Documente Academic

Documente Profesional

Documente Cultură

Cable Calc

Încărcat de

Víctor RojasTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cable Calc

Încărcat de

Víctor RojasDrepturi de autor:

Formate disponibile

DOCUMENT NO.

E-CAL-001

TITLE CABLE SIZE CALCULATION

Your Project Number

REV Your Project

BY Your Client

CHKD Your Name here

APPRV'D

DATE 1 OF 1 A

Cable Number Load

Load Data

Motor Rating kW No. of Parallel Conductor

Rated voltage V No. of Adjacent Circuits

FL power factor (cosq) Full load current A

Power Frequency Current / Conductor (Io) A

Allowable Voltage Drop % Allowable Voltage Drop (Starting) %

Cable Data

Conductor size mm

2

Copper Tmax operating

(

R

)

o

C

Number of Cores Ambient Air Temperature

(

A

)

o

C

Total Cable length (L) m Temp. Cable Derating (DF)

Conductor rating

(I

R1

)

A Grouping Factor (GF)

Operating Temperature:

Conductor derating = = A

Operating temperature = [I

o

/I

R2

]

2

x [(

R

A

A

]

= deg Celcius

Voltage Drop (Normal Operating):

Conductor resistance, 20

O

C

= Ohm/km = Ohm/m

Conductor resistance, 40

O

C

= Ohm/km = Ohm/m

Conductor reactance = Ohm/km = Ohm/m

MCC busbar Voltage = V

Cable volt drop V

d3 = Io L [3 (R

C

cosq + X

C

sinq] = V %

Voltage at the load = - = V

Min. load volts = V @ Voltage Drop

Starting Current = X = A

Cable volt dip V

d3 = Io L [3 (R

C

cosq + X

C

sinq] = V %

Voltage at the load = - = V

Min. load volts = V @ Voltage Dip (Motor Starting)

Short Circuit Withstand (3 Fault):

I"k = kA (From Short Circuit Calculations result)

t = s (Fault clearing time 5s)

K = (143 for Copper conductors PVC Insulated)

S = [(I"k x 1000)

2

t]/K = mm

2

(Minimum cable size to withstand short circuit)

Notes:

The methods used in this calculation are based on the recommendations of IEC 60228, IEC 60364-5-54

Copyright 2008 - Ver Pangonilo - http://www.filipinoengineer.org - its free to use and modify but leave this copyright note.

Short Circuit Withstand OK

2

<5

143

0.5

18

394.2 400

(I

R2

)

72.88

4

0.8

50

CABLE SIZE CALCULATION

COMPANY

LOGO

COMPANY NAME

50

50

0.000422 (R

40C

) 0.4217

O

)

400

667.6

166.9

90

40

15

Operating temperature is Acceptable!

(Vmin)

3

196

5.8

I

R1

x DF x GF

(V

L

)

PROJECT No:

ENGINEERED BY:

CLIENT:

A

REV PAGE

PROJECT:

89.01

0.1040

392

370

(X

C

)

365.3

400

2%

1.44 5.778

Voltage Drop is Acceptable!

34.67 8.67

400

1.05

1

205.8

0.000391

0.0001

(R

20C

) 0.3910

340 15%

Voltage Dip is Acceptable!

(Vmin)

6 166.9 1,001.3

34.7

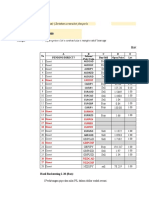

Note: These data are based on a cable manufacturer's datasheet. Refer to your cable manufacturer for more information.

Cable Data (PVC Insulated Cables Only)

Item

Cross section

core, mm

Cross

section

screen, mm

Max.

conductor

resistance at

20C,

Ohm/km

Max.

conductor

resistance at

90C,

Ohm/km

Reactance at

50Hz,

Ohm/km

Reactance at

60Hz,

Ohm/km

Current

rating IEC,

Ampere

Short circuit

rating

1second,

Ampere

1 16 2.5 1.16 1.48 0.116 0.14 96 2240

2 25 4 0.734 0.936 0.11 0.132 127 3500

3 35 6 0.529 0.675 0.106 0.128 157 4900

4 50 6 0.391 0.499 0.104 0.125 196 7000

5 70 6 0.27 0.344 0.099 0.119 242 9800

6 95 10 0.195 0.249 0.097 0.116 293 13300

7 120 10 0.154 0.196 0.094 0.113 339 16800

8 150 10 0.126 0.161 0.092 0.111 389 21000

9 185 10 0.1 0.128 0.091 0.109 444 25900

10 240 16 0.0762 0.0972 0.089 0.107 522 33600

11 300 16 0.0607 0.0774 0.087 0.105 601 42000

Temperature Correction Factor Frequency Parallell Conductors

50 1

Item Temp, Deg C Factor 60 2

1 35 1.1 3

2 40 1.05 4

3 45 1 5

4 50 0.94

5 55 0.88

6 60 0.82

7 65 0.74

8 70 0.67

9 75 0.58

10 80 0.47

IEC 60364-5-54

Table 54B Values for K for insulated protective conductors not incorporated in cables

PVC XLPE EPR Butyl Rubber

Final Temperature, degC 160 250 250 220 1

1 Copper 143 176 176 166 2

2 Aluminium 95 116 116 110 3

3 Steel 52 64 64 60 4

Below this line are References Only

Note: These data are based on a cable manufacturer's datasheet. Refer to your cable manufacturer for more information.

Final Temp

PVC 160

XLPE 250

EPR 250

Butyl Rubber 220

Below this line are References Only

Notes to Cable Calculations

1. Cable data provided in here are based on a manufacturer's datasheet. Refer to your cable manufacturer for project specific values.

2. Cable calculation is based on IEC standards.

3. Load data is based on motor load and 3 phase

4. This calculation is just a sample. It is always a good practice to verify the results.

5. I"k should be based on the short circuit calculation result. It is not part of this worksheet.

6. Please read the Disclaimer Statement before using this calculation worksheet.

1. Cable data provided in here are based on a manufacturer's datasheet. Refer to your cable manufacturer for project specific values.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Rtaa Svx01a en - 09012005Document178 paginiRtaa Svx01a en - 09012005jars03180950100% (1)

- Rtaa IomDocument140 paginiRtaa IomFabian Lopez100% (1)

- 4 1 PDFDocument28 pagini4 1 PDFVíctor RojasÎncă nu există evaluări

- Calculate Fault LevelsDocument46 paginiCalculate Fault LevelsPichumani100% (4)

- Bussman - How To Size A FuseDocument15 paginiBussman - How To Size A FuseSJS68Încă nu există evaluări

- Wiring Diagram-Split System Air ConditionerDocument1 paginăWiring Diagram-Split System Air ConditionerSohail Ejaz Mirza83% (12)

- HVAC & Refrigeration SystemDocument22 paginiHVAC & Refrigeration SystemSivakumar NadarajaÎncă nu există evaluări

- IBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECDocument10 paginiIBM System Storage DS4700 Express Models Offer A 4 Gbps High-Performance DS4000 Midrange Disk System For HVECVíctor RojasÎncă nu există evaluări

- 3 CH 2Document20 pagini3 CH 2Mary HarrisonÎncă nu există evaluări

- Bureau of Energy EfficiencyDocument23 paginiBureau of Energy Efficiencypbs0707Încă nu există evaluări

- Electrical Standard Products: Switchgear Training Centre, CoonoorDocument20 paginiElectrical Standard Products: Switchgear Training Centre, CoonoorVíctor RojasÎncă nu există evaluări

- 4 4Document34 pagini4 4Samir Ranjan ParidaÎncă nu există evaluări

- UPSDocument63 paginiUPSgavinilaa100% (1)

- Selective Coordination EATONDocument22 paginiSelective Coordination EATONBrenda Naranjo MorenoÎncă nu există evaluări

- MCC 15B CalculationV3Document2 paginiMCC 15B CalculationV3Wimalasiri DissanayakeÎncă nu există evaluări

- MCC & ContactorsDocument9 paginiMCC & ContactorsbimboawotikuÎncă nu există evaluări

- Constr Esb750Document127 paginiConstr Esb750Erica MosesÎncă nu există evaluări

- Case Studies On Paralleling of TransformersDocument7 paginiCase Studies On Paralleling of Transformersmuaz_aminu1422Încă nu există evaluări

- Parcial 1 Distribuciones Abril-Jul 2010Document12 paginiParcial 1 Distribuciones Abril-Jul 2010Víctor RojasÎncă nu există evaluări

- Setting Calulation For Gen Tms TRF and BusbarDocument10 paginiSetting Calulation For Gen Tms TRF and BusbarVíctor Rojas100% (1)

- Temp CalculationDocument1 paginăTemp CalculationVíctor RojasÎncă nu există evaluări

- AP01200003E - Fault Current - Coordination CalculatorDocument13 paginiAP01200003E - Fault Current - Coordination CalculatorVíctor RojasÎncă nu există evaluări

- LT Cable Sizing Calculation SheetDocument12 paginiLT Cable Sizing Calculation Sheet2003vinay100% (5)

- Assignment SUBJECT: Industrial Power System Analysis and DesignDocument1 paginăAssignment SUBJECT: Industrial Power System Analysis and DesignthavaselvanÎncă nu există evaluări

- 11 KV transformer and power system analysisDocument18 pagini11 KV transformer and power system analysisAbdulyunus Amir100% (1)

- Relay Setting CoordinationDocument8 paginiRelay Setting Coordinationsmepp100% (2)

- Short Circuit HayabusaDocument3 paginiShort Circuit Hayabusameeng2014Încă nu există evaluări

- Cable size calculation chart for electrical installationsDocument6 paginiCable size calculation chart for electrical installationsnicrajesh90% (10)

- 4.Ht Short Circuir CalculationDocument11 pagini4.Ht Short Circuir CalculationPrabhash VermaÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 2-A-GNLW363CD Standard Decanter CentrifugeDocument6 pagini2-A-GNLW363CD Standard Decanter CentrifugeGeorgeÎncă nu există evaluări

- Maximizing Energy Production Through Innovative Geothermal TechnologiesDocument7 paginiMaximizing Energy Production Through Innovative Geothermal TechnologiesRidho Adrianto SitepuÎncă nu există evaluări

- Saif Power Initial Public OfferingDocument6 paginiSaif Power Initial Public OfferingDebbie JacobsonÎncă nu există evaluări

- Performance Evaluation of Alaoji Thermal Power PlantDocument8 paginiPerformance Evaluation of Alaoji Thermal Power PlantIjaems JournalÎncă nu există evaluări

- Company Profile Aditya - REVISEDDocument4 paginiCompany Profile Aditya - REVISEDNandkumar Chinai100% (1)

- Mehods To Initiate VenturesDocument29 paginiMehods To Initiate VenturesAngelie AnilloÎncă nu există evaluări

- Sample: Insert Company Name/Logo HereDocument4 paginiSample: Insert Company Name/Logo Herealdi HaldiatnoÎncă nu există evaluări

- Philippine Star, Oct. 14, 2019, PHL Railway Systems Way Behind International Standards - LRTA Exec PDFDocument1 paginăPhilippine Star, Oct. 14, 2019, PHL Railway Systems Way Behind International Standards - LRTA Exec PDFpribhor2Încă nu există evaluări

- 700 150 Corrected PDFDocument40 pagini700 150 Corrected PDFRamakrishnan Ramachandran57% (7)

- AIR-X Circuit Replacement InstructionsDocument9 paginiAIR-X Circuit Replacement InstructionsscabdÎncă nu există evaluări

- Nishant Chaba: Mobile: 91-9990078569,8130736734Document4 paginiNishant Chaba: Mobile: 91-9990078569,8130736734Wedding FilmÎncă nu există evaluări

- Assignment Movement of GoodsDocument9 paginiAssignment Movement of GoodsAnnaIzzatÎncă nu există evaluări

- 6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDDocument18 pagini6850/6890 GC Column Installation and Instrument Setup Guide - PPIP/TCDWaleed El-azabÎncă nu există evaluări

- ITP-SV-M-FAN-CENTRIFUGAL&AXIALDocument7 paginiITP-SV-M-FAN-CENTRIFUGAL&AXIALgauravamberkarÎncă nu există evaluări

- Non Destructive Testing of Rotors From The BoreDocument2 paginiNon Destructive Testing of Rotors From The BorePankaj KambleÎncă nu există evaluări

- Chilled Water SystemDocument48 paginiChilled Water SystemLarry Bea80% (5)

- 302 E. Carson Marketing FlyerDocument2 pagini302 E. Carson Marketing Flyercassie_cataniaÎncă nu există evaluări

- Writing PieDocument20 paginiWriting PieBishal PunksÎncă nu există evaluări

- GIM Stof Sustainability MarljlkDocument11 paginiGIM Stof Sustainability MarljlkLorenzoÎncă nu există evaluări

- Installation of Large Diameter PRT-ES Cable Jacket (ZT07-98-003Document7 paginiInstallation of Large Diameter PRT-ES Cable Jacket (ZT07-98-003Mahmoud Tobala100% (1)

- Oil DA - MichiganClassic 2013Document254 paginiOil DA - MichiganClassic 2013deabtegoddÎncă nu există evaluări

- SitaDocument16 paginiSitaAhmad MasoodÎncă nu există evaluări

- Air Curtain Catalog 2017 NewDocument7 paginiAir Curtain Catalog 2017 NewME SHOPÎncă nu există evaluări

- (Silakan Diubah Jika Tidak Sesuai) - Sertakan Screenshot Jika PerluDocument56 pagini(Silakan Diubah Jika Tidak Sesuai) - Sertakan Screenshot Jika Perlufaishal idrisÎncă nu există evaluări

- TD Esc 03 de en 15 048 Rev001 Electrical SiteworksDocument19 paginiTD Esc 03 de en 15 048 Rev001 Electrical SiteworksarhipadrianÎncă nu există evaluări

- Jtekt e Report2016Document142 paginiJtekt e Report2016Amit AryaÎncă nu există evaluări

- ABB High Voltage ProductsDocument255 paginiABB High Voltage Productsemre kabatas100% (1)

- ZJMY Business PlanDocument16 paginiZJMY Business PlanAnonymous fe4knaZWjmÎncă nu există evaluări

- China Polyether Polyols Weekly Report (20130408-20130412)Document5 paginiChina Polyether Polyols Weekly Report (20130408-20130412)renagoncÎncă nu există evaluări

- Australian Standard: Pressure Equipment-BoilersDocument9 paginiAustralian Standard: Pressure Equipment-BoilersTurbo Snail RÎncă nu există evaluări