Documente Academic

Documente Profesional

Documente Cultură

Katalog Danoline

Încărcat de

Prihananto Setyo AdiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Katalog Danoline

Încărcat de

Prihananto Setyo AdiDrepturi de autor:

Formate disponibile

creat i ng expressi ve cei l i ngs

w w w . d a n o l i n e . c o m

Expressive

gypsum

ceilings

E

x

p

r

e

s

s

i

v

e

g

y

p

s

u

m

c

e

i

l

i

n

g

s

C

I

/

S

f

b

:

(

3

5

)

C o n t e n t s

Preface

Danoline, history, possibilities Page 3

Products

SUSPENDED CEILINGS

Contur 600 Page 12

Linear 600 Page 16

Markant 500 and 600 Page 20

Belgravia 600 Page 26

Plaza 600 Page 30

Danoline tiles 600, White and Metallic Page 34

Danoline tiles 600, Medley Page 36

ACCESSORIES

Danopor Page 40

SELF-SUPPORTING CEILINGS

Corridor 300 Page 42

Corridor F30 Page 46

Corridor Swing 600 Page 50

LININGS

Danopanel Page 54

Combipanel Page 58

Designpanel 900 and 1200 Page 62

Tectopanel Page 66

Contrapanel Page 70

Kinopanel Page 74

DESIGNELEMENTS

Curvex Page 78

Mitex Page 80

Solopanel and Stratopanel Page 82

Properties

SURFACING

Gypsum as a natural palette Page 88

ACOUSTICS

Gypsum regulates sound Page 90

FIRE

Gypsum as natures sprinkler Page 98

INDOOR CLIMATE AND ENVIRONMENT

Gypsum can breathe Page 100

LOAD-BEARING CAPACITY AND WEIGHT

Gypsum as a weightlifter Page 102

MOISTURE

Gypsum as a natural skin Page 104

LUMINOUS REFLECTANCE

Gypsum mirrors the light Page 106

Perforations

Perforations and patterns Page 111

Globe, G Page 112

Quadril, Q Page 113

Micro, M Page 114

Designpanel Page 115

Cleaning and maintenance

Suspended and Self-supporting ceilings Page 118

Ceiling linings, acoustic and plain Page 119

Summary

Suspended ceilings Page 122

Linings Page 124

Self-supporting ceilings Page 126

Designelements Page 127

Accessories Page 128

H o w t o u s e t h e i n d e x

Al l i nformati on i n the i ndex i s general di recti ons about the Danol i ne products. There may be proj ect- speci fi c detai l s whi ch

have not been accounted for. It i s a foregone concl usi on that users of Danol i ne data have techni cal bui l di ng ski l l s and that

they have the usual proj ect responsi bi l i ty. Informati on on our websi te w w w . d a n o l i n e . c o m i s al ways up to date

and appl i cabl e. Our techni cal servi ce department i s al ways at your di sposal wi th further i nformati on and gui dance.

The di fference between the ordi nary and the uni que may

l i e i n the ti ny detai l s. The observers feel i ng of harmony

i n a bui l di ng, the surpri se when hi s eye spots a sol uti on

that i s sl i ghtl y more beauti ful than expected at fi rst si ght.

Archi tecture i s i mpressi ve when functi onal i ty bl ends wi th

aestheti cs and form a perfect whol e.

Al l the el ements of a bui l di ng must form i ntegral parts

of the whol e, al l owi ng the expressi on of the archi tects

l anguage of form and ori gi nal i ntenti on. The cei l i ng must

be characteri sed as a not qui te i nessenti al feature of the

whol e bui l di ng. When deal i ng wi th pl aster board cei l i ngs

Danol i nes mul ti pl e resources are at your di sposal any

ti me. We are pl eased to offer you a devel opi ng partnershi p

any ti me to hel p you achi eve your speci fi cati ons and meet

your wi shes i n terms of archi tectoni c sol uti ons. If you

thi nk Danol i ne as earl y as i n the i ni ti al concept, you wi l l

benefi t most from our experi ence and techni cal know- how.

We are competent sparri ng partners who create i ndi vi dual

products. Hel pi ng you turn your creati ve concepti ons i nto

i mpl ementi bl e sol uti ons woul d be a pl easure to us.

Pl aster i s a fl exi bl e materi al whi ch can easi l y be moul ded.

In the Danol i ne cei l i ngs we take advantage of the

moul dabl e properti es of the materi al by punchi ng hol es

and patterns whi ch add a di fferent di mensi on of aestheti cs

to the pl aster. At the same ti me thi s materi al offers a

number of good properti es whi ch i n thei r manner add to

the bui l di ng.

Y o u r w a y s o f c r e a t i n g e x p r e s s i v e c e i l i n g s

m a d e o f p l a s t e r b o a r d p a n e l s s t a r t h e r e

Pl aster gi ves good opportuni ti es for creati ng speci al /uni que

sol uti ons that meet your speci fi cati ons and wi shes as to

cei l i ng expressi on. At Danol i ne we stress conti nuous product

devel opment to ensure that we meet the conti nuous

requi rements of beauti ful and persuasi ve sol uti ons.

Pl asterboards for the manufacture of Danol i ne cei l i ngs

have been devel oped by Knauf Danogi ps, the l eadi ng

Scandi navi an producer of pl asterboards. Danol i nes and

Knauf Danogi ps efforts wi thi n product devel opment and

producti on have secured our posi ti on as partners to any

type of bui l di ng proj ect i n Northern Europe.

3

4

5

1165

1165:

Architect: Semren Arkitektkontor, Gteborg

Project: Ungdoms bolig, Gteborg - Sweden

Product: Designpanel 1200

F o r g o o d r e a s o n s p l a s t e r h a s b e e n

t h e p r e f e r r e d m a t e r i a l f o r

c e i l i n g s f o r c e n t u r i e s

Pl aster forms a natural part of modern bui l di ng desi gn,

but as a materi al i t dates back i n hi story. For centuri es

pl aster has been used to meet both functi onal and aestheti c

requi rements of bui l di ngs. Pl aster has been used i n as

di fferent pl aces as decorati ve cei l i ngs i n the beauti ful

Ital i an and French Renai ssance pal aces as for the pyrami ds

i n Pharaoni c Egypt. Wherever i t has been used, bui l ders

have had the abi l i ty to expl oi t i ts characteri sti c properti es

to create outstandi ng resul ts.

The method used to process gypsum i s qui te si mpl e, and

thi s i s the most essenti al reason why i t was known as a

bui l di ng materi al way back. The use of pl aster found favour

i n earnest i n the anti que Roman cul ture around the year

0 A.D. At that ti me many bui l di ngs were made i n marbl e

and then covered wi th a thi n coat of pl aster and pai nted

i n bri ght col ours. At the same ti me the great fl exi bi l i ty

and moul dabi l i ty of the pl aster meant that thi s materi al

was wi del y used for stuccowork i nsi de bui l di ngs. Pl aster i s

sui tabl e for detai l i ng, and i t was therefore used for the fi ne

and arti sti c ornamentati on and embel l i shments on wal l s and

cei l i ngs, whi ch may be seen i n Ital i an Baroque and Rococo

archi tecture. Thi s materi al al l owed for the creati on of

rel i efs and ornamentati on whi ch had an outstandi ng i mpact

on the rooms, whereas thei r wei ght was unsubstanti al .

In year 1775 French Lavoi si er found the chemi cal formul a

for gypsum whi ch paved the way for i ndustri al processi ng

of the materi al . Pl aster i s made from the gypsum stone

mi neral whi ch i s found natural l y i n Germany, France and

Ital y. Gypsum stone i s converted i nto burnt gypsum vi a

heati ng, crushi ng and mi xi ng wi th water. The materi al then

sol i di fi es i n the shape whi ch i t i s i n.

6

7

1290

1276 1157

8

1276:

Architect: Erik Eriksen, Grlse

Project: Daginstition, Maglekrvej, Grlse - Denmark

Product: Danopanel - G1, R

1157:

Architect: MA Arkitekter, Bors

Project: Hgskolan i Bors- Sweden

Product: Corridor Swing 600 - Q1

1290:

Architect: S og I arkitekter

Project: OBH Gruppen, Odense - Denmark

Product: Contur 600 - M1 , Designpanel 900 - M1F

1287:

Architect: Hune & Elkjr

Project: Korsvang, Assens - Denmark

Product: Tectopanel - G1

1284:

Architect: Rudolf Lolk A/S

Project: Arkitektfirmaet Rudolf Lolk A/S, Esbjerg - Denmark

Product: Designpanel 1200 - M1F

1137:

Architect: Wingrd Arkitekt kontor

Project: Astra Zeneca tnghuset, Gteborg - Sweden

Product: Mitex - R

N o w o u r e x t e n s i v e a s s o r t m e n t o f

p l a s t e r b o a r d p a n e l s a f f o r d s

e n d l e s s d e s i g n o p t i o n s

Smooth surfaces and cl ean l i nes are characteri sti cs

of contemporary beauti ful , mi ni mal i st bui l di ngs and

the si mpl i sti c expressi on of the pl aster contri butes to

archi tectoni c cl ari ty. It i s possi bl e to create el ements whi ch

recede i nto the background and do not di stract attenti on

from the archi tectoni c expressi on of the room. Wi th pl aster

the stri ct and mi ni mal i st expressi on i s preserved and the

extensi ve moul dabi l i ty of the materi al al so affords wi de

opportuni ti es for creati ng i ndi vi dual sol uti ons wi th a hi gh

degree of detai l i ng.

The great fl exi bi l i ty of the materi al , means that

functi onal i ty and aestheti cs can form a synthesi s so the

fi ni sh of the room becomes j ust as i ntended. Wi th Danol i ne

cei l i ngs there are i nfi ni te combi nati ons of expressi ons,

as the surface of the pl aster al l ows for the appl i cati on

of many types of pai nt, foi l s or punchi ngs, so i t may be

adapted ful l y to the expressi on of the room.

Besi de the evi dent aestheti c advantages of usi ng pl aster,

thi s materi al al so offers a number of other properti es whi ch

contri bute favourabl y to the bui l di ng. Gypsum i s a natural

materi al wi th a l ong l i fe and i t i s envi ronmental l y fri endl y.

Pl aster can emi t and adsorb vapour whi ch makes i t pl ay

an i mportant part i f the bui l di ng i s to have a good i ndoor

cl i mate.

Pl aster al so affords good acousti c properti es. The di fferent

types of perforati on offer varyi ng properti es i n the form of

sound absorpti on and refl ecti on, i n thi s way cei l i ng panel s

can tune the room and render fi ne acousti c condi ti ons. The

refl ecti on of l i ght i s al so easi l y i nfl uenced by the use of

pl aster as the surface structure appears hi ghl y vari ed and

wi th di fferent refl ecti ve properti es, dependi ng on the type

of pai nt appl i ed.

1137

1284

1287

9

Products

1149

12

1324

13

Contur gi ves the appearance of a monol i thi c surface

fi ni shed wi th fi ne l i ne marki ngs. The perforati ons on Contur

appear more di sti nctl y than on other types of cei l i ngs

and aestheti cal l y, therefore, wi l l accentuate the acousti c

sol uti on sel ected.

Choosi ng fi xed dados, arches or fol ded pl aster achi eves

an el egant framework to the cei l i ng. Contur produces a

conceal ed gri d appearence, and i s si mi l ar to Danopanel and

Tectopanel .

E x p r e s s i o n a n d a c o u s t i c s e n h a n c e d b y t h e

s u b t l e p e r f o r a t i o n o n C o n t u r

1149:

Architect: Liljewall Arkitekter, Gteborg

Project: Biotechhuset, Gteborg - Sweden

Product: Designpanel 900 - M2F

1324:

Architect: Dall & Lindhardtsen

Project: Nrum Gymnassium - Denmark

Product: Contur 600 - G1

1278:

Architect: Dall & Lindhardtsen

Project: Holbk Sygehus - Denmark

Product: Contur 600 - G1

1223:

Architect: Sisustusarkkitehdit Gullstn-Inkinen Oy

Project: Teknos Oy, Rajamki, paint factry - Finland

Product: Contur 600 - G1

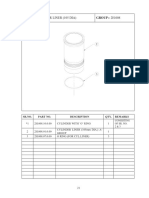

Contur 600

1223

1278 1324

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

14

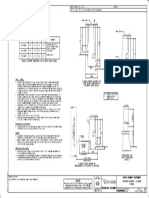

S u s p e n s i o n s y s t e m

The spacer bars shal l be fi xed max. 100 mm from the

hangers. At j oi nts of mai n T- runners, hangers shal l be fi xed.

The suspensi on hanger must be fi xed to the mai n runner

at 1500 mm centres and not l ess than 100 mm from the

wal l angl e.

Measurements are i n mm.

Drawi ng no.: 10

D e t a i l

Cross secti on 4,

Contur 600, wi th shadow edge tri m.

Drawi ng no.: 10.2.006

Cross secti on 3,

Contur 600, wi th shadow edge tri m.

Drawi ng no.: 10.2.005

Longi tudi nal secti on,

Contur 600, wi th shadow edge tri m.

Drawi ng no.: 10.2.004

Longi tudi nal secti on,

Contur 600 wi th pai nted fi x fri eze of gypsum board

screw- fi xed on 35 mm T- profi l e.

Drawi ng no.: 10.2.003

Cross secti on 2,

Contur 600 wi th pai nted fi x fri eze of gypsum board

screw- fi xed on 35 mm T- profi l e.

Drawi ng no.: 10.2.002

Cross secti on 1,

Contur 600 wi th pai nted fi x fri eze of gypsum board

screw- fi xed on 35 mm T- profi l e.

Drawi ng no.: 10.2.001

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

600 x 600 x 12.5 mm

625 x 625 x 12.5 mm

Other si zes on request.

D r a f t s p e c i f i c a t i o n

Danol i ne Contur 600, M1, 600 x 600 x 12.5 mm,

Whi te pai nted as standard, for conceal ed 24 mm

suspensi on systems.

15

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

C o m p o n e n t s

MAIN RUNNER

Part no.

85030

W x L x H

24 x 3600 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

SPACER BAR

Part no.

8260013

8269913

L

600

300

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

12 + 19 x 3050 x 10 + 24

WALL ANGLE

Part no.

1438

W x L x H

19 x 3050 x 32

I n s t a l l a t i o n

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d

be screwed to the soffi t. It i s

i mportant that the suspensi on

i s pl umb. The mai n runners are

fi xed paral l el at 300 mm or 600

mm centres.

C h e c k i n g t h e

s u s p e n s i o n s y s t e m

a n d s p a c e r b a r

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

The spacer bar shoul d be i nstal l ed

at a maxi mum of 100 mm from

the hangers and wi th a di stance

of max. 1500 mm c/c.

W a l l T r i m

The wal l angl e shoul d be fi xed

at max. 300 mm centres. At

corners the tri m shoul d be mi tred

accuratel y.

M a i n r u n n e r

The suspensi on hanger must be

fi xed to the mai n runner at 1500

mm centres and not l ess than

100 mm from the wal l angl e.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted.

Gl oves shoul d be worn at al l

ti mes when handl i ng the ti l es and

a saw or kni fe used to cut the

ti l es to si ze.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

J o i n i n g t h e M a i n

R u n n e r s

The mai n runners have

i nterl ocki ng tongues at both

ends enabl i ng them to be j oi ned

together, an addi ti onal hanger

must be used at thi s poi nt.

Contur 600

A A

16

1124

17

Li near i s percei ved as fl oati ng, sel f- contai ned panel s,

defi ned by sharp, al most navi gati onal l y conti nuous

al i gnments. Di agonal to the al i gnments, the cei l i ng gi ves

the appearance of l arge i nterconnected surfaces. The cei l i ng

i s wel l sui ted to renovati ng exi sti ng cei l i ngs and on account

of i ts styl i ng i s very si mpl e to mount and demount. Li near

al most covers the gri d system. Thi s has the advantage of

conceal i ng ol d gri d.

The opti on of havi ng an i nstal l ati on hei ght of j ust 63

mm ensures greater fl oor- to- cei l i ng hei ght, thus provi di ng

i mproved space for engi neeri ng i nstal l ati ons. In addi ti on,

the cei l i ng can be pai nted whi l e actual l y i n the rai l system.

The desi gn and assembl y cl i ps prevent the board from

bei ng pushed up out of the rai l system duri ng cl eani ng and

pai nti ng.

G e o m e t r i c a l c h a r a c t e r i s t i c s e m p h a s i z e d b y t h e

s h a r p e d g e s o f t h e i n d i v i d u a l L i n e a r b o a r d

1124:

Architect: KHR Arkitekter

Project: Arlanda Pir F/5:an - Arlandaflygplats - Sweden

Product: Linear 600 - M1

0950:

Architect: CF Mller

Project: Vejle Sygehus - Denmark

Product: Linear 600 - G1

Linear 600

0950

0950 0950

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

18

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

600 x 600 x 12.5 mm

D r a f t s p e c i f i c a t i o n ,

Danol i ne Li near 600, M1, 600 x 600 x 12.5 mm,

Whi te pai nted as standard, for exposed 24 mm suspensi on

systems.

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 600 mm, and shal l be made

from 1200 mm cross- Tee. The suspensi on hanger must be

fi xed to the mai n runner at 1200 mm centres and not l ess

than 400 mm from the wal l angl e.

Danol i ne recommends the use of suspensi on systems wi th

strai ght connecti ons between mai n runners and cross tees,

so any di fferences i n l evel s are avoi ded, i .e. the suspensi on

systems components are al l at the same l evel .

Measurements are i n mm.

Drawi ng no.: 15

D e t a i l

Li near 600, wi th fri eze of Pl aza 600 Regul a, pl ai n.

Drawi ng no.: 15.2.004

Li near 600 wi th pai nted fi x fri eze of gypsum board

screw- fi xed on 35 mm T- profi l e.

Drawi ng no.: 15.2.005

Li near 600, wi th i ntermedi ate fri eze of Pl aza 600 Regul a.

Drawi ng no.: 15.2.008

19

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

85030

W x L x H

24 x 3600 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

85130

85230

85430

W x L x H

24 x 300 x 38

24 x 600 x 38

24 x 1200 x 38

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

12 + 19 x 3050 x 10 + 24

WALL ANGLE

Part no.

1420

W x L x H

24 x 3050 x 24

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The wal l angl e shoul d be fi xed

at max. 300 mm centres. At

corners the tri m shoul d be mi tred

accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

Note: The undersi de of the

fi ni shed cei l i ng wi l l be 11 mm

l ower than the undersi de of the

wal l tri m.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d be

fi xed wi th eye screws, brackets or

si mi l ar. If di rect hangers are used

they shoul d be screwed to the

soffi t. Start wi th the fi rst hanger

not more than 400 mm from the

wal l i n the l ongi tudi nal di recti on

of the mai n runner, and then at a

maxi mum of 1200 mm centres.

If addi ti onal fi xtures are fi xed

to the suspensi on system, extra

hangers shoul d be used.

M a i n r u n n e r

The profi l es are fi xed i n paral l el

wi th centres of 1200 mm, or

600 mm. The mai n runners have

i nterl ocki ng tongues i n both

ends and can therefore be l ocked

together.

C r o s s - T e e s

The cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The ti l es are fi tted i nto the system from bel ow, wi th an upward

movement.

Sl i de i n one si de of the ti l e unti l i t i s supported by the gri d, bri ng the

ti l e l evel and then sl i de i n the opposi te si de.

To demount ti l es appl y upward pressure. Sl i de the ti l e out, move i t

forward, to the si de and then l et the ti l e drop bel ow.

Gl oves shoul d be worn at al l ti mes when handl i ng the ti l es and a saw or

kni fe used to cut the ti l es to si ze.

Linear 600

A A

20

1269

21

Markant i s the cl assi c cei l i ng sol uti on, featuri ng strong

shaded marki ngs between cei l i ng panel s.

The cei l i ng wi l l often be seen fi tted i nto a pattern adapted

to the shape of the room, thus achi evi ng a l i ghtness and

dynami c of desi gn.

The bevel l ed edges of the cei l i ng panel s ensure easy,

strai ghtforward assembl y, and combi ned wi th recessi ng i nto

the suspensi on system thi s provi des a di recti onal l y stabl e

cei l i ng.

C l a s s i c a l c e i l i n g s o l u t i o n a c h i e v e d w i t h M a r k a n t ,

6 0 0 m o d u l e s a l l o w u p g r a d i n g t o s w i n g f u n c t i o n

1269:

Architect: Dissing og Weitling

Project: Rdhusparken, Glostrup - Denmark

Product: Markant 600 - M1

9999:

Architect: Interoc, Stockholm

Project: Konferensrum Interoc, Stockholm - Sweden

Product: Markant 600, Swing

0990:

Architect: Fich og Bengaard

Project: Knud Engsig A/S, Aalborg - Denmark

Product: Markant 500 - G1

Markant 500 and Markant 600

0990

9999 9999

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

22

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons..

P r o d u c t

Si zes

600 x 600 x 12.5 mm

600 x 1200 x 12.5 mm

625 x 625 x 12.5 mm

625 x 1250 x 12.5 mm

Other si zes on request.

600 x 600 x 12.5 wi th swi ng functi on, S24

D r a f t s p e c i f i c a t i o n ,

Danol i ne Markant 600, G1, 600 x 600 x 12.5 mm,

(12.5 x 610 x 610 mm) Whi te pai nted as standard,

for exposed suspensi on systems 15/24 mm for modul e

600 (24 mm for modul e 610).

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 600 mm, and shal l be made

from 1200 mm cross- Tees. The suspensi on hanger must be

fi xed to the mai n runner at 1200 mm centres and not l ess

than 400 mm from the wal l angl e.

Measurements are i n mm.

Drawi ng no.: 20

D e t a i l

Markant 600, wi th fri eze of Pl aza 600 Regul a.

Drawi ng no.: 20.2.003

Markant 600, wi th wal l tri m.

Drawi ng no.: 20.2.011

Markant 600, wi th shadow edge tri m.

Drawi ng no.: 20.2.004

Markant 600 wi th pai nted fi x fri eze of gypsum board

screw- fi xed on 35 mm T- profi l e.

Drawi ng no.: 20.2.002

23

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

85030

W x L x H

24 x 3600 x 38

MAIN RUNNER

Part no.

750030

W x L x H

15 x 3000 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

85130

85230

85430

W x L x H

24 x 300 x 38

24 x 600 x 38

24 x 1200 x 38

CROSS TEE

Part no.

751130

751230

751430

W x L x H

15 x 300 x 38

15 x 600 x 38

15 x 1200 x 38

WALL ANGLE

Part no.

1420

W x L x H

24 x 3050 x 24

WALL ANGLE

Part no.

1438

W x L x H

19 x 3050 x 32

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

10 + 24 x 3050 x 12 + 19

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at maxi mum 300 mm

centres. At corners the angl e

shoul d be mi tred accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d be

screwed to the soffi t. Start wi th the

fi rst hanger not more than 400 mm

from the wal l i n the l ongi tudi nal

di recti on of the mai n runner, and

then at a maxi mum of 1200 mm

centres. If addi ti onal fi xtures are

fi xed to the suspensi on system,

extra hangers shoul d be used.

C r o s s - T e e s

The cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted. Gl oves shoul d be worn

at al l ti mes when handl i ng the

ti l es and a saw or kni fe used to

cut the ti l es to si ze.

M a i n r u n n e r

The mai n runners are i nstal l ed

paral l el to each other at di stances

1200 mm, or 600 mm, c/c

dependi ng on system modul e.

The mai n runners have

i nterl ocki ng tongues i n both ends,

and can be l ocked together.

Markant 600

A A

5

0

0

M

ax. 5

0

0

5

0

0

M

a

x

.

5

0

0

5

0

0

1

0

0

0

24

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

500 x 500 x 9.5 mm

D r a f t s p e c i f i c a t i o n ,

Danol i ne Markant 500, G1, 500 x 500 x 9.5 mm,

Whi te pai nted as standard, for exposed 15 mm suspensi on

systems.

Measurements are i n mm.

Drawi ng no.: 25

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 500 mm, and shal l be made

from 1000 mm cross- Tees. The suspensi on hanger must be

fi xed to the mai n runner at 1000 mm centres and not l ess

than 400 mm from the wal l angl e.

D e t a i l

Markant 500 wi th peri meter of cut Markant Regul a.

Drawi ng no.: 25.2.001

Markant 500 wi th peri meter of Pl aza Regul a.

Drawi ng no.: 25.2.002

25

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

750010

W x L x H

15 x 3000 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

751210

751410

W x L x H

15 x 500 x 38

15 x 1000 x 38

WALL ANGLE

Part no.

1438

W x L x H

19 x 3050 x 32

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

12 + 19 x 3050 x 10 + 24

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at maxi mum 300mm

centres. At corners the angl e

shoul d be mi tred accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d be

screwed to the soffi t. Start wi th the

fi rst hanger not more than 400 mm

from the wal l i n the l ongi tudi nal

di recti on of the mai n runner, and

then at a maxi mum of 1000mm

centres. If addi ti onal fi xtures are

fi xed to the suspensi on system,

extra hangers shoul d be used.

C r o s s - T e e s

The cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted. Gl oves shoul d be worn

at al l ti mes when handl i ng the

ti l es and a saw or kni fe used to

cut the ti l es to si ze.

M a i n r u n n e r

The mai n runners are i nstal l ed

paral l el to each other at di stances

1000 mm, or 500 mm c/c

dependi ng on system modul e.

The mai n runners have

i nterl ocki ng tongues i n both ends,

and can be l ocked together.

Markant 500

A A

26

1201

27

Bel gravi a i s the cei l i ng wi th a gri d system that i s semi -

recessed. Suppl i ed wi th tegul ar and bevel l ed edges, the

ti l es guarantee a very di recti onal l y stabl e cei l i ng and are

l ess sensi ti ve to damagi ng the edges.

As they are bei ng i nstal l ed, they fal l i nto pl ace i n the

suspensi on system wi th di sti nct ease and si mpl i ci ty.

E a s y a n d e f f o r t l e s s p e r f o r m a n c e s e c u r e d b y t h e

g e o m e t r i c a l c h a r a c t e r i s t i c s o f B e l g r a v i a

1201:

Architect: Arkkitehtitoimisto Larkas & Laine Oy

Project: Kontor bygning, Outokumpu - Finland

Product: Belgravia 600 - Stardust

1198:

Architect: Suunnittelukeskus Oy

Project: Sygehus, Kerava - Finland

Product: Belgravia 600

1131:

Architect: MA Arkitekter Bors

Project: hlenshuset, Bors - Sweden

Product: Belgravia 600 - M1

Belgravia 600

1131

1198

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

28

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

600 x 600 x 12.5 mm

625 x 625 x 12.5 mm

D r a f t s p e c i f i c a t i o n

Danol i ne Bel gravi a 600, M1, 600 x 600 x 12.5 mm, (610

x 610 x 12.5 mm) whi te pai nted as standard, for exposed

suspensi on systems 15 mm system for modul e 600 (24

mm system for modul e 610).

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 600 mm, and shal l be made

from 1200 mm cross- Tees. The suspensi on hanger must be

fi xed to the mai n runner at 1200 mm centres and not l ess

than 400 mm from the wal l angl e.

D e t a i l

Bel gravi a 600, wi th shadow l i ne edge tri m - S15

Drawi ng no.: 22.2.004

Bel gravi a 600, wi th shadow l i ne edge tri m - S24

Drawi ng no.: 22.2.005

Measurements are i n mm.

Drawi ng no.: 22

29

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

750030

W x L x H

15 x 3000 x 38

MAIN RUNNER

Part no.

85030

W x L x H

24 x 3600 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

751130

751230

751430

W x L x H

15 x 300 x 38

15 x 600 x 38

15 x 1200 x 38

CROSS TEE

Part no.

85130

85230

85430

W x L x H

24 x 300 x 38

24 x 600 x 38

24 x 1200 x 38

WALL ANGLE

Part no.

1438

Bx L x H

19 x 3050 x 32

WALL ANGLE

Part no.

1420

Bx L x H

24 x 3050 x 24

SHADOW LINE

EDGE TRIM

Part no.

1466

W x L x H

15 + 15 x 3050 x 8 + 25

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are pai nted

i n CMC 001 Gl obal whi te

(equi val ent to NCS 0902

G48Y). Suspensi on gri d

avai l abl e i n ul tral i ne, contact

techni cal department.

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s al so makes

i nstal l ati on qui cker and easi er. It wi l l al so be easi er to carry out i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the

ti l es wi l l be easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at maxi mum 300 mm

centres. At corners the angl e

shoul d be mi tred accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d be

screwed to the soffi t. Start wi th the

fi rst hanger not more than 400 mm

from the wal l i n the l ongi tudi nal

di recti on of the mai n runner, and

then at a maxi mum of 1200 mm

centres. If addi ti onal fi xtures are

fi xed to the suspensi on system,

extra hangers shoul d be used.

C r o s s - T e e s

The cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted. Gl oves shoul d be worn

at al l ti mes when handl i ng the

ti l es and a saw or kni fe used to

cut the ti l es to si ze.

M a i n r u n n e r

The mai n runners are i nstal l ed

paral l el to each others at

di stances 1200 mm, or 600 mm,

c/c dependi ng on system modul e.

The mai n runners have

i nterl ocki ng tongues i n both ends,

and can be l ocked together.

Belgravia 600

A A

30

1317

31

The setti ng of a Pl aza cei l i ng i s maybe best hi ghl i ghted by

usi ng a narrow gri d system.

Pl aza 600 i s fast and easy to mount and adapt, as al l

edges remai n hi dden above the gri d system.

Pl aza 600 i s often used as a fri eze/margi n panel for

Markant and Li near. Pl aza 600 combi nes the qual i ti es of

gypsum wi th favourabl e pri ci ng.

P l a z a i s t h e s i m p l e d e s i g n w h i c h c a n b e

c o m b i n e d w i t h c o n s i s t e n t p e r f o r a t i o n s

1317:

Architect: Initiative in Design

Project: Sir Williams Perkins School - UK

Product: Plaza 600 - M1

1210, 1211, 1212:

Architect: H & M Arkkitehdit Oy

Project: School Veikkola - Finland

Product: Plaza 600 - M1

Plaza 600

1212

1210

1211

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

32

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

600 x 600 x 9.5 mm

600 x 1200 x 9.5 mm

600 x 600 x 12.5 mm

600 x 1200 x 12.5 mm

625 x 625 x 12.5 mm

625 x 1250 x 12.5 mm Other si zes on request.

D r a f t s p e c i f i c a t i o n ,

Danol i ne Pl aza 600, M1, 600 x 600 x 9.5 mm,

(610 x 610 x 9.5 mm) Whi te pai nted as standard, for

exposed suspensi on systems 15/24 mm system for modul e

600 (15/24 mm system for modul e 610)

Measurements are i n mm.

Drawi ng no.: 30

D e t a i l

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 600 mm, and shal l be made

from 1200 mm cross- Tees. The suspensi on hanger must be

fi xed to the mai n runner at 1200 mm centres and not l ess

than 400 mm from the wal l angl e.

Danol i ne recommends the use of suspensi on systems wi th

strai ght connecti ons between mai n runners and cross tees,

so any di fferences i n l evel s are avoi ded, i .e. the suspensi on

systems components are al l i n the same l evel .

Pl aza 600 wi th wal l tri m.

Drawi ng no.: 30.2.001

Pl aza 600 wi th shadow l i ne edge tri m.

Drawi ng no.: 30.2.002

33

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

750030

W x L x H

15 x 3000 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

751130

751230

751430

W x L x H

15 x 300 x 38

15 x 600 x 38

15 x 1200 x 38

WALL ANGLE

Part no.

1438

Bx L x H

19 x 3050 x 32

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

12 + 19 x 3050 x 10 + 24

Alternative suspension S24 see Markant 600.

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at maxi mum 300 mm

centres. At corners the angl e

shoul d be mi tred accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d be

screwed to the soffi t. Start wi th the

fi rst hanger not more than 400 mm

from the wal l i n the l ongi tudi nal

di recti on of the mai n runner, and

then at a maxi mum of 1200 mm

centres. If addi ti onal fi xtures are

fi xed to the suspensi on system,

extra hangers shoul d be used.

C r o s s - T e e s

The Cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the Cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted. Gl oves shoul d be worn

at al l ti mes when handl i ng the

ti l es and a saw or kni fe used to

cut the ti l es to si ze.

M a i n r u n n e r

The mai n runners are i nstal l ed

paral l el to each others at

di stances 1200 mm, or 600 mm,

c/c dependi ng on system modul e.

The mai n runners have

i nterl ocki ng tongues i n both ends,

and can be l ocked together.

Plaza 600

A A

34

1300

1306 1321

35

Danol i ne Ti l es are mounted wi th a vi si bl e Lay- i n gri d system.

The cei l i ng panel s l ook l i ke a smooth, whi te faced surface,

whi ch i s envi ronmental l y fri endl y and ensures great usabi l i ty

i n rooms wi th rel ati vel y hi gh humi di ty.

The surface i s easy to mai ntai n and wi l l therefore wi thstand

rough washi ng, as i t has a good mechani cal resi stance.

Apart from Danol i ne Ti l es fi ne qual i ti es, i t i s al so an

economi cal l y advantageous sol uti on.

D u r a b l e s u r f a c e s a n d g o o d e c o n o m y a c c o m p l i s h e d

w i t h t h e s i m p l e p r o d u c t D a n o l i n e T i l e s

1306:

Architect: Aukett Ltd, London

Project: SAS Radisson, Stansted, - UK

Product: Danoline Tiles 600 - White

1321:

Architect: Bluestone

Project: ABL Factory/ warehouse - UK

Product: Danoline Tiles 600 - White

1300:

Architect: Kinnersley Kent Design, London

Project: House of Fraser, Croydon, Surrey - UK

Product: Danoline Tiles 600 - White

1119:

Project: Close up

Product: Danoline Tiles 600, White

1120:

Project: Close up

Product: Danoline Tiles 600, Metallic

1122:

Architect: Arkitektkontoret Waage as, Bergen

Project: Amficenter Voss, Bergen - Norway

Product: Danoline Tiles 600, Metallic

Danoline Tiles 600, White and Metallic

1122

1120 1119

36

1109

37

Danol i ne Ti l es Medl ey i s mounted i n a vi si bl e Lay- i n gri d

system. The ti l es are avai l abl e wi th squared or rebated

edges.

The cei l i ng ti l es appear l i ke a smooth ti nted l ami nated

surface. It i s envi ronmental l y fri endl y and ensures great

usabi l i ty i n rooms wi th rel ati vel y hi gh humi di ty.

The surface i s easy to mai ntai n as i t can wi thstand rough

washi ng, because of the good mechani cal resi stance i n

the surface. Danol i ne Ti l es Medl ey offers good i nherent

properti es and i t i s al so an economi cal l y advantageous

sol uti on.

P e r f o r a t e d D a n o l i n e T i l e s M e d l e y c o m p l e t e

w i t h e d g e d e t a i l s a n d f o i l s u r f a c e

1109, 1111, 1114, 1117:

Architect: Villum Kirkegaard

Project: Kontor, Hobro - Denmark

Product: Danoline Tiles 600 - Medley

Danoline Tiles 600, Medley

1114

1117 1111

6

0

0

M

ax. 6

0

0

6

0

0

M

a

x

.

6

0

0

6

0

0

1

2

0

0

38

S u r f a c e

Regul a R, Lami nated whi te, metal l i c and medl ey

foi l . Medl ey i s al so avai l abl e wi th Gl obe G1

perforati on.

P r o d u c t

S i z e s

600 x 600 x 6.5 mm

600 x 1200 x 6.5 mm

600 x 600 x 9.5 mm

600 x 1200 9.5 mm

625 x 625 x 9.5 mm

Other si zes on request.

D r a f t s p e c i f i c a t i o n ,

Danol i ne Danol i ne Ti l es 600, R, 600 x 600 x 6.5 mm,

Lami nated type whi te 600 x 600 x 6.5 mm for exposed

15/24 mm suspensi on systems

Measurements are i n mm.

Drawi ng no.: 40

D e t a i l

Danol i ne Ti l es 600 wi th wal l tri m.

Drawi ng no.: 40.2.001

Danol i ne Ti l es 600 wi th shadow l i ne edge tri m.

Drawi ng no.: 40.2.002

S u s p e n s i o n s y s t e m

Cut cross- Tees may not exceed 600 mm, and shal l be made

from 1200 mm cross- Tees. The suspension hanger must be

fixed to the mai n runner at 1200 mm centres and not less than

400 mm from the wall angle.

Danol i ne recommends the use of suspensi on systems wi th

strai ght connecti ons between mai n runners and cross tees,

so any di fferences i n l evel s are avoi ded, i .e. the suspensi on

systems components are al l i n the same l evel .

E d g e

A

A

A / E - Medl ey G1 and R

A

A

39

C o m p o n e n t s

I n s t a l l a t i o n

MAIN RUNNER

Part no.

750030

W x L x H

15 x 3000 x 38

ADJUSTABLE HANGERS

Part no. Length

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

CROSS TEE

Part no.

751130

751230

751430

W x L x H

15 x 300 x 38

15 x 600 x 38

15 x 1200 x 38

WALL ANGLE

Part no.

1438

Bx L x H

19 x 3050 x 32

SHADOW LINE

EDGE TRIM

Part no.

1459

W x L x H

12 + 19 x 3050 x 10 + 24

Alternative suspension S24 see Markant 600.

C o m p o n e n t s

Suspension grid, hangers

etc. are made from

galvanised steel. The

exposed sections are painted

in CMC 001 Gl obal whi te

(equi val ent to NCS 0902

G48Y).

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

L a y o u t

General l y start setti ng out from

the centre of the room ensuri ng

that peri meter edge cuts are

of equal si ze on both si des of

the room.

The posi ti oni ng of l i ght fi tti ngs,

venti l ati on uni ts and spri nkl er

heads shoul d be consi dered at

thi s stage.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at maxi mum 300 mm

centres. At corners the angl e

shoul d be mi tred accuratel y.

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

S u s p e n s i o n H a n g e r s

The adj ustabl e hangers shoul d

be fi xed wi th eye screws, angl e

brackets or si mi l ar. If di rect

hangers are used they shoul d be

screwed to the soffi t. Start wi th the

fi rst hanger not more than 400 mm

from the wal l i n the l ongi tudi nal

di recti on of the mai n runner, and

then at a maxi mum of 1200 mm

centres. If addi ti onal fi xtures are

fi xed to the suspensi on system,

extra hangers shoul d be used.

C r o s s - T e e s

The cross- Tees are i nstal l ed by

i nserti ng snap- i n tongues i nto the

correct sl ot on the stal k of the

mai n runner and are l ocked i nto

posi ti on by a sl i ght downward

pressure. If the cross- Tee i s not

conti nued i nto the adj oi ni ng

modul e, the tongue has to be

spl i t and bent fl at.

C h e c k i n g t h e

S u s p e n s i o n S y s t e m

When the suspensi on system

i s i nstal l ed, the l evel s and

angl es shoul d be checked and

i f necessary the hangers adj usted.

T i l e s

The l evel of the ti l es shoul d be

checked when the i nstal l ati on i s

compl eted. Gl oves shoul d be worn

at al l ti mes when handl i ng the

ti l es and a saw or kni fe used to

cut the ti l es to si ze.

M a i n r u n n e r

The mai n runners are i nstal l ed

paral l el to each others at

di stances 1200 mm, or 600 mm,

c/c dependi ng of system modul e.

The mai n runners have

i nterl ocki ng tongues i n both ends,

and can be l ocked together.

Danoline Tiles 600

A A

40

A demand for a hi gher sound reducti on (STC) can be

requi red i f the drywal l s or parti ti ons are not extended to

the soffi t of the deck, but to the suspended cei l i ng onl y.

The constructi on therefore provi des great freedom of choi ce

wi th regard to creati ng or movi ng wal l s.

S y s t e m s

Danopor i s avai l abl e for cei l i ng products wi th

edge D, C, E, and A.

S i z e s

600 x 600 x 25 mm

600 x 600 x 50 mm

Other si zes on request.

D r a f t s p e c i f i c a t i o n

Danol i ne Danopor i s i nstal l ed on the back of

Pl aza 600, M1, 600 x 600 x 9.5 mm whi te

pai nted as standard i n 15/24 mm exposed

suspensi on system.

Product:

Edge:

Suspensi on:

Contur 600

D

S24

Li near 600

C

S24

Bel gravi a 600

E

S15/S24/Ul tral i ne

Markant 600

E

S15/S24

Pl aza 600

A

S15/S24

41

The natural properti es of gypsum ensure that the Danol i ne

products have a good sound reducti on i n l ow frequenci es.

In combi nati on wi th Danapor a l ow densi ty i nsul ati on pad

pl aced i nsi de seal ed PE- faced bags and posi ti oned on the

back of the Danol i ne products a good resul t wi th sound

reducti on of both l ow, medi um and hi gh frequenci es from

room to room can be achi eved.

Sound- reduci ng characteri sti cs can be vari ed further by

sel ecti ng di fferent thi cknesses of Danopor. In addi ti on to i ts

sound- reduci ng properti es, the constructi on al so has good

sound- absorbent properti es throughout the frequency range.

In parti cul ar the bass frequency sound absorpti on i s good.

I n c r e a s e d s o u n d r e d u c t i o n a n d a b s o r p t i o n

r e a c h e d w i t h D a n a p o r w i t h o u t a f f e c t i n g

d e s i g n a n d e x p r e s s i o n

1267:

Architect: Berg Arkitekter

Project: Frsvarshgskolan, Stockholm - Sweden

Product: Markant 600 - M1

Danopor

1267

42

1179

43

Corri dor gi ves the appearance of fi ne l i ne marki ngs i n a

rectangul ar pl ank pattern. The cei l i ng i s pri mari l y used i n

corri dors and i s sel f- supporti ng for up to 2.4 m between

wal l s.

Corri dor i s often used i n smal l uti l i ty and anci l l ary rooms

for reasons of desi gn and/or economy. Demounti ng reveal s

a compl etel y free area wi thout transverse suspensi on

secti ons, opti mal for work on techni cal i nstal l ati ons.

The cei l i ng panel s can ei ther be del i vered to the bui l di ng

si te and adj usted i n si tu or suppl i ed i n fi xed di mensi ons.

Fi xed di mensi ons reduce wastage as wel l as bui l di ng waste,

maki ng assembl y faster and thus cheaper.

1195:

Architect: Suunnittelukeskus Oy, Helsinki

Project: Health care centre Kerava, Helsinki - Finland

Product: Corridor 300

1176, 1177, 1179:

Architect: White Arkitekter

Project: Halmstads Fastighetsbolag - Sweden

Product: Corridor 300 - M1

N e w a r c h i t e c t u r a l p o s s i b i l i t i e s c r e a t e d b y t h e

u n i q u e y e t s i m p l e d e s i g n o f C o r r i d o r

Corridor 300

1195

1176 1177

M

a

x

. 2

4

0

0

44

Measurements are i n mm.

Drawi ng no.: 35

D e t a i l

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

300 x 1200 x 9.5 mm

300 x 1500 x 9.5 mm

300 x 1800 x 9.5 mm

300 x 2100 x 9.5 mm

300 x 2400 x 9.5 mm

Can be manufactured to speci al l ength, max. 2400 mm.

D r a f t s p e c i f i c a t i o n

Danol i ne Corri dor 300, M1, 300 x 1200 x 9.5

mm, 300 x 2400 x 9.5 mm. Whi te pai nted as

standard.

Instal l ed on rei nforced shadowl i ne tri m 1469.

S u s p e n s i o n s y s t e m

The fl exprofi l e i s an i ntegrated part of the Corri dor cei l i ng

pl ank. Mai n Tee runner i s used between secti ons and l i nes

of Corri dor pl anks, when the di stance between the wal l s i s

greater than 2400 mm.

Corri dor 300. Joi ni ng of 2 short- edges usi ng mai n runner

65020.

Drawi ng no.: 35.2.003

Corri dor 300 wi th shadow l i ne edge tri m 1469.

Drawi ng no.: 35.2.005

Corri dor 300 wi th wal l tri m.

Drawi ng no.: 35.2.004

45

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated,

see secti on Moi sture . It i s equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on

of the cei l i ng i s carri ed out. It i s i mportant for the end resul t that the cei l i ng ti l es are i nstal l ed at ri ght- angl es, thi s makes

i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as removal of the ti l es wi l l be

easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

C o m p o n e n t s

FLEX RUNNER

Delivered in loose

parts with the

elements

W x L x H

65 x 1194 x 44

65 x 1494 x 44

65 x 1794 x 44

65 x 2094 x 44

65 x 2394 x 44

ADJUSTABLE HANGERS

Part no. Lenght

11022 120-200

11030-99 200-270

11030 250-320

11040 250-440

11070 380-690

11090 500-940

11120 750-1210

11150 750-1440

11200 1000-1940

MAIN RUNNER

Part no.

65020

W x L x H

35 x 3600 x 38

SHADOWLINE TRIM

Part no.

1469

W x L x H

20 + 20 x 3050 x 20 + 20

WALL ANGLE

Part no.

1430

W x L x H

20 x 3050 x 40

I n s t a l l a t i o n

C o m p o n e n t s

Suspensi on gri d, hangers

etc. are made from

gal vani sed steel . The

exposed secti ons are

pai nted i n CMC 001 Gl obal

whi te (equi val ent to NCS

0902 G48Y).

S e t t i n g o u t

The posi ti on of the wal l tri m

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the peri meter tri m i s the l evel

of the proposed cei l i ng.

L a y o u t

The cei l i ng i s normal l y di vi ded

i n the centre, i n thi s way the

adj ustments are the same si ze.

Pl ease note that the pl aci ng of

fi xtures and venti l ati on uni ts can

affect the correct l ayout

S u s p e n s i o n h a n g e r s

Where there i s a change of

di recti on i n the corri dor, a

suspended mai n runner must be

used to support the pl anks. The

maxi mum di stance between the

suspensi on hangers i s 750 mm,

and a maxi mum 300 mm from

the wal l s.

W a l l T r i m

The peri meter tri m i s fi xed to

the wal l at max. 300 mm. At

corners the tri m shoul d be mi tred

accuratel y.

M a i n R u n n e r 6 5 0 2 0

Mai n Runner 65020 can be used

to support Corri dor pl anks at

maxi mum 2400 centres.

It i s necessary to secure the

mai n runner at the peri meter,

and to fi x the Fl ex profi l e to

the mai n runner at every si xth

pl ank. Where the short edges of

the Corri dor pl ank abut the mai n

runner, the Fl ex profi l es on ei ther

si de of the Tee are secured to

each other.

P l a n k s

Where possi bl e, Corri dor pl anks

shoul d be i nstal l ed after al l maj or

work i n the cei l i ng voi d has been

compl eted. The fl ex- profi l e must

not be over 6 mm shorter than

the pl anks. The l evel of the ti l es

shoul d be checked when the

i nstal l ati on i s compl eted. Gl oves

shoul d be worn at al l ti mes when

handl i ng the ti l es and a saw or

kni fe used to cut the ti l es to si ze.

A d j u s t i n g t h e F l e x

p r o f i l e

If the fl ex profi l e i s broken

because of fi tti ngs, i nstal l ati ons

or other i mpl ementati ons, the

Fl ex profi l e has to be suspended.

L e v e l l i n g t h e

S u s p e n s i o n S y s t e m

If suspensi on hangers have been

used, they must be adj usted to

obtai n an accurate l evel . Where

there i s a change i n di recti on of

pl anks, the mai n runner must be

secured to the wal l constructi on.

Corridor 300

46

0563

47

The panel s consi st of l ong- format panel s wi th an effecti ve

span of up to 2.8 m. Corri dor F30 has the appearance

of fi ne stroke marki ngs i n a rectangul ar pl ank pattern.

The product has been styl ed to cope wi th the tough

fi re requi rements set out i n DIN 4102 (see secti on on

properti es).

The uni que qual i ty about Corri dor F30 i s that i t i s the

onl y cei l i ng wi thout mi neral wool to compl y wi th thi s fi re

requi rement.

As a resul t of i ts fi re properti es, the cei l i ng provi des great

safety and i s an obvi ous choi ce for use i n escape routes.

0563, 0564, 0560:

Architect: Hupach und Partner

Project: DESY, Hamburg - Germany

Product: Corridor F30

E x c e l l e n t f i r e p r o p e r t i e s y e t d i s c r e e t j o i n t s

b e t w e e n t h e e l e m e n t s c r e a t e d w i t h C o r r i d o r F 3 0

Corridor F30

0560

0564

49

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated, see secti on Moi sture . It i s

equal l y i mportant to take account of other work such as techni cal i nstal l ati ons before i nstal l ati on of the cei l i ng i s carri ed out. It i s i mportant for the end resul t

that the cei l i ng ti l es are i nstal l ed at ri ght- angl es, thi s makes i nstal l ati on qui cker and easi er. It wi l l faci l i tate i nspecti ons to i nstal l ati ons above the cei l i ng as

removal of the ti l es wi l l be easi er. It i s not recommended that cei l i ngs are i nstal l ed at a temperature consi stantl y over 50C.

C o m p o n e n t s

WALL ANGLE

Part no.

F3000012

W x L x H

40 x 3000 x 60

I n s t a l l a t i o n

C o m p o n e n t s

The wal l profi l es are made

from al uzi nc. Pai nted to

RAL 9016

S e t t i n g o u t

The posi ti on of the wal l angl es

shoul d be marked on the wal l s

and col umns. The bottom fl ange

of the wal l angl es i s the l evel

of Corri dor pl anks. Fi xati on wi th

screws at max 400 mm c/c.

A d j u s t m e n t

The Corri dor panel s are cross

cut wi th a j i gsaw for metal .

Longi tudi nal l y cuts are made wi th

a normal saw.

F i r e c a p

Into the back of the panel a

square furri ng cap i s i nserted.

Thi s must cl ose the openi ngs i nto

the Corri dor panel .

A i r i n l e t s a n d

o u t l e t s

Cutti ng out for openi ng i s done

by a j i gsaw, from the front si de.

Fi nal adj ustment by a fi ne tooth

saw or a Stanl ey kni fe.

L i g t h f i x t u r e s

Instal l ati on of 300 mm

l i ghtfi xture. Thi s i nstal l ati on

requi res a speci al Corri dor panel

wi th an extra l ayer of gypsum

board. The cut end adj acent to

the l umi nari e shal l be fi l l ed out

by GKF gypsum board. On the

back of the l i ght fi xture a GKF

gypsum board shal l be fi xed, and

the 3 el ements are now i nstal l ed

between 2 standard panel s. The

l i ght fi xture al so has to be screw

fi xed to the 2 adj acent panel s.

W a l l t r i m

The wal l angl es shal l be furred

by Fi reboard sri ps of 120 mm.

At el ements whi ch are cut

l ongi tudi nal an extra stri p of

Fi reboard shal l be fi xed. Fi xati on

by drywal l screw.

L a y - i n

The Corri dor panel s are l ai d i n

di rectl y on the wal l angl es. The

panel s are sel f- supporti ng to

2800 mm free span.

E n d - e l e m e n t s

Measurement A for the second

l ast panel s i s set, and the

measurement B i s made for the

l ast panel . The end panel i s

then cut to si ze and i s l ai d i n

on the wal l angl e wi th the extra

Fi reboard stri p.

C l o s i n g

The second l ast panel can now

be l ai d i n between the end panel

and the thi rd l ast panel .

Cotten gl oves shoul d be worn

at al l ti me when handl i ng the

Corri dor panel s.

L i g t h f i x t u r e s

Instal l ati on of l i ght fi xture l ess

than 300 mm. Cut out for the

si ze of the l i ght fi xture. Al l open

end i n the panel s to be cl osed

by GKF gypsum board, whi ch

shal l be screw fi xed to the metal

profi l e i n the panel . If necessary,

addi ti onal metal profi l e i s added

to secure the gypsum fi l l - out.

Fi l l - out gypsum stri ps to be screw

fi xed. The l i ght fi xture shal l be

screw fi xed to the panel . On the

back of the panel an addi ti onal

l ayer of GKF board shal l be fi xed.

F i r e c a p f i x i n g

The fi re protecti on cap shal l be

fi xed wi th angl e brackets, and

the voi d between the cap and

the ai r i nl et/outl et shal l be fi l l ed

wi th gypsum mortar.

A B

Corridor F30

50

1266

M

a

x

. 2

8

0

0

M

a

x

. 2

8

0

0

48

Measurements are i n mm.

D e t a i l

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

P r o d u c t

S i z e s

300 x (l ength) x 12.5 x mm

Max. Length 2800 mm.

D r a f t s p e c i f i c a t i o n

Danol i ne Corri dor F30, Whi te l ami nated as

standard, Instal l ed on wal l angl e F3000012.

Drawi ng no.: 36

S u s p e n s i o n s y s t e m

Corri dor F30 i s a sel fsupporti ng cei l i ng system wi th

i ntegrated steel profi l es, maki ng a free span of max. 2800

mm

Corri dor F30, adj ustment panel at wal l angl e, and wi th

gypsum shadow edge tri m.

Drawi ng no.: 36.2.004

Corri dor F30, j oi nti ng of l ong- edge agai nst short edge.

Drawi ng no.: 36.2.003

Corri dor F30 fi xed wi th wal l angl e at gypsum boards on

steel structure.

Drawi ng no.: 36.2.001

Corri dor F30 panel s wi th wal l angl e and gypsum board

shadow tri m.

Drawi ng no.: 36.2.002

51

Corri dor swi ng i s a hi nged cei l i ng constructi on whereby

apertures on al l four l ateral edges achi eve a rough yet

fl oati ng, l i ght desi gn.

The panel s are rectangul ar i n appearance, wi th l engths

of up to 1.8 m. Corri dor Swi ng i s fi tted wi th a hi nge and

swi vel s down wi thout the use of tool s.

The panel remai ns suspended duri ng i nspecti on work,

al l owi ng si mpl e and fast access to i nstal l ati ons.

D i s t i n c t i v e p e r f o r a t i o n s f a v o u r t h e f u n c t i o n a l

d e s i g n o f C o r r i d o r S w i n g 6 0 0

1266:

Architect: Arkitektgruppen Aarhus

Project: Greve Rdhus - Denmark

Product: Corridor Swing - M1

1156, 1158:

Architect: White Arkitekter Gteborg

Project: Medicinskt Kunskapshus, Gteborg - Sweden

Product: Corridor Swing - M1

Corridor Swing 600

1158

1156

1158

1

2

0

0

, 1

5

0

0

, 1

8

0

0

6

0

0

1

2

0

0

, 1

5

0

0

, 1

8

0

0

6

0

0

52

Measurements are i n mm.

D e t a i l

P e r f o r a t i o n

Gl obe: G1

Quadri l : Q1

Mi cro: M1

Regul a: R

Other perforati on patterns are manufactured to

order. Pl ease see secti on Perforati ons.

P r o d u c t

S i z e s

600 x 1200 x 12.5 mm

600 x 1500 x 12.5 mm

600 x 1800 x 12.5 mm

D r a f t s p e c i f i c a t i o n

Danol i ne Corri dor Swi ng 600, G1,

600 x 1200 x 12.5 mm, i nstal l ed i n suspensi on

system 721000.

Drawi ng no.: 52

S u s p e n s i o n s y s t e m

The Swi ng profi l es on the wal l s and the suspended fri ezes

to be i nstal l ed as per modul e of Corri dor 600

Corri dor Swi ng 600, j oi nt of 2 short- edges wi th profi l e

W- Swi ng 3.

Drawi ng no.: 52.2.003

Corri dor Swi ng 600 wi th fi x fri eze of pai nted Mi tex panel .

Drawi ng no.: 52.2.001

Corri dor Swi ng 600, l ongi tudi nal j oi nt between 2 panel s.

Drawi ng no.: 52.2.002

53

S t o r a g e & I n s t a l l a t i o n

Storage and i nstal l ati on shoul d not be carri ed out i n rooms wi th a rel ati ve humi di ty greater than 70%, unl ess otherwi se stated, see secti on Moi sture . It i s