Documente Academic

Documente Profesional

Documente Cultură

IronPython Calculator Fillable

Încărcat de

boy_scouttDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IronPython Calculator Fillable

Încărcat de

boy_scouttDrepturi de autor:

Formate disponibile

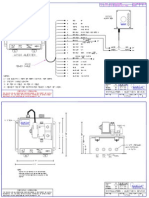

Please answer the six questions below to calculate the potential savings and revenue increases

that could result from adding the Iron Python to your operation.

1. On average, how many trains are built in your yard each day?

2. How many cuts does it typically take to build a train?

3. How many employees on a standard 8 hour shift spend the majority

of their time applying and releasing handbrakes and/or conducting

a locomotive to build trains?

4. How many employee accidents related to the applying and releasing

of handbrakes are reported each year?

5. How many trains per month depart from the yard with a handbrake

left applied?

6. On average, how many wheel sets are replaced within your yard

each month?

Potential annual cost savings:

See page 2 for details

Total potential annual value:

If you could increase yard effciency and build more trains per

day, that would amount to a potential additional annual revenue of:

Contact your AAA representative today for more information.

$ 0

0

$ 0

$ 0

The potential for savings resulting from incorporating an Iron Python in your operation is calculated by the information weve gathered

through the following:

Fuel Savings:

Holding cars while setting and releasing handbrakes as cuts are brought to the departure track requires an idling locomotive, which on

average burns 5 gallons of fuel per hour. Alternatively, using the Iron Python to hold cars eliminates the need for the setting and releasing

of handbrakes, and therefore the fuel expense from the idling locomotive. Assuming a locomotive burns fuel at a rate of 5 gallons

per hour at idle, with an average cost of $3.00 per gallon, we can multiply this number by the number of trains built within your

yard, the number of cuts used based on the information youve supplied, and the average time it takes to set and release handbrakes

for each cut. Assuming that each cut requires the application and release of 8 to 16 handbrakes, taking approximately 20 minutes to

accomplish the task, we can determine the annual fuel savings.

Labor Effciency:

A typical operation requires a two person crew when moving cars and building trains, with one person operating a locomotive, and the

second applying and releasing handbrakes. The Iron Python holds the weight of the cars when building trains and eliminates the need

to apply and release handbrakes, reducing the workload. This allows your crews to work more effciently and makes them available for

other tasks. The labor costs incurred while building trains is therefore decreased. If your yard employs crews for three shifts at eight

hours per shift, and an employee costs you on average $50 per hour, the potential for savings on labor is signifcant.

Yard Safety/Insurance Savings:

Applying and releasing handbrakes can be a dangerous job. Weather conditions and time constraints are some of the factors that can

contribute to the danger, and accidents do happen. By eliminating the need for applying and releasing handbrakes during the process of

building trains, the Iron Python helps you eliminate this danger and greatly reduce the number of accidents that take place. Considering

the wages paid while an employee misses work, the medical expenses, insurance premiums, etc., the average cost of an incident

occurring is approximately $25,000. The potential for savings is clear, and more importantly, you have the ability to improve safety and

risk to your employees.

Yard Effciency:

Applying and releasing handbrakes is a monotonous task, and occasionally a handbrake is left engaged when a train leaves a yard.

When this happens, a dragging wheel will trigger a heat sensor outside of the yard, and the train must be stopped and the situation

investigated. When these types of situations occur, we can assume that a train could be delayed on average for 1 1/2 hours, as well

as tying up the main track, wasting both time and money, an estimated $1,000 per hour. By eliminating the need for applying and

releasing handbrakes, the Iron Python eliminates this potential for human error, and increases proftability.

The normal life span of a wheel set is 5 years. When a train leaves the yard with a handbrake applied, a wheel set is damaged and must

be replaced sooner. Studies have shown that repair expenses are 20% greater for emergency maintenance vs. scheduled maintenance.

In addition to creating a more effcient yard, the Iron Python decreases your expenses such as the need to replace defective wheel sets

resulting from handbrake related accidents. The Transportation Technology Center attributes the majority (assuming 75%) of wheel

slide defects to handbrake related incidents. A conservative estimate is that half of these could have been prevented by using the Iron

Python. The number of wheel sets replaced each month, multiplied by a $1,000 average cost of replacement, is a considerable savings.

The Iron Python is revolutionizing the industry, creating safer, more effcient yards. The potential for savings goes well beyond keeping

money in your pocket, consider the ability it gives you to increase your throughput. If two more trains can be built each day, and

on average a train contains seventy cars, each car representing a $100 of income, the potential for additional revenue is over

$5,000,000 annually!

$ 0

$ 0

$ 0

$ 0

$ 0

$ 0

S-ar putea să vă placă și

- Documentation For Power Generation Using Speed BreakerDocument7 paginiDocumentation For Power Generation Using Speed BreakerVigneshwaran SrinivasanÎncă nu există evaluări

- Thesis On Vehicle Maintenance ManagementDocument7 paginiThesis On Vehicle Maintenance Managementashleykoetterwichitafalls100% (2)

- Refueling Automated and Autonomous Trucks - Challenges and OpportunitiesDocument14 paginiRefueling Automated and Autonomous Trucks - Challenges and OpportunitiesSylvie PerronÎncă nu există evaluări

- Maintenance Cost Reduction Project: Solving Problems With Labor and Maintenance CostsDocument24 paginiMaintenance Cost Reduction Project: Solving Problems With Labor and Maintenance CostsTee YeesiangÎncă nu există evaluări

- Veh Eng CWDocument2 paginiVeh Eng CWBali AminÎncă nu există evaluări

- Research Paper On Air Powered Car PDFDocument6 paginiResearch Paper On Air Powered Car PDFfvgy6fn3100% (1)

- Americas 4 10 HitachiDocument4 paginiAmericas 4 10 HitachikannonzkÎncă nu există evaluări

- 15 - p3 - Jun - 2011 - QuDocument10 pagini15 - p3 - Jun - 2011 - QuAmeena FatimaÎncă nu există evaluări

- Contrasting EV and ICE VehiclesDocument6 paginiContrasting EV and ICE VehiclesJoshua Michael MarianiÎncă nu există evaluări

- 360 Degree Rotating Car DesignDocument5 pagini360 Degree Rotating Car DesignabiÎncă nu există evaluări

- Homebuilt Wood CarDocument26 paginiHomebuilt Wood Carsjdarkman1930100% (3)

- Homebuilt Car With Wood Frames - Practical MechanicsDocument39 paginiHomebuilt Car With Wood Frames - Practical Mechanicssjdarkman1930100% (3)

- Estimation of Costs of Heavy Vehicle Use Per Vehicle-Kilometre in CanadaDocument71 paginiEstimation of Costs of Heavy Vehicle Use Per Vehicle-Kilometre in Canada07103091Încă nu există evaluări

- Off RD HaulingDocument7 paginiOff RD Haulingfgghy5666Încă nu există evaluări

- Planning Cement Terminal OperationsDocument10 paginiPlanning Cement Terminal Operationsasad55001Încă nu există evaluări

- Literature Review of Automatic Car Parking SystemDocument4 paginiLiterature Review of Automatic Car Parking Systemluwop1gagos3Încă nu există evaluări

- Atlas Honda Plant VisitDocument4 paginiAtlas Honda Plant VisitZEHRA AHMEDÎncă nu există evaluări

- Schneider Tractor Balancing ProblemDocument2 paginiSchneider Tractor Balancing ProblemAbhishek ChandnaÎncă nu există evaluări

- Iot Based Refueling System: (Hf2071Seeng)Document12 paginiIot Based Refueling System: (Hf2071Seeng)nadeeshanÎncă nu există evaluări

- Equipment Cost Estimating - Otuonye - 2000Document42 paginiEquipment Cost Estimating - Otuonye - 2000Rotax_Kid0% (1)

- Vertical Car Parking System: October 2019Document7 paginiVertical Car Parking System: October 2019Nandar KPMÎncă nu există evaluări

- Automated Manual Transmission ThesisDocument5 paginiAutomated Manual Transmission ThesisWriterPaperCanada100% (2)

- Thesis Statement For Electric CarsDocument6 paginiThesis Statement For Electric Carsafkoliddh100% (2)

- Innovation Design PackageDocument10 paginiInnovation Design Packageapi-345931616100% (1)

- m3 Challenge DocumentDocument28 paginim3 Challenge Documentapi-585773971Încă nu există evaluări

- Example Problem (English) A Contractor Is Planning To Put The Following Spread On A Dam Job. What Is The Estimated Production and cost/BCY?Document5 paginiExample Problem (English) A Contractor Is Planning To Put The Following Spread On A Dam Job. What Is The Estimated Production and cost/BCY?Anonymous nm4qliÎncă nu există evaluări

- Conversion of Vehicle To Electric - Kapil - Shrivastava - and - Ram - BansalDocument10 paginiConversion of Vehicle To Electric - Kapil - Shrivastava - and - Ram - BansalankurÎncă nu există evaluări

- MET2019 Saliba CodyDocument25 paginiMET2019 Saliba Codysantosjillian866Încă nu există evaluări

- Design and Development of a Motorized Screw JackDocument8 paginiDesign and Development of a Motorized Screw JackTom Dulin BitangaÎncă nu există evaluări

- MSIS 511 Operations Management Problem SetsTITLEMSIS 511 Operations Management Problem Set SolutionsDocument8 paginiMSIS 511 Operations Management Problem SetsTITLEMSIS 511 Operations Management Problem Set SolutionsjarjonaeÎncă nu există evaluări

- Automotive History: Evolution of the CarDocument14 paginiAutomotive History: Evolution of the CarJohanamae DimarucutÎncă nu există evaluări

- Automatically Tyre PressureDocument18 paginiAutomatically Tyre PressureMujeeb RahmanÎncă nu există evaluări

- Top 10 Future Transportation InnovationsDocument19 paginiTop 10 Future Transportation Innovations정소연Încă nu există evaluări

- Hydrogen and Fuel Cell Scooters - Electric Bicycles - WheelchairsDocument6 paginiHydrogen and Fuel Cell Scooters - Electric Bicycles - WheelchairsHasanUSLUMÎncă nu există evaluări

- Research Paper On Hybrid Vehicles PDFDocument5 paginiResearch Paper On Hybrid Vehicles PDFafeekqmlf100% (1)

- Factors Affecting Fuel Consumption of Heavy EquipmentDocument3 paginiFactors Affecting Fuel Consumption of Heavy EquipmentSIVACHANDRANÎncă nu există evaluări

- Saving Fuel Tips Booklet1Document27 paginiSaving Fuel Tips Booklet1Miguel MartinÎncă nu există evaluări

- Solution Manual For Om 6Th Edition Collier Evans 1305664795 978130566479 Full Chapter PDFDocument46 paginiSolution Manual For Om 6Th Edition Collier Evans 1305664795 978130566479 Full Chapter PDFjoyce.willoughby377100% (11)

- Dissertation On Electric VehiclesDocument5 paginiDissertation On Electric VehiclesWriteMyPaperApaFormatToledo100% (1)

- CH #1 NumericalsDocument2 paginiCH #1 NumericalsMs Noor ul AinÎncă nu există evaluări

- E Rickshaw (Electric Tuk Tuks) Manufacturing Business 74545Document65 paginiE Rickshaw (Electric Tuk Tuks) Manufacturing Business 74545Nikita MotwaniÎncă nu există evaluări

- E Rickshaw Electric Tuk Tuks Manufacturing Business PDFDocument65 paginiE Rickshaw Electric Tuk Tuks Manufacturing Business PDFdeepu kumar100% (2)

- BMX Cycles Case SolutionDocument4 paginiBMX Cycles Case SolutionamatulmateennoorÎncă nu există evaluări

- AbstractDocument14 paginiAbstractbernabasÎncă nu există evaluări

- Chapter 8 Operating CostingDocument13 paginiChapter 8 Operating CostingDerrick LewisÎncă nu există evaluări

- Mie12 094Document6 paginiMie12 094S.m. FerdousÎncă nu există evaluări

- Auto Car WashDocument20 paginiAuto Car WashAmeya Pai AngleÎncă nu există evaluări

- Research Paper On Automatic Transmission System PDFDocument7 paginiResearch Paper On Automatic Transmission System PDFaflbodayoÎncă nu există evaluări

- Vehicle Lifecycle Costs Analysis: Sponsored byDocument32 paginiVehicle Lifecycle Costs Analysis: Sponsored byJairo Iván SánchezÎncă nu există evaluări

- Hypercar ReportDocument24 paginiHypercar Reportdevhx67% (6)

- Tractor Engine TypesDocument18 paginiTractor Engine Typeswajid aliÎncă nu există evaluări

- Feasibility of Parking Plaza in Sadar Town of KarachiDocument15 paginiFeasibility of Parking Plaza in Sadar Town of KarachiArif SamoonÎncă nu există evaluări

- Hybrid Engine Research PaperDocument8 paginiHybrid Engine Research Paperzijkchbkf100% (1)

- Design and Construction of A Solar Powered VehicleDocument10 paginiDesign and Construction of A Solar Powered VehicleSaket SharmaÎncă nu există evaluări

- Microsoft Word - CEV633 Tutorial - CHP 1 PDFDocument2 paginiMicrosoft Word - CEV633 Tutorial - CHP 1 PDFmuhammadÎncă nu există evaluări

- 6/9/2008 Mechanical Engineering Seminar Topic: Echalone C OMDocument25 pagini6/9/2008 Mechanical Engineering Seminar Topic: Echalone C OMPrabir Kumar PatiÎncă nu există evaluări

- Cars And Auto Accessories: The Little Gadgets That Personalise Luxury...De la EverandCars And Auto Accessories: The Little Gadgets That Personalise Luxury...Încă nu există evaluări

- The Xybrid Vehicle Expanding on the Hybrid: Select Your Electric Car, #2De la EverandThe Xybrid Vehicle Expanding on the Hybrid: Select Your Electric Car, #2Încă nu există evaluări

- Aceleracion y FrenadoDocument8 paginiAceleracion y Frenadoboy_scouttÎncă nu există evaluări

- Rail ResistanceDocument14 paginiRail Resistancehalf2liferÎncă nu există evaluări

- VSD Paper Ictam 2000Document16 paginiVSD Paper Ictam 2000riyyo2424Încă nu există evaluări

- C2518d AlerterDocument2 paginiC2518d Alerterboy_scouttÎncă nu există evaluări

- Esfuerzo TractivoDocument6 paginiEsfuerzo Tractivoboy_scouttÎncă nu există evaluări

- 15 - How Important Is Sequence in A TaskDocument2 pagini15 - How Important Is Sequence in A Taskboy_scouttÎncă nu există evaluări

- Formula Davis - AremaDocument4 paginiFormula Davis - Aremaboy_scouttÎncă nu există evaluări

- FHA FULL Condo Questionnaire 12-09Document2 paginiFHA FULL Condo Questionnaire 12-09The Pinnacle TeamÎncă nu există evaluări

- Best Practices Risk Mapping RR 07 01 04 PDFDocument4 paginiBest Practices Risk Mapping RR 07 01 04 PDFVitalis MutsimbaÎncă nu există evaluări

- Case Study On Sachet InsuranceDocument2 paginiCase Study On Sachet Insurancesmd.naeem2Încă nu există evaluări

- Star Health Corporate BrochureDocument4 paginiStar Health Corporate BrochureRajendiran SundaravelÎncă nu există evaluări

- TARRIFFDocument4 paginiTARRIFFAnoop KalathillÎncă nu există evaluări

- 11 Usc 522Document387 pagini11 Usc 522BlaqRubi100% (1)

- Airsoft WaiverDocument1 paginăAirsoft Waiverinfo8339Încă nu există evaluări

- Passing MantraDocument23 paginiPassing MantraVenkatesh NaiduÎncă nu există evaluări

- Need For Indemnity in Commercial ContractsDocument13 paginiNeed For Indemnity in Commercial ContractsUdit KapoorÎncă nu există evaluări

- Project 1Document25 paginiProject 1Pinto Joseph100% (1)

- Insurance Code RevDocument13 paginiInsurance Code RevPaterno S. Brotamonte Jr.Încă nu există evaluări

- Bajaj Allianz General Insurance Company LTDDocument16 paginiBajaj Allianz General Insurance Company LTDAYUSH PRADHANÎncă nu există evaluări

- Irrevocable Documentary Credit - Appl (EN) v1.1Document2 paginiIrrevocable Documentary Credit - Appl (EN) v1.1Firaol BelayÎncă nu există evaluări

- Case On Special ContractDocument6 paginiCase On Special ContractShrestha Steve SalvatoreÎncă nu există evaluări

- IBLP-990s 2002-2006Document93 paginiIBLP-990s 2002-2006oh_frabjous_joyÎncă nu există evaluări

- Cenro San Isidro Swot AnalysisDocument2 paginiCenro San Isidro Swot Analysisleahtabs100% (1)

- The Accounting Cycle:: Accruals and DeferralsDocument41 paginiThe Accounting Cycle:: Accruals and Deferralsmahtab_rasheedÎncă nu există evaluări

- Latest Tax CalculatIor 3.3.2Document16 paginiLatest Tax CalculatIor 3.3.2Bijender Pal Choudhary100% (3)

- Mypolicy-SBI Life Customer Self Service Portal PDFDocument1 paginăMypolicy-SBI Life Customer Self Service Portal PDFArjun SrinivasÎncă nu există evaluări

- Form16 Mar 2019 PDFDocument9 paginiForm16 Mar 2019 PDFManish Kumar SinghÎncă nu există evaluări

- Insurance Policy Dispute Arbitration Clause WaivedDocument2 paginiInsurance Policy Dispute Arbitration Clause WaivedJosef GutierrezÎncă nu există evaluări

- As 4303-1995 (Reference Use Only) General Conditions of Subcontract For Design and ConstructDocument8 paginiAs 4303-1995 (Reference Use Only) General Conditions of Subcontract For Design and ConstructSAI Global - APACÎncă nu există evaluări

- Lee v. Lee Air Farming Ltd.Document8 paginiLee v. Lee Air Farming Ltd.aruba ansariÎncă nu există evaluări

- MOTOR INSURANCE TITLEDocument5 paginiMOTOR INSURANCE TITLEVara PrasadÎncă nu există evaluări

- Etihad Credit Export Insurance-02.01.20Document3 paginiEtihad Credit Export Insurance-02.01.20kidamanÎncă nu există evaluări

- Automotive, Banking & Other Sectors Top Companies HR ContactsDocument15 paginiAutomotive, Banking & Other Sectors Top Companies HR ContactsMohitÎncă nu există evaluări

- MBA Entrance Exams GK Guide Wins PulitzerDocument77 paginiMBA Entrance Exams GK Guide Wins Pulitzersakshi raiÎncă nu există evaluări

- Air Macau - Rated and Non-Type Rated A320 Captains - JS November 2018Document6 paginiAir Macau - Rated and Non-Type Rated A320 Captains - JS November 2018Ghardaddou YasserÎncă nu există evaluări

- 129 - Placing Slip (MH) - PT. Sentra Makmur Lines - RevisiDocument4 pagini129 - Placing Slip (MH) - PT. Sentra Makmur Lines - RevisiAKHMAD SHOQI ALBIÎncă nu există evaluări

- About Bharti AxaDocument6 paginiAbout Bharti AxaNoman AkhtarÎncă nu există evaluări