min 19

Max. concrete Pump (bear) 85

Placing Boom S 36X

Pumping line diameter (mm) 125

Length of end hoes (m) 4

Reaching height (m) 35.2

Hori. Reach from Centre of slewing axis

(m)

31.25

Lifting angle 96

1

st

folding angle 180

2

nd

folding angle 180

3

rd

folding angle 238

Slewing range 2 x 360

2.3.4 ENABLING WORKS

Ramp construction

House keeping

81

Safety Harness provision

Diesel Generator provision (for keeping up vibration during power cutoff )

2.3.5 CONCRETE POUR CARD (FOR TOWER 32 SHEAR WALLS)

Table 2.2.3 Concrete Pour card (Shear walls)

Date 25/01/2014

Grade of concrete M40

Quantity of concrete 5.4 m

3

Location Tower 32

Are shuttering, Reinf. & Services completed Yes

Starting time 4 pm

Completion time 4:30 pm

Number of cubes taken for testing --

Slump value 120 mm

2.3.6 CONSTRUCTION PROCEDURE

Observations for shear walls 4SW12 (plastic formwork) and 4SW22 (PERI formwork) of

certain tower (Tower 32) starting from the starter construction till deshuttering have been

made.

1. Starter construction

In starter construction, one carpenter and 2 helpers have been deployed. It took 2 hours to

finish the starters of both the walls. Wooden runners of 50mm (width) x 70mm (depth)

are used for fabricating starter. Before fixing the starter, reinforcement is fixed into place

which is preceded by removal of wooden pieces used for making shear keys beneath the

shear walls. Shear keys are approximately 150mm (length) x 30mm (depth) spaced at

450mm clear spacing (and parallel to length of wall).

The wooden runners are cut into required lengths so that the internal corners of starter

coincide with the corners of walls as marked on the raft top by surveyors. The alignment

of starter is ensured by means of line-dori tied at the ends of walls through rods secured to

the reinforcement of wall. Line-dori is tied along one face of the wall.

To prevent inward or outward tilting of starter, rods (tied to reinforcement) and wooden

strips (nailed to runners) are used. The grade of concrete used for starter has to be one

grade higher than grade used for shear wall. Thus M45 grade of concrete is used for

starter. Once it is concreted, it is compacted by rodding it through a rod at several

locations.

82

This is followed by placing of wooden pieces parallel to length of wall so as to have shear

keys with dimensions as mentioned before. These wooden pieces are removed at a later

stage.

Figure 2.2.1 Starter arrangement

2. Shuttering

The plan (or drawings) of panels to be used for a particular shear wall is rendered to the

carpenter so that he becomes aware regarding the panel lengths, numbers and their

arrangement. As per the requirement, the PVC pipes are cut down by the labor.

The shutter plates are cleaned and formwork releasing agent is applied (2 coats). In case

of PERI formwork, the shutter plates are held at the position and are tied to the

reinforcement of wall through binding wire (for this purpose, a hole is provided at the top

PERI plates). Two such adjacent plates are clamped at three locations by standard wedge

clamp (height of each plate=3m).

In case of plastic formwork, connections are secured by insertion of plastic handle locks

in the slots and rotating them 90 through steel spigot. The connections are secured

between 2 adjacent vertical and 2 adjacent horizontal panels (height of each

panel=1.24m).

The tie rods are provided at the junctions of plates in both formwork systems. These tie

rods are put into the sleeves (PVC tube and cone) and are tightened by

wingnuts/griplocks.

In PERI formwork, wherever the fillers are encountered, the wedge compensation clamp

or domino alignment couplers are used (depending upon the filler thickness) to secure

connection. Moreover, for the insertion of tie rods, walers are put into place at such

locations.

Wooden spreaders are placed at about 400mm clear spacing near the top of formwork to

prevent inward tilting of formwork. Once erection of formwork is done, they are aligned

83

by placing adjustable props. For checking the plumb, a plumb bob is provided on two

perpendicular faces at the ends of wall.

To bring the wall into plumb, the props are adjusted accordingly (before concreting and

just after concreting). To ensure the horizontality, a line dori is also tied at the top of the

wall along one face.

Table 2.2.4 Comparison between PERI and Plastic formworks

Sr.no. PERI formwork PLASTIC formwork

1

Difficult to handle since it is heavy (35

kg/m

2

)

Easy to handle since it is light-weight.

2

Productivity is more since number of

connections is less.

Productivity is less since number of

connections are more.

3 Number of lateral props required is less. Number of lateral props required is more.

4

Cost incurred for material and labour is

less.

Cost incurred for material and labour is

more.

3. Concreting and Deshuttering

Concreting in shear walls is carried out by Boom placer. Five unskilled labors were

deployed for concreting in following manner.

o 2 labors- for compaction/vibration of concrete

o 1 labor- for delivering concrete through hose.

o 2 labors- for adjusting props and tamping at the bottom (to prevent honeycombing)

It took about 30 minutes to concrete both the walls. The concrete pour height was 3 m

(opposed to 1.5m as prescribed by IS code). The concrete is poured into 2 layers and each

layer compacted by needle vibrator at four locations (2-at boundary elements and 2-in

between). The concrete which gets deposited on formwork top is removed by trowel.

Once the top layer of concrete is vibrated, shear keys as mentioned before are placed over

it (which are removed later on).

After about 16 hours of concreting, deshuttering is carried out. Number of labors involved

in deshuttering is 3. It takes about 4 hours to deshutter PERI formwork whereas 7 hours

for PLASTIC formwork.

The pipe use as sleeve was just 1mm thick (instead of 3mm stipulated value) because of

which it got broken by concrete pressure thereby leading to sticking up of tie rods inside

84

the wall. Hence, the only resort was to cut off the projecting tie rods (which is not

permitted as per contract specifications).

After deshuttering, the shear walls are cured through water sprinkling and hessian cloth

coverings for 14 days. Also, the verticality and cover adequacy are checked by clients

quality department.

2.3.7 MANPOWER EMPLOYED, PRODUCTIVITY AND COST

ASPECT

1. Labor wages & Productivity

Table 2.2.5 Labor wages and productivity for both formworks

Sr. Item Peri Liwa Plastic

1

Labour (nos.)

Skilled

Helper

2

3

1

2

2

Labour wages (paid by labour contractor)

Skilled

Helper

230/8 hrs.

200/8 hrs.

250/8 hrs.

180/8 hrs.

3 SPCL pays to labour contractor 110/m 130/m

4 Quantity of formwork payable 25.27 m 21.05 m

5 SPCL paid for labour Rs.2779.7 Rs.2763.5

6 Time taken 10 hrs 21 hrs

7

Productivity (actual)

(estimated)

0.525 m/lab/hr

0.375m/lab/hr

0.358/m/lab/hr

0.375m/lab/hr

8 Labour contractor pays to labour Rs.1450 Rs.1601.5

9 Profit of labour contractor

Rs.1329.7

Rs.52.69/m

Rs.1135.5

Rs.53.94/m

85

10

If SPCL had their own labour then,

Profit + overheads/m

(Wages: Skilled-300/8 hrs

Unskilled-250/8 hrs)

[2779.7-1687.5]

=Rs.1092.2

=Rs.45.22/m

2736.5-2100

=Rs.636.5

=Rs.30.24/m

2. Rate analysis for Plastic formwork (Shear wall 4SW12)

Table 2.2.6 Rate analysis for Plastic formwork

Sr.no. Item description Unit Quantity

Rate

(Rs./Unit)

Amount

(Rs.)

(1)

Materials

-Plastic shutter plate & locks (571

nos.)

m

22.59

5000/80

1411.87

Shuttering oil (2 coats)

lit.

1.3

78/lit

101.4

Tie rods (1m)

(0.5m)

nos.

nos.

22

12

83/200

47/200

9.13

5.64

Props nos.

39

1555/100

606.45

Walers (1.98m)

(1.2m)

Kg

Kg

36.96 x 13

22.43 x 7

48/250

48/200

92.25

30.14

PVC tube M 8.2 14/m

114.8

PVC cone nos. 56 2.5/piece 140

Wingnut nos. 68 48/100 32.64

I- beam (1.7m) nos. 4 1195/100 47.8

(2)

Labor

m 21.05 130 2736.5

Total cost incurred for 22.59 m m 244.75/m 5328.8

Rate quoted in BOQ 567/m

(Profit margin + over heads) /m

322.24/m

(131.66%)

86

3. Rate analysis for PERI formwork(Shear wall 4SW22)

Table 2.2.7 Rate analysis for PERI formwork

Sr.

No

Item Description Unit Quantity Rate (Rs.)

Amount

(Rs)

(1)

Materials

-PERI shutter plate & wedge clamps (19

nos.

m

25.8

8000/120

1720

Shuttering oil (2 coats) lit 1.5 78/lit 117

Tie rods (1m)

(0.5m)

nos.

nos.

27

9

83/200

47/200

11.2

2.11

Props nos. 29 1555/100 450.95

Walers (1.98m)

(1.2m)

kg

kg

32.96x5

22.43x7

48/250

48/250

35.48

30.14

Edge walers kg 2.75x7 48/250 3.7

PVC tube m 7.32 14 102.48

PVC cone nos. 48 2.5 120

Wingnut nos. 60 48/100 28.8

(2) Labors m 25.26 110 2778.6

Total cost incurred for 26.25m 211.65/m 5400.46

Rate quoted in BOQ 567/m

(Profit margin + over heads) / m

567-211.65.

= 366.27/m

(175.6%)

4. Rate analysis & Productivity for Concreting

Grade of concrete used for shear walls- M 40

Mix design proportion- 1 : 1.9 : 2.47 : 0.36

(Cementitious) (FA) (CA) (Water)

1 : 1.9 : 2.47 : 0.36

(kg/m

3

)- (320+100) 798 1034.4 151.2

Here, 320 kg is cement and 100 kg is GGBS.

Chemical admixture (ECMAS HP-900): 250 ml per 50 kg of cementitious material.

Cost per m

3

= 320x5.2 + 100x3.128 + 798x0.67 + 622.44x0.6 + 414.96x0.53 + 2.1x54

87

= 3218.2528 Rs/m

3

Concrete volume for 4SW12

o Concrete level up to 2.45 height

o Concrete volume= plan area x height

= (1.015) x 2.45

= 2.487 m

3

Concrete volume for 4SW22

o Concrete level up to 2.99 m height

o Concrete volume= plan area x height

= 0.965 x 2.99

= 2.885 m

3

Concrete productivity = 10.59 m

3

/hour

(a) Labor cost

Time taken for concrete for both shear walls is 30 minutes.

o No. of labors= 5

o Wages (Rs) = 200/8 hrs.

o Labor cost incurred= Rs. 62.5

= Rs. 11.63 / m

3

Total cost / m

3

= Rs. 3229.88/ m

3

Rate quoted in BOQ = Rs. 5456/m

3

(Profit + Overheads) per m

3

= Rs. 2226.12 /m

3

(68.92 %)

5. Rate Analysis for Reinforcement

For Shear wall 4SW12

o Quantity of reinforcement in kg from BBS= 413.91 Kg

o Total cost of material= 43 x 413.91= Rs. 17798.13

o Labor cost= Rs. 4.5/kg x 413.91= Rs. 1862.59

o Total cost incurred= Rs. 19660.725

o Now cost per kg= 47.5 Rs/kg

o Cost quoted in BOQ= 60.645 Rs./kg

o (Profit + Overheads)/kg = 13.145 Rs./kg (27.67 %)

For Shear wall 4SW22

o Reinforcement in kg from BBS = 389.31 kg

o Total cost of material= 389.31 kg x 43 Rs/kg= 16740.33 Rs.

o Labor cost = Rs. 4.5/kg x 389.31= 1751.89 Rs

o Total cost incurred= 18492.22 Rs

o (Profit + Overheads)/kg= 13.145 Rs/kg (27.67%)

88

6. Analysis of Total Cost & Profit + Overheads

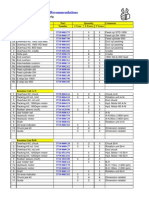

Table 2.2.8 Analysis of Total Cost & Profit + Overheads for Shear walls

Sr. No. Activity

Price as per BOQ

(Rs.)

Cost incurred (Rs.)

Profit + Overheads

(Rs.)

SW 12 SW 22 SW 12 SW 22

SW 12

(Plasti

c)

SW 22

(PERI)

1 Formwork 11935.35 14322.42 5328.8 5400.46 6606.55 8921.96

2 Reinforcement 25101.57 23609.7 19660.73 18492.22 5440.8 5117.48

3 Concreting 13569.07 15740.56 8033.14 9318.7 5535.93 6421.8

Total 53605.99 53672.68 33022.67 33211.38

17583.32

(53.2

5%)

20461.3

(61.61%

)

2.3.8 INSPECTION AND QUALITY CHECKS

1. Checklist for shuttering

Are all the safety norms being covered as per HSEM process?

Check for shuttering for availability and arrangement.

Are all the plates / plywood cleaned and polished properly.

Type of oil / polish used on the surface of shuttering.

Check for suitability, stability, safety & rigidity of assembled forms.

Check for provision for service piping.

Vertical members-Shear walls

o Checking alignment of all vertical members at floor level with respect to grid lines.

o Check plumb for vertical members (minimum 2 sides)

o Check right angle and diagonals of the vertical members from the top.

o Check for alignment with respect to adjacent vertical members.

o Check for adequate support as per shattering design

o Check for adequate of cover block.

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Four Quadrant ChopperDocument18 paginiFour Quadrant ChopperShipra singhÎncă nu există evaluări

- Nr-311104 Biological Control SystemsDocument4 paginiNr-311104 Biological Control SystemsSrinivasa Rao GÎncă nu există evaluări

- MS Samsung Ar7000 Inverter Airconditioning PDFDocument2 paginiMS Samsung Ar7000 Inverter Airconditioning PDFMacSparesÎncă nu există evaluări

- Western India Group - PresentationDocument32 paginiWestern India Group - PresentationZamir MujawarÎncă nu există evaluări

- Chapter 3 Dec 50143Document29 paginiChapter 3 Dec 50143Kohilan VenugopalÎncă nu există evaluări

- Unit-5 Wheels and TyresDocument31 paginiUnit-5 Wheels and TyresRahul Verma50% (2)

- Analysis of Portal FrameDocument16 paginiAnalysis of Portal FrameKanchana RandallÎncă nu există evaluări

- USFDADocument59 paginiUSFDADontYou KnowMeÎncă nu există evaluări

- WI - C.4.1 Set Up Site Documentation V1.1aDocument5 paginiWI - C.4.1 Set Up Site Documentation V1.1ayoen_anÎncă nu există evaluări

- Practice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Document10 paginiPractice Final Exam For CH 1-10 IT Essentials PC Hardware and Software Version 4.1Raine Bao75% (4)

- Ttgn5 Bostraben MainDocument71 paginiTtgn5 Bostraben MainjavierÎncă nu există evaluări

- Dynamic Prog Rod CuttingDocument10 paginiDynamic Prog Rod CuttingSreshtha KashyapÎncă nu există evaluări

- P18Xt Series Tube-Ice MachineDocument2 paginiP18Xt Series Tube-Ice MachineNanda SujiartoÎncă nu există evaluări

- Midterm JavaDocument4 paginiMidterm Javaمحمد سمورÎncă nu există evaluări

- ANITS College ProfileDocument5 paginiANITS College ProfilemurthygvrÎncă nu există evaluări

- Cyberpunk 2020 Ammo & Add-Ons PDFDocument6 paginiCyberpunk 2020 Ammo & Add-Ons PDFFabricio MoreiraÎncă nu există evaluări

- Your Love Bass Tabs - The Outfield @Document3 paginiYour Love Bass Tabs - The Outfield @Álvaro Diogo S. TeixeiraÎncă nu există evaluări

- Rec Erc 78 08Document22 paginiRec Erc 78 08Jerry PellerÎncă nu există evaluări

- Abraçando o Amanhã - Martin ScottDocument200 paginiAbraçando o Amanhã - Martin ScottAndréiaPerioto75% (4)

- NSR M2031 - PH24-NSR-B2A - Survey - AIRDOC - Smart LTE 2024Document18 paginiNSR M2031 - PH24-NSR-B2A - Survey - AIRDOC - Smart LTE 2024threesome.efryllapinaÎncă nu există evaluări

- Biology Practical 2Document8 paginiBiology Practical 2N.THEVAÎncă nu există evaluări

- Vehicle Air ConditioningDocument32 paginiVehicle Air ConditioningAkshay Chandel100% (2)

- CIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumDocument8 paginiCIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumEmil-Wendtland100% (1)

- Implementing The Euro As Functional Currency For Oracle HRMS Release 12.1 HRMS RUP5 - 2015Document67 paginiImplementing The Euro As Functional Currency For Oracle HRMS Release 12.1 HRMS RUP5 - 2015Saken RysbekovÎncă nu există evaluări

- Cisco LetterDocument1 paginăCisco LetterAlexandru DrăganÎncă nu există evaluări

- Diamec U6 Spare PartDocument3 paginiDiamec U6 Spare PartJairo Boechat JuniorÎncă nu există evaluări

- References PDFDocument7 paginiReferences PDFresigjeflinÎncă nu există evaluări

- Ethernet Captures Using Wireshark: Doc. No. Rev. Fieldserver Technologies How To Take Ethernet Captures Enote0063 6Document4 paginiEthernet Captures Using Wireshark: Doc. No. Rev. Fieldserver Technologies How To Take Ethernet Captures Enote0063 6Elvis Paiva ViteÎncă nu există evaluări

- Why 50 OhmDocument2 paginiWhy 50 Ohmwrite2arshad_mÎncă nu există evaluări

- Coca ColaDocument12 paginiCoca ColaNishtha JainÎncă nu există evaluări