Documente Academic

Documente Profesional

Documente Cultură

A380-Level III - Ata 38 Water - Waste

Încărcat de

Abolfazl Mazloomi100%(2)100% au considerat acest document util (2 voturi)

3K vizualizări40 paginiAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Titlu original

a380-Level III - Ata 38 Water_waste

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(2)100% au considerat acest document util (2 voturi)

3K vizualizări40 paginiA380-Level III - Ata 38 Water - Waste

Încărcat de

Abolfazl MazloomiAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 40

A380

TECHNICAL TRAINING MANUAL

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

This document must be used for training purposes only

Under no circumstances should this document be used as a reference

It will not be updated.

All rights reserved

No part of this manual may be reproduced in any form,

by photostat, microfilm, retrieval system, or any other means,

without the prior written permission of AIRBUS S.A.S.

LEVEL III - ATA 38 WATER/WASTE

Potable Water System Description (3) . . . . . . . . . . . . . . . . . . . . . . . . . 2

Toilet System Description (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Waste Water Drain System Description (3) . . . . . . . . . . . . . . . . . . . . 28

Water/Waste System Maintenance (3) . . . . . . . . . . . . . . . . . . . . . . . . 30

Water/Waste System Component Location (3) . . . . . . . . . . . . . . . . . 34

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TABLE OF CONTENTS Mar 21, 2006

Page 1

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

POTABLE WATER SYSTEM DESCRIPTION (3)

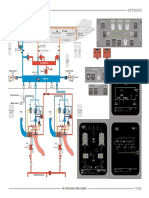

General Architecture

The potable water tanks are installed in the FWD area of the AFT cargo

compartment, above the body landing gear boxes (three on the LH side

and three on the RH side). As option, two additional tanks can be installed

(one on each side). Each tank has a capacity of 283 liters (75 US gallons)

for a basic total volume of 1700 liters (449 US gallons).

The potable water is distributed to the galley and lavatory faucets and to

the toilets and Galley Waste Disposal Units (GWDUs) for flushing.

Two compressors fulfill the tanks pressurization. For maintenance, it is

possible to pressurize the tanks by using a ground pressure connection.

Before distribution, a treatment module filters, heats and purifies the

potable water.

The filling of the water tanks is done from the potable water service panel

installed in the AFT lower fuselage. The draining of the complete system

is done from the potable water service panel and from the FWD drain

panel installed in the FWD lower fuselage.

A depress valve, installed near the service panel, is used for system

depressurization on ground.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 2

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

GENERAL ARCHITECTURE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 3

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Potable Water Storage

The potable water tanks numbering is organized as follows:

- tanks number 1, 3, 5 (and 7 as option) on the LH side,

- tanks number 2, 4, 6 (and 8 as option) on the RH side.

Each tank has a recirculation port, an overflow port and a fill/drain port.

The middle tanks number 3 and 4 have an ultrasonic level sensor installed

in the bottom.

Note that the level sensors transmit the water level data to the Potable

Water Indication Panel (PWIP) for calculation. The average value of the

water quantity in the tanks is shown on the FAPs and on the PWIP.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 4

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER STORAGE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 5

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Air Supply System

The air supply system supplies pressurized air to the potable water system

by means of two compressors installed on the LH side near the potable

water tanks.

The normal operating pressure of the system is between 35 psi and 41

psi.

An electric motor operates each compressor. An air compressor motor

controller, installed near the compressors, controls each motor.

The air is picked-up in the cargo compartment through an inlet filter

mounted on each compressor, and sent under pressure to an air manifold

assembly installed above the compressors.

The air manifold assembly has:

- two pressure switches (one low pressure and one high pressure) for a

feedback to the controllers,

- an over pressure relief valve, which opens when the pressure reaches

130 psi,

- a ground pressure connection,

- filters, to make sure that unwanted material do not go into the potable

water system,

- air check valves, to prevent a backflow of air.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 6

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

AIR SUPPLY SYSTEM

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 7

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Potable Water Treatment Module

The potable water treatment module, installed on the RH side near the

potable water tanks, has:

- a circulation pump, installed just near the treatment module on the inlet

pipe. The pump, driven by an electric motor, helps the water circulation

inside the module,

- an inhibition of scaling module, which has a magnetic tube removing

scale deposits and particles. There is no maintenance servicing on it,

- a water heater, which warms-up the water entering in the loop.

The heating and disinfection control unit manages all the electrical

components of the potable water treatment module. It switches ON/OFF

the circulation pump as well as the water heater, in order to keep a

temperature range of 6-15C.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 8

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER TREATMENT MODULE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 9

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Lavatory Water Supply Assembly

The lavatory water supply assembly has:

- a manual shut-off valve, installed below the sink. It isolates the water

going to the faucet and also to the toilet unit for flushing,

- a water heater, which warms-up the water up to 50C,

- a mixing unit, which mixes the hot and cold water to satisfy the water

supply temperature demand.

The lavatory water supply assembly control device receives the

temperature demand from the infrared controlled faucet and manages the

mixing process accordingly.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 10

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

LAVATORY WATER SUPPLY ASSEMBLY

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 11

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Control System Architecture

The PWIP, the heating and disinfection control unit, the air compressor

motor controllers and the lavatory water supply assembly control devices

monitor and control the performance of their related system components.

Note that the PWIP manages the potable water quantity (level sensors

signal), the pre-selection and the valves operations (fill/drain, FWD drain

and depress valves).

The PWIP and the FAPs are the main controllers and indicators of the

potable water system.

The Cabin Intercommunication Data System (CIDS) directors, through

the vacuum system control function, manage the data exchange between

the potable water system components and some A/C systems like:

- the FAPs,

- the Onboard Maintenance System (OMS) for failure report and tests,

- the Landing Gear Extraction Retraction System (LGERS).

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 12

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

CONTROL SYSTEM ARCHITECTURE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 13

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

POTABLE WATER SYSTEM DESCRIPTION (3)

Water/Waste FAP Page

The Water/Waste FAP page has the following functions:

- indication of potable water quantity in the tanks,

- indication of A/C configuration (location of lavatories and galleys),

- indication of system status,

- indication of failure messages,

- system depressurization on ground ("Water Depr." button),

- system depressurization in flight ("Shut Down" button),

- isolation of water distribution areas ("Shut Off LH" and "Shut Off RH"

buttons),

- water pre-selection ("Pre-Select" button).

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 14

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

WATER/WASTE FAP PAGE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

POTABLE WATER SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 15

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

1

P

O

T

A

B

L

E

0

1

TOILET SYSTEM DESCRIPTION (3)

General Architecture

The toilet system is divided into four independent subsystems, which

are:

- the LH main deck,

- the RH main deck,

- the LH upper deck and,

- the RH upper deck.

Each subsystem has:

- toilet assemblies,

- Galley Waste Disposal Units (GWDUs),

- a waste tank,

- a waste separator with filter,

- a high level sensor,

- two absolute pressure sensors,

- an overboard check valve,

- a vacuum generator,

- a waste drain valve connected to an individual control handle on the

waste service panel.

The waste tanks are installed in the under floor area behind the bulk cargo

compartment. The tanks for the main deck toilets and GWDUs have a

capacity of 675 liters each (178 US gallons). The tanks for the upper deck

toilets and GWDUs have a capacity of 373 liters each (98 US gallons).

The toilet system uses potable water to flush the toilets and the GWDUs.

The waste materials are transported into the waste tanks through flush

valves by cabin differential pressure.

When this differential pressure is insufficient, at altitudes below 16000

ft., the vacuum generators generate the necessary vacuum in the waste

tanks to fulfill the waste flow.

During servicing, the waste tanks are drained then rinsed from the waste

service panel installed in the AFT lower fuselage.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 16

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

GENERAL ARCHITECTURE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 17

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET SYSTEM DESCRIPTION (3)

Toilet Assembly and GWDU

The toilet assembly and the GWDU have:

- a flush switch, which initiates the actuation of a flush sequence,

- a rinse valve, which opens to spray potable water into the bowl for

rinsing,

- a flush valve, which opens to evacuate the waste materials to the waste

tanks,

- a Multi Purpose Interface (MPI) installed on the toilet or the GWDU

frame, which controls and sequences the rinse and flush functions.

Using the data from the weight sensing device, the toilet assembly MPI

can discriminate between a "seated" and a "standing" user and vary the

rinse water quantity accordingly. The MPI starts a short flush cycle for

a "standing" user and a long flush cycle for a "seated" user.

The GWDU has two flushing modes:

- mode 1: wet flush, used for waste materials discard. The GWDU MPI

carries out a flush sequence with rinsing by using potable water.

- mode 2: dry flush, used for liquids discard only. The GWDU MPI carries

out a flush sequence without rinsing, in order to reduce the consumption

of potable water when not required. Pressing twice in a second the flush

switch activates this special mode.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 18

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET ASSEMBLY AND GWDU

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 19

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET SYSTEM DESCRIPTION (3)

Waste Tank Assembly and Associated Equipment

The waste tank assembly has:

- a waste tank,

- a waste inlet with a flow diverter, which directs the waste materials to

the bottom of the tank,

- a waste separator with a filter, which separates the waste materials from

the air to make sure that only clean air will flow overboard,

- an ambient absolute pressure sensor installed on the air outlet of the

waste separator, which measures the air pressure above the waste surface

in the waste tank,

- a hydrostatic absolute pressure sensor installed at the bottom of the

waste tank, which measures the hydrostatic pressure. It calculates the

waste level in the tank with the received ambient and hydrostatic data,

- a high level sensor installed in the upper section of the waste tank, which

provides the "full tank" signal in order to stop the related subsystem,

- three rinse nozzles installed on the top of the tank to rinse the tank and

introduce disinfection fluids.

A differential pressure is necessary to move the waste materials from the

toilets assemblies and the GWDUs to the waste tank. To obtain the

necessary vacuum in the tank when the altitude is below 16000 ft., a

vacuum generator operates, creating a differential pressure between 4 psi

(0,28 bar) and 9 psi (0,62 bar) below the cabin pressure.

A Motor Controller Interface (MCI) installed adjacent to the vacuum

generator controls the operation of the vacuum generator.

When a flush sequence is initiated at a toilet assembly or a GWDU, the

MCI receives a signal from the related MPI.

Before the MCI supplies electrical power to the related vacuum generator,

it controls the flight phase data (ground signal, altitude) received from

the Landing Gear Extraction Retraction System (LGERS) and the Air

Data/Inertial Reference Units (ADIRUs) through the Cabin

Intercommunication Data System (CIDS).

Note that the MCI also receives a discrete landing gear status signal in

case of CIDS lost.

The MCI is connected to the service panel limit switch. Thus, when the

waste service panel door is opened and the A/C is on ground, the operation

of the toilet system is inhibited.

Finally, the MCI is connected to the related high level sensor. Thus, when

a "full tank" signal is detected, the related subsystem is inhibited in order

to prevent an overflow of the waste materials storage.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 20

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

WASTE TANK ASSEMBLY AND ASSOCIATED EQUIPMENT

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 21

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET SYSTEM DESCRIPTION (3)

Flush Sequence

The activation of the flush switch on a toilet assembly or on a GWDU

initiates the actuation of a flush sequence.

The related MPI starts a timed sequence that includes the analysis of the

flush requirements (control of the flight phase data, "standing" or "seated

user", dry or wet flush...) before the flush cycle starts.

For a toilet assembly:

- 2.1 seconds after the beginning of the flush cycle, the rinse valve opens

during 0.9 second for a long flush ("seated" user), and during 0.3 second

for a short flush ("standing" user).

- 2.5 seconds after the beginning of the flush cycle, the flush valve opens

during 4 seconds.

The duration of the complete flush cycle is 9 seconds.

For a GWDU:

- 8 seconds maximum (according to the required vacuum pressure) after

the beginning of the flush cycle, the rinse valve opens during 0.95 second

for a normal wet flush. For a dry flush the rinse valve is not activated.

- 1 second after the actuation of the rinse valve, the flush valve opens

during 4 seconds.

- 9 seconds after the actuation of the flush valve, the flush cycle is

complete.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 22

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

FLUSH SEQUENCE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 23

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET SYSTEM DESCRIPTION (3)

Control System Architecture

The following components have a microprocessor and are interconnected

via CAN bus:

- toilet assembly MPIs,

- GWDU MPIs

- vacuum generator MCIs,

- hydrostatic and ambient absolute pressure sensors,

- high level sensors.

The CIDS directors, through the vacuum system control function, manage

the data exchange between the toilet system components and some A/C

systems like the FAPs, the Onboard Maintenance System (OMS), the

LGERS and the ADIRUs.

The FAPs are the main controllers and indicators of the toilet system.

The interface with the OMS is used for failure report and test of the toilet

system.

The LGERS and ADIRUs give flight phase data (ground signal and

altitude) for the control of the vacuum system.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 24

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

CONTROL SYSTEM ARCHITECTURE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 25

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

TOILET SYSTEM DESCRIPTION (3)

Water/Waste FAP Page

The Water/Waste FAP page has the following functions:

- indication of waste quantity in the tanks,

- indication of A/C configuration (location of lavatories and galleys),

- indication of system status,

- indication of failure messages,

- auto flush ("Auto Flush" button),

- rinse valve warning reset ("Reset Warn." button).

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 26

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

WATER/WASTE FAP PAGE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

TOILET SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 27

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

2

T

O

I

L

E

T

0

0

1

WASTE WATER DRAIN SYSTEM DESCRIPTION (3)

General Architecture

The waste water drain-system discards overboard the waste water from

the galley sinks and the lavatory washbasins.

The waste water flows through the drain valves to the FWD and the AFT

heated drain masts installed on the lower fuselage.

The waste water is achieved by gravity on ground and by differential

pressure in flight.

The diaphragm type drain valves are usually closed. They open only if

a sufficient amount of waste water is collected. This prevents a continuous

leakage of the cabin air through the drain lines.

To prevent icing, the drain masts are electrically heated.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WASTE WATER DRAIN SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 28

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

3

W

A

S

T

E

0

0

0

1

GENERAL ARCHITECTURE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WASTE WATER DRAIN SYSTEM DESCRIPTION (3) Mar 17, 2006

Page 29

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

D

3

W

A

S

T

E

0

0

0

1

WATER/WASTE SYSTEM MAINTENANCE (3)

Potable Water System Tests

Potable Water System (PWS) tests are done to check several functions

of the system.

OMS Interactive Tests Overview

The PWS has the following interactive tests:

- system test,

- valve test.

These tests are launched from the OMS HMI (using the OMT, OIT

or PMAT).

System Test

The system test does a check of all monitored components of the PWS:

- the Potable Water Indication Panel (PWIP),

- the level sensors,

- the air compressor motor controllers,

- the heating and disinfection control unit,

- the fill/drain valve,

- the FWD drain valve,

- the depress valve,

- the optional valves.

Valve Test

The valve test does a check of all installed valves of the PWS:

- the fill/drain valve,

- the FWD drain valve,

- the depress valve,

- the optional valves.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM MAINTENANCE (3) Mar 17, 2006

Page 30

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

Y

1

M

A

I

N

T

0

0

0

1

POTABLE WATER SYSTEM TESTS - OMS INTERACTIVE TESTS OVERVIEW ... VALVE TEST

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM MAINTENANCE (3) Mar 17, 2006

Page 31

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

Y

1

M

A

I

N

T

0

0

0

1

WATER/WASTE SYSTEM MAINTENANCE (3)

Vacuum Toilet System Tests

Vacuum Toilet System (VTS) tests are done to check several functions

of the system.

OMS Interactive Tests Overview

The VTS has the following interactive tests:

- system test,

- subsystem test MD/LH,

- subsystem test MD/RH,

- subsystem test UD/LH,

- subsystem test UD/RH.

These tests are launched from the OMS HMI (using the OMT, OIT

or PMAT).

System Test

The system test does a check of all monitored components of the VTS:

- the vacuum generator Motor Controller Interfaces (MCIs) of all four

subsystems,

- the liquid level sensors of all four subsystems,

- the absolute pressure sensors of all four subsystems,

- the Multi Purpose Interfaces (MPIs) of all toilet assemblies and

Galley Waste Disposal Units (GWDUs) (refer to cabin layout).

Subsystem Test

The test of each vacuum toilet subsystem does a check of its related

monitored components:

- the vacuum generator MCI,

- the liquid level sensor,

- the two absolute pressure sensors,

- the MPIs of the related toilet assemblies and GWDUs.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM MAINTENANCE (3) Mar 17, 2006

Page 32

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

Y

1

M

A

I

N

T

0

0

0

1

VACUUM TOILET SYSTEM TESTS - OMS INTERACTIVE TESTS OVERVIEW ... SUBSYSTEM TEST

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM MAINTENANCE (3) Mar 17, 2006

Page 33

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

Y

1

M

A

I

N

T

0

0

0

1

WATER/WASTE SYSTEM COMPONENT LOCATION (3)

FWD Fuselage

Rear Cargo Compartment

Potable Water

Waste Equipments

Cabin

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM COMPONENT LOCATION (3) Mar 17, 2006

Page 34

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

C

1

L

E

V

E

L

0

3

0

1

This Page Intentionally Left Blank

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 38 Water/Waste

WATER/WASTE SYSTEM COMPONENT LOCATION (3) Mar 17, 2006

Page 35

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

3

8

C

1

L

E

V

E

L

0

3

0

1

AIRBUS S.A.S.

31707 BLAGNAC cedex, FRANCE

STM

REFERENCE L0Y06082

MARCH 2006

PRINTED IN FRANCE

AIRBUS S.A.S. 2006

ALL RIGHTS RESERVED

AN EADS JOINT COMPANY

WITH BAE SYSTEMS

S-ar putea să vă placă și

- A380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsDocument22 paginiA380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiÎncă nu există evaluări

- Level III - Ata 38 Water - WasteDocument40 paginiLevel III - Ata 38 Water - WastewagdiÎncă nu există evaluări

- Level II - Ata 28 Fuel SystemsDocument40 paginiLevel II - Ata 28 Fuel SystemswagdiÎncă nu există evaluări

- A380-Level I - Ata 36 PneumaticDocument26 paginiA380-Level I - Ata 36 PneumaticAbolfazl Mazloomi100% (3)

- A380-LEVEL I - ATA 30 Ice - Rain ProtectionDocument44 paginiA380-LEVEL I - ATA 30 Ice - Rain ProtectionAbolfazl Mazloomi100% (5)

- A380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsDocument20 paginiA380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiÎncă nu există evaluări

- A380 Fuel System Training ManualDocument84 paginiA380 Fuel System Training ManualSantty JamiÎncă nu există evaluări

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 paginiA380-LEVEL I - ATA 31 Indicating - Recording SystemsAbolfazl Mazloomi100% (1)

- Level I - Ata 46 Nss & OisDocument20 paginiLevel I - Ata 46 Nss & OiswagdiÎncă nu există evaluări

- ATA 44 Cabin Systems PDFDocument26 paginiATA 44 Cabin Systems PDFGoitom Teclai100% (3)

- A380-LEVEL I - ATA 21 Air ConditioningDocument62 paginiA380-LEVEL I - ATA 21 Air ConditioningAbolfazl Mazloomi100% (10)

- Level III - Ata 35 OxygenDocument58 paginiLevel III - Ata 35 Oxygenwagdi0% (1)

- A380-LEVEL III - ATA 26 Fire - Smoke DetectionDocument42 paginiA380-LEVEL III - ATA 26 Fire - Smoke DetectionAbolfazl Mazloomi100% (2)

- A380 25 B2X1Document24 paginiA380 25 B2X1Elijah Paul Merto100% (1)

- LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 paginiLEVEL I - ATA 31 Indicating - Recording SystemswagdiÎncă nu există evaluări

- A380-Level I - Ata 33 LightsDocument90 paginiA380-Level I - Ata 33 LightsAbolfazl Mazloomi67% (3)

- A380-LEVEL II - ATA 26 Fire Protection SystemsDocument52 paginiA380-LEVEL II - ATA 26 Fire Protection SystemsAbolfazl Mazloomi100% (6)

- LEVEL I - ATA 28 FuelDocument66 paginiLEVEL I - ATA 28 Fuelwagdi100% (1)

- Level II - Airbus DocumentationDocument24 paginiLevel II - Airbus DocumentationwagdiÎncă nu există evaluări

- A380-Level I - Ata 51 StructureDocument10 paginiA380-Level I - Ata 51 StructureAbolfazl MazloomiÎncă nu există evaluări

- A380-LEVEL I - ATA 23 CommunicationsDocument50 paginiA380-LEVEL I - ATA 23 CommunicationsAbolfazl Mazloomi100% (4)

- A340 Doors Training Manual SectionsDocument188 paginiA340 Doors Training Manual SectionsJoe HoÎncă nu există evaluări

- 23 CommunicationsDocument250 pagini23 CommunicationsAhmed ShahÎncă nu există evaluări

- A380-LEVEL I - ATA 46 Network Server System - Onboard InformationDocument20 paginiA380-LEVEL I - ATA 46 Network Server System - Onboard InformationAbolfazl Mazloomi100% (6)

- Level I - Ata 52 DoorsDocument40 paginiLevel I - Ata 52 Doorswagdi100% (3)

- LEVEL III - ATA 25 Equipment - FurnishingDocument72 paginiLEVEL III - ATA 25 Equipment - Furnishingwagdi0% (1)

- LEVEL I - ATA 49 Airborne Auxiliary PowerDocument36 paginiLEVEL I - ATA 49 Airborne Auxiliary PowerwagdiÎncă nu există evaluări

- LEVEL I - ATA 45 Onboard Maintenance SystemDocument40 paginiLEVEL I - ATA 45 Onboard Maintenance Systemwagdi100% (9)

- LEVEL III - ATA 23 CommunicationsDocument50 paginiLEVEL III - ATA 23 CommunicationswagdiÎncă nu există evaluări

- Level I - Ata 36 PneumaticDocument26 paginiLevel I - Ata 36 PneumaticwagdiÎncă nu există evaluări

- LEVEL I - ATA 30 Ice & Rain ProtectionDocument44 paginiLEVEL I - ATA 30 Ice & Rain ProtectionwagdiÎncă nu există evaluări

- A380-Level I - Ata 44 Cabin SystemsDocument42 paginiA380-Level I - Ata 44 Cabin SystemsAbolfazl Mazloomi100% (10)

- Ata 49 ApuDocument77 paginiAta 49 ApuSohaib Aslam Chaudhary100% (1)

- Level I - Ata 44 Cabin SystemsDocument42 paginiLevel I - Ata 44 Cabin Systemswagdi67% (3)

- Trent 700 - L & B Maintenance TrainingDocument1 paginăTrent 700 - L & B Maintenance TrainingIrfan05Încă nu există evaluări

- LEVEL I - ATA 29 Hydraulic PowerDocument24 paginiLEVEL I - ATA 29 Hydraulic PowerwagdiÎncă nu există evaluări

- Level III - Ata 28 Fuel SystemDocument90 paginiLevel III - Ata 28 Fuel SystemwagdiÎncă nu există evaluări

- Level II - Ata 36-21-30 Air SystemsDocument88 paginiLevel II - Ata 36-21-30 Air SystemswagdiÎncă nu există evaluări

- A321 Ata21-00 PDFDocument1 paginăA321 Ata21-00 PDFkpilÎncă nu există evaluări

- A380 Level I Ata 28 FuelDocument84 paginiA380 Level I Ata 28 FuelGuyÎncă nu există evaluări

- A380-Level II&III - Ata 29 Hydraulic PowerDocument56 paginiA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Încă nu există evaluări

- LEVEL II - Aircraft VisitDocument54 paginiLEVEL II - Aircraft Visitwagdi0% (1)

- 29 Hydraulic PowerDocument234 pagini29 Hydraulic PowerUcok BabaÎncă nu există evaluări

- A380-Level I - Ata 32 Landing GearDocument50 paginiA380-Level I - Ata 32 Landing GearAbolfazl Mazloomi100% (3)

- 45 Onboard Maintenance SystemsDocument56 pagini45 Onboard Maintenance SystemsWilliam Jaldin CorralesÎncă nu există evaluări

- 24 Electrical PowerDocument172 pagini24 Electrical PowerNurlan CebrayilzadeÎncă nu există evaluări

- A340 Hydraulic System Training ManualDocument232 paginiA340 Hydraulic System Training ManualJoe HoÎncă nu există evaluări

- LEVEL I - ATA 46 Air Traffic Control SystemDocument12 paginiLEVEL I - ATA 46 Air Traffic Control SystemwagdiÎncă nu există evaluări

- A330/340E Indicating and Recording Systems Technical ManualDocument54 paginiA330/340E Indicating and Recording Systems Technical ManualMark McKinsnkeyÎncă nu există evaluări

- Level III - Ata 36 PneumaticDocument62 paginiLevel III - Ata 36 PneumaticwagdiÎncă nu există evaluări

- LEVEL I - ATA 27 Flight ControlsDocument66 paginiLEVEL I - ATA 27 Flight ControlswagdiÎncă nu există evaluări

- LEVEL III - ATA 31 Indicating - Recording SystemsDocument116 paginiLEVEL III - ATA 31 Indicating - Recording Systemswagdi50% (2)

- 49 Apu PDFDocument68 pagini49 Apu PDFAaron Harvey50% (2)

- Level III - Ata 51 StructureDocument244 paginiLevel III - Ata 51 Structurewagdi100% (1)

- LEVEL I - ATA 23 CommunicationsDocument50 paginiLEVEL I - ATA 23 Communicationswagdi100% (1)

- A318 Technical Training Manual Part 1 Aircraft DimensionsDocument216 paginiA318 Technical Training Manual Part 1 Aircraft DimensionsMrityunjay Kumar JhaÎncă nu există evaluări

- 38 Water WasteDocument100 pagini38 Water Wastefourj747Încă nu există evaluări

- ATA 38 Water SystemsDocument40 paginiATA 38 Water Systemspluto3531Încă nu există evaluări

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 38 Water & WasteDocument164 paginiA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 38 Water & WasteAhmedHamdyElsaidy100% (4)

- Falcon 7X-Water and WasteDocument36 paginiFalcon 7X-Water and WasteParas Daryanani100% (1)

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaDocument66 paginiA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- A380-LEVEL I - ATA 42 Integrated Modular Avionics - Avionics DataDocument20 paginiA380-LEVEL I - ATA 42 Integrated Modular Avionics - Avionics DataAbolfazl Mazloomi78% (9)

- A380-LEVEL III - ATA 46 Network Server System - Onboard InformatiDocument52 paginiA380-LEVEL III - ATA 46 Network Server System - Onboard InformatiAbolfazl Mazloomi100% (11)

- A380-Level I - Ata 33 LightsDocument90 paginiA380-Level I - Ata 33 LightsAbolfazl Mazloomi67% (3)

- A380-Level I - Ata 51 StructureDocument10 paginiA380-Level I - Ata 51 StructureAbolfazl MazloomiÎncă nu există evaluări

- A380-Level II - Ata 49 Apu SystemsDocument36 paginiA380-Level II - Ata 49 Apu SystemsAbolfazl Mazloomi100% (1)

- A380-LEVEL III - ATA 26 Fire - Smoke DetectionDocument42 paginiA380-LEVEL III - ATA 26 Fire - Smoke DetectionAbolfazl Mazloomi100% (2)

- A380-Level II&III - Ata 29 Hydraulic PowerDocument56 paginiA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Încă nu există evaluări

- A380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsDocument20 paginiA380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiÎncă nu există evaluări

- A380-Level II - Ata 27 Flight ControlsDocument36 paginiA380-Level II - Ata 27 Flight ControlsAbolfazl Mazloomi100% (1)

- A380-Level I - Ata 32 Landing GearDocument50 paginiA380-Level I - Ata 32 Landing GearAbolfazl Mazloomi100% (3)

- A380-Level II - Ata 29 Hydraulic PowerDocument54 paginiA380-Level II - Ata 29 Hydraulic PowerAbolfazl Mazloomi100% (2)

- A380-LEVEL II - ATA 26 Fire Protection SystemsDocument52 paginiA380-LEVEL II - ATA 26 Fire Protection SystemsAbolfazl Mazloomi100% (6)

- A380-LEVEL I - ATA 46 Network Server System - Onboard InformationDocument20 paginiA380-LEVEL I - ATA 46 Network Server System - Onboard InformationAbolfazl Mazloomi100% (6)

- A380-Level I - Ata 44 Cabin SystemsDocument42 paginiA380-Level I - Ata 44 Cabin SystemsAbolfazl Mazloomi100% (10)

- A380-LEVEL I - ATA 27 Flight ControlsDocument66 paginiA380-LEVEL I - ATA 27 Flight ControlsAbolfazl Mazloomi86% (7)

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsDocument70 paginiA380-LEVEL I - ATA 31 Indicating - Recording SystemsAbolfazl Mazloomi100% (1)

- A380 Fuel System Training ManualDocument84 paginiA380 Fuel System Training ManualSantty JamiÎncă nu există evaluări

- A380-LEVEL I - ATA 25 Equipment - FurnishingsDocument54 paginiA380-LEVEL I - ATA 25 Equipment - FurnishingsAbolfazl Mazloomi100% (1)

- A380-LEVEL I - ATA 24 Electrical PowerDocument62 paginiA380-LEVEL I - ATA 24 Electrical PowerAbolfazl Mazloomi82% (11)

- A380-LEVEL I - ATA 23 CommunicationsDocument50 paginiA380-LEVEL I - ATA 23 CommunicationsAbolfazl Mazloomi100% (4)

- A380-LEVEL I - ATA 21 Air ConditioningDocument62 paginiA380-LEVEL I - ATA 21 Air ConditioningAbolfazl Mazloomi100% (10)

- Parallel AES Algorithm for Fast GPU EncryptionDocument6 paginiParallel AES Algorithm for Fast GPU EncryptionAbolfazl MazloomiÎncă nu există evaluări

- Civil Aircraft Advacned Avionics Architectures - Shri. C.M. AnandaDocument23 paginiCivil Aircraft Advacned Avionics Architectures - Shri. C.M. AnandaKeerthiPratheek ReddyÎncă nu există evaluări

- Aircraft Radio Systems - James Powell - 1981Document260 paginiAircraft Radio Systems - James Powell - 1981Abolfazl Mazloomi100% (18)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Dwyer Instruments International Online Catalog 2012 157-238 Flow PDFDocument83 paginiDwyer Instruments International Online Catalog 2012 157-238 Flow PDFcccirmusÎncă nu există evaluări

- Chapter 3 Force & Teacher) 2009Document22 paginiChapter 3 Force & Teacher) 2009Mohd Khairul Anuar100% (9)

- M.SC Sugar Tech SyllabusDocument39 paginiM.SC Sugar Tech SyllabusCandra AvengerzÎncă nu există evaluări

- BAM-S10-07 CO2 in Beer in Bulk - Zahm Nagel - Feb99aDocument10 paginiBAM-S10-07 CO2 in Beer in Bulk - Zahm Nagel - Feb99aRiyanÎncă nu există evaluări

- Method 6 Determination of Sulfur Dioxide Emissions From Stationary SourcesDocument13 paginiMethod 6 Determination of Sulfur Dioxide Emissions From Stationary Sourceseliovcr1977Încă nu există evaluări

- Engineering Thermodynamics Practice Problems Online ReviewDocument8 paginiEngineering Thermodynamics Practice Problems Online ReviewEj ParañalÎncă nu există evaluări

- Vacuum Box: Bubble Leak Testing For Storage Tank Weld SeamsDocument4 paginiVacuum Box: Bubble Leak Testing For Storage Tank Weld Seamsmt1742k4Încă nu există evaluări

- FM 16 Mark - 2019Document16 paginiFM 16 Mark - 2019Praveen Sakthivel. C6Încă nu există evaluări

- 023 QBM9903 A6V10935160 en - BDocument10 pagini023 QBM9903 A6V10935160 en - BMinh nhut LưuÎncă nu există evaluări

- TG08-Underfloor PlenumDocument7 paginiTG08-Underfloor PlenumAbdul Mohid SheikhÎncă nu există evaluări

- Flow Measurement Lab Tests Using Rotameters, Orifice Plates & MoreDocument7 paginiFlow Measurement Lab Tests Using Rotameters, Orifice Plates & MorejanÎncă nu există evaluări

- 3095MV Calibration Procedure W QuickCal Merian 4010Document8 pagini3095MV Calibration Procedure W QuickCal Merian 4010luisalbertopumaÎncă nu există evaluări

- Institutional Assessment NC IIDocument7 paginiInstitutional Assessment NC IIDonnald YambaÎncă nu există evaluări

- Calibrate Tisch Environmental TE-5000 TSP Air SamplerDocument22 paginiCalibrate Tisch Environmental TE-5000 TSP Air SamplerAhmad Heri SetiyawanÎncă nu există evaluări

- Lifluba: Basic Fluid Mechanics Integrated LaboratoryDocument32 paginiLifluba: Basic Fluid Mechanics Integrated LaboratoryAnonymous PTbgo8Încă nu există evaluări

- Operation Manual rhs680 Rev 1 PDFDocument13 paginiOperation Manual rhs680 Rev 1 PDFLuis Felipe ZuñigaÎncă nu există evaluări

- Transport ProcessDocument32 paginiTransport Processpidexhitam67% (3)

- Vaccuperm VGS-147, - 148, Service PDFDocument20 paginiVaccuperm VGS-147, - 148, Service PDFSreenubabu KandruÎncă nu există evaluări

- MOF Unit 2 PDFDocument23 paginiMOF Unit 2 PDFvinay PydikondalaÎncă nu există evaluări

- Exp.5#Venturimeter and OrificemeterDocument6 paginiExp.5#Venturimeter and OrificemeterPrince SinghÎncă nu există evaluări

- Medical Physics QuestionsDocument110 paginiMedical Physics QuestionsmodadadÎncă nu există evaluări

- Experiment 2 - Hydrostatic BenchDocument10 paginiExperiment 2 - Hydrostatic BenchUb Usoro100% (1)

- AG 200-800 Series PilotsDocument13 paginiAG 200-800 Series Pilotstxlucky80Încă nu există evaluări

- 3 Ceraphant Ptc31 Ptp31 Ptp35Document24 pagini3 Ceraphant Ptc31 Ptp31 Ptp35brunofj1985Încă nu există evaluări

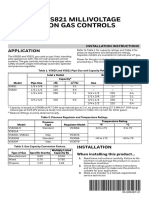

- Valvula de Gas HoneyWell VS820 - VS821Document16 paginiValvula de Gas HoneyWell VS820 - VS821John Carmona100% (1)

- Compressor Trial 1Document5 paginiCompressor Trial 1sahil bonganeÎncă nu există evaluări

- Exhaust Gas EconomizerDocument59 paginiExhaust Gas EconomizerThái Phan TrọngÎncă nu există evaluări

- An overview of the ECU and sensors for the Mitsubishi 4G93 engineDocument6 paginiAn overview of the ECU and sensors for the Mitsubishi 4G93 engineSyahiratul Nadiah MoktarÎncă nu există evaluări

- Lab 2 SensorDocument9 paginiLab 2 Sensorahmad faizÎncă nu există evaluări

- Thermodynamics 1 Course SyllabusDocument66 paginiThermodynamics 1 Course SyllabusReyno D. Paca-anas33% (3)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDe la EverandArizona, Utah & New Mexico: A Guide to the State & National ParksEvaluare: 4 din 5 stele4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDe la EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoEvaluare: 5 din 5 stele5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDe la EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptEvaluare: 5 din 5 stele5/5 (1)

- The Bahamas a Taste of the Islands ExcerptDe la EverandThe Bahamas a Taste of the Islands ExcerptEvaluare: 4 din 5 stele4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksDe la EverandNew York & New Jersey: A Guide to the State & National ParksÎncă nu există evaluări

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe la EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensÎncă nu există evaluări