Documente Academic

Documente Profesional

Documente Cultură

Cotton and Products Annual Dhaka Bangladesh 4-1-2013

Încărcat de

iamnahid0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări12 paginiUnited states Department of Agriculture Annual Cotton Bangladesh

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentUnited states Department of Agriculture Annual Cotton Bangladesh

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

36 vizualizări12 paginiCotton and Products Annual Dhaka Bangladesh 4-1-2013

Încărcat de

iamnahidUnited states Department of Agriculture Annual Cotton Bangladesh

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 12

THIS REPORT CONTAINS ASSESSMENTS OF COMMODITY AND TRADE ISSUES MADE BY

USDA STAFF AND NOT NECESSARILY STATEMENTS OF OFFICIAL U.S. GOVERNMENT

POLICY

Date:

GAIN Report Number:

Approved By:

Prepared By:

Report Highlights:

Bangladesh raw cotton imports in MY 2012/13 are estimated at 3.7 million bales, a 15.6 percent

increase from MY 2011/12, Strong demand from the spinning sub-sector, as well as lower international

prices, will likely continue to encourage raw cotton imports, which are forecast to reach 3.8 million

bales in MY 2013/14. U.S. cotton sales to Bangladesh, however, have fallen sharply as a number of

Bangladesh importers defaulted on contract commitments. The U.S. share of the Bangladesh raw

cotton has declined from 14 percent in MY 2010/11 to 5 percent in MY 2011/12. At the same, imports

from India and Uzbekistan are increasing.

Sayed Sarwer Hussain

David Leishman

2013

Cotton and Products Annual

Bangladesh

BG3005

4/1/2013

Required Report - public distribution

Commodities:

Production:

Assuming normal weather conditions, Bangladesh cotton production is forecast to reach 144,000

Bangladeshi bales (26,182 tons a Bangladeshi bale is 400 lbs) from 45,000 hectares in MY 2013/14.

Bangladesh cotton production in MY 2012/13 is estimated 129,000 Bangladeshi bales (23,455 tons),

harvested from 40,000 hectares. This includes 114,000 bales of American variety medium staple, and

15,000 bales of short staple up-land cotton (locally known as Comilla cotton).

Cotton is the second most important cash crop in Bangladesh after Jute. However, the lack of short

duration, high yielding, and pest tolerant cotton seed varieties, along with increasing competition for

very limited acreage in Bangladesh, constrain an expansion of cotton production. While cotton

cultivation is very susceptible to excessive rainfall and flooding, cotton growing conditions over last

few years, have been generally favorable during the critical growing period (July to December).

While Bangladesh does not have a cotton research institute, the Bangladesh Cotton Development Board

(CDB) conducts adoptive field trails of cotton varieties/hybrids, and is also responsible for providing

extension services to the cotton farmers.. Collaborating with private seed companies, the CDB has

introduced a few short duration and high yielding Chinese hybrids. As a result, cotton production has

grown. The CDB has undertaken a program to gradually increase domestic cotton production to

670,000 Bangladeshi bales (from 100,000 hectares) by the end of 2015. The CDB strategy includes

expanded use of new high yielding varieties, introduction of summer cotton, a gradual conversion of

20,000 hectares from tobacco to cotton cultivation, and increased cultivation in the saline prone coastal

areas in the South. The cotton growing areas of Bangladesh are shown in Figure-1. Under normal

conditions, domestic cotton production can only meet about 3 percent of the countrys current demand

for raw cotton.

Value Added Cotton:

In MY 2012/13, Bangladesh yarn production is estimated at 688,000 tons, and increase of about 12

percent from MY 2011/12 production. Fabric production in MY 2012/13 is estimated to reach at 3.95

billion meters, up 4 percent from MY 2011/12 production. In addition, an estimated 650 million meters

of fabric are produced by the small-scale handloom industry which meets about one third of the

domestic demand for fabrics. In MY 2013/14 yarn production and fabric production are forecast to

increase further to 720,000 tons and 4 billion meters respectively.

Bangladeshs spinning sub-sector of the textile industry has grown significantly over the last two

decades in response to a growing demand for yarn from domestic textile producers and the export-

oriented ready-made garment (RMG) sector (Table 8). However, the rate of growth has slowed

considerably recent years due to ongoing energy constraints (i.e the limited availability of electric power

and natural gas). Most spinning mills are now operating at less than full capacity as they also face

Cotton

increasing international competition, with imported products generally selling for about 4 percent below

the domestic price.

The textile industry is the largest manufacturing sector in Bangladesh, providing employment to

approximately 5.5 million people, contributing to around 12 percent of GDP, 40 percent of value

addition in manufacturing, and accounting for 78 percent of the countrys export earnings. During the

last three decades, Bangladesh textile sector has received a total investment of more than $5.5 billion.

The Bangladesh primary textile sector (PTS) meets almost 95 percent of domestic yarn and fabric

requirements, 90 percent of yarn requirements for export oriented knitwear, 40 percent of yarn

requirements for woven RMG and 40 percent of the demand for woven fabrics as part of the export

oriented RMG sector. Domestic yarns are also supplied to home-textile, terry towel, and denim

production units of the country. The current structure of the Bangladesh textile industry is presented in

Table-3 and the growth in its spinning sub-sector is shown in table 4. The Bangladesh PTS accounts for

more than 54 percent of foreign exchange earnings through manufacturing and supplying local yarn and

fabrics to the export oriented RMG sector (Table-5). Foreign currency retention is 40 percent from

woven garments export, while it is 90 percent from the knit garments exports. Despite significant

growth in the development of backward linkage industries, Bangladeshs current demand-supply gap for

fabric is about 50 percent for cotton-based use and around 25 percent for non-cotton based use in the

RMG sector.

Consumption:

In MY 2012/13, raw cotton consumption is estimated at 3.7 million bales, an increase of approximately

12 percent from MY 2011/12. With a continued rebound in imports, as well as strong demand from the

spinning sub-sector, raw cotton consumption is forecast to reach 3.9 million bales in MY 2013/14.

In MY 2012/13 consumption of yarn is estimated at 980,000 tons, an increase of 4.3 percent from MY

2011/12. Yarn consumption in MY 2013/14 is forecast to increase to 1 million tons. Fabric

consumption in MY 2012/13 is estimated at 6.4 billion meters up by about 4 percent from MY 2011/12,

due mainly to growth in RMG demand. MY 2013/14 fabric consumption is forecast to reach 6.6 billion

meters.

Bangladesh has numerous recently-constructed spinning and weaving mills capable of supplying quality

yarns and fabrics for the export-oriented RMG sector, however production costs are believed to be about

4 percent higher than in India or China. Efforts to improve environmental and labor standards may

affect costs in the short run, but over the longer term, this will undoubtedly help ensure continued

competitiveness as more global retailers demand assurances from their suppliers. There has been some

concern that imported fabrics for the RMG sector (under a special duty drawback incentive) may also be

threatening the competitiveness of the locally produced fabrics. However, recent trends seem to

indicate that Bangladesh competitiveness is improving, particularly in the higher quality categories.

Local knitters and weavers are increasingly using domestically produced yarn and fabric as

transportation costs and delivery schedules are improving.

Trade:

Bangladesh raw cotton imports in MY 2012/13 are estimated at 3.7 million bales, a 15.6 percent

increase from the MY 2011/12. Strong demand from the spinning sub-sector, as well as lower

international prices, will likely continue to encourage raw cotton imports, which are forecast to reach

3.8 million bales in MY 2013/14.

Uzbekistan and India are the current major suppliers of raw cotton to Bangladesh, benefitting from

competitive pricing and short delivery time. Bangladesh is currently negotiating agreements with India

and Uzbekistan to import 1.5 million bales and 200,000 bales. U.S. cotton sales to Bangladesh fell

dramatically in MY 2011/12. The U.S. share of the Bangladesh raw cotton market declined from 14

percent in MY 2010/11 to 5 percent in MY 2011/12 as a number of Bangladesh importers defaulted on

contract commitments. A number of these importers have since renegotiated contracts and are

continuing to import U.S. cotton.

Value Added Cotton:

Yarn imports in calendar year (CY) 2012 are estimated to increase to 270,000 tons from 240,000 tons in

CY 2011. With increased demand from both the domestic textile market and the export oriented RMG

sector, CY 2013 imports of yarn are forecast to increase to 280,000 tons. India continues to remain as

the principal supplier of yarn to Bangladesh with around 75 percent of the market share. Fabric imports

in CY 2012 are estimated at 2.4 billion meters, almost unchanged from the CY 2011 levels, as domestic

supplies remain high. In CY 2013 fabric imports are forecast to reach 2.6 billion meters as demand

from the export oriented RMG sector is expected to increase. With price advantages for quality fabrics,

China continues to be the preferred supplier accounting for about 73 percent of the total imported

fabrics in Bangladesh.

According to WTO International Trade Statistics-2012, Bangladesh is now the worlds eleventh largest

fabric importer, with imports totaling $5.6 billion in 2011. In recent years, Bangladesh successfully

expanded its RMG customer base beyond the traditional markets of the U.S., the EU and Canada.

Exporting to countries like Russia, India, China, Australia, South Korea and Saudi Arabia, high value

RMG products like blazers, trousers, suits, jackets and women under-garments have seen significant

growth in recent years.

After growing 44 percent in FY 2010/11, Bangladesh RMG export earnings grew by a further 7 percent,

reaching over $20 billion in FY 2011/12 (Table 5).

Policy:

Yarn and fabric imports for the RMG sector enjoy a customs duty draw-back incentive. The provision

of an alternative cash incentive (set at 5 percent of the export value) for the export- oriented textile

sector continues in the current fiscal year. For more than a decade, raw cotton imports have been free

from all customs duties. Since FY 2011/12, import duties on polyester, viscose, acrylic, synthetic and

modacrylic staple fiber have been completely withdrawn and the duty on textile chemical dyes have

been reduced to 5 percent. There are no quantitative restrictions on imports of textile raw material

including fabrics.

As the Bangladesh textile industry is largely dependent on imports, industry leaders are asking the

Government of Bangladesh (GOB) to increase the cash incentive rate to 15 percent, to provide export

subsidies and a withdrawal of import duties on capital machinery and spare-parts for textile

manufacturing. The Bangladesh Textile Mills Association (BTMA) has successfully lobbied the GOB

to raise the minimum export price of cotton waste from $1.8 to $4.5 per kilogram and to impose a 25

percent export duty on cotton waste. The Bangladesh duty structure on raw cotton, yarn, fabric and

textile dyes-chemicals imports are shown in Table-6.

Marketing:

Bangladesh is almost entirely dependent on imports to meet its demand for raw cotton. More than 40

percent of raw cotton imports are destined for the export oriented RMG sector. Bangladesh spinning

mills generally recognize the value of U.S. cotton, particularly Pima and Upland, for their quality,

consistency and ginning output. Aside from price considerations, Bangladesh cotton buyers generally

also look at transportation freight and delivery times.

Production, Supply and Demand Data Statistics:

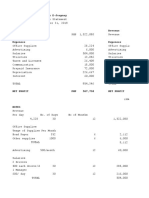

Table 1: Commodity, Cotton, PSD

Cotton

Bangladesh

2011/2012 2012/2013 2013/2014

Market Year

Begin: Aug 2011

Market Year

Begin: Aug 2012

Market Year

Begin: Aug 2013

USDA

Official

New

Post

USDA

Official

New

Post

USDA

Official

New

Post

Area Planted 0 36 0 40

45 (1000 HA)

Area Harvested 36 36 40 40

45 (1000 HA)

Beginning Stocks 842 842 807 818

914 1000 480 lb.

Bales

Production 75 86 90 108

120 1000 480 lb.

Bales

Imports 3,200 3,200 3,700 3,700

3,800 1000 480 lb.

Bales

MY Imports from U.S. 0 0 0 0

0 1000 480 lb.

Bales

Total Supply 4,117 4,128 4,597 4,626

4,834 1000 480 lb.

Bales

Exports 0 0 0 0

0 1000 480 lb.

Bales

Use 3,300 3,300 3,700 3,700

3,900 1000 480 lb.

Bales

Loss 10 10 10 12

11 1000 480 lb.

Bales

Total Dom. Cons. 3,310 3,310 3,710 3,712

3,911 1000 480 lb.

Bales

Ending Stocks 807 818 887 914

923 1000 480 lb.

Bales

Total Distribution 4,117 4,128 4,597 4,626

4,834 1000 480 lb.

Bales

Stock to Use % 24 25 24 25

24 (PERCENT)

Yield 454. 520. 490. 588.

581. (KG/HA)

TS=TD

0

0

0

Table 2: Commodity, Cotton, Import Trade Matrix

Import Trade Matrix

Country: Bangladesh

Commodity: Cotton

Time period: Aug-Jul Units: Metric tons

Imports for 2011 2012

U.S. 114000 U.S. 34000

Others Others

Uzbekistan 200000 Uzbekistan 180000

India 164000 India 260000

Australia 33000 Australia 41000

Pakistan 40000 Pakistan 30000

Other CIS 100000 Malaysia 31000

Brazil 16000 Other CIS 80000

Africa 90000 Brazil 16000

Total for Others 643000 638000

Others not listed 50000 25000

Grand Total 807000 697000

Table 3: Commodity, Cotton, Yarn, Import Trade Matrix

Import Trade Matrix

Country: Bangladesh

Commodity: Cotton Yarn

Time period: Jan-Dec Units: Metric tons

Imports for 2011 2012

U.S. 0 U.S. 0

Others Others

India 182000 India 190000

Pakistan 5000 Pakistan 5000

Thailand 5000 Thailand 5000

Taiwan 8000 Taiwan 10000

China 20000 China 40000

Total for Others 220000 250000

Others not listed 20000 20000

Grand Total 240000 270000

Table 4: Commodity, Cotton, Fabric, Import Trade Matrix

Import Trade Matrix

Country: Bangladesh Units: Mil. Meters

Commodity: Fabric

Time period: Jan-Dec

Imports for 2011 2012

U.S. 0 U.S. 0

Others Others

China 1750 China 1850

Pakistan 100 Pakistan 100

India 300 India 400

Thailand 100 Thailand 100

Total for Others 2250 2450

Others not listed 150 150

Grand Total 2400 2600

Table 5: Area and Production of Raw Cotton in Bangladesh

YEAR AREA HARVESTED (Hectare) PRODUCTION

Bales* Tons

2004-05 44,000 73,190 13,310

2005-06 49,770 77,000 14,000

2006-07 42,100 70,530 12,824

2007-08 28,707 42,380 7,705

2008-09 32,600 50,600 9,200

2009-10 31,500 66,000 12,000

2010-11 33,500 80,000 14,545

2011-12 36,000 103,000 18,727

2012-13 39,000 129,000 23,455

*1 bale = 400 lbs.

Source: Cotton Development Board (CDB), Government of Bangladesh

Table 6: Bangladesh: Production and Consumption estimates of Yarn and Fabric by years

Year

Production Consumption

Yarn

(000 tons)

Fabrics

(Mill. Meters)

Yarn

(000 tons)

Fabrics

(Mill. Meters)

2004/05 430 2,500 630 4,200

2005/06 464 2,700 680 4,500

2006/07 550 2,850 720 5,200

2007/08 602 3,000 760 5,600

2008/09 640 3,250 820 5,800

2009/10 731 3,450 880 6,000

2010/11 694 3,600 920 6,150

2011/12 615 3,800 940 6,180

Sources: Bangladesh Textile Mills Association (BTMA), and Ministry of Textiles

Table 7: Structure of Bangladesh Textile Industry - 2012

Number of Member Mills (BTMA) 1405

Textile Spinning 394

Textile Weaving 777

Woven 635

Denim 22

Home Textiles 20

Knit Fabrics 100

Dyeing-Printing-Finishing 234

Spindle Capacity 9,600,000

Rotor / Open-end 230,000

Yarn Manufacturing Capacity (Subject to 100% Capacity

Utilization)

2000,000,000 Kgs.

Fabric Manufacturing Capacity 2100,000,000 Meter

Fabric Processing Capacity 2200,000,000 Meter

Raw Material Requirements

Raw Cotton 7.5 million Bales (if 100% capacity is utilized)

Raw-Cotton Import / Consumed 4.0 million Bales

Raw Cotton Source USA, Australia, CIS, Russia, India, Pakistan, China, Central

America, East & West Africa

Type of Raw Cotton Imports 1-1/8", 1-1/6", 1-32", 1-5/32" etc.

Other Raw Material Used

Polyester, Viscose and Acrylic Staple Fiber, Pet-Chips,

Cotton Waste and Waste Cotton

Yarn 5-10 counts (both for Knit and Woven)

Synthetic and Filament Yarn

All kinds of Cotton & Knit Fabrics

Source: Bangladesh Textile Mills Association (BTMA)

Table 8: Growth in the Primary Textile Sector (Spinning)

Years No. of Mills Spindle Capacity Growth in No. of Mills Growth in Spindle Capacity

1995 84 1,701,823 10.52% 19.56%

2000 116 2,289,280 38.09% 34.52%

2005 230 4,937,353 16.75 % 25.58%

2006 260 5,500,000 8.7% 11.39%

2007 283 6,000,000 8.85% 9.09%

2008 341 7,200,000 20.0% 20.0%

2009 350 7,600,000 2.6% 5.6%

2010 373 8,700,000 6.6% 14.5%

2011 394 9,600,000 5.6% 10.3%

Source: Bangladesh Textile Mills Association (BTMA)

Table 9: Bangladesh Garments Exports Earning by Fiscal Year (July-June) In Million US$

Item/Year 2007-08 2008-09 2009-10 2010-11 2011-12

Knitwear 5,533 6,429 6,483 9,482 9,486

Woven 5,267 5,919 6,013 8,432 9,603

Home Textiles 291 418 403 789 906

Specialized Textiles 67 146 186 165 139

Total 11,158 12,912 13,085 18,868 20,134

Earning Growth 16.2% 15.7% 1.3% 44.2% 6.7%

Source: Bangladesh Textile Mills Association (BTMA)

Table 10: Bangladesh: Foreign Currency (F. C) Retention by Primary Textile Sector

2009 - 10 2010 - 11 2011 - 12

Description Export

Retention of

F.C.

Export

Retention of

F.C.

Export

Retention of

F.C.

Knitwear export using

local input 4,862 3,647 7,111 5,333 7,115 5,336

Knitwear export using

imported input 1,621 405 2,371 593 2,371 593

Woven export using local

input 2,405 1,804 3,373 2,530 3,841 2,881

Woven export using

imported input 3,608 902 5,059 1,265 5,762 1,441

Home Textile export

using local input 301 226 592 444 680 510

Home Textile export

using imported input 101 26 197 49 228 57

Total 12,898 7,010 18,703 10,214 19,997 10,818

Retention of F.C 54.35% 54.61% 54.10%

Source: Bangladesh Textile Mills Association (BTMA)

Table 11: Bangladesh: Duty Structure of Textile Sector imports (FY 2012-13)

Items Custom

Duty

Supplementary

Duty

VAT Adv.

Income

Tax

Regulatory

Duty

Advance

Trade VAT

Raw Cotton 0 0 0 0 0

Man-made

Fibres

0% 0% 15% 5% 0 4%

Yarn 12% 0 15% 5% 0 4%

Fabric 25% 45% 15% 5% 5% 4%

Textile dyes-

chemicals

5% 0 15% 5% 0 4%

Source: National Board of Revenue (NBR), Government of Bangladesh

Figure1. Bangladesh: Cotton Growing Areas

Source: Cotton Development Board, Bangladesh

Note: With a total cultivable land of 8.5 million hectare, land area suitable for cotton

cultivation is estimated at 242,000 hectares. Cotton production is taking place in 35 to 40

thousand hectares spreading on 35 districts out of total 64 districts in Bangladesh.

S-ar putea să vă placă și

- Cambodia Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapDe la EverandCambodia Agriculture, Natural Resources, and Rural Development Sector Assessment, Strategy, and Road MapÎncă nu există evaluări

- Food Outlook: Biannual Report on Global Food Markets July 2018De la EverandFood Outlook: Biannual Report on Global Food Markets July 2018Încă nu există evaluări

- Bangladesh's Textile Industry: An Overview of Its Structure, Size, and Contribution to the EconomyDocument19 paginiBangladesh's Textile Industry: An Overview of Its Structure, Size, and Contribution to the EconomyTanzina HaqueÎncă nu există evaluări

- Cotton UpdateDocument6 paginiCotton UpdateAngel BrokingÎncă nu există evaluări

- Bangladesh Is A Large Contributor To The Global Textile IndustryDocument8 paginiBangladesh Is A Large Contributor To The Global Textile IndustryVvajahat AliÎncă nu există evaluări

- Section A: Basic Description About The Industry Present Scenario of The IndustryDocument4 paginiSection A: Basic Description About The Industry Present Scenario of The IndustryDipPaulÎncă nu există evaluări

- University of Dhaka Bba Program Department of A&Is Cource Code:4201 Term Paper On "Backward Linkage Position of Readymade Garments Industries of Bangladesh"Document11 paginiUniversity of Dhaka Bba Program Department of A&Is Cource Code:4201 Term Paper On "Backward Linkage Position of Readymade Garments Industries of Bangladesh"Manjur Hossain ShovonÎncă nu există evaluări

- Bangladesh's Textile & Apparel Industry Growth PotentialDocument7 paginiBangladesh's Textile & Apparel Industry Growth PotentialAl-Imran Bin KhodadadÎncă nu există evaluări

- Cotton Export Ban Call as Prices DoubleDocument4 paginiCotton Export Ban Call as Prices DoubleAbhijeet GangulyÎncă nu există evaluări

- Cotton and Products India 2013Document22 paginiCotton and Products India 2013Kannan KrishnamurthyÎncă nu există evaluări

- Cotton OutlookDocument16 paginiCotton Outlookskouroudis_443636363Încă nu există evaluări

- Research Report On Spinning Sector of Bangladesh-InitiationDocument24 paginiResearch Report On Spinning Sector of Bangladesh-InitiationjohnsumonÎncă nu există evaluări

- Bgmea University of Fashion & Technology (Buft) : Assignment OnDocument12 paginiBgmea University of Fashion & Technology (Buft) : Assignment OnNeFariOus ArYan AraFat AnikÎncă nu există evaluări

- Managerial Economics: Cotton Price Movements and Its Implications On Indian Fashion and Apparel MarketDocument15 paginiManagerial Economics: Cotton Price Movements and Its Implications On Indian Fashion and Apparel MarketRahulKumbhareÎncă nu există evaluări

- Bangladesh's RMG Industry: Growth, Challenges and FutureDocument22 paginiBangladesh's RMG Industry: Growth, Challenges and FutureMd Razwanul IslamÎncă nu există evaluări

- Problems and Prospects of The Jute Product in BangladeshDocument19 paginiProblems and Prospects of The Jute Product in BangladeshSagor199492% (13)

- Cotton FibreDocument30 paginiCotton Fibreankit161019893980Încă nu există evaluări

- Overview - Garments Industry in BangladeshDocument24 paginiOverview - Garments Industry in Bangladeshzubair07077371100% (1)

- Cotton Spinning Note - ICRADocument4 paginiCotton Spinning Note - ICRAblindamÎncă nu există evaluări

- A Project On Bangladesh's "RMG Sector"Document8 paginiA Project On Bangladesh's "RMG Sector"OjantaÎncă nu există evaluări

- India's textile industry continues to dominate cotton usage but lags in manmade fibersDocument19 paginiIndia's textile industry continues to dominate cotton usage but lags in manmade fibersyuvaraj sÎncă nu există evaluări

- Final Project On Innovation of Textiles (NCBA&E)Document29 paginiFinal Project On Innovation of Textiles (NCBA&E)Amna KhanÎncă nu există evaluări

- Cotton: Trends in Global Production, Trade and PolicyDocument14 paginiCotton: Trends in Global Production, Trade and PolicyInternational Centre for Trade and Sustainable DevelopmentÎncă nu există evaluări

- Assignment On JuteDocument12 paginiAssignment On JuteAbid hasan0% (1)

- Issues and Challenges of Textile Business in Global ScenarioDocument11 paginiIssues and Challenges of Textile Business in Global ScenarioSiddharth GuptaÎncă nu există evaluări

- Assignment: Bangladesh's RMG On Global Business.: Submitted By: Md. Nasrath Faisal (1210914)Document5 paginiAssignment: Bangladesh's RMG On Global Business.: Submitted By: Md. Nasrath Faisal (1210914)NasrathFaisalÎncă nu există evaluări

- Bangladesh RMG Industry: Key Facts & FiguresDocument46 paginiBangladesh RMG Industry: Key Facts & Figuresnahidul202Încă nu există evaluări

- Recent Development in Sweater Industry of BangladeshDocument11 paginiRecent Development in Sweater Industry of BangladeshArittro ChakmaÎncă nu există evaluări

- Bangladesh's Home Textile Share Rising in Global MarketDocument8 paginiBangladesh's Home Textile Share Rising in Global MarketAdmay Saney CM VBD Pabna DistrictÎncă nu există evaluări

- Cotton Yarn SectorDocument6 paginiCotton Yarn SectorBala GangadharÎncă nu există evaluări

- Pakistan textile exports rise on investment and efficiency gainsDocument3 paginiPakistan textile exports rise on investment and efficiency gainsHaroon FareedÎncă nu există evaluări

- Taare Zameen ParDocument8 paginiTaare Zameen ParAnonymous mAB7MfÎncă nu există evaluări

- Assignment 6 - Cotton Cloth Industry in PakistanDocument4 paginiAssignment 6 - Cotton Cloth Industry in PakistanHaider RazaÎncă nu există evaluări

- History of Textile Production in BangladeshDocument3 paginiHistory of Textile Production in Bangladeshsamihaz02Încă nu există evaluări

- Group - 9: Assignment On Brand Case & EssayDocument15 paginiGroup - 9: Assignment On Brand Case & EssayfaizaÎncă nu există evaluări

- Modern Development in Garments Sector: HistoryDocument15 paginiModern Development in Garments Sector: HistoryTamanna TasnimÎncă nu există evaluări

- Spinning Mill Organizational StudyDocument37 paginiSpinning Mill Organizational Studykarthick1679100% (5)

- Swot Analysis of Apparel Export Business For Bangladesh With Respect To IndiaDocument15 paginiSwot Analysis of Apparel Export Business For Bangladesh With Respect To IndiaGovindasamy ArumugamÎncă nu există evaluări

- Bangladesh TextileDocument4 paginiBangladesh Textilesamihaz02Încă nu există evaluări

- Cotton and Products Annual New Delhi India IN2022 220325 200552Document16 paginiCotton and Products Annual New Delhi India IN2022 220325 200552Raghavan KÎncă nu există evaluări

- After Effect of Corona Virus in Garments Industry PDFDocument9 paginiAfter Effect of Corona Virus in Garments Industry PDF360 degree TextileÎncă nu există evaluări

- Diversification of RMGDocument8 paginiDiversification of RMGফাহমিদা আহমদÎncă nu există evaluări

- Bangladesh RMG Industry Report-May, 2020Document2 paginiBangladesh RMG Industry Report-May, 2020Farhan ShariarÎncă nu există evaluări

- Indian Textile Industry Segments & ContributionDocument19 paginiIndian Textile Industry Segments & ContributionMahak GuptaÎncă nu există evaluări

- SWOT Analysis of Bangladesh's RMG IndustryDocument3 paginiSWOT Analysis of Bangladesh's RMG IndustryMd.Latifull Alam100% (1)

- ICAPDocument34 paginiICAP53Gunjan DubeyÎncă nu există evaluări

- Problems and Prospects of Exporting Jute From BangladeshDocument25 paginiProblems and Prospects of Exporting Jute From BangladeshNurul Absar RashedÎncă nu există evaluări

- Ethiopia Cotton Production Annual - Addis Ababa - Ethiopia - 5-29-2019Document8 paginiEthiopia Cotton Production Annual - Addis Ababa - Ethiopia - 5-29-2019DemelashÎncă nu există evaluări

- Sri Anjaneya Cotton Mills LimitedDocument63 paginiSri Anjaneya Cotton Mills LimitedPrashanth PB50% (2)

- Exporting Leather Industry of BangladeshDocument20 paginiExporting Leather Industry of BangladeshKamrul HasanÎncă nu există evaluări

- Textile Industry's Export Potential Post-COVIDDocument33 paginiTextile Industry's Export Potential Post-COVIDyuvaraj sÎncă nu există evaluări

- TEXTILESDocument4 paginiTEXTILEStina21jangidÎncă nu există evaluări

- SEMINAR ECONOMIESDocument14 paginiSEMINAR ECONOMIESMehvishTalhaÎncă nu există evaluări

- Ca3 Cis Sec 11 Id 2222650Document12 paginiCa3 Cis Sec 11 Id 2222650OjantaÎncă nu există evaluări

- Bangladesh RMG Industry: An Analysis of Growth, Market, and Value ChainDocument41 paginiBangladesh RMG Industry: An Analysis of Growth, Market, and Value Chaintanvir75% (4)

- Contribution of Import and Export On Indian EconomyDocument5 paginiContribution of Import and Export On Indian EconomySuraj S NairÎncă nu există evaluări

- Textile Industries in Bangladesh and Challenges of Growth: February 2013Document8 paginiTextile Industries in Bangladesh and Challenges of Growth: February 2013Shovon BasakÎncă nu există evaluări

- Import of Manmade Fibres A Substantial 45.72 Per Cent To Reach Compared To 68,348 Tonnes During The Corresponding Period in 2020Document5 paginiImport of Manmade Fibres A Substantial 45.72 Per Cent To Reach Compared To 68,348 Tonnes During The Corresponding Period in 2020signÎncă nu există evaluări

- Cotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingDe la EverandCotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingHua WangÎncă nu există evaluări

- Food Outlook: Biannual Report on Global Food Markets: June 2022De la EverandFood Outlook: Biannual Report on Global Food Markets: June 2022Încă nu există evaluări

- The Power of Nature Taxation of Wind Power 2020Document128 paginiThe Power of Nature Taxation of Wind Power 2020iamnahidÎncă nu există evaluări

- Royalty Remittance Procdures 1622404086Document11 paginiRoyalty Remittance Procdures 1622404086iamnahidÎncă nu există evaluări

- Bangladesh - A Compelling Growth StoryDocument38 paginiBangladesh - A Compelling Growth StoryiamnahidÎncă nu există evaluări

- Daccadye 2013-2014 AnnualDocument59 paginiDaccadye 2013-2014 Annualiamnahid100% (1)

- Destination BangladeshDocument36 paginiDestination BangladeshiamnahidÎncă nu există evaluări

- Utopia (Thomas More)Document183 paginiUtopia (Thomas More)chris21592% (12)

- OthelloDocument28 paginiOthelloCesarÎncă nu există evaluări

- Vat and SD Act 2012: Rahman Rahman HuqDocument28 paginiVat and SD Act 2012: Rahman Rahman HuqbappyÎncă nu există evaluări

- IELTS Handbook 2007Document22 paginiIELTS Handbook 2007srikwaits4u100% (15)

- PWC Illustrative Ifrs Consolidated Financial Statements 2018 Year EndDocument239 paginiPWC Illustrative Ifrs Consolidated Financial Statements 2018 Year Endiamnahid100% (1)

- GRE - Basic Algebra RefresherDocument4 paginiGRE - Basic Algebra RefresherRakesh_Ranjan_3304100% (2)

- If PPT 9Document21 paginiIf PPT 9NazmulBDÎncă nu există evaluări

- HTG Cheatsheet Photoshop CS5Document1 paginăHTG Cheatsheet Photoshop CS5coolczoneÎncă nu există evaluări

- MJLBL 1st Quarter Financial Statement Unaudited As of 31mar2016Document1 paginăMJLBL 1st Quarter Financial Statement Unaudited As of 31mar2016iamnahidÎncă nu există evaluări

- Defining SMEs - September 2008Document29 paginiDefining SMEs - September 2008srikrishna21Încă nu există evaluări

- Expository and Narrative Writing in Science Class What Is Expository Writing?Document2 paginiExpository and Narrative Writing in Science Class What Is Expository Writing?iamnahidÎncă nu există evaluări

- Electrical Energy SystemsDocument1 paginăElectrical Energy SystemsiamnahidÎncă nu există evaluări

- International Finance SlidesDocument26 paginiInternational Finance SlidesiamnahidÎncă nu există evaluări

- HD200 Road Steel Bridge Installation Instruction: CRSBG 2012/06Document18 paginiHD200 Road Steel Bridge Installation Instruction: CRSBG 2012/06iamnahidÎncă nu există evaluări

- ShowDocument3 paginiShowiamnahidÎncă nu există evaluări

- BD 2Document22 paginiBD 2iamnahidÎncă nu există evaluări

- Rahimafrooz 2006 Technical ReportDocument4 paginiRahimafrooz 2006 Technical ReportShihab DipÎncă nu există evaluări

- Runes Break Even ChartDocument4 paginiRunes Break Even ChartiamnahidÎncă nu există evaluări

- 1Document2 pagini1iamnahidÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Schedule 3rd SemesterDocument1 paginăSchedule 3rd SemesteriamnahidÎncă nu există evaluări

- ScheduleDocument1 paginăScheduleiamnahidÎncă nu există evaluări

- Torrent Trackers ListDocument2 paginiTorrent Trackers ListiamnahidÎncă nu există evaluări

- Training Plan Template PDFDocument6 paginiTraining Plan Template PDFHemanta Kumar DashÎncă nu există evaluări

- Recent List of Additions Jan.2016 PDFDocument25 paginiRecent List of Additions Jan.2016 PDFchirurocksÎncă nu există evaluări

- GR No. 182045Document12 paginiGR No. 182045EdenFielÎncă nu există evaluări

- Vvinehab VeronaDocument29 paginiVvinehab VeronaGuillermo Aranda-MenaÎncă nu există evaluări

- How Interest Rates Impact Stocks and InflationDocument7 paginiHow Interest Rates Impact Stocks and InflationSandeep BabajiÎncă nu există evaluări

- News Bulletin Volume 1-4 2011Document21 paginiNews Bulletin Volume 1-4 2011Haniff NazimuddinÎncă nu există evaluări

- Diagonal Leap Spread Portfolio StrategyDocument17 paginiDiagonal Leap Spread Portfolio StrategyFernando ColomerÎncă nu există evaluări

- Ancient Egyptian Economics - Ashby, MuataDocument82 paginiAncient Egyptian Economics - Ashby, MuataAntonio Michael100% (25)

- Chapter 3Document50 paginiChapter 3wudineh debebeÎncă nu există evaluări

- The Macroeconomic Impact of Remittances in the PhilippinesDocument46 paginiThe Macroeconomic Impact of Remittances in the PhilippinesBrian Jason PonceÎncă nu există evaluări

- Crisil Sme Connect Jul10Document44 paginiCrisil Sme Connect Jul10atia2kÎncă nu există evaluări

- EducationDocument321 paginiEducationManish Kapadiya100% (1)

- Final - LST - Candidates PDFDocument137 paginiFinal - LST - Candidates PDFSHREYASI PATILÎncă nu există evaluări

- Balance Sheet 20 21Document2 paginiBalance Sheet 20 21Mishra SanjayÎncă nu există evaluări

- IBT Outline F09Document74 paginiIBT Outline F09emin_karimov100% (3)

- #34 SHIRLEY F. TORRES v. IMELDA PEREZ, GR No. 188225, 2012-11-28Document3 pagini#34 SHIRLEY F. TORRES v. IMELDA PEREZ, GR No. 188225, 2012-11-28Denise DianeÎncă nu există evaluări

- Chapter 2eco740Document29 paginiChapter 2eco740HarlinniÎncă nu există evaluări

- Subhash Dey's IED Textbook 2024-25 Sample PDFDocument46 paginiSubhash Dey's IED Textbook 2024-25 Sample PDFravinderd2003Încă nu există evaluări

- Member'S Data Form (MDF) : Membership CategoryDocument2 paginiMember'S Data Form (MDF) : Membership CategoryJewo CanterasÎncă nu există evaluări

- 10th US History - Globalization - WorksheetDocument2 pagini10th US History - Globalization - Worksheetangelicamiaot2Încă nu există evaluări

- Draft 2Document61 paginiDraft 2jeyologyÎncă nu există evaluări

- Aatmanirbhar Bharat Swatantra Bharat: InitiativesDocument3 paginiAatmanirbhar Bharat Swatantra Bharat: InitiativesNavneet ValechaÎncă nu există evaluări

- 25 Taka Platforms Fy 2023-24Document4 pagini25 Taka Platforms Fy 2023-24KOTHAPATNAM SACHIVALAYAMÎncă nu există evaluări

- Analysis of Procter & GambleDocument5 paginiAnalysis of Procter & Gamblesumair_khaan88Încă nu există evaluări

- Bgy Appropriations & Commitments Revised .5.8.07Document48 paginiBgy Appropriations & Commitments Revised .5.8.07AnnamaAnnama100% (1)

- Bank RegistrationDocument87 paginiBank Registrationclaude olekaÎncă nu există evaluări

- Chapter 3 Appendix ADocument16 paginiChapter 3 Appendix AOxana NeckagyÎncă nu există evaluări

- Kent's E-Jeepney Kent's E-Jeepney: TotalDocument20 paginiKent's E-Jeepney Kent's E-Jeepney: TotalKentÎncă nu există evaluări

- GE3 Prelim Exam1Document4 paginiGE3 Prelim Exam1Edrose WycocoÎncă nu există evaluări

- Microstrategy Consulting Services in Saudi ArabiaDocument19 paginiMicrostrategy Consulting Services in Saudi ArabiaMitchel JohnsonÎncă nu există evaluări

- Versapak Insulated Pathology Sample Carrier (Medium)Document2 paginiVersapak Insulated Pathology Sample Carrier (Medium)tohunabohunÎncă nu există evaluări