Documente Academic

Documente Profesional

Documente Cultură

Lubrication - Maintenance Cost or Opportunity?: Noria Corporation

Încărcat de

marcalasanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lubrication - Maintenance Cost or Opportunity?: Noria Corporation

Încărcat de

marcalasanDrepturi de autor:

Formate disponibile

Lubrication - Maintenance Cost or

Opportunity?

Noria Corporation

Tags: lubrication programs

To those in the maintenance department, precision

lubrication is a no-brainer. It stands to reason that

lubrication excellence is a good investment. Put

simply, machines run better when they are properly

lubricated. However, for those in other parts of the

organiation who don!t understand the nuances of

elastohydrodynamic lubrication, lithium complex

grease thic"eners or filtration beta ratios #or perhaps

don!t care$%, spending money on lubrication upgrades

and improvements is simply another overhead cost.

&rom this viewpoint, lubrication, li"e every other cost, should be minimied to help

the organiation survive in today!s ultracompetitive global mar"etplace.

'o how do we convince management that spending money on lubrication and other

reliability-based maintenance improvement initiatives is a good idea( )fter all, we

in maintenance understand that such improvements must ma"e a difference. 'urely

management should be able to see the value that improved lubrication can have on

e*uipment and productivity.

+he issue is not that management doesn!t care, but rather that most managers

simply don!t have the depth of "nowledge about how lubrication can affect

e*uipment reliability - beyond the last catastrophe that shut down production - to

ma"e an informed decision.

'hould we send our managers to a lubrication training class( Perhaps, but while

there is no doubt that some education is re*uired for management, expecting our

management team #outside the maintenance group% to become conversant with the

details of lubrication excellence is an unrealistic proposition. Instead, it is necessary

for those in the maintenance team to become internal salespeople, convincing

management that an investment in lubrication is worthwhile.

&or many, this is an uncomfortable proposition. ,ust the thought of selling

something con-ures up images of a used car salesman, trying to convince a

suspicious and wary purchaser that the beat-up Pinto with balding tires and rusty

doors is indeed a solid car. However .sales/ doesn!t have to be a dirty or taboo s"ill

to learn. In fact, most of us are selling on a daily basis. 0ven mundane family

decisions, such as which restaurant should we eat at or which movie to watch, are

in fact sales transactions. 1oth parties express their needs, wants and desires, and

a decision is made based on the available facts. +o some degree, we are all

salespeople.

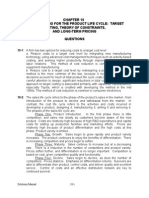

Table 1. Calculating Opportunity Costs for Lubrication Excellence

Table 2. Summarizing the Cost to Deelop a Lubrication Excellence

!rogram

Table ". Compiling a #ie$year Cost %enefit &nalysis for Lubrication

Excellence

+he "ey to selling management is to spea" their language. ,ust li"e learning to

spea" &rench will be of no benefit for a vacation in 2exico, to convey our message

we must translate the language of lubrication, which is foreign to most managers,

into the universal management language of dollars and cents. +he "ey to an

effective translation is to develop a solid model which outlines the issues at hand

#excessive maintenance costs, lost production costs, production derating, poor

product *uality, etc.%, outlines a proposed solution #including estimated costs%, and

finally, and most importantly, estimates a return on this investment. ,ust li"e every

other investment opportunity, management wants to "now whether a dollar

invested in this pro-ect will yield an appropriate return. 3therwise, that dollar is

li"ely to be invested elsewhere, and rightly so.

'etting Starte(

+he first step is to identify the opportunity costs4 those costs that the organiation

currently bears that could be eliminated through planned improvements. Consider a

hypothetical plant where little has changed in the lubrication department for the

past 56 years. Its maintenance budget has dropped by 76 percent over the last

three years. However, during the same time frame, the plant has experienced some

significant unscheduled downtime and production losses. Conse*uently,

management is demanding improvements in e*uipment reliability. 1ased on articles

in Machinery Lubrication and other magaines, we believe a lubrication best

practices program can eliminate a significant number of e*uipment failures and help

reduce total maintenance costs.

)n evaluation of the current state of the lubrication program reveals that few

machines have been e*uipped for a modern-day lubrication best practice

#appropriate breathers, appropriate dedicated filtration for all ma-or hydraulics

circulating systems, *uic"-connects for off-line filtration for all critical wet sump

systems, oil sample valves etc. etc.%. ) significant investment in both time and

money is re*uired to bring upgrade e*uipment to modern-day best practice if we

are to have any hope of significantly reducing downtime costs.

Now consider the mechanics of how lubrication is performed. In addition to poor

e*uipment configuration, basic lubrication P2s, regreasing, top-offs and decisions

about machine inspections are being performed, but *uantity, fre*uency and other

tas" details are left to the lubrication technicians. 1ased on experience, we believe

a number of problems were a direct result of either insufficient or excessive

lubrication. 8e also believe that some of these problems can be resolved by a

careful review of all lubrication P2 activities so that both fre*uency and tas" details

are based on sound lubrication engineering fundamentals, not -ust the lube tech!s

best guess. 1y rationaliing our new P2s into more efficient lube routes, we also

believe we can become more efficient in our activities.

&inally, let!s loo" at the oil analysis program. 9egardless of the inability to ta"e a

*uality sample due to the lac" of sample valves, our program is poorly designed

with few if any targets and limits, and an outdated test slate more appropriate to

diesel engines than modern production e*uipment. In summary, this hypothetical

plant is in rough shape$

The Opportunities

+he first and most obvious opportunity in the hypothetical plant is to try to reduce

unscheduled downtime. +he assumption is that some portion of these unscheduled

events can be attributed to poor contamination control or lubrication practices. 1y

modifying e*uipment to control contaminants while allowing best lubrication

practices to be deployed, some or all of the lubrication-related failure events can be

eliminated.

)nother area of opportunity is in right-siing the lubrication P2s. :ue to a reduced

maintenance budget, we are faced with doing more with less. It is believed that by

carefully reviewing all lubrication P2s for both fre*uency and tas" details, not only

will we ensure our e*uipment is properly lubricated, but our wor" load will decrease

by eliminating unnecessary maintenance activities #for example, regreasing a

bearing every month, when every six months is more appropriate, or changing oil

unnecessarily when a condition-based change is more appropriate%.

Defining the Opportunity Costs

+he *uestion is, how can we estimate our opportunity costs from the plethora of

financial, #maintenance costs and annual downtime costs%, substantive #failure

history or machine uptime% and anecdotal #for example we thin" the most recent

failure was due to lac" of lubrication% data available to us(

+he model in +able 7 attempts to account for these factors. 8e begin by

estimating, in round numbers, the current annual maintenance cost. In order to

brac"et the opportunity #provide a low and high estimate%, we will then review the

maintenance budget history to establish a low and high limit. &rom this history, we

can now pro-ect a best case #costs are lower than expected%, li"ely case #costs are

as expected% and worst case #costs are higher than expected due to unplanned

expenditures% scenarios.

Next, determine the total annual downtime costs. +his is where it can start to get

tric"y. 8hile in some plants, this figure is relatively straightforward, varying

production schedules, mar"et conditions #not all product is sellable% and poor

record-"eeping can ma"e obtaining realistic estimates challenging. In obtaining

estimated downtime costs, it!s often a good idea to involve production and plant

management; after all, it is these people to whom we are attempting to sell.

Involving management in the process early on by providing their best guess of

estimated costs, this creates buy-in and ownership in the process. It also prevents

cynicism when it!s time to present the final cost benefit analysis. +he .low/, .li"ely/

and .high/ case scenarios are helpful here. 8here downtime costs are well "nown,

a fairly narrow window can be selected, brac"eted by the low and high cost

estimates. 8here downtime costs are difficult to obtain, a fairly broad window can

be selected.

+he next step is to identify from the maintenance and downtime figures, how much

of these costs can be eliminated through a well-designed, well-executed lubrication

program. It!s advantageous to involve people with a vested interest in ma"ing this

assessment. )fter all, it!s difficult to argue against a number you!ve helped to

determine in the first place$

In order to estimate the opportunity costs #maintenance and downtime cost

reduction% that are attributable to repairs re*uired as a direct result of poor

lubrication, we need to estimate the following #see +able 7%4

Percentage of costs due to repair (A)

+his includes parts, labor, supervision and management, overheads, insurance,

ris"-based costs and incidentals

Percentage due to wear or lubricated components (B)

It is important to itemie and consider replacement costs for both lubricated and

associated nonlubricated components #shafts, housings, cages, fans, couplings,

etc.% affected by failure of lubricated components. +his estimate should include all

scheduled and unscheduled repair wor", such as replacements and rebuilds, and

follow-up wor" for commissioning and assessment of newly deployed e*uipment.

Percentage of wear problems due to poor lubrication (C)

+his is an estimate of the negative impact of current practices on lubricated

components. Influences could include4 incorrectly selected lubricants, too much and

too little lubricant, incorrect relubrication fre*uency, ineffective contamination

control #fairly to maintain best practice targets% and poor oil analysis practices.

Percentage of wear that could have been avoided (D)

+his can be a tric"y number to estimate. However, a combination of the lubrication

team!s best guess plus case study-based information from other sources can be

useful in .guestimating/ this number.

3nce these estimates have been made, the opportunity costs resulting from the

repair of lubricated components as a direct conse*uence of ineffective lubrication is

simply4

Opportunity Costs )repair* + ),aintenance Cost - Do.ntime Cost* x & x %

x C x D

+he final cost attribute to consider is the cost of inefficiency associated with

deploying a poorly designed lubrication practice. 8hile the effect of poor design #for

example, incorrect regrease fre*uency, volume and product selection% is accounted

for in the repair opportunity costs, the wasted time and effort associated with that

design must also be recognied. +his value is derived by estimating the percentage

of the maintenance budget associated with lubrication P2s and other lubrication-

based nonrepair activities #<, including labor and materials%, and then estimating

the percentage of this value that is unnecessary #=%.

Opportunity Costs )inefficiency* + ),aintenance Cost* x / x 0

>sing the example in +able 7, it is estimated that based on an annual maintenance

budget #li"ely case% or ?7@,666,666 and estimated annual downtime costs of

?A,666,666, we have a total of ?7,B5C,666 in repair and inefficiency costs that can

be eliminated through a well-designed, well-executed best practices program.

&ssessing the Cost of 1mproement

3nce we have identified the .opportunity/, we must estimate the real cost of

improvement. +his estimate will include the cost to scope, design and manage the

ongoing pro-ect, as well as costs associated with purchasing and installing any

hardware that is necessary to bring production e*uipment up to modern best

practice standards. +he cost for training should be included in this estimate.

+raining allows for those who will be impacted by the proposed program to

understand the overwhelming need for change. +raining should be tailored to each

individual!s roles and responsibilities. 0veryone from supervisors to managers,

operators to millwrights should be included in this training in the effort to accelerate

acceptance of new standards and practices. +raining courses and modules should

be geared toward both fundamental "nowledge development and s"ills-based tas"

training, according to the type of role the employee provides. &or some, web-based

training offers an efficient, inexpensive way to obtain training, while for those more

intimately involved in lubrication, more detailed .live/ training is li"ely to be more

effective.

Doing bac" to the hypothetical plant, +able 5 shows an example of the estimated

costs associated with the proposed program upgrades.

Closing the Sale

+he final step in ma"ing the sale is to assess the benefits E the opportunity costs E

versus the cost to develop the program. In doing so, it is customary to ta"e a

three-, five- or seven-year planning horion and calculate a present value return,

which is explained below, and to calculate the rate of return on the proposed

investment. &or the hypothetical example, this is shown in +able @.

1ased on the calculation of opportunity costs and ta"ing the most li"ely case

scenario annual opportunity costs are estimated to be ?7,B5C,666. 1ecause this is a

result of current inefficient maintenance practices and current downtime costs, we

can expect to realie these savings each year that the new and improved program

is in place. However, it is unrealistic to expect full benefits to "ic" in during the first

year.

&or the first year, it is more realistic to place a conservative estimate of A6 percent

of these savings, or ?F7@,666. +he message is simple4 while the ob-ective is to

ensure the pro-ect and costs benefit analysis loo" attractive, we must remember to

not overstate the benefits. In the second year, we typically estimate FA percent of

the annual savings for the same reasons. &or years three to five and beyond, the

full and compete annual savings "ic" in, resulting in net positive cash flow of

?7,B5C,666 #based on the current value of the dollar% each year due to improved

lubrication practices.

In the financial world, the savvy investor "nows that the value of money

depreciates over time. Put simply, a dollar in your poc"et today will be worth

significantly less #have less buying power% next year and even less the following

year. &or this reason, the model needs to include a discount rate to allow for this

depreciation factor. In +able @, we have assumed an eight percent rate E not

unrealistic E resulting in our dollar being worth only G@ cents in the first year, HC

cents in the second year, etc. +his discount factor needs to be assessed against our

annualied savings to provide an annual cash flow benefit for each year based on

todays dollar value base.

&inally, the annual cash flow figures are summed for the five-year period to give a

net present value #again in today!s dollars% of ?B,6H@,BF6. +his return, which is the

li"ely return from the initial investment to develop the program, can be assessed

against the original investment to develop the program. In the example, this is

?BHA,666 from +able 5. In essence, we!re saying .if we invest ?BHA,666 today in

developing a lubrication excellence program, over five years, we should receive a

return, in today!s dollar e*uivalents of more than ?B,666,666, giving us an annual

rate-of-return of 7F7 percent./ +his is a very healthy investment on par with the

High +ech rally of the late 7GG6s$

It is not uncommon for senior management to simultaneously demand increased

reliability and reduced maintenance costs. +hey are not see"ing to be

counterproductive, but rather they are as"ing us to wor" smarter, not harder.

9ather than swimming upstream, constantly battling for increased funding while

fighting fires with limited resources, give them what they want$ 2anagers are paid

to ma"e sound decisions based on rational facts and arguments. 'how them a

structured, well-thought out financial plan to bring increased reliability and reduced

cost.

S-ar putea să vă placă și

- Maintenance StrategyDocument9 paginiMaintenance Strategyganeshji@vsnl.comÎncă nu există evaluări

- Best Practice 37findng Value in Oil AnalysisDocument5 paginiBest Practice 37findng Value in Oil AnalysisAntonio CastilloÎncă nu există evaluări

- Published in The Independent Lubricant Marketers Association, June 2005Document3 paginiPublished in The Independent Lubricant Marketers Association, June 2005ahmed mohamedÎncă nu există evaluări

- How To Write A Lubrication ProcedureDocument5 paginiHow To Write A Lubrication ProceduremawooaÎncă nu există evaluări

- It Has Been Said A Fleet Manager Can Do His or Her Job Pretty Well by Managing Just Two Costs Associated With The Provision of Fleet VehiclesDocument8 paginiIt Has Been Said A Fleet Manager Can Do His or Her Job Pretty Well by Managing Just Two Costs Associated With The Provision of Fleet VehiclesDila Suarpawan MadeÎncă nu există evaluări

- How To Build A Successful Oil Analysis Program-WhitepaperDocument15 paginiHow To Build A Successful Oil Analysis Program-Whitepaperaabejaro100% (1)

- QuestionsDocument2 paginiQuestionsRza Rustamli0% (2)

- Noria 201001Document10 paginiNoria 201001Hesham MahdyÎncă nu există evaluări

- A Best Practice Approach To Refinery Inventory LogisticsDocument14 paginiA Best Practice Approach To Refinery Inventory LogisticshdquanÎncă nu există evaluări

- AutoDocument8 paginiAutoShwetank TÎncă nu există evaluări

- Justifying Investment in CNC TechnologyDocument3 paginiJustifying Investment in CNC TechnologyPassmore DubeÎncă nu există evaluări

- 100 Ways To Improve Lubrication ProgramDocument21 pagini100 Ways To Improve Lubrication ProgramTalha NizamiÎncă nu există evaluări

- Maintenance BusinessDocument13 paginiMaintenance BusinessArdyas Wisnu BaskoroÎncă nu există evaluări

- Rationalizing The Benefits of Condition-Based Maintenance - An Oil Analysis ExampleDocument11 paginiRationalizing The Benefits of Condition-Based Maintenance - An Oil Analysis ExampleJHON ANGEL VARGAS HUAHUASONCCOÎncă nu există evaluări

- Effectonotherwork in The Business: 12-1 AccountingDocument29 paginiEffectonotherwork in The Business: 12-1 AccountingTATATAHERÎncă nu există evaluări

- CBP Case Study of D&C CarwashDocument3 paginiCBP Case Study of D&C CarwashMuhammad Shakir Bin ZulkafliÎncă nu există evaluări

- Mastering Maintenance BudgetingDocument19 paginiMastering Maintenance BudgetingInghon SilalahiÎncă nu există evaluări

- Sliding Oil Prices: Predicament or ProspectDocument5 paginiSliding Oil Prices: Predicament or ProspectCognizantÎncă nu există evaluări

- Increasing Capacity Without Increasing HeadcountDocument7 paginiIncreasing Capacity Without Increasing HeadcountRileShampionÎncă nu există evaluări

- Spare Parts Pricing PDFDocument6 paginiSpare Parts Pricing PDFPraveenÎncă nu există evaluări

- Chap 023Document23 paginiChap 023Neetu RajaramanÎncă nu există evaluări

- Balakrishnan MGRL Solutions Ch09Document53 paginiBalakrishnan MGRL Solutions Ch09Rachna Menon100% (1)

- MaintenanceDocument3 paginiMaintenanceIoana Popescu0% (1)

- Mini Project ReportDocument18 paginiMini Project ReportClash With KAIÎncă nu există evaluări

- Gas StationDocument15 paginiGas Stationshemsu sunkemoÎncă nu există evaluări

- Revenue ManagementDocument5 paginiRevenue Managementabdulazeez111Încă nu există evaluări

- 3amt Four Part Question Answer Section 3 TestDocument3 pagini3amt Four Part Question Answer Section 3 Testdongsara2006Încă nu există evaluări

- Case QuestionsDocument7 paginiCase QuestionsAbbey LiÎncă nu există evaluări

- 8 Conclusions: 8.1 ReflectionsDocument6 pagini8 Conclusions: 8.1 ReflectionsGanesh KothandapaniÎncă nu există evaluări

- 11 LasherIM Ch11Document26 pagini11 LasherIM Ch11jimmy_chou1314100% (1)

- Guide For Painting ProjectDocument16 paginiGuide For Painting ProjectWaqar Siddique100% (2)

- Delivering Desired Outcomes Efficiently:: The Creative Key T O Competitive StrategyDocument19 paginiDelivering Desired Outcomes Efficiently:: The Creative Key T O Competitive StrategyOrlando RamosÎncă nu există evaluări

- CVP Analysis - International Finance and AccountingDocument14 paginiCVP Analysis - International Finance and AccountingJamesÎncă nu există evaluări

- CH 04 Kinney 9e SM Final PDFDocument41 paginiCH 04 Kinney 9e SM Final PDFSeanLejeeBajanÎncă nu există evaluări

- ?y ?y ?y ?y ?yDocument4 pagini?y ?y ?y ?y ?yDisha ChhabraÎncă nu există evaluări

- 1 Profit and Customer Centered Benefi 2015 Reliable Maintenance PlanningDocument9 pagini1 Profit and Customer Centered Benefi 2015 Reliable Maintenance PlanningIrsyad Saiful M.Încă nu există evaluări

- Getting The Most From Lube Oil AnalysisDocument16 paginiGetting The Most From Lube Oil AnalysisGuru Raja Ragavendran Nagarajan100% (2)

- Full Download Solution Manual For Operations Management 13th Edition PDF Full ChapterDocument6 paginiFull Download Solution Manual For Operations Management 13th Edition PDF Full Chapterdewdrop.threat.7ia4yn100% (17)

- Solution Manual For Operations Management 13th EditionDocument36 paginiSolution Manual For Operations Management 13th Editiongowdie.mornward.b50a100% (48)

- MBA 540 Final - ExamDocument4 paginiMBA 540 Final - ExamJoeÎncă nu există evaluări

- Complex Decisions in Capital BudgetingDocument4 paginiComplex Decisions in Capital BudgetingDeven RathodÎncă nu există evaluări

- Break Even AnalysisDocument3 paginiBreak Even AnalysisNikhil AgrawalÎncă nu există evaluări

- AnswersDocument5 paginiAnswersVarudhini PatkiÎncă nu există evaluări

- 6.business Tools For Service ManagerDocument53 pagini6.business Tools For Service ManagerAftab AhmadÎncă nu există evaluări

- Cost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingDocument44 paginiCost Planning For The Product Life Cycle: Target Costing, Theory of Constraints, and Strategic PricingSunny Khs100% (1)

- Integrated Solutions DCDocument5 paginiIntegrated Solutions DCAlexVillagómezJacomeÎncă nu există evaluări

- CMMS - A Timesaving Implementation Process-Edit - Daryl MatherDocument95 paginiCMMS - A Timesaving Implementation Process-Edit - Daryl MatherMisael Acosta cortes100% (1)

- Optimized Service Intervals For Caterpillar EquipmentDocument34 paginiOptimized Service Intervals For Caterpillar EquipmentGracia SediÎncă nu există evaluări

- Chap 010Document38 paginiChap 010Steven Andrian GunawanÎncă nu există evaluări

- Essential Fleet Metrics You Should Be Watching and WhyDocument6 paginiEssential Fleet Metrics You Should Be Watching and WhyAdarsh PoojaryÎncă nu există evaluări

- Prestige Institute of Mangement Dewas: Managing Risk and Returns Akeyto Organization SuccessDocument11 paginiPrestige Institute of Mangement Dewas: Managing Risk and Returns Akeyto Organization SuccessRameez KhanÎncă nu există evaluări

- 17 Ways Aucerna Whitepaper 2020Document12 pagini17 Ways Aucerna Whitepaper 2020mstorentÎncă nu există evaluări

- All You Ever Wanted To Know About Gainsharing But Were Afraid To AskDocument9 paginiAll You Ever Wanted To Know About Gainsharing But Were Afraid To AskAnonymous p0bBEKÎncă nu există evaluări

- Mba Thesis On Supply Chain Management PDFDocument6 paginiMba Thesis On Supply Chain Management PDFamandagraytulsa100% (2)

- F5 Target Costing and Life Cycle CostingDocument6 paginiF5 Target Costing and Life Cycle CostingGT Boss AvyLaraÎncă nu există evaluări

- Chap 7: Material Management in JIT EnvironmentDocument12 paginiChap 7: Material Management in JIT Environmentsandyhandy6Încă nu există evaluări

- Analyzing and Quantifying Your Company Asset Management OpportunityDocument8 paginiAnalyzing and Quantifying Your Company Asset Management OpportunityWojtek MaczynskiÎncă nu există evaluări

- Managerial Accounting ProjectDocument22 paginiManagerial Accounting ProjectMaulshri Bhardwaj100% (1)

- Klüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling BearingsDocument2 paginiKlüberplex BEM 41-132: High-Temperature Long-Term Grease For Rolling Bearingsmarcalasan0% (1)

- Symptoms of Common Hydraulic Problems and Their Root CausesDocument3 paginiSymptoms of Common Hydraulic Problems and Their Root CausesmarcalasanÎncă nu există evaluări

- Preventing Mechanical FailuresDocument15 paginiPreventing Mechanical Failuresmarcalasan0% (1)

- Sludge and Varnish in Turbine SystemsDocument10 paginiSludge and Varnish in Turbine SystemsmarcalasanÎncă nu există evaluări

- Grease BasicsDocument5 paginiGrease Basicsmarcalasan100% (1)

- How Not To Lubricate A GearboxDocument5 paginiHow Not To Lubricate A GearboxmarcalasanÎncă nu există evaluări

- Detecting and Controlling Water in OilDocument9 paginiDetecting and Controlling Water in OilmarcalasanÎncă nu există evaluări

- Nine Reasons Why Oil Analysis Programs FailDocument4 paginiNine Reasons Why Oil Analysis Programs FailmarcalasanÎncă nu există evaluări

- Labyrinth Seals and Lip SealsDocument5 paginiLabyrinth Seals and Lip SealsmarcalasanÎncă nu există evaluări

- Journal Bearing PreDocument4 paginiJournal Bearing PremarcalasanÎncă nu există evaluări

- Managing The Risk of Mixing Lubricating OilsDocument5 paginiManaging The Risk of Mixing Lubricating OilsmarcalasanÎncă nu există evaluări

- Filter Flow RateDocument2 paginiFilter Flow RatemarcalasanÎncă nu există evaluări

- To Other Needs, Example,: 1956 Twenty-Ti-Ii RD ConferenceDocument11 paginiTo Other Needs, Example,: 1956 Twenty-Ti-Ii RD ConferencemarcalasanÎncă nu există evaluări

- Hydraulic Pump and Motor Case DrainsDocument3 paginiHydraulic Pump and Motor Case DrainsmarcalasanÎncă nu există evaluări

- Proper Pump Piping Procedure - 10 StepsDocument9 paginiProper Pump Piping Procedure - 10 StepsmarcalasanÎncă nu există evaluări

- Droop Calc 0.0166 HZ DB 5pct Droop Steam UnitDocument132 paginiDroop Calc 0.0166 HZ DB 5pct Droop Steam UnitmarcalasanÎncă nu există evaluări

- Corrosion FailuresDocument1 paginăCorrosion FailuresmarcalasanÎncă nu există evaluări

- 1958 - Van Hengel - Some Notes On TheDocument11 pagini1958 - Van Hengel - Some Notes On ThemarcalasanÎncă nu există evaluări

- 02chapters1 2Document44 pagini02chapters1 2marcalasanÎncă nu există evaluări

- Maintenance of Mining MachineryDocument22 paginiMaintenance of Mining Machineryjorgeluis2000100% (1)

- Mathematical Modeling-OptimisationDocument12 paginiMathematical Modeling-OptimisationDr Srinivasan Nenmeli -K100% (1)

- Maintenance and Troubleshooting of Electric MotorsDocument8 paginiMaintenance and Troubleshooting of Electric MotorsmarcalasanÎncă nu există evaluări

- Pump Efficiency With Electric Motor DriverDocument3 paginiPump Efficiency With Electric Motor DrivermarcalasanÎncă nu există evaluări

- 3.2 Electric Motors - Revised (Table Format)Document8 pagini3.2 Electric Motors - Revised (Table Format)Sumit AgrawalÎncă nu există evaluări

- 2.2 BoilersDocument9 pagini2.2 BoilersSalihibnuali KpÎncă nu există evaluări

- 3.1 Electrical System - Revised (Table Format)Document9 pagini3.1 Electrical System - Revised (Table Format)shahidehamzaÎncă nu există evaluări

- Chapter 18 - Price Setting in The Business WorldDocument34 paginiChapter 18 - Price Setting in The Business WorldRayhanÎncă nu există evaluări

- Hire PurchaseDocument6 paginiHire PurchaseGanesh Bokkisam100% (1)

- Accounting Information System Individual AssignmentDocument3 paginiAccounting Information System Individual Assignmentmarlon_akay100% (1)

- Multi Level MarketingDocument74 paginiMulti Level Marketingsandeep_dhuriÎncă nu există evaluări

- Selling ProcessDocument16 paginiSelling ProcessAnkit MehtaÎncă nu există evaluări

- Competitive Advantage: National Foods One of The Largest and Oldest Food CompaniesDocument4 paginiCompetitive Advantage: National Foods One of The Largest and Oldest Food CompaniesRafay HussainÎncă nu există evaluări

- 06 Merchandising ActivitiesDocument68 pagini06 Merchandising ActivitiesshashankÎncă nu există evaluări

- AvariDocument21 paginiAvariWaqas AslamÎncă nu există evaluări

- Bab 12 - 13 Akuntansi Derivatif Dan Lindung Nilai SP Jan 2016Document52 paginiBab 12 - 13 Akuntansi Derivatif Dan Lindung Nilai SP Jan 2016RifqiÎncă nu există evaluări

- ERP Case Study - Nike (FAILURE)Document2 paginiERP Case Study - Nike (FAILURE)scibid100% (1)

- CH 14Document26 paginiCH 14SaAl-ismail100% (1)

- Airbus Versus BoeingDocument23 paginiAirbus Versus BoeingShyam SrinivasanÎncă nu există evaluări

- Mapro Food Private LimitedDocument41 paginiMapro Food Private Limitedlaxmiprasad gudaÎncă nu există evaluări

- Contracts II OutlineDocument16 paginiContracts II OutlineEva CrawfordÎncă nu există evaluări

- Ae 19Document18 paginiAe 19mary rose silaganÎncă nu există evaluări

- Simple Interest and Simple Discount PDFDocument29 paginiSimple Interest and Simple Discount PDFandisetiawan90100% (5)

- Customer Relationship and Its Impact On SalesDocument38 paginiCustomer Relationship and Its Impact On Salesmbaadarsh75% (4)

- Suffolk Times Classifieds and Service Directory: Dec. 21, 2017Document10 paginiSuffolk Times Classifieds and Service Directory: Dec. 21, 2017TimesreviewÎncă nu există evaluări

- Swift Transportation Company Porter Five Forces AnalysisDocument5 paginiSwift Transportation Company Porter Five Forces AnalysisAshrafulÎncă nu există evaluări

- Evolution of Indian Retail IndustryDocument8 paginiEvolution of Indian Retail IndustryVenkata Pratap Reddy MÎncă nu există evaluări

- Business LettersDocument14 paginiBusiness Lettersakash sheelvanthÎncă nu există evaluări

- Module 14. Budgeting 11.10Document41 paginiModule 14. Budgeting 11.10NajlaÎncă nu există evaluări

- Canyon Ranch ReportDocument17 paginiCanyon Ranch ReportAndrew Denchik100% (1)

- Whole Foods MarketDocument8 paginiWhole Foods Marketosho2000100% (1)

- Wal-Mart'S Foreign Expansion: Case Discussion QuestionsDocument7 paginiWal-Mart'S Foreign Expansion: Case Discussion QuestionshasziahyazidÎncă nu există evaluări

- Internal Sales Order SetupDocument35 paginiInternal Sales Order SetupVeerendra ReddyÎncă nu există evaluări

- Diversification Strategy of NikeDocument4 paginiDiversification Strategy of Nikejmathew1150% (2)

- Marketing Case PavadermDocument4 paginiMarketing Case PavadermPlacebogsu0% (1)

- MarutiDocument10 paginiMarutiKedar JoshiÎncă nu există evaluări

- Depreciation Practice in BangladeshDocument17 paginiDepreciation Practice in BangladesharafatÎncă nu există evaluări

- The Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeDe la EverandThe Millionaire Fastlane, 10th Anniversary Edition: Crack the Code to Wealth and Live Rich for a LifetimeEvaluare: 4.5 din 5 stele4.5/5 (89)

- $100M Offers: How to Make Offers So Good People Feel Stupid Saying NoDe la Everand$100M Offers: How to Make Offers So Good People Feel Stupid Saying NoEvaluare: 5 din 5 stele5/5 (23)

- $100M Leads: How to Get Strangers to Want to Buy Your StuffDe la Everand$100M Leads: How to Get Strangers to Want to Buy Your StuffEvaluare: 5 din 5 stele5/5 (18)

- Summary of Noah Kagan's Million Dollar WeekendDe la EverandSummary of Noah Kagan's Million Dollar WeekendEvaluare: 5 din 5 stele5/5 (1)

- Broken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterDe la EverandBroken Money: Why Our Financial System Is Failing Us and How We Can Make It BetterEvaluare: 5 din 5 stele5/5 (3)

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverDe la EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverEvaluare: 4.5 din 5 stele4.5/5 (186)

- Portfolio management strategies for technical analystsDe la EverandPortfolio management strategies for technical analystsÎncă nu există evaluări

- 12 Months to $1 Million: How to Pick a Winning Product, Build a Real Business, and Become a Seven-Figure EntrepreneurDe la Everand12 Months to $1 Million: How to Pick a Winning Product, Build a Real Business, and Become a Seven-Figure EntrepreneurEvaluare: 4 din 5 stele4/5 (2)

- Fascinate: How to Make Your Brand Impossible to ResistDe la EverandFascinate: How to Make Your Brand Impossible to ResistEvaluare: 5 din 5 stele5/5 (1)

- Think Faster, Talk Smarter: How to Speak Successfully When You're Put on the SpotDe la EverandThink Faster, Talk Smarter: How to Speak Successfully When You're Put on the SpotEvaluare: 5 din 5 stele5/5 (1)