Documente Academic

Documente Profesional

Documente Cultură

Welleman Illustrated Assembly Manual k8081 Rev2

Încărcat de

adibzz0 evaluări0% au considerat acest document util (0 voturi)

143 vizualizări36 paginiManual

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentManual

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

143 vizualizări36 paginiWelleman Illustrated Assembly Manual k8081 Rev2

Încărcat de

adibzzManual

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 36

Total solder points: 383

Difficulty level: beginner 1 2 3 4 5 advanced

POWERBLOCK - POWER AMPLIFIER

ILLUSTRATED ASSEMBLY MANUAL H8081IP-1

T

his

am

p

lifie

r is a

n ide

al s

et-u

p for a

ctiv

e s

pe

ake

r us

e.

K8081

K8081

VELLEMAN NV

Legen Heirweg 33

9890 Gavere

Belgium Europe

www.velleman.be

www.velleman-kit.com

3

Features & specifications

This power amplifier is an ideal set-up for active speaker use.

Build a high-quality system, using two (stereo) or more (surround) amplifiers.

Due to its auto switch-on, through input signal sensing, the unit can be installed

at almost any place.

Comes complete with enclosure and transformer.

Features :

fully discrete design using Epitaxial Darlington transistors

includes all connectors, transformer and enclosure

overload and short-circuit protection

DC error protection with LED indication

automatic switch-on upon input signal sensing (automatic switch-off)

Specifications

200W music power @ 4 ohm load

100W rms power @ 4 ohm load @ 10%THD

distortion: 0.02% @ 1KHz/10W

damping factor: >800

frequency response: 3Hz to 200KHz (-3dB)

sensitivity: 0.6V rms

signal to noise ratio: 115dB

power supply: 235 or 115 Vac

Auto sensing on time : 15min.

dimensions: 195 x 180 x 60mm (7.7" x 7" x 2.4")

4

Assembly hints

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful.

Read them carefully.

1.1 Make sure you have the right tools:

A good quality soldering iron (25-40W) with a small tip.

Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the

tip, to give it a wet look. This is called thinning and will protect the tip, and

enables you to make good connections. When solder rolls off the tip, it needs

cleaning.

Thin raisin-core solder. Do not use any flux or grease.

A diagonal cutter to trim excess wires. To avoid injury when cutting excess leads,

hold the lead so they cannot fly towards the eyes.

Needle nose pliers, for bending leads, or to hold components in place.

Small blade and Phillips screwdrivers. A basic range is fine.

For some projects, a basic multi-meter is

required, or might be handy

1.2 Assembly Hints :

Make sure the skill level matches your experience, to avoid disappointments.

Follow the instructions carefully. Read and understand the entire step before you per-

form each operation.

Perform the assembly in the correct order as stated in this manual

Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

Values on the circuit diagram are subject to changes.

Values in this assembly guide are correct*

Use the check-boxes to mark your progress.

Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute manual updates, indicated as NOTE

on a separate leaflet.

1.3 Soldering Hints :

1- Mount the component against the PCB surface and

carefully solder the leads

2- Make sure the solder joints are cone-shaped

and shiny

3- Trim excess leads as close as possible to the solder joint

0

.

0

0

0

5

Assembly hints

DO NOT BLINDLY FOLLOW THE ORDER OF THE COMPONENTS ONTO THE TAPE.

ALWAYS CHECK THEIR VALUE ON THE PARTS LIST!

REMOVE THEM FROM THE TAPE ONE AT A TIME !

6

Construction

R1 : 330 (3 - 3 - 1 - B)

R2 : 220 (2 - 2 - 1 - B)

R3 : 47 (4 - 7 - 0 - B)

R4 : 3K3 (3 - 3 - 2 - B)

R5 : 100 (1 - 0 - 1 - B)

R6 : 22K (2 - 2 - 3 - B)

R7 : 120 (1 - 2 - 1 - B)

R8 : 2K2 (2 - 2 - 2 - B)

R9 : 680 (6 - 8 - 1 - B)

R10 : 3K3 (3 - 3 - 2 - B)

R11 : 3K3 (3 - 3 - 2 - B)

R12 : 10 (1 - 0 - 0 - B)

R13 : 18K (1 - 8 - 3 - B - 9)

R14 : 2K7 (2 - 7 - 2 - B - 9)

R15 : 1K5 (1 - 5 - 2 - B)

R16 : 47 (4 - 7 - 0 - B)

R17 : 3K3 (3 - 3 - 2 - B)

R18 : 680 (6 - 8 - 1 - B)

R19 : 1K (1 - 0 - 2 - B)

R20 : 220 (2 - 2 - 1 - B)

R21 : 470 (4 - 7 - 1 - B)

R22 : 470K (4 - 7 - 4 - B)

R23 : 100K (1 - 0 - 4 - B)

R24 : 1K (1 - 0 - 2 - B)

R25 : 1M (1 - 0 - 5 - B)

R26 : 470K (4 - 7 - 4 - B)

R27 : 100 (1 - 0 - 1 - B)

R28 : 15K (1 - 5 - 3 - B)

R29 : 470K (4 - 7 - 4 - B)

R30 : 100K (1 - 0 - 4 - B)

R31 : 47K (4 - 7 - 3 - B)

R32 : 2K7 (2 - 7 - 2 - B - 9)

4. 1/4W resistors.

R...

J

1. Jump wires.

D1 : 1N4148

D2 : 1N4148

D3 : 1N4148

D4 : 1N4148

D5 : 1N4148

D6 : 1N4148

D7 : 1N4148

D8 : 1N4148

D9 : 1N4007

D10 : 1N4007

Mounting Diode D11 :

D11 : 1N4007

Mount D11.

2. Diodes (check the polarity)

CATHODE

D...

ZD1 : 5V1

ZD2 : 9V1

3. Zener diodes (check the polarity)

CATHODE

ZD...

7

Construction

IC1 : 8p

IC2 : 8p

IC3 : 6p

5. IC sockets. Watch the position

of the notch!

RV1 : 1K

Bias adjustment

6. Trim potentiometer

R4

T1 : BC640

T2 : BC640

T3 : BC639

T4 : BC547

T5 : BC557

T6 : BC547

T7 : BC547

8. Transistors

T1

Make sure that transistor T7 is

bent towards diode D11.

Make sure that the transistor and

diode leads do not touch each

other.

C1 : 47pF (47)

C2 : 47pF (47)

C3 : 1nF (102)

C4 : 680pF (680)

C5 : 680pF (680)

C6 : 10nF (103)

C7 : 10nF (103)

C8 : 47nF (473)

C9 : 100nF (104)

C10 : 100nF (104)

C11 : 100nF (104)

C12 : 100nF (104)

7. Capacitors

c...

R33 : 3K3 (3 - 3 - 2 - B)

R34 : 560 (5 - 6 - 1 - B - 9)

R35 : 10K (1 - 0 - 3 - B)

R36 : 47K (4 - 7 - 3 - B)

R37 : 1K (1 - 0 - 2 - B)

R38 : 10K (1 - 0 - 3 - B)

R39 : 1K (1 - 0 - 2 - B)

R40 : 2K2 (2 - 2 - 2 - B)

R41 : 10K (1 - 0 - 3 - B)

LD4 : Power (red)

9. LEDs. Watch the polarity!

LD1

CATHODE

8

Construction

GND : 1 pin

TEST : 1 pin

+40V : 1 pin

T8 : 6 pins

T9 : 6 pins

10. Pinheaders

R42 : 0,47

R43 : 0,47

12. 5W resistors

R...

2mm

LS+

LS-

AC RED

AC GREY

AC YELLOW

AC BLUE

13. Flat receptacles

SK...

SK5 : IN

11. Male board wire connector

LD1 : yellow (standby)

LD2 : Blue (on)

LD3 : red (check)

CATHODE

IMPORTANT

Mount these LED's exactly like in the

drawing, otherwise some LED's will

not fit correctly in the front panel.

C13 : 10F

C14 : 10F

C15 : 10F

C16 : 47F / 16V

C17 : 100F / 50V

C18 : 100F / 50V

C19 : 220F / 16V

C20 : 220F / 16V

C21 : 220F / 16V

C22 : 470F / 16V

14. Electrolytic capacitors.

Watch the polarity !

C...

7mm

CATHODE

+/- 3mm

LD...

1

1

9

construction

Mount following diodes 15mm

above the PCB :

D14 : 1N5404

D15 : 1N5404

Mount following diodes 10mm

above the PCB :

D12 : 1N5404

D13 : 1N5404

15. Power diodes

(check the polarity)

CATHODE

D...

RY1 : VR5V242C

( 24VDC - 5A - 2C)

16. Relay

C23 : 3300F / 50V

C24 : 3300F / 50V

17. Electrolytic capacitors.

Watch the polarity !

C...

Mount all 4 brackets,

fasten them using 6mm

M3 bolt + M3 nut

19.Brackets

brackets

brackets

IC1 : LM258P

IC2 : VK8081 (programmed PIC10F200-I/PG)

IC3 : TIL111 or 4N27

18. IC's. Watch the position of the

notch!

10

20. ASSEMBLY OF THE UNIT

Assembly

cut all connections to 1.5mm

Make sure that the solder connections don't

touch the housing.

1

fix rubber foot in center of PCB

2

Use the colour pictures on packaging as guideline

Max. 1.5mm

11

3

slide the PCB into the heatsink

4

fix the PCB using 4 bolts + nut

fix the 4 nuts inside

Assembly

12

Assembly

5

bend C4 away from T9

bend C5 away from T8

13

6

apply some heat conductive silicone grease to tran-

sistor and diode.

7

place the M3 bolt for T8 and T9

mount the isolator to heatsink, apply grease to both sides

Assembly

M3 bolt

isolator

14

8

bend the leads for T8 (TIP142) and T9

(TIP147) like in the photograph.

9

lock washer

6mm M3 nut

position the transistors T8 (TIP142) and T9

(TIP147) and fix using lock washer and 6mm M3

nut.

Assembly

15

Assembly

10

solder the connections carefully, check by trying

to move the leads after soldering

prepare the speaker output cables (red &

black), one side with terminal + cover,

other side with eyelet connector

11

Remove the isolation

speaker output connection set

16

mount all connectors and fuse, check position of speaker connector

and switch holder to the rear panel

12

position the fuse holder exactly

like in the picture

13

Assembly

rear panel inside view

17

Assembly

15

Twist the connector wire

14

align the RCA mounting nut

solder the 2 wire connector cable to the RCA, brown = signal ground &

red = signal.

r

e

d

b

r

o

w

n

18

16

connect the speaker wires exactly like in the picture ( + = red wire)

Assembly

insert 2 A slow blow fuse

17

18

cut 3 pcs. of 3cm

from the shrink tube

3cm 3cm 3cm

19

19

solder one 8cm brown wire to the switch and one to the fuse holder

Assembly

20

slide a piece of shrink tube over the transformer mains connections :

black wire

brown wire (100-120VAC) or the orange wire (220-245VAC)

connect the black wire to the power switch

connect the orange (~230VAC) or brown (~115VAC) wire with the

center connector of the fuseholder.

21

slide the shrinking tube over the

switch and fuse holder

20

22

isolate the not used transformer wire using a piece of tape.

Assembly

23

shrink the tube using heater or hair dryer.

21

24

apply glue to the transformer protector

25

position the protector like in the drawing

Assembly

solder terminal + cover to the 4

transformer wires

26

22

Assembly

position the rear panel and the transformer

27

fix the rear panel, use 4 self tapping screws.

23

29

connect the AC connectors RED, BLUE, GREY and YELLOW

Assembly

28

connect the input signal connector

24

Assembly

30

connect the speaker +LS red and -LS black wires

-LS (black)

+LS (red)

31

check the wire styling and apply straps

25

Assembly

stick the isolator foil to the transformer

33

32

position the transformer insulation rubber

26

Test

21. TESTING THE DC PROTECTION CIRCUIT :

1

Preliminary test:

Verify that the amplifier is turned off (switch at rear panel)

Turn the RV1 bias adjust trimmer fully counter clockwise

(turn left)

For first time testing, insert a 60W light bulb in series

with the AC power line.

Connect the power cord (it is possible that the supplied cord or

connector must be replaced to comply with the requirements of your country)

Turn ON the amplifier using the switch at the rear panel

If the light bulb lights up continuously, disconnect the mains volt-

age and check all your wiring and assembly.

The power LED LD4 should lit.

If the 60W lamp remains off or lights up briefly, then everything is OK,

Remove the light bulb from the circuit.

Recheck carefully if the selection of primary AC voltage, complies to your

mains voltage.

120Vac: black / brown.

230Vac: black /orange.

IMPORTANT: Insulate the wire that is not being

used.

2

Setting the bias:

Connect a multimeter (lowest DC voltage range 1V or

lower) over the leads of R42 or R43.

Turn on the power.

Check the multimeter, it should read 0V, adjust RV1

carefully to about 10-15mV (0.010V-0.015V) Wait a

few minutes until the meter reading remains stable.

Note: the amplifier will turn itself off after about 15 minutes.

Remove the multimeter

27

Briefly connect the +40V test point with the TEST pin. The RED check

LED should BLINK and the relay should switch off.

3

DC error detection test:

Turn off the AC power.

The amplifier is now ready for use.

Test

40V test voltage

Test point

Check LED

28

4

mount the front panel

fix the front panel, use 4 self tapping screws.

check the position of the LEDs

5

mount the transformer positioning plate

6

Test

29

Test

7

position 4 spacer nuts

Check that the fixation bolt does not

make contact with the wires!

30

mount the bottom panel using 4 hexagonal bolts and fix in each

corner a rubber foot

8

Test

rubber foot

hexagonal bolt

31

22. Connection

Connection

POWER SUPPLY

~ 235VAC or

~115 VAC

Loudspeaker (-)

4- 8

Loudspeaker (+)

4- 8

INPUT SIGNAL

Connect the input signal, coming from a pre amplifier, volume and tone control

(ex K8084), mixing panel..

Connect speakers, it is advised to use 4 ohm speakers for maximum output

power.

Connect mains voltage

Turning ON

Turn on the amplifier using the mains switch

The amplifier will stay on for about 15 minutes (ON LED is LIT)

If the input senses no signal during this time, the amplifier will turn off

automatically.

REMARK: Strike out the NOT used mains voltage indication at the back of the housing !!

e.g. cross out with a permanent black marker.

Rear panel connections:

32

STANDBY: LIT when mains power is ON ( Fuse OK)

ON: LIT when amplifier is ON ( input signal is amplified )

CHECK: has 2 functions

1 Blinks short if no signal is sensed during ON

2 Blinks fast if error detected, the amplifier is turned OFF

If an amplifier error is detected, this can be due to extreme loud sound or due to

an amplifier error.

Reset the amplifier by turning the amplifier off, wait 10 sec, then turn ON.

In case of unrecoverable error, please check the amplifier circuit.

Front panel indications:

Connection

STANDBY ON CHECK

33

PCB

23. PCB

34

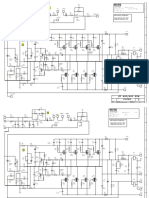

24. Schematic diagram

Schematic diagram

R

4

2

0

.

4

7

R

4

2

0

.

4

7

Modifications and typographical errors reserved

Velleman nv - H8081IP - 2007 - ED1 (rev.2.0)

5 4 1 0 3 2 9 3 6 0 0 5 4

Learn how to connect your computer

with the outside world, master the

USB communication with tutorial

examples.

Play with LED indicators and learn how

to drive LCDisplays.

This board with different signals will

teach you how to use an oscilloscope.

Optimized instructions for use of our

HPS140 oscilloscope. YouTube demo

movies.

Fun solar powered projects.

Learn all about solar energy.

EXPERIMENT KIT

SOLAR ENERGY

Enter the world of microcontroller

programming, easy step by step instructions.

Includes programmer and test board.

TUTOR KIT

PIC

TM

The Microchip name and logo, PIC, and PICmicro are registered trademarks of Microchip

Technology Inc. in the USA and other countries.

Learn how to solder, build different exciting

projects. Includes spare components and

demo boards.

The EDU01 basic experiment kit is the first step into the world of

modern electronics. Build your own circuits in a fun, safe and

educative way.

EDUCATIVE STARTERBOX

SOLDERLESS

03

02

01

06

05

04

EDUKIT SCOPE

SOLDER STARTER BOX

TUTOR BOARD USB

S-ar putea să vă placă și

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDe la EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesEvaluare: 4.5 din 5 stele4.5/5 (7)

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDe la EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsEvaluare: 3 din 5 stele3/5 (2)

- Nursing Practice Skills: Adult Intensive Care Unit PatientsDocument10 paginiNursing Practice Skills: Adult Intensive Care Unit PatientsMona Doria67% (3)

- Manual Servico TV LCD Philips 42pfl3604Document67 paginiManual Servico TV LCD Philips 42pfl3604abe_1962100% (1)

- Hemodynamic Monitoring in ICUDocument111 paginiHemodynamic Monitoring in ICUManjunath Gemini100% (2)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsDe la EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsÎncă nu există evaluări

- CP Lithium Ion BatteriesDocument4 paginiCP Lithium Ion BatteriesvaseemalikhanÎncă nu există evaluări

- Beginning Digital Electronics through ProjectsDe la EverandBeginning Digital Electronics through ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Seat Altea Owners Manual - English - 2006 VersionDocument302 paginiSeat Altea Owners Manual - English - 2006 VersionMaxT94% (35)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- DIY Geiger Counter Radiation Detector Kit Ver.2 PDFDocument16 paginiDIY Geiger Counter Radiation Detector Kit Ver.2 PDFLeonardo VelezÎncă nu există evaluări

- Grade 6 2nd Periodical Test With TOS Answer Keys MATH 1 PDFDocument6 paginiGrade 6 2nd Periodical Test With TOS Answer Keys MATH 1 PDFmafeh caranogÎncă nu există evaluări

- Full Site PDFDocument23 paginiFull Site PDFpursuwÎncă nu există evaluări

- Porkbarrel Ver 2 Chorus BossDocument5 paginiPorkbarrel Ver 2 Chorus BossWellington CordeiroÎncă nu există evaluări

- Action Research MAPEHDocument9 paginiAction Research MAPEHEloPoPo100% (4)

- ADA MN3007 Rev5 Jan2010 Documentation Rev20120225Document12 paginiADA MN3007 Rev5 Jan2010 Documentation Rev20120225ismaelsleiferÎncă nu există evaluări

- Today! 2 Activity Book AKDocument10 paginiToday! 2 Activity Book AKMark Arenz Corixmir80% (5)

- Role of Packaging in Sales of FMCG Products and Its TrendsDocument57 paginiRole of Packaging in Sales of FMCG Products and Its TrendsSaurabh0% (1)

- 4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsDocument12 pagini4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsNikola TesanovicÎncă nu există evaluări

- Led Theo NhacDocument16 paginiLed Theo NhacNguyễn Thắng LợiÎncă nu există evaluări

- Audio Video Transmitter KitDocument0 paginiAudio Video Transmitter KitKiTrojan Hadikusumo Jr.Încă nu există evaluări

- 2 X 15 Led Stereo Vu Meter: For High PR Ecision Aud Io Level IndicationDocument16 pagini2 X 15 Led Stereo Vu Meter: For High PR Ecision Aud Io Level IndicationCarlos Enrique Falcon ZapataÎncă nu există evaluări

- Led Circuit Diagram 3WDocument12 paginiLed Circuit Diagram 3WVinod Kumar Guravareddigari100% (1)

- Illustrated Assembly Manual k8040 Rev2Document24 paginiIllustrated Assembly Manual k8040 Rev2sankar ramasavarÎncă nu există evaluări

- Manual K8048 PicDocument0 paginiManual K8048 PicRed WarrantÎncă nu există evaluări

- Injetor Seguidor de SinalDocument12 paginiInjetor Seguidor de SinalLuiz Henrique SantosÎncă nu există evaluări

- DC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or LightsDocument0 paginiDC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or Lightsapostol_menÎncă nu există evaluări

- Illustrated Assembly Manual - Velleman K8042 Symmetric 1A Power SupplyDocument12 paginiIllustrated Assembly Manual - Velleman K8042 Symmetric 1A Power Supplymr_sharkÎncă nu există evaluări

- K8050 - IR ReceiverDocument20 paginiK8050 - IR ReceiverAnonymous Af4ORJÎncă nu există evaluări

- Illustrated Assembly Manual k8018Document16 paginiIllustrated Assembly Manual k8018FitzGritzÎncă nu există evaluări

- Video & Audio ModulatorDocument16 paginiVideo & Audio ModulatorChristian FitriyonoÎncă nu există evaluări

- RF modulator-CAJITA TV DIGITAL PDFDocument16 paginiRF modulator-CAJITA TV DIGITAL PDFboyerosÎncă nu există evaluări

- Pana Bežični Manujal kx-tcd150FXDocument77 paginiPana Bežični Manujal kx-tcd150FXi4004Încă nu există evaluări

- tcm3.1l La 312278518651 101126Document67 paginitcm3.1l La 312278518651 101126acostaricciÎncă nu există evaluări

- Cricket 80 AmanualDocument9 paginiCricket 80 Amanualdanielboiangiu4754Încă nu există evaluări

- C Audio ST400-600i Modification ListDocument13 paginiC Audio ST400-600i Modification ListB100% (1)

- Goldpic PDFDocument6 paginiGoldpic PDFMuhammad BashirÎncă nu există evaluări

- Micro80D Builders Guide-Ver3Document18 paginiMicro80D Builders Guide-Ver3knujdloÎncă nu există evaluări

- EmperorDocument12 paginiEmperorRafik HergéÎncă nu există evaluări

- Snow White AutowahDocument21 paginiSnow White AutowahDakovic AleksandarÎncă nu există evaluări

- Illustrated Assembly Manual k7300Document16 paginiIllustrated Assembly Manual k7300Vlad IulianÎncă nu există evaluări

- Segment Digital Clock KitDocument16 paginiSegment Digital Clock KitsiogÎncă nu există evaluări

- Illustrated Assembly Manual k8062Document12 paginiIllustrated Assembly Manual k8062Richard LeiteÎncă nu există evaluări

- Power Supply Kit: Model Xp-720KDocument20 paginiPower Supply Kit: Model Xp-720Kjulian2109Încă nu există evaluări

- k4700 PDFDocument16 paginik4700 PDFKeidesh RamnanansinghÎncă nu există evaluări

- Sound Effects Generator KitDocument12 paginiSound Effects Generator KitsiogÎncă nu există evaluări

- 42PFL4007G-78 Service+fonte PDFDocument74 pagini42PFL4007G-78 Service+fonte PDFeletronicaavenida0% (1)

- 42PFL3604Document67 pagini42PFL3604Robert Van SchijndelÎncă nu există evaluări

- Illustrated Assembly Manual k2601Document12 paginiIllustrated Assembly Manual k2601Long Nguyen KimÎncă nu există evaluări

- Concrete Distortion Building Instructions V1.0Document9 paginiConcrete Distortion Building Instructions V1.0ultratumbaÎncă nu există evaluări

- FM Transmitter PDFDocument6 paginiFM Transmitter PDFGoncalo EscusaÎncă nu există evaluări

- Deep Blue DelayDocument18 paginiDeep Blue DelayGasa RafliÎncă nu există evaluări

- Modification To AMP REV1Document14 paginiModification To AMP REV1augustinetezÎncă nu există evaluări

- Illustrated Assembly Manual k8012Document20 paginiIllustrated Assembly Manual k8012War LinuxÎncă nu există evaluări

- Illustrated Assembly Manual k4003 Rev1 PDFDocument12 paginiIllustrated Assembly Manual k4003 Rev1 PDFMilan MilosavljevićÎncă nu există evaluări

- Cable Tester Build DocDocument9 paginiCable Tester Build DocJacek Seweryn PodgórskiÎncă nu există evaluări

- 80M 40M Receiver Manual FinalDocument19 pagini80M 40M Receiver Manual FinalcasagrandeÎncă nu există evaluări

- HW 8 TR V2 Manual BDocument12 paginiHW 8 TR V2 Manual Bbcpsr7sc86Încă nu există evaluări

- HW 8 TR V3 ManualDocument11 paginiHW 8 TR V3 Manualbcpsr7sc86Încă nu există evaluări

- V4H Rev2 SetupDocument5 paginiV4H Rev2 SetupbobannesicÎncă nu există evaluări

- Beaver InstructionsDocument29 paginiBeaver InstructionsMyles de BastionÎncă nu există evaluări

- Tu RCV 27MHz PCB Not AssembledDocument8 paginiTu RCV 27MHz PCB Not AssembledAndrei-Daniel BotezatuÎncă nu există evaluări

- Temporizator Start StopDocument12 paginiTemporizator Start StopeliboyzzÎncă nu există evaluări

- Infinity Rs-6 B 100w Speaker System SMDocument1 paginăInfinity Rs-6 B 100w Speaker System SMadibzzÎncă nu există evaluări

- Tippmann A 5 Basic 2010 DiagramDocument1 paginăTippmann A 5 Basic 2010 DiagramadibzzÎncă nu există evaluări

- Electronica Amplificator Stereo As-3220 SCHDocument1 paginăElectronica Amplificator Stereo As-3220 SCHadibzzÎncă nu există evaluări

- Plantilla para Cortar La Sim Card A Nanosim o Microsim PDFDocument1 paginăPlantilla para Cortar La Sim Card A Nanosim o Microsim PDFJuniorBasquezÎncă nu există evaluări

- Hitachi AX M81Document16 paginiHitachi AX M81adibzzÎncă nu există evaluări

- Dantax SpeakersDocument12 paginiDantax Speakersadibzz100% (1)

- Stereo Power Amplifier Model: Wpa-600 Pro Owner'S ManualDocument6 paginiStereo Power Amplifier Model: Wpa-600 Pro Owner'S ManualGay InkognitoÎncă nu există evaluări

- Kenwood K 511usb EngDocument59 paginiKenwood K 511usb EngadibzzÎncă nu există evaluări

- Compatibilitate Casete 2012Document6 paginiCompatibilitate Casete 2012adibzzÎncă nu există evaluări

- Network Data Tools - Gap Analysis - 20091117Document10 paginiNetwork Data Tools - Gap Analysis - 20091117adibzzÎncă nu există evaluări

- Aiwa CX Lfa600Document52 paginiAiwa CX Lfa600adibzzÎncă nu există evaluări

- Alesis Ra150 300 500 ManualDocument38 paginiAlesis Ra150 300 500 ManualadibzzÎncă nu există evaluări

- Alesis Ra150 300 500 ManualDocument38 paginiAlesis Ra150 300 500 ManualadibzzÎncă nu există evaluări

- Eltax Tangent Amp50Document20 paginiEltax Tangent Amp50adibzzÎncă nu există evaluări

- Edifier s550 en v1.4 BMDocument1 paginăEdifier s550 en v1.4 BMadibzzÎncă nu există evaluări

- Stirling Motor HistoryDocument1 paginăStirling Motor HistoryadibzzÎncă nu există evaluări

- Arcam-AV50Amp User ManualDocument15 paginiArcam-AV50Amp User ManualadibzzÎncă nu există evaluări

- Pioneer A209 A209r-Au Service ManualDocument34 paginiPioneer A209 A209r-Au Service ManualadibzzÎncă nu există evaluări

- General InformationDocument15 paginiGeneral InformationadibzzÎncă nu există evaluări

- Giantbicycles-48478-Xtc 1 29 ErDocument1 paginăGiantbicycles-48478-Xtc 1 29 EradibzzÎncă nu există evaluări

- Dantax SpeakersDocument12 paginiDantax Speakersadibzz100% (1)

- BassgegenkopplungDocument5 paginiBassgegenkopplungadibzzÎncă nu există evaluări

- IBM ThinkPad T42 Service ManualDocument260 paginiIBM ThinkPad T42 Service ManualluissilvaleiriaÎncă nu există evaluări

- Journal of Environmental Management: Ajay Singh TDocument7 paginiJournal of Environmental Management: Ajay Singh TNestor Garay CahuanaÎncă nu există evaluări

- Aljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossDocument3 paginiAljac Sampler: Environmentally Acceptable, Operationally Efficient and Safe, Eliminating Any Product LossT. LimÎncă nu există evaluări

- Slidex StrepDocument9 paginiSlidex StrepLizeth Daniela RojasÎncă nu există evaluări

- DinmjgDocument10 paginiDinmjghaker linkisÎncă nu există evaluări

- 1Document3 pagini1Pradeep PunterÎncă nu există evaluări

- Tugas Topic 4 Devi PermatasariDocument8 paginiTugas Topic 4 Devi PermatasariMartinaÎncă nu există evaluări

- EPTT5100 - Pressure - Temperature Sensor - 1308 - GDocument2 paginiEPTT5100 - Pressure - Temperature Sensor - 1308 - GHendry Putra RahadiÎncă nu există evaluări

- Al Khudari Company Profile FP PDFDocument14 paginiAl Khudari Company Profile FP PDFAnonymous bgYdp4Încă nu există evaluări

- Unit-3: Grid FrameworkDocument44 paginiUnit-3: Grid FrameworkMUKESH KUMAR P 2019-2023 CSEÎncă nu există evaluări

- HISTOPATHDocument38 paginiHISTOPATHDennis Louis Montepio BrazaÎncă nu există evaluări

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Document1 paginăProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanÎncă nu există evaluări

- Nfpa 13d 2007 IndexDocument3 paginiNfpa 13d 2007 Indexsaladin1977Încă nu există evaluări

- Middle East ManufacturerDocument6 paginiMiddle East Manufacturerhsco rdÎncă nu există evaluări

- Brochure Smart Grid Foundation CourseDocument6 paginiBrochure Smart Grid Foundation CourseKULDEEP MEENAÎncă nu există evaluări

- TAS360VoIP ExDocument56 paginiTAS360VoIP ExOscar Damián Gómez HernándezÎncă nu există evaluări

- Interactions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CDocument22 paginiInteractions of Microplastic Debris Throughout The Marine Ecosystem Final Tracked-Galloway, TS Cole, M Lewis, CTrydawÎncă nu există evaluări

- COR5500U Series: Digital and CRT Readout OscilloscopeDocument7 paginiCOR5500U Series: Digital and CRT Readout OscilloscopeFlavio FalcãoÎncă nu există evaluări

- Excess Fluid VolumeDocument27 paginiExcess Fluid VolumeAdrian Ardamil100% (1)

- Symmetry & Space GroupsDocument49 paginiSymmetry & Space GroupsfaysaljamilÎncă nu există evaluări

- Manual CaladoraDocument32 paginiManual CaladoraMiguel Angel Vega TrejoÎncă nu există evaluări

- Architect As An Environmental PlannerDocument14 paginiArchitect As An Environmental PlannerJames Adrian MoralÎncă nu există evaluări

- Conference Programme Critical EmancipationsDocument3 paginiConference Programme Critical Emancipationswr7md5b55fÎncă nu există evaluări