Documente Academic

Documente Profesional

Documente Cultură

147 Choong - Sustainable Industrial Systems - A Case Study From The Malaysian Palm Oil Industry

Încărcat de

Aw Yeong Pei Yee0 evaluări0% au considerat acest document util (0 voturi)

73 vizualizări12 paginiSustainable Industrial Systems - A Case Study From the Malaysian Palm Oil Industry

Titlu original

147 Choong - Sustainable Industrial Systems - A Case Study From the Malaysian Palm Oil Industry

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentSustainable Industrial Systems - A Case Study From the Malaysian Palm Oil Industry

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

73 vizualizări12 pagini147 Choong - Sustainable Industrial Systems - A Case Study From The Malaysian Palm Oil Industry

Încărcat de

Aw Yeong Pei YeeSustainable Industrial Systems - A Case Study From the Malaysian Palm Oil Industry

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 12

PLM11 - 8th International Conference on Product Lifecycle Management 147

IFIP Working Group 5.1, 2011

Sustainable Industrial Systems: A Case Study from

the Malaysian Palm Oil Industry

Choong Chee Guan*

School of Mechanical Engineering

University of Leeds, LS2 9JT, UK

Fax: +44 113 343 2150, Tel: +44 113 343 2113

Email: mngcc@leeds.ac.uk

*Corresponding author

Alison McKay

School of Mechanical Engineering

University of Leeds, LS2 9JT, UK

Fax: +44 113 343 2150, Tel: +44 113 343 2113

Email: a.mckay@leeds.ac.uk

Abstract: Regulatory drivers such as the EUs Sustainable Procurement

Directive are creating a need for sustainable products where suppliers must

provide evidence of the environmental impact of the products they deliver to

customers. The environmental impact of the products is closely connected to

the environmental performance of the supply networks that transform the

product from raw materials and deliver it to customers. In this paper we argue

that lifecycle management approaches can usefully be applied to such supply

networks to support the design of sustainable industrial systems. Using the

Malaysian palm oil industry as a case study, the paper focuses on the definition

of a case study supply network with a view to creating information needed to

support lifecycle assessments of its operation under alternative environmental

management systems. Early results from studies exploring the influence of the

ISO 14001-based environment management systems on the operation of

Malaysian palm oil industry supply network are presented.

Keywords: Systems engineering, strategic management, environmental

management system, ISO 14001, sustainability

1 Introduction

In order to achieve improved standards of sustainability, there is a need for the Malaysian

palm oil industry to develop sustainability indicators to pursue certification of sustainably

produced palm oil with full traceability. As demand for low cost and high quality

vegetable oil increases, to feed the worlds growing population, frameworks to support

the visualisation of sustainability of palm oil supply networks will contribute to

improving the sustainability of palm oil production.

The need to produce palm oil sustainably has led to the establishment of the Round

Table on Sustainable Palm Oil. This acts as a platform to reach mutual understanding at

an international level among a range of palm oil stakeholders, including; palm oil

growers, palm oil processors/traders, consumer goods manufacturers, retailers,

investment organisations, social and development non-governmental organisations and

environmental or nature conservation non-governmental organisations. Such

understanding could be translated into common actions towards improving the

sustainability of palm oil production and used in its entire supply chain. The Round table

on Sustainable Palm Oil has progressed by formulating a set of principles and criteria for

148 Choong Chee Guan; Allison McKay

sustainable production, but has yet to implement a scheme to enable sustainably produced

palm oil to be certified with full traceability.

Roundtable on Sustainable Palm Oil ISO 14001

Principles and Criteria

Principle 1 The RSPO requirements for this principle are

Commitment to transparency consistent with the ISO 14001 communication

sub-element, with the exception that ISO 14001

does not specifically mention the reporting of

information on social issues.

Principle 2 This is a mandatory requirement of ISO 14001

Compliance with applicable laws that is checked by internal and external auditors.

and regulations It is important to note that ISO states that

appropriate information about legal and other

requirements should be communicated to all

persons working for or on behalf of the

organisation.

Principle 3 This commitment is additional to the

Commitment to long-term economic requirements of the ISO 14001 standard.

and financial viability

Principle 4 The ISO 14001 guideline does not specifically

Use of appropriate best practices by refer to best practices.

growers and millers

Principle 5 The ISO 14001 standard requires the preparation

Environmental responsibility and of management plans and environmental

conservation of natural resources and improvement plans for reducing the negative

biodiversity environmental impacts associated with the

significant issues.

Principle 6 An additional to those of the ISO 14001

Responsible consideration of employees management system specification.

and individuals and communities affected

by growers and mills

Principle 7 The ISO 14001 standard requires any changes to

Responsible development of new plantings the scope of the companys activities to be

included in the environmental management

systems.

Principle 8 Continuous improvement is one of the doctrines

Commitment to continuous improvement of ISO 14001 and the company must commit to

in key areas of activity this process in order to achieve certification.

Table 1: Links between the Roundtable on Sustainable Palm Oil principles and criteria and ISO

14001 elements

In this research, potential influences of ISO 14001-based environment management

systems on the operation of Malaysian palm oil industry supply networks are explored.

ISO 14001 is an internationally recognised standard for environmental management

systems and provides the requirements according to the standards outlined.

Environmental management system implementation requires that companies obtain ISO

14001 certification. The Roundtable on Sustainable Palm Oil principles and criteria

provide an interpretation of the sustainable palm oil requirements for incorporation within

the ISO 14001-based environment management systems framework. The implementation

of an environmental management system as a tool in this study can be regarded as a

response to the requirements of the Roundtable on Sustainable Palm Oil principles and

Sustainable Industrial Systems: A Case Study from the Malaysian Palm Oil Industry 149

criteria (as shown in Table 1) in realising the design of sustainable industrial systems. To

date, 20 mills in Malaysia have obtained Roundtable Sustainable Palm Oil certification.

1

However, the authors argue that standard operating procedures need to be modified not

only to incorporate the requirements of specific Roundtable on Sustainable Palm Oil

principles and criteria but also for the realisation of more sustainable industrial systems.

Market pressures coupled with regulatory drivers such as the EUs Sustainable

Procurement Directive are demanding sustainable products where suppliers are required

to provide evidence regarding the environmental performance of the industrial systems

that produce the products along with the products themselves. In response, ISO 14001-

based environmental management systems provide a means of tracking, managing and

improving performance regarding to these environmental requirements. The influence of

ISO 14001 on the implementing organisation performance plays a new way of thinking of

a balance economic, societal and environmental growth for sustainability. ISO 14001

certification has a positive impact on both economic and environmental performance

(Ann, et.al, 2006). In the future, the implementation of an environmental management

system framework model, through registration with ISO 14001, could become the norm.

2 Structure of the Paper

Figure 1: Research method

An overview of the regulatory framework within which the Malaysian palm oil

industry sits is given in Section 3. This is followed by a literature review, in Section 4,

which collects together information on Malaysian palm oil industry supply networks. The

research method used in this research is shown in Figure 1. It can be seen that the

research is based on a definition of a supply network of the Malaysian palm oil industry;

this was used to identify potential problems for the implementation of ISO 14001-based

environmental management system in the case study network and is provided in Section

5.1. The supply network map was used to identify potential problems from the

implementation of ISO 14001-based environmental management systems; these are

reported in Section 5.2. Step 3 involved the application of the so-called Enterprise

Engineering Framework (McKay, A et. al, 2009). This framework brings together ideas

from systems engineering and strategic management and supports their application to the

design of enterprise networks. The framework was used to develop sustainability

questions as uncertainties affecting the implementation of the design of sustainable

1

Fourth ASEAN State of the Environment Report 2009. Available at: http://www.aseansec.org/

publications/SoER4-Report.pdf

Map out supply network of Malaysian palm oil industry

Identify potential problems from the implementation of ISO14001-based EMS

Apply Enterprise Engineering Framework to manage transition processes

Develop a template questions assessing sustainability solutions

Benchmark sustainability indicators as critical success factors

150 Choong Chee Guan; Allison McKay

industry system in the Malaysian palm oil industry. The template questions can establish

relationship between the Malaysian palm oil industry as an organisation collaborating

with its supply networks that are responsible for the process of managing the

sustainability of the palm oil it produces. From the delivery of these sustainable solutions,

the benchmarked sustainability indicators can be used as critical success factors for the

redesign of materials flow, new technology advances for recycling, and environmental

and socio-economic impacts assessments in the future.

3 An overview of the regulatory environment Malaysian palm oil

In Malaysia, ISO 14001 certification is carried out by Standards and Industrial Research

Institute of Malaysia (SIRIM), QAS International Sdn. Bhd. At present, the evaluation of

the effectiveness of the ISO 14001-based environmental management system in reducing

environmental pollution is difficult to make. Nevertheless, the evaluation is only based on

the number of companies certified to ISO 14001. The high number of companies awarded

the certificate indicate high level of environmental awareness among the industrial sector.

As up to November 2010, a total of 56 companies have been certified with ISO 14001 by

Standards and Industrial Research Institute of Malaysia (SIRIM), QAS International Sdn.

Bhd., Malaysia as an approved Roundtable on Sustainable Palm Oil (RSPO) supply chain

certification body.

2

4 Literature review

The Malaysian palm oil industry is a highly regulated industry. Being sensitive and

proactive on current environmental concerns, the Malaysian palm oil industry is actively

pursuing international series of standards notably on climate change, life cycle

assessment, eco-labelling, environmental communications, and environmental

management systems. Although the ISO 14001-based environmental management

systems model was intended to foster continual environmental improvement, the standard

does not establish absolute requirements for environmental performance, other than a

commitment to compliance with applicable regulations, nor is environmental

performance a factor in certification. ISO 14001 provides a framework for organisations

to implement their environmental policies and third party verification that they are doing

so. As a management system standard it allows more flexibility in the practices applied

and the speed of implementation. ISO 14001does not provide verification that specific

performance requirements have been applied, unless linked to a code of practice which

defines the performance requirements. In addition, it does not permit product labelling.

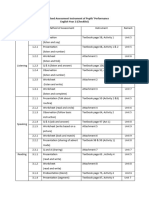

Table 2 showed a matrix of environmental management systems implementation

which can be related to the supply network map from the summary of literature review.

From the matrix shown, the researchers agreed that the successful implementation of

environmental management system were due to the on-going commitment and support

from the top management and better environmental improvement. For instant, Zutshi, et

al. (2004) examined the role of employees and suppliers as organisational stakeholders

during the ISO 14001-based environmental management systems adoption process. Some

empirical findings indicated that the adoption was influenced by organisation cultures

(GE Ann et al., 2006), regulatory and customer pressures (TK ElTayeb et al., 2010), and

reducing ecological impacts of economic activities (D Walker et al., 2007). It was also a

systematic approach to manage environmental issues in identifying opportunities of

conserving material and energy consumptions, reducing emission and waste, thus

2

Standards and Industrial Research Institute of Malaysia (SIRIM), QAS International Sdn. Bhd.,

Malaysia.

Sustainable Industrial Systems: A Case Study from the Malaysian Palm Oil Industry 151

improving process efficiency (B. Poksinska et al., 2003). While other results indicated

that involvement of all employees and flow of information factors influence the

efficiency and effectiveness of environmental management system implementation (L

Lawrence et al., 2002).

Table 2: Matrix of Environmental Management System Implementation

Strengths Weaknesses

1. Defines a companys environmental Ambiguous definitions and general vagueness of

philosophy terms (environmental aspect, environmental

impact, continual improvement, etc.)

2. Identifies environmental impacts and Lack of substantial public environmental

aspects reporting and public communication requirements

3. Sets regular objectives and targets Inconsistent global applications and

for managing environmental impacts interpretations of the standard

4. Creates a thorough employee Lack of clarity about the ISO 14001-based

training programme environmental management system auditing

criteria

5. Provides documentation/record No requirements for tracking the financial guidelines

success or failure of an ISO 14001-based

environmental management system (via

environmental cost accounting, cost benefit

analysis, etc.)

6. Ensures top management commitment No guidelines for standard environmental

and involvement as well as system performance indicators, which consequently

improvements makes the comparison of certified firms

environmental performance virtually impossible.

Table 3: Strengths and Weaknesses of ISO 14001-based environmental management system

T

o

p

m

a

n

a

g

e

m

e

n

t

s

u

p

p

o

r

t

D

o

c

u

m

e

n

t

a

t

i

o

n

&

C

o

n

t

r

o

l

M

a

t

e

r

i

a

l

C

o

n

s

u

m

p

t

i

o

n

s

B

i

o

d

i

v

e

r

s

i

t

y

&

E

c

o

l

o

g

i

c

a

l

I

m

p

a

c

t

s

E

n

e

r

g

y

&

W

a

t

e

r

U

s

a

g

e

E

m

i

s

s

i

o

n

&

W

a

s

t

e

s

Authors Environmental Management Systems

A Zutshi, AS Sohal. (2004)

B Poksinska, JJ Dahlgaard,

JAE Eklund. (2003)

D Walker, M Pitt, UJ

Thakur. (2007)

GE Ann, S Zailani, NA

Wahid. (2006)

L Lawrence, D Andrews, B

Ralph, C France. (2002)

MA Balzarova, P Castka,

CJ Bamber. (2006)

N Johnstone, J Labonne.

(2009)

Sebhatu SP, and Enquist B.

(2007)

TK ElTayeb, S Zailani, K

Jayaraman. (2010)

152 Choong Chee Guan; Allison McKay

Sustainability can be achieved through optimisation of the use of resources along the

product lifecycle, while maintaining quality of products and services (Ciceri et al., 2009).

However, optimization and quality of product related processes are strongly based on the

flow of information. The context of information and knowledge sharing between

producers and consumers is important for delivering service and sustainability along the

product lifecycle. There is also a need of addressing topics such as interoperability

throughout the supply network, knowledge sharing in the product chain and social

implications of sustainability. For this reason, product lifecycle management represents a

very important approach for achieving a more sustainable paradigm of in the design of

sustainable industrial systems.

There were both strengths and weaknesses to ISO 14001-based environmental

management systems in heightening organisation awareness of the importance of

managing environmental impacts and actions as shown in Table 3.

5 Case study results

5.1 Map of an example Malaysian Palm Oil Industry supply network

A map of the Malaysian Palm Oil industry supply network is given in Figure 2. The

boundary of the system considered in this research is shown by the dashed box; these are

the parts of the supply system that are located in Malaysia. The information about

customers is included in the map because they influence the requirements for

sustainability-related information. For example, the regulatory framework under which

food producers operate differs both across national boundaries and with the regulations

that, for example, cosmetic and detergent producers must comply with.

Figure 2: Supply network map for palm oil industry

The focus of mapping out the supply network for Malaysian palm oil was to review

the implementation of ISO 14001-based environmental management systems from

cradle-to-gate of the supply network. The system served as a boundary to identify, predict

and communicate information about the impacts on environment. The boundary covers

Plant-

ati on

c

A B

c fl ows from Or ganisation A to

Organisation B

Mil l

fresh frui t

bunches

Refinery

crude

palm oil

Crushing

Plant

palm

kernels

Trader

crude

kernel oil

empty fruit

bunches

palm kernel

meal

Manu-

facturers

Value-added

products such as

fibreboard,

pulp/paper and

ferti liser

Feed

Manufact

urers

Animal

feed

Farmers

Meat

products

Trader

palm

oil

Trader

Trader

Food

pr oducers

Trader

Trader

Detergent &

Cosmeti c

pr oducers

Trader

Trader

Chemi cal

pr oducer s

Trader

Trader

Biofuel

pr oducer s

Trader

Trader

Retail ers

palm

oil

KEY

Sustainable Industrial Systems: A Case Study from the Malaysian Palm Oil Industry 153

from plantation mill refinery crushing plant (dashed box). From the production

processes side, the implementation of ISO 14001-based environmental management

systems should be enhanced with proper procedures so that the entire production process

becomes more environmentally friendly.

However, sustainability solutions should include issues and flows that extend beyond

the nodes up to the retailers of end of life. In order to do so, the Malaysian palm oil

industry and its research and development arm are continuously working to improve the

industrys environmental performance. Various approaches and technologies aimed to

reduce the impact of the industry on the environment have been converted to successful

practices in palm oil plantation, palm oil mill, and refineries. The industry envisions

achieving the highest standards of sustainability of palm oil.

5.2 Potential Problems from the Implementation of ISO 14001-based

Environmental Management System Model in the Malaysian Palm Oil

Industry

Environmental management systems have potentially complementary and significant

implications for an organisations environmental sustainability of defining and

establishing sustainability among supply networks (refer to Figure 2). However, when

environmental management systems are adopted without consideration of a whole

sustainable industrial system, environmental benefits are likely to diminish. This is

because the organisation supply networks partners are unlikely share its environmental

goals and environmental sustainability of any organisation is inevitably limited by if

sustainability related questions are not incorporated in the design of its supply network.

From the supply network mapped out in Figure 2, the boundary of the system

considered in this research can be seen to range from the plantation (raw materials) to

retailers (end of life); as such the research relates to the management of a large portion of

the palm oil cycle. ISO 14001certification is applied to organisation rather than the

products of that organisation (within the dashed box in Figure 2). In this case, product

labelling (beyond the dashed box in Figure 2) was not permitted. In the absence of

product labelling, chain of custody is not normally traced. The implementation of ISO

14001-based environmental management systems help to reduce the costs of regulation,

in terms of government enforcement effort and the costs of compliance of the individual

enterprise. Hence, ISO 14001 certification can be used to replace some statutory reporting

requirements and was not a substitute for a regulatory framework, but the monitoring and

reporting systems of a well-managed enterprise might substitute for some of the statutory

inspections, audits, and reports normally required under government regulations. There

was also considerable evidence that an informed public has a strong influence on the

environmental performance of industrial enterprises, through a variety of mechanisms

that include market forces, social pressures, and support for improved regulatory controls.

Hence, it is argued that issues related to product life cycle management such as costs of

regulation, product labelling, documentation in proving compliancy, and product

information should be taken into considerations when designing a supply network where

product sustainability is a key factor.

5.3 Application of Enterprise Engineering Framework for Design of Sustainable

Industrial Systems

The implementation of product lifecycle management helps to regroup organisational

structure, operation process and resource configuration as facing customers and markets.

In this case, the enterprise engineering framework can be used to develop template

questions on sustainability issues that build upon the view of an entire product lifecycle.

154 Choong Chee Guan; Allison McKay

Building better understanding of sustainability related questions is an important in the

delivery of sustainable palm oil products. Applying the enterprise engineering framework

to the design of a Malaysian palm oil supply network can facilitate the translation of

environmental related requirements towards achieving sustainability solutions.

Define Develop Deploy

Purpose

Explore and define

sustainability issues

Agency

Sustainable industrial

products

supply network

Environmental

Management

Systems

Products &

services

Sustainability oriented

products & services

Design of

sustainable industrial

system solutions

Figure 3: Enterprise Engineering Framework for Design of Sustainable Industrial systems

Under the enterprise engineering framework, ISO 14001-based environmental

management systems can respond as strategic management approach that helps to define

how an organisation will address its impact on the environment. The ISO 14001-based

environmental management systems can be an agency in the enterprise engineering

framework in establishing an environmental policy; undergoing internal assessments of

the organizations environmental impacts; creating quantifiable goals to reduce

environmental impacts, providing resources and training workers; checking

implementation progress through systematic auditing to ensure that goals are being

achieved; correcting deviations from goal attainment; and undergoing management

review. By doing so, organisations can embed environmental practices deep within their

operational systems so that protecting the environment becomes an integral element of

their overall business strategy.

In Figure 3, the ISO14001-based environmental management systems sit in the

Agency row and served as the intended organisation that applies developed framework or

tools to serve the purpose to define sustainability issues in order to deliver sustainable

products and services. By applying the ISO 14001-based environmental management

systems as an enterprise operating system will mobilise the enterprise capabilities to

deliver value to stakeholders through assessing sustainability solutions (from the

plantation to retailers in Figure 2). The palm oil products, which sits in the Products and

Services row of the enterprise engineering framework, comprises a physical product and

associated services that support the product life through the supply networks. During the

enterprise realisation process, the design of sustainable industrial systems requirements

can be translated to deliver sustainability solutions. Hence, it is argued that the success of

sustainable industrial systems is determined by the ability to monitor and verify the

implementation of an organisations quality and environmental policy within the supply

networks. It is important that this framework can be adapted to develop template

questions to assess sustainability solutions for strategic management that integrates

environment, economy and social aspects.

5.4 Developing Template Questions to assess Sustainability Solutions by using

the Enterprise Engineering Framework

Applying the enterprise engineering framework to the design of sustainable industrial

systems is presented in the format of Template Questions in Table 4. The Purpose row of

Sustainable Industrial Systems: A Case Study from the Malaysian Palm Oil Industry 155

the enterprise engineering framework defined sustainability issues to answer the triple

bottom line implications and supply network influence to the entire supply network (from

the plantation to retailers in Figure 2). As for the Agency row, the organization in-charge

of the Malaysian palm oil industry sits to provide sustainable solutions by implementing

tool such as the environmental management system to establish relationship between the

sustainability questions and parameters by developing sustainability indicators to

benchmark critical success factors. Once the sustainable indicators were identified, the

Products and Services row of the enterprise engineering framework can then define

sustainability oriented products and services by answering to the needs and desires for

successful attributes in designing of sustainable industrial systems.

Level Aspects for an enterprise Template questions assessing sustainability solutions

1. Purpose What are the triple bottom line implications and the best

-defining sustainability issues possible sustainable solutions?

How can the sustainable supply network influence the

entire supply chain?

2. Agency Which organisation is in charged in providing sustainable

-defining sustainable industrial solutions?

products supply network How can the implementations of Environmental

Management System by the related agencies influence the

sustainable supply network?

What are the critical success factors to benchmark

sustainable indicators?

3. Products and Services What are the need and desire for sustainable attributes

-defining sustainability oriented in products & services?

products and services How can the sustainability oriented products and services

be developed?

Can the design of sustainable industrial systems solve

sustainability issues?

Table 4: Template questions for assessing sustainable industrial systems using the

Enterprise Engineering Framework

5.5 Benchmarking sustainability indicators as critical success factors

By assessing sustainable industrial systems through answering the template questions

provided, the authors anticipate to benchmark sustainability indicators of the mapped out

supply network performance (refer to Figure 2) in future research.

From the summary of studies done by researchers in Table 5, the management

approach success factor emphasized on the commitment and support from top

management was seen to be a successful implementation of the environmental

management systems beginning from the palm oil plantation itself. The researchers

argued that without top management supports, failure of any environmental management

system is likely. Employees must be able to trust managements decision for ISO 14001

implementation and feel the continuing support for the decision. A successful

implementation of ISO 14001-based environmental management systems also requires

changes within an organisation in structure with clearly defined responsibilities,

authorities, and communication channels throughout the supply networks. Due to

growing pressure from customers, governments and other stakeholders to the companies

to demonstrate their commitment to environment, ISO 14001 certification is seen as an

evidence of such a commitment. This helps to strengthen team spirit and venture business

into the international market. However, regular monitoring needs to be done by using

appropriate monitoring and measuring equipments to improve the processes. In order to

do so, the authors suggest that the provided template questions should be answered to

156 Choong Chee Guan; Allison McKay

assess to sustainable industrial systems and benchmarking of sustainability indicators as

critical success factors of the supply network performance should be an important

element.

Critical Success Factors References

1. Management Approach A Zutshi, AS Sohal. (2004),

Top management approach can be seen in the form of Ambika, Z, Amrik, S. (2004),

commitment and support, appropriate environmental policy Clement, R.B. (1996),

that is accepted by every employee in the organisation, and Kuhre WL. (1995),

regular management reviews. Lim-Teck G, Lee-PT. (2001),

Nalini, G., et al. (2004),

Wee & HA Quazi (2005).

2. Organizational Change

Organisational changes associated with the implementation can Clement, R.B. (1996),

lead to a continual improvement in environmental performance. Lim-Teck G, Lee-PT. (2001).

3. External and Social Aspects

The effective development and implementation of ISO 14001 Lin CM. (1995).

-based EMS is influenced to a great extent by external and Sayre D. (1996),

social aspects that include environmental legislation, market Thornton R. (2000).

pressure, customer requirements, and employee relations.

4. Technical Aspects

The effective implementation of ISO 14001-based EMS in Kuhre WL. (1995),

technical aspects include assistance from environmental Clement, R.B. (1996),

specialists, availability of monitoring and measuring equipment, Lin CM. (1995).

and the production process enhancement.

Table 5: Critical Success Factors by References

6 Conclusions

This case study was to explore the need to integrate sustainability considerations into

organisational structures and supply networks. The aim was to propose a framework to be

used for the design of sustainable industrial systems that can translate requirements to

deliver sustainability solutions. Hence, the relationship and linkages between

sustainability, organisational structures and supply networks need to be better understood

and therefore more research and case studies are needed. It is intended that the template

of sustainability questions created can be used to inform the design of supply networks

intended to deliver more sustainable products. In addition, we anticipate that they could

be used to inform benchmarking activities as critical success factors to aid decision

making and the measurement of supply networks performance. The novelty of this case

study was that it identifies the significance of sustainable industry systems from the

viewpoint of the enterprise engineering framework model and provides a basis for

evaluations with respect to the environmental and socio-economic impacts assessments in

the future.

The adaptation of the enterprise engineering framework towards the design of

sustainable industrial systems can be further analysed with a case study on the life cycle

assessment as the enterprise operating system. The expected outcomes can be compared

to investigate the importance between environmental management systems and life cycle

assessment which later will be coupled to address two major research questions:-

1. How can sustainability be defined and applied to the supply networks of

Malaysian palm oil industry?

2. What are the capabilities needed to develop sustainable new products, and how

might such capabilities be assessed?

Sustainable Industrial Systems: A Case Study from the Malaysian Palm Oil Industry 157

References

1 A Zutshi, AS Sohal. (2004). Adoption and maintenance of environmental management

systems: Critical success factors. Management of Environmental Quality: An

International Journal, Vol. 15 No. 4. pp. 399-419.

2 Ambika, Z. and Amrik, S. (2004). A study of the environmental management system

(EMS) adoption process within Australasian organizations 2. Role of stakeholders.

Technovation, 24. pp. 371-386.

3 B Poksinska, JJ Dahlgaard, JAE Eklund. (2003). Implementing ISO14000 in Sweden:

Motives, benefits and comparisons with ISO9000. International Journal of Quality and

Reliability Management Vol.20 No. 5. pp. 585-606.

4 Ciceri, N.D., Garetti, M. And Terzi, S. (2009). Product lifecycle management approach

for sustainability. Proceedings 19

th

CIRP Design Conference. Cranfield University.

5 Clement, R.B. (1996). Complete guide to ISO 14000. Englewood Cliffs, NJ: Prentice

Hall.

6 D Walker, M Pitt, UJ Thakur. (2007). Environmental management systems: Information

management and corporate responsibility. Journal of Facilities Management, Vol. 5 No.

1. pp. 49-61.

7 GE Ann, S Zailani, NA Wahid. (2006). A study on the impact of EMS certification

towards firms performance in Malaysia. Management of Environmental Quality: An

International Journal, Vol. 17 No.1. pp. 73-93.

8 Kuhre WL. (1995). ISO 14001 certification. Englewood Cliffs, NJ: Prentice Hall.

9 L Lawrence, D Andrews, B Ralph, C France. (2002). Techniques identify and assessing

environmental impacts: Investigating ISO14001 approaches. The TQM Magazine, Vol.

14 No. 1. pp. 43-50.

10 Lim-Teck G, Lee-PT. (2001). ISO 14000: the answer for environmental management

implementation: the Malaysian case. Total Quality Management, Vol. 12(2). pp. 223-

229.

11 Lin CM. (1995). The significance of ISO 14000 environmental standards for Asia

Pacific. APO Productivity Journal, Vol. 4. pp. 65-82.

12 Linton, J.D. and Jayaraman, V. (2005). A conceptual framework for product life

extension. International Journal of Production Research, Vol. 43 (9), pp. 1807-1829.

13 MA Balzarova, P Castka, CJ Bamber. (2006). How organizational culture impacts on the

implementation of ISO14001:1996 A UK multiple case view. Journal of

Manufacturing Technology Management, Vol. 17 No. 1. pp. 89-103.

14 McKay, A., Kundu, S. and Pennington, A.d. (2009). Supply networks: an approach to

Designing an extended enterprise. International Conference on Product Lifecycle

Management, Inderscience Publishing Limited.

15 MS ISO 14001. (2004). Handbook of Malaysian Standard: Environmental Management

System: Requirements with Guidance for Use. Department of Standards Malaysia.

16 N Johnstone, J Labonne. (2009). Why do manufacturing facilities introduce

environmental management systems? Improving and/or signaling performance.

Ecological Economics, Vol. 68 No. 3. pp. 719-730.

17 Nalini, G. et al. (2004). Motivating employees for environmental improvement.

Industrial Management & Data Systems, Vol. 104(4). pp. 364-372.

18 Sayre D. (1996). Inside ISO 14000: the competitive advantage of environmental

management. Delray Beach, FL: St. Lucie Press.

19 Sebhatu SP, and Enquist B. (2007). ISO 14001 as a driving force for sustainable

development and value creation. TQM Magazine, Vol. 19 No. 5. pp. 468484.

20 TK El Tayeb, S Zailani, K Jayaraman. (2010). The examination on the drivers for green

purchasing adoption among EMS 14001 certified companies in Malaysia. Journal of

Manufacturing Technology Management, Vol. 21 No. 2. pp. 206-225.

21 Thornton R. (2000). ISO 14001 certification mandate reaches automobile industry.

Environmental Quality Management, Vol. 10(1). pp. 89-93.

158 Choong Chee Guan; Allison McKay

22 Wee and HA Quazi. (2005). Development and validation of critical factors of

environmental management. Industrial Management & Data Systems, Vol. 105(1). pp.

96-114.

S-ar putea să vă placă și

- Heat Recovery From Process To Process Exchanger by Using Bypass ControlDocument9 paginiHeat Recovery From Process To Process Exchanger by Using Bypass ControlAw Yeong Pei YeeÎncă nu există evaluări

- Distillation Ch1Document22 paginiDistillation Ch1conker4Încă nu există evaluări

- 5 12Document1 pagină5 12Aw Yeong Pei YeeÎncă nu există evaluări

- Water Treatment2010baruDocument48 paginiWater Treatment2010baruAw Yeong Pei YeeÎncă nu există evaluări

- CP302 Example 01 OKDocument5 paginiCP302 Example 01 OKAw Yeong Pei Yee100% (1)

- Force in Bend PipeDocument4 paginiForce in Bend PipeAw Yeong Pei YeeÎncă nu există evaluări

- Fluid at RestDocument25 paginiFluid at RestZinb HimdanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Enterprise Exam Style QuestionsDocument2 paginiEnterprise Exam Style Questionsapi-301785352Încă nu există evaluări

- Cs 1410Document2 paginiCs 1410David DengÎncă nu există evaluări

- End of Semester ReflectionDocument3 paginiEnd of Semester Reflectionapi-242745290Încă nu există evaluări

- Ethnic Groups and RacismDocument21 paginiEthnic Groups and RacismNichaella BiscochoÎncă nu există evaluări

- Human Genome ProjectDocument28 paginiHuman Genome Projectمحمد بلال سرورÎncă nu există evaluări

- Multicast Live Video Broadcasting Using Real Time TransmissionDocument2 paginiMulticast Live Video Broadcasting Using Real Time Transmissionaruna2707Încă nu există evaluări

- South Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisDocument15 paginiSouth Coast LIDAR Project, 2008 - Delivery 1 QC AnalysisariesugmÎncă nu există evaluări

- Learning StoryDocument13 paginiLearning Storyapi-582461316Încă nu există evaluări

- Guide To Information Technology Security ServicesDocument84 paginiGuide To Information Technology Security ServicesSecurity Face to FaceÎncă nu există evaluări

- Resume Updated 12 31Document2 paginiResume Updated 12 31api-436752595Încă nu există evaluări

- TCS Verbal Placement QuestionsDocument5 paginiTCS Verbal Placement QuestionsNivashini100% (1)

- Manual To KivyDocument2 paginiManual To KivyvalkmaxÎncă nu există evaluări

- Training D112 - V3 - 02E PDFDocument77 paginiTraining D112 - V3 - 02E PDFkratmelÎncă nu există evaluări

- The Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Document1 paginăThe Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Costa, PatríciaÎncă nu există evaluări

- Wisdom Blog - Sri Sri Ravi Shankar Art of LivingDocument3 paginiWisdom Blog - Sri Sri Ravi Shankar Art of LivingShrikrishna PotdarÎncă nu există evaluări

- Condition Surveys and Asset Data Capture - Sample PDFDocument5 paginiCondition Surveys and Asset Data Capture - Sample PDFfghabboonÎncă nu există evaluări

- 04 Vaca Muerta Shale PDFDocument14 pagini04 Vaca Muerta Shale PDFsanty222Încă nu există evaluări

- Anomalous Worldwide SEISMIC July 2010Document130 paginiAnomalous Worldwide SEISMIC July 2010Vincent J. CataldiÎncă nu există evaluări

- TS en 12697-6 A1 Yoğunluk Ve Öz Kütle Tayi̇ni̇Document17 paginiTS en 12697-6 A1 Yoğunluk Ve Öz Kütle Tayi̇ni̇DEFNEÎncă nu există evaluări

- The Year's Best Horror Stories - Karl Edward Wagner PDFDocument298 paginiThe Year's Best Horror Stories - Karl Edward Wagner PDFAmbaejo96100% (1)

- Clinical OpticsDocument88 paginiClinical OpticsKris ArchibaldÎncă nu există evaluări

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Document2 paginiPenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingÎncă nu există evaluări

- Btstack Gettingstarted 1.1Document51 paginiBtstack Gettingstarted 1.1Christian WangÎncă nu există evaluări

- JjiDocument64 paginiJjiPriyanka YaduÎncă nu există evaluări

- Pathway Foundation T'SDocument113 paginiPathway Foundation T'SDo HuyenÎncă nu există evaluări

- W3: Assess 2 On Self-PerceptionDocument2 paginiW3: Assess 2 On Self-PerceptionGielyn Camilo100% (1)

- If The fYR of "Macedonia" Needs A Lie in Order To Exist, Its Existence Is Redundant by M.A.TemplarDocument157 paginiIf The fYR of "Macedonia" Needs A Lie in Order To Exist, Its Existence Is Redundant by M.A.TemplarMakedonas Akritas50% (4)

- SCHLEICH - Advanced Test Technologies - GLP1-e - PE+IR+HVAC PDFDocument4 paginiSCHLEICH - Advanced Test Technologies - GLP1-e - PE+IR+HVAC PDFRakesh Kumar VermaÎncă nu există evaluări

- Intelligent Design of Industrial Steel Buildings - A BIM ApproachDocument8 paginiIntelligent Design of Industrial Steel Buildings - A BIM Approachshubham kothawadeÎncă nu există evaluări

- CV 4Document2 paginiCV 4api-312667938Încă nu există evaluări